Form 6-K SSR MINING INC. For: Oct 23

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 6-K

REPORT OF FOREIGN PRIVATE ISSUER

PURSUANT TO RULE 13a-16 OR 15d-16

UNDER THE SECURITIES EXCHANGE ACT OF 1934

For October 23, 2017

Commission File Number: 000-26424

SSR MINING INC.

(Translation of registrant’s name into English)

#800—1055 Dunsmuir Street

PO Box 49088, Bentall Postal Station

Vancouver, British Columbia

Canada V7X 1G4

(Address of principal executive offices)

Indicate by check mark whether the registrant files or will file annual reports under cover Form 20-F or Form 40-F. ☐ Form 20-F ☒ Form 40-F

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(1): ☐

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(7): ☐

DOCUMENTS FILED AS PART OF THIS FORM 6-K

See the Exhibit Index hereto.

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| SSR Mining Inc. (Registrant) | ||||||||

| Date: October 23, 2017 | By: | Signed: “Gregory Martin” | ||||||

| Gregory Martin | ||||||||

| Title: | Chief Financial Officer | |||||||

SUBMITTED HEREWITH

Exhibits

| 99.1 | NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | |

| 99.2 | Consent of Dominic Chartier | |

| 99.3 | Consent of Jeffrey Kulas | |

| 99.4 | Consent of Mark Liskowich | |

| 99.5 | Consent of Michael Selby | |

| 99.6 | Certificate of Qualified Person—Dominic Chartier | |

| 99.7 | Certificate of Qualified Person—Jeffrey Kulas | |

| 99.8 | Certificate of Qualified Person—Mark Liskowich | |

| 99.9 | Certificate of Qualified Person—Michael Selby | |

Table of Contents

Exhibit 99.1

NI 43-101 Technical Report

for the Seabee Gold Operation,

Saskatchewan, Canada

Report Prepared for

SSR Mining Inc./SGO Mining Inc.

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page i |

NI 43-101 Technical Report

for the Seabee Gold Operation,

Saskatchewan, Canada

SSR Mining Inc. and SGO Mining Inc.

Suite 800, Four Bentall Centre

1055 Dunsmuir Street

Vancouver, British Columbia, V7X 1G4, Canada

Website: www.ssrmining.com

Tel: +1 (604) 689-3846

SRK Consulting (Canada) Inc.

Suite 101, 1984 Regent St. South

Sudbury, Ontario, P3E 5S1, Canada

E-mail: [email protected]

Website: www.srk.com

Tel: +1 705 682 3270

SRK Project Number 5CS010.001

Effective date: December 31, 2016

Signature date: October 20, 2017

Qualified Persons:

| [“Original signed”] | [“Original signed”] | |

| Michael Selby, PEng Principal Consultant (Mining) SRK Consulting (Canada) Inc. APEGS#30781 |

Dominic Chartier, PGeo Senior Consultant (Geology) SRK Consulting (Canada) Inc. APEGS#39656 | |

| [“Original signed”] | [“Original signed”] | |

| Mark Liskowich, PGeo Principal Consultant (Environment) SRK Consulting (Canada) Inc. APEGS#10005 |

Jeffrey Kulas, PGeo Manager Geology, Mining at Seabee Gold Operation SSR Mining Inc. APEGS#12374 | |

Reviewed by:

| [“Original signed”] | [“Original signed”] | |

| Gary Poxleitner, PEng Principal Consultant (Mining) SRK Consulting (Canada) Inc. PEO#100059860 |

Glen Cole, PGeo Principal Consultant (Resource Geology) SRK Consulting (Canada) Inc. APGO#1416 |

Contributing Authors:

| Trevor Podaima, PEng |

G. Ross MacFarlane, PEng |

Caitlyn Adams, GIT |

Cover: Seabee mine site, Seabee Gold Operation.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page ii |

This technical report (Report) was prepared as a National Instrument 43-101 – Standards of Disclosure for Mineral Projects (NI 43-101) technical report for SSR Mining Inc. (SSR Mining) by SRK Consulting (Canada) Inc. (SRK). The quality of information, conclusions, and estimates contained herein are consistent with the quality of effort involved in SRK’s services. The information, conclusions, and estimates contained herein are based on: i) information available at the time of preparation; ii) data supplied by outside sources; and iii) the assumptions, conditions, and qualifications set forth in this Report. This Report is intended for use by SSR Mining subject to the terms and conditions of its contract with SRK and relevant securities legislation. The contract permits SSR Mining to file this Report as a technical report with Canadian securities regulatory authorities pursuant to NI 43-101. Except for the purposes legislated under provincial securities law, any other uses of this Report by any third party is at that party’s sole risk. The responsibility for this disclosure remains with SSR Mining. The user of this document should ensure that this is the most recent NI 43-101 technical report for the property as it is not valid if a new NI 43-101 technical report has been issued.

© 2017 SRK Consulting (Canada) Inc.

This document, as a collective work of content and the coordination, arrangement and any enhancement of said content, is protected by copyright vested in SRK Consulting (Canada) Inc. (SRK).

Outside the purposes legislated under provincial securities laws or stipulated in SRK’s client contract, this document shall not be reproduced in full or in any edited, abridged or otherwise amended form unless expressly agreed in writing by SRK.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page iii |

CAUTIONARY NOTE REGARDING FORWARD-LOOKING STATEMENTS

This Report contains “forward-looking information” and “forward-looking statements” (collectively, “forward-looking statements”) within the meaning of applicable Canadian and United States securities legislation. These forward-looking statements include, but are not limited to, SSR Mining’s objectives, strategies, intentions, expectations, production, costs, capital and exploration expenditure guidance, including the estimated economics of the Seabee Gold Operation; future financial and operating performance and prospects; the expansion of the Seabee Gold Operation based on the results of the PEA; the PEA representing production growth and improved margins; processing facilities and events that may affect Seabee Gold Operation’s operations; anticipated cash flows from the Seabee Gold Operation and related liquidity requirements; the anticipated effect of external factors on revenue, such as commodity prices, estimation of Mineral Reserves and Mineral Resources, mine life projections, recovery rate and concentrate grade projections, reclamation costs, economic outlook, government regulation of mining operations; expectations regarding the timing and ability to obtain the necessary environmental approvals under the PEA; and anticipated mine plan. All statements in this Report that address events or developments that SSR Mining expects to occur in the future are forward-looking statements. Forward-looking statements are statements that are not historical facts and are generally, although not always, identified by words such as “expect”, “plan”, “anticipate”, “project”, “target”, “potential”, “schedule”, “forecast”, “budget”, “estimate”, “intend” or “believe” and similar expressions or their negative connotations, or that events or conditions “will”, “would”, “may”, “could”, “should” or “might” occur. All such forward-looking statements are based on the opinions and estimates of SSR Mining as of the date such statements are made. All of the forward-looking statements in this Report are qualified by this cautionary note.

Forward-looking statements are not, and cannot be, a guarantee of future results or events. Forward-looking statements are based on, among other things, opinions, assumptions, estimates and analyses that, while considered reasonable at the date the forward-looking statements is provided, inherently are subject to significate risks, uncertainties, contingencies and other factors that may cause actual results and events to be materially different from those expressed or implied by the forward-looking statement. The material factors or assumptions that SSR Mining identified and were applied by SSR Mining in drawing the conclusions or making forecasts or projections set in the forward-looking statements include, but are not limited to: the factors identified in Table i, Table 9 and Table 34 and Sections 14.5 and 24.3.2 of this Report which may affect the Mineral Resource estimate; the assumptions identified in Table ii, Table 11 and Table 35 and Section 15.2 of this Report which may affect the Mineral Reserve estimate; the capital and operating cost assumptions identified in Sections 21 and 24.6 of the Report; the assumptions identified in Section 24.9 of this Report that may affect the economic analysis under the PEA; dilution and mining recovery assumptions; assumptions regarding stockpiles; the success of mining, processing, exploration and development activities; the accuracy of geological, mining and metallurgical estimates; anticipated metal prices and the costs of production; no significate unanticipated operational or technical difficulties; the availability of personnel for exploration, development and operation of the Seabee Gold Operation; maintaining good relations with the communities surrounding the Seabee Gold Operation; no significant events or changes relating to regulatory, environmental, health and safety matters; certain tax matters and no significate and continuing adverse changes in general economic conditions or conditions in the financial markets (including commodity prices, foreign exchange rates and inflation rates).

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page iv |

The risks, uncertainties, contingencies and other factors that may cause actual results to differ materially from those expressed or implied by the forward-looking statements may include, but are not limited to, risks generally associated with the mining industry, such as economic factors (including future commodity prices, currency fluctuations, inflation rates, energy prices and general cost escalation); uncertainties relating to the development of the Seabee Gold Operation; dependence on key personnel and employee relations; risks relating to political and social unrest or change, operational risk and hazards, including unanticipated environmental, industrial and geological events and developments and the inability to insure against all risks; failure of plant, equipment, processes, transportation and other infrastructure to operate as anticipated; compliance with government and environmental regulations, including permitting requirements and anti-bribery legislation; depletion of Mineral Reserves; the failure to obtain required approvals or clearances from government authorities on a timely basis; uncertainties related to the geology, continuity, grade and estimates of Mineral Reserves and Mineral Resources and the potential for variations in grade and recovery rates; uncertainties relating to reclamation activities; tax refunds; hedging contracts; as well as other factors identified and as described in more detail under the heading “Risk Factors” in SSR Mining’s most recent Annual Information Form, which may be viewed at www.sedar.com. The list is not exhaustive of the factors that may affect the forward-looking statements. There can be no assurance that such statements will prove to be accurate, and actual results, performance or achievements could differ materially from those expressed in, or implied by, these forward-looking statements. Accordingly, no assurance can be given that any events anticipated by the forward-looking statements will transpire or occur, or if any of them do, what benefits or liabilities SSR Mining will derive therefrom. The forward-looking statements reflect the current expectations regarding future events and operating performance and speak only as of the date hereof and SSR Mining does not assume any obligation to update the forward-looking statements if circumstances or management’s beliefs, expectations or opinions should change other than as required by applicable law. For the reasons set forth above, undue reliance should not be placed on forward-looking statements.

This disclosure includes certain terms or performance measures commonly used in the mining industry that are not defined under International Financial Reporting Standards (IFRS), including cash costs and all-in sustaining costs per payable ounce of gold sold. Non-GAAP measures do not have any standardized meaning prescribed under IFRS and, therefore, they may not be comparable to similar measures employed by other companies. The data presented is intended to provide additional information and should not be considered in isolation or as a substitute for measures of performance prepared in accordance with IFRS. Readers should also refer to SSR Mining’s management’s discussion and analysis, available under its corporate profile at www.sedar.com or on its website at www.ssrmining.com, under the heading “Non-GAAP and Additional GAAP Financial Measures” for a more detailed discussion of how SSR Mining calculates such measures.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page v |

| 1 | Executive Summary |

The Seabee Gold Operation is an underground gold mining and milling operation, located in Saskatchewan, Canada, approximately 125 kilometres northeast of the town of La Ronge. SSR Mining Inc. (SSR Mining) holds a 100 percent interest in the property through its wholly-owned subsidiary, SGO Mining Inc. (formerly Claude Resources Inc. (Claude Resources)) (SGO Mining).

SSR Mining, formerly Silver Standard Resources Inc., is a Vancouver-based mining company focused on the operation, development, exploration and acquisition of precious metal projects. It is listed under the ticker symbol SSRM on the NASDAQ Capital Markets and the Toronto Stock Exchange. SSR Mining is a precious metals producer with three operations, including the Seabee Gold Operation, the Marigold gold mine in Nevada, U.S., and the 75 percent owned and operated Puna Operations joint venture in Jujuy Province, Argentina. Puna Operations consists of the Pirquitas operation and the Chinchillas project.

In May 2017, SSR Mining commissioned SRK Consulting (Canada) Inc. (SRK) to visit the property to audit and prepare a NI 43-101 technical report in support of its Mineral Resource models, Mineral Reserve estimate, and preliminary economic assessment (PEA) that considers an expansion scenario and includes Inferred Mineral Resources in respect of such proposed expansion scenario. The services were rendered between May 2017 and August 2017 leading to the preparation of the Mineral Resource Statement and Mineral Reserve Statement reported herein and the PEA summarized herein that were disclosed publicly by SSR Mining in a news release on September 7, 2017.

This NI 43-101 technical report (Report) provides a summary of the current Seabee Gold Operation, including the current Mineral Resources and Mineral Reserves estimates for such operation, as at the effective date of this Report. Section 24 provides a proposed PEA expansion scenario currently being considered by SSR Mining. Unless specified otherwise, disclosure outside of Section 24 of this Report describes the Seabee Gold Operation as presently conducted and not as contemplated under the PEA.

Property Description and Ownership

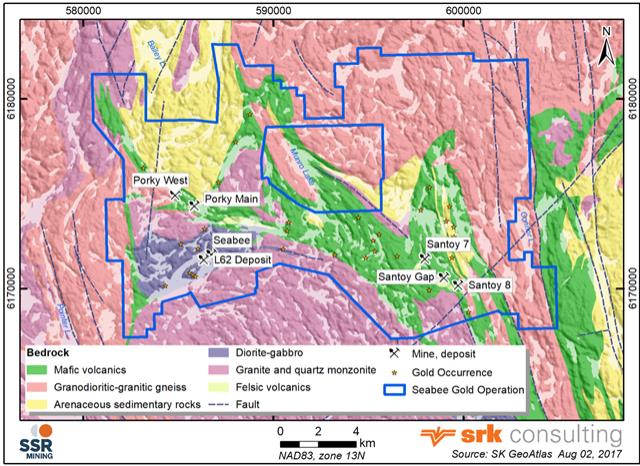

The Seabee Gold Operation is located at the north end of Laonil Lake, approximately 125 kilometres northeast of the town of La Ronge, Saskatchewan, Canada. The property hosts two operating mines – the Seabee mine and the Santoy mine – with the Santoy mine situated approximately 14 kilometres to the east of the Seabee mine.

A central milling facility is located on the property near the Seabee mine. The centre of the property is located at approximately 55.7 degrees latitude north and 103.5 degrees longitude west.

The Seabee Gold Operation is comprised of six mineral leases and 40 mineral claims that cover an area of approximately 23,700 hectares. SSR Mining holds a 100 percent interest in the property through its wholly-owned subsidiary, SGO Mining.

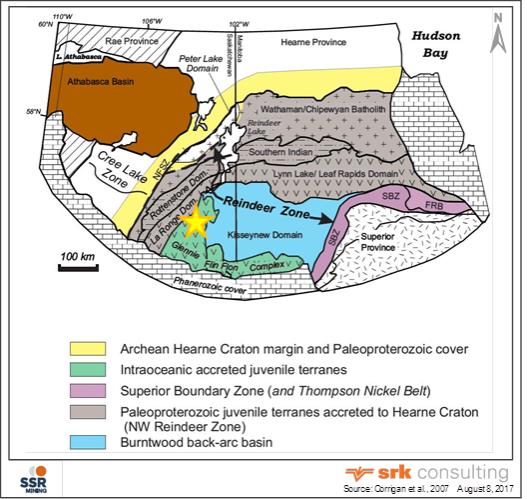

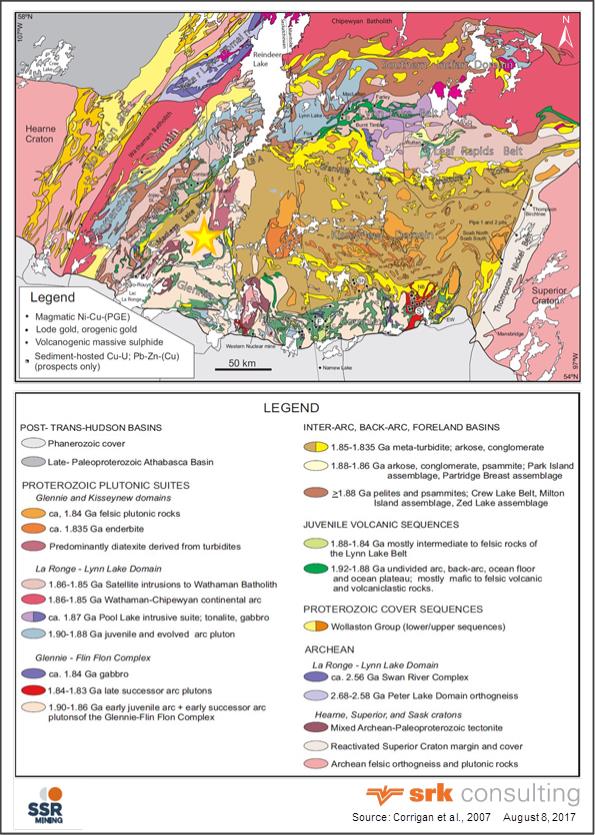

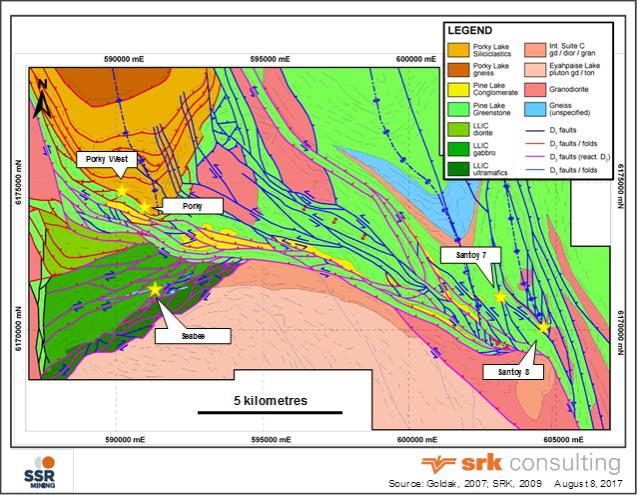

The Seabee Gold Operation is located within the northern portion of the Pine Lake greenstone belt. The belt has a strike length in excess of 50 kilometres and comprises a variety of geochemically distinct tholeiitic mafic volcanic rocks formed in juvenile island arc settings, along with contemporaneous mafic intrusive rocks, volcaniclastics, sediments and felsic intrusions of varying age. Metamorphic grade across the Pine Lake greenstone belt ranges from upper greenschist to upper amphibolite, with the Seabee Gold Operation hosted in the latter. The belt has been complexly folded by at least four major phases of deformation that are observed across the Seabee Gold Operation site and elsewhere in the Glennie domain of the Proterozoic Trans-Hudson Orogen.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page vi |

The Seabee Gold Operation can be subdivided into three main geological domains:

| • | The Seabee mine area is hosted within a coarsely layered mafic intrusion dominated by gabbro in the mine sequence. |

| • | The Santoy mine area is hosted within a sequence of mafic volcano-sedimentary rocks separated by generally north-south trending thrust faults. |

| • | The Porky deposit area is a mineralized trend hosted along a 12-kilometre long openly folded unconformity, separating arenaceous sedimentary rocks of the Rae Lake synform to the north from mafic volcanic rocks of the Seabee mine area to the south. |

Gold mineralization at the Seabee mine is hosted within an extensive network of sub-parallel shear structures, which crosscut the Laonil Lake intrusive complex. Vein mineralogy is dominantly quartz with pyrite, pyrrhotite and chalcopyrite, and accessory tourmaline and carbonate. Gold occurs primarily as free, finely disseminated flakes and films replacing pyrite or at sulphide boundaries. Higher grade gold values are most often associated within sulphide rich zones or at vein junctions. Silicification is the most common alteration type observed at the Seabee mine.

Gold mineralization at the Santoy mine is hosted within calc-silicate altered shear structures with diopside-albite +/- titanite-bearing quartz veins, and occurs in gold-sulphide-chlorite-quartz veins in the shear zones, near or in the granodiorite and granite sills. Diopside-albite calc-silicate alteration facies are the main host to gold mineralization in the Santoy 8A and Santoy Gap 9A, 9B and 9C zones. The Santoy Gap deposit occurs along a major inflection of the Santoy shear zone between the Santoy 7 and Santoy 8 deposits.

At the Porky deposit, the brittle-ductile lode gold system is hosted along a thick corridor of calc-silicate altered mafic volcanics and arenaceous sedimentary rocks that straddle a major unconformity along the southern margin of the Rae Lake synform. Both the Porky Main and Porky West deposits are characterized by the same calc-silicate alteration package; however, the unconformity and arenites host most of the auriferous quartz veins at the Porky West deposit.

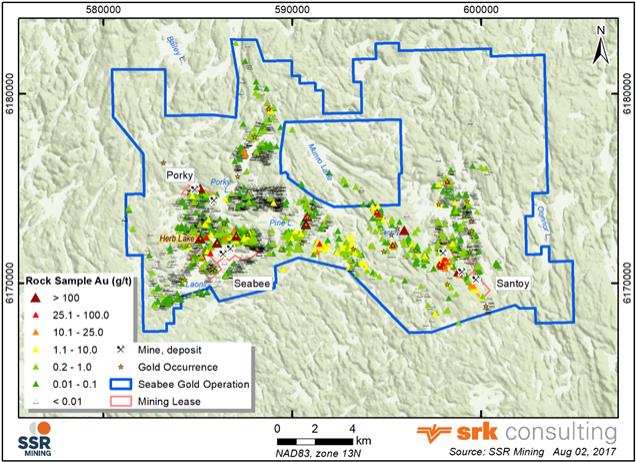

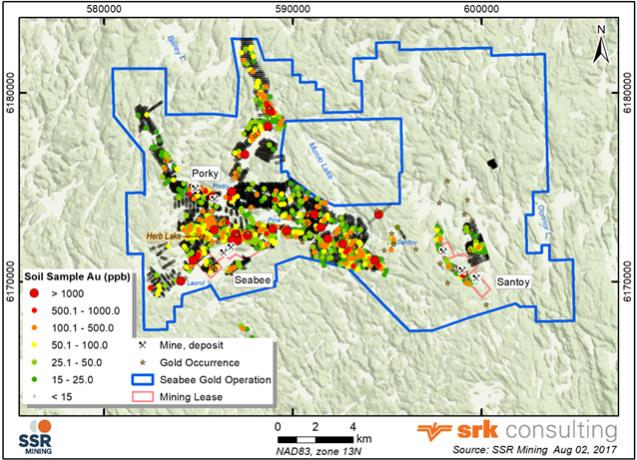

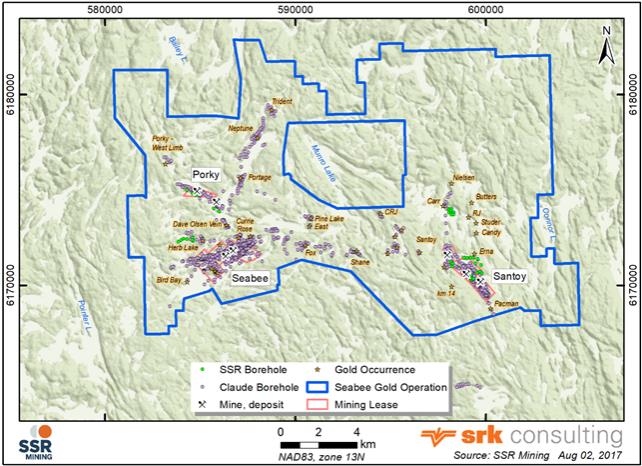

The Laonil Lake region has been explored since the 1940s, with the first gold discovery made by prospectors in 1947. Since that time, exploration at the Seabee Gold Operation has comprised of surficial geochemical sampling, airborne and ground geophysical surveys and extensive drilling. To date, drilling on the Seabee Gold Operation property by SSR Mining and previous operators includes 2,134 surface boreholes totaling 431,849 metres and 5,208 underground boreholes totaling 959,474 metres. Exploration surface drilling and infill surface and underground drilling completed by SSR Mining in 2017 has been executed in the Carruthers, Herb Lake, Porky Main, Porky West, Seabee, and Santoy areas, where a total of 55,690 metres have been drilled from 130 boreholes.

The objective of ongoing exploration conducted by SSR Mining is to delineate, increase and upgrade Mineral Resources. Underground drilling in the first quarter of 2017 focused on the Santoy Gap, Santoy 8A vein and the Santoy Gap Hanging Wall. Drilling at Santoy Gap aims to increase or upgrade Inferred Mineral Resources, and drilling at Santoy 8 is focused on upgrading existing Mineral Resources at the Santoy 8A vein. At the Santoy Gap Hanging Wall, surface drilling is designed to confirm the potential of the new target. Further drilling at all three targets will determine the continuity of the gold mineralization.

At the Seabee Gold Operation, the 2017 surface and underground infill diamond drilling program plan is to complete up to 60,000 metres of drilling to upgrade existing Mineral Resources and to discover additional Inferred Mineral Resources at Santoy Gap, Santoy 8 and the Seabee mine. At the Seabee mine, approximately 30 percent of underground drilling is allocated for testing of targets to maximize Mineral Resource potential at the mine as SSR Mining develops its long-term strategy. A surface and underground infill diamond drilling program of 300,000 metres is proposed by SSR Mining between 2018 and 2022. This program is focused on upgrading the Inferred Mineral Resource and other near mine targets within the infrastructure corridor between the Seabee mine and Santoy mine.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page vii |

Surface exploration drilling in the first quarter of 2017 focused on the Porky Main, Carr and Herb deposits. Encouraging results have prompted additional exploration drilling to define additional Inferred Mineral Resources. Surface drilling at the Seabee Gold Operation is expected to complete approximately 28,500 metres on up to nine regional targets in 2017. Continued surface exploration is planned for the Seabee and Santoy deposits, with more aggressive 20,000 metre programs scheduled for 2018 and 2019, and programs of 12,000 metres scheduled for 2020 and 2021.

In addition, 5,000 soil samples are planned to be collected in 2017 to compliment the 2016 geochemical soil sampling program near Santoy Lake. This exploration program is scheduled to be followed-up with prospecting and trenching to delineate drill targets for 2018.

A total of C$2.9 million is budgeted for the 2017 Seabee and Santoy exploration programs.

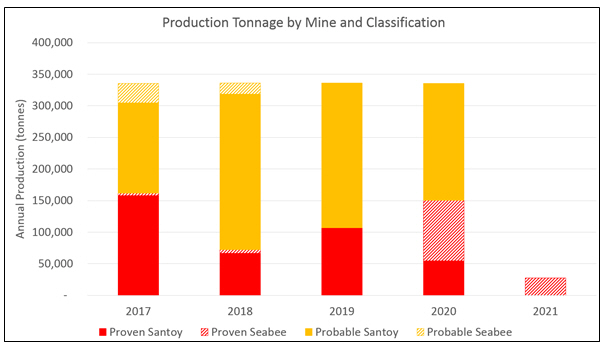

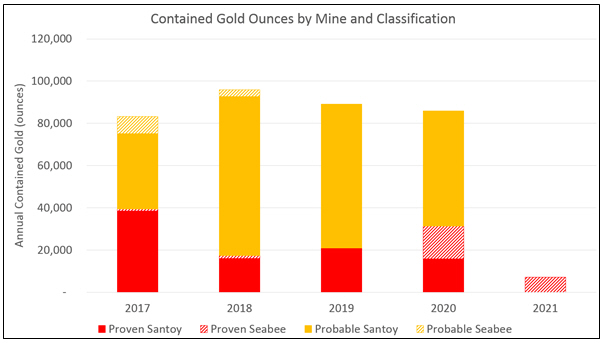

The life of mine plan of the Mineral Reserve at the Seabee Gold Operation, commencing January 1, 2017, includes 1.371 million tonnes at an average grade of 8.19 grams of gold per tonne (g/t gold). A total of 361,000 ounces of gold will be delivered to the mill.

There are currently two operating mines as part of the Seabee Gold Operation, Santoy mine and Seabee mine. Mining will take place at both the Santoy mine and Seabee mine at an average combined total production rate of 920 tonnes per day. Continuous production from the Seabee mine is scheduled to be completed in 2018, with some lower value remnant mining planned to coincide with the closure of the entire Seabee Gold Operation in 2021. Thus, the Santoy mine will provide most of the production included in the Mineral Reserve estimate. To achieve the Mineral Reserve production plan, 14,300 metres of capital and operating development is required.

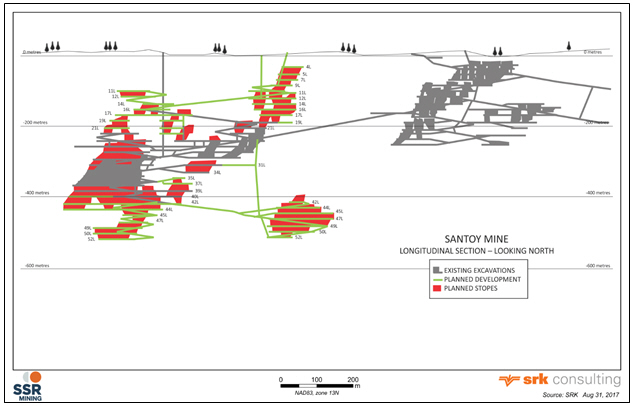

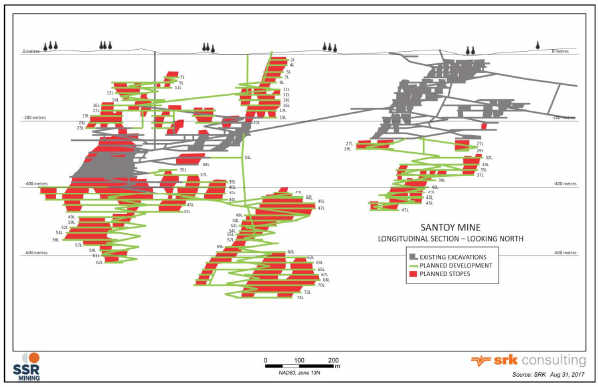

Access underground at the Santoy mine is provided from surface at the Santoy portal via a main ramp. Sublevels are typically spaced 17 metres vertically. At the Santoy mine, stoping will take place between 7 Level and 52 Level. Stopes are mined and will continue to be mined via a longhole mining method. The planned stopes range in width from 2.2 up to 26.0 metres and can be up to 40.0 metres in length. Once mined, where sequencing and access requirement dictate, stopes are backfilled with waste rock or cemented waste rock. The mining sequence will continue to proceed in several longitudinally retreating, bottom-up advancing mining fronts. Current practice for material handling will remain with ore being truck hauled to surface and then hauled 14.0 kilometres to the mill located at the Seabee mine.

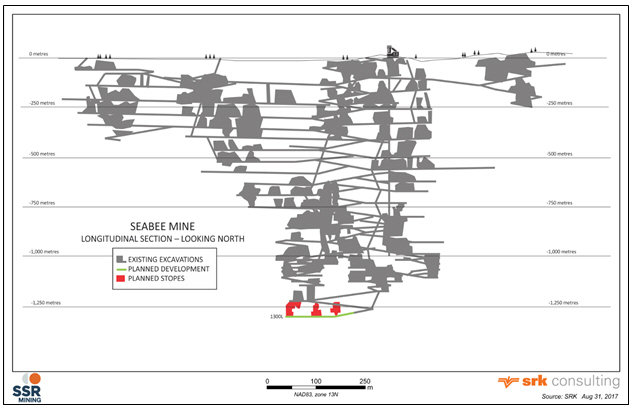

At the Seabee mine, mining will occur on 1300 Level. Access from surface from the Seabee portal will be provided via a main ramp to the deepest levels. Alimak mining methods will be used to recover the remaining planned stopes. The Seabee shaft will continue to be used to hoist the ore to surface.

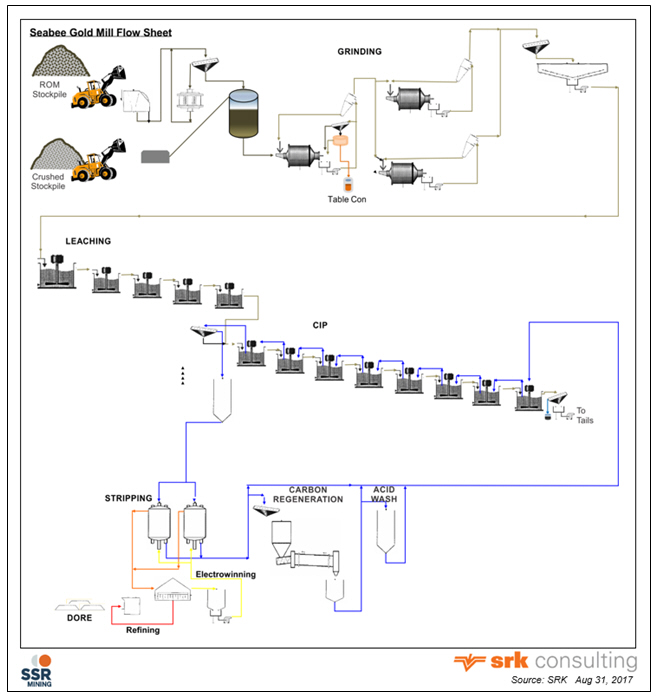

Material has been processed for 25 years in the mill constructed immediately adjacent to the Seabee shaft. The operation was initially developed and operated on diesel power and later connected to Saskatchewan grid power in 1992. The initial capacity of the mill was 500 tonnes per day, which was later expanded to a nameplate capacity of 1,000 tonnes per day, with the addition of a third grinding mill in 2005. The mill flowsheet is a conventional crushing and grinding circuit employing gravity concentration and cyanide leaching and carbon-in-pulp for recovery and production of doré gold on site. Currently, an addition to the gravity recovery circuit is being installed that will increase the gravity gold recovery and reduce the limitations of the main cyanide leach circuit.

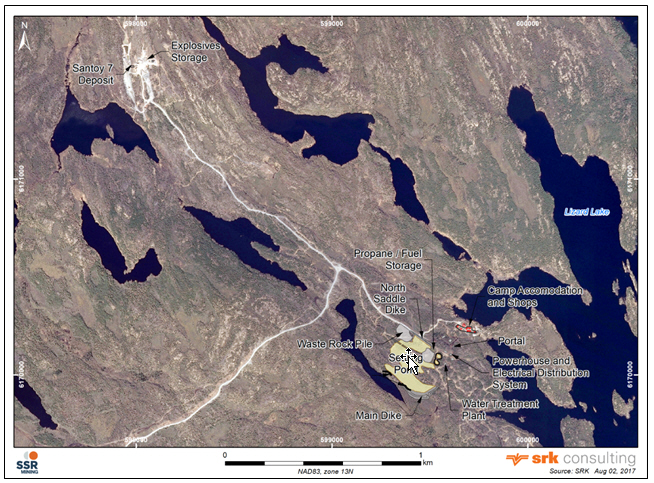

The major infrastructure at the Seabee Gold Operation site includes roads and an airstrip, powerhouse and electrical distribution system, mill buildings and related services facilities, Seabee shaft and headframe, portals and ventilation raises, fuel storage, explosive storage, water supply and distribution, water management ponds and water treatment plant, tailings management facilities, administrative buildings, and camp accommodation.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page viii |

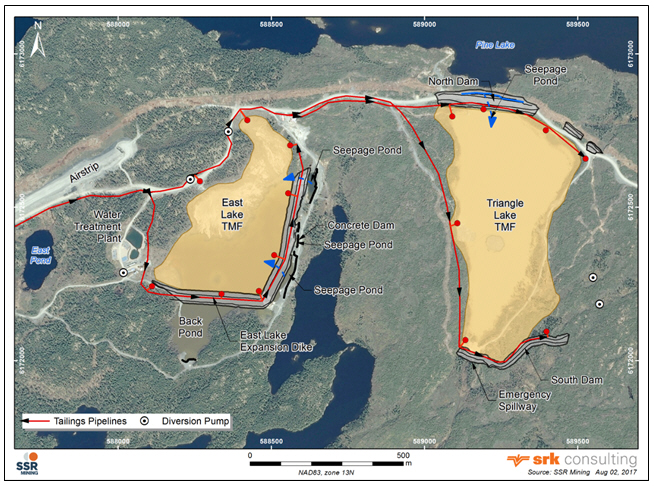

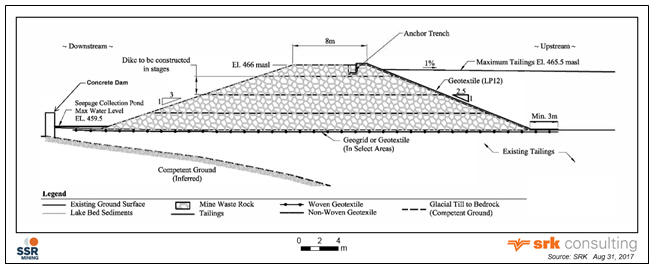

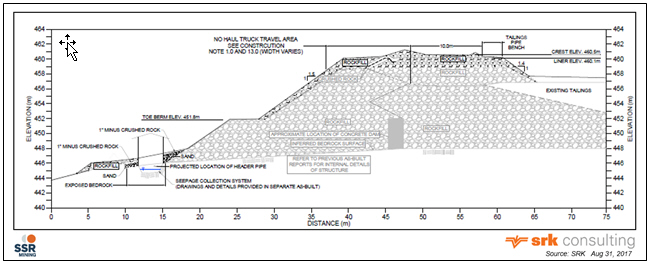

There are currently two tailings management facilities that are being used by the mill: the East Lake tailings management facility (East Lake TMF) and the Triangle Lake tailings management facility (Triangle Lake TMF). Tailings deposition alternates between the two tailings management facilities where winter deposition occurs in the Triangle Lake TMF and summer deposition is in the East Lake TMF. The remaining storage capacities of both facilities, based on the planned production rates, will potentially reach maximum capacity in early 2021. To ensure that water treatment volumes are attained, a new water treatment plant at East Lake TMF has been constructed in 2017.

Mineral Resource and Mineral Reserve Estimates

The Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards for Mineral Resources and Mineral Reserves (May 2014) defines a Mineral Resource as follows:

“A Mineral Resource is a concentration or occurrence of solid material of economic interest in or on the Earth’s crust in such form, grade or quality and quantity that there are reasonable prospects for eventual economic extraction.

The location, quantity, grade or quality, continuity and other geological characteristics of a Mineral Resource are known, estimated or interpreted from specific geological evidence and knowledge, including sampling.”

The “reasonable prospects for eventual economic extraction” requirement generally implies that the quantity and grade estimates meet certain economic thresholds and that the Mineral Resources are reported at an appropriate cut-off grade, taking into account extraction scenarios and processing recoveries. In order to meet this requirement, SSR Mining considers that the majority of the Seabee Gold Operation is amenable for underground extraction.

The block model and polygonal quantities and grade estimates were also reviewed to determine the portions of the Seabee mine, Santoy mine, and Porky deposits having “reasonable prospects for eventual economic extraction” from an underground mine, based a cut-off grade of 4.40 g/t gold at the Seabee mine and 3.26 g/t gold at the Santoy mine assuming a gold price of US$1,400 per ounce, and metallurgical gold recovery of 96.5 percent. The reporting parameters were selected based on production experience at the Seabee Gold Operation.

SSR Mining considers that the blocks located within the classification domains and the polygonal estimates show “reasonable prospects for eventual economic extraction” and can be reported as a Mineral Resource. The Mineral Resource Statement for the Seabee Gold Operation is presented in Table i.

The Mineral Reserve estimate was completed by the SSR Mining technical department on site at the Seabee Gold Operation. SRK reviewed the assumptions, parameters, and methods used to prepare the Mineral Reserve Statement and is of the opinion that the Mineral Reserve is estimated in conformity with CIM Mineral Resource and Mineral Reserves Estimation Best Practices Guidelines (November 2003) and is classified according to CIM Definition Standards for Mineral Resources and Mineral Reserves (May 2014) guidelines.

The Mineral Reserve Statement is reported in Table ii and is in accordance with National Instrument 43-101 – Standards of Disclosure for Mineral Projects (NI 43-101). The reference point at which the Mineral Reserve is identified is where ore is delivered to the processing plant (i.e. “mill feed”). SRK is unaware of any environmental, permitting, legal, title, taxation, socio-economic, marketing, political, or other relevant issues that may materially affect the Mineral Reserve estimate. However, the Mineral Reserve may be affected by further infill and exploration drilling that may result in increases or decreases in subsequent Mineral Resource and Mineral Reserve estimates. The Mineral Reserve may also be affected by subsequent assessments of mining, environmental, processing, permitting, taxation, socio-economic, and other factors. The effective date of the Mineral Reserve Statement is December 31, 2016.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page ix |

Table i: Mineral Resource Statement, Seabee Gold Operation, Saskatchewan, SSR Mining Inc., December 31, 2016

| Classification/Area |

Quantity (‘000 t) |

Grade Gold (g/t) |

Contained Gold (‘000 oz) |

|||||||||

| Measured |

||||||||||||

| Seabee |

175 | 6.76 | 38 | |||||||||

| Santoy Gap |

598 | 7.90 | 152 | |||||||||

| Santoy 8 |

33 | 9.29 | 10 | |||||||||

| Porky West |

— | — | — | |||||||||

|

|

|

|

|

|

|

|||||||

| Total Measured |

807 | 7.71 | 200 | |||||||||

|

|

|

|

|

|

|

|||||||

| Indicated |

||||||||||||

| Seabee |

111 | 8.39 | 30 | |||||||||

| Santoy Gap |

688 | 8.40 | 186 | |||||||||

| Santoy 8 |

367 | 9.12 | 108 | |||||||||

| Porky West |

101 | 3.57 | 12 | |||||||||

|

|

|

|

|

|

|

|||||||

| Total Indicated |

1,267 | 8.22 | 335 | |||||||||

|

|

|

|

|

|

|

|||||||

| Total M&I |

2,074 | 8.02 | 535 | |||||||||

|

|

|

|

|

|

|

|||||||

| Inferred |

||||||||||||

| Seabee |

356 | 8.62 | 99 | |||||||||

| Santoy Gap |

510 | 9.23 | 151 | |||||||||

| Santoy 8 |

1,454 | 7.14 | 334 | |||||||||

| Porky West |

175 | 5.48 | 31 | |||||||||

|

|

|

|

|

|

|

|||||||

| Total Inferred |

2,495 | 7.66 | 615 | |||||||||

|

|

|

|

|

|

|

|||||||

Notes: Mineral Resources are not Mineral Reserves and have not demonstrated economic viability. Mineral Resources are reported inclusive of Mineral Reserves. All figures are rounded to reflect the relative accuracy of the estimates. Mineral Resources are reported within classification domains inclusive of in-situ dilution at a diluted cut-off grade of 4.40 g/t gold at the Seabee mine and 3.26 g/t gold at the Santoy mine assuming an underground extraction scenario, a gold price of US$1,400/oz, C$:US$ exchange rate of 1.25; and metallurgical recovery of 96.5%. Block modelling techniques were used for Mineral Resource estimates for the Santoy mine and the majority of the Seabee mine. Polygonal techniques were used in areas of historical mining at the Seabee mine at Porky West.

Table ii: Mineral Reserve Statement, Seabee Gold Operation, Saskatchewan, Canada SRK Consulting (Canada) Inc., December 31, 2016

| Category |

Quantity (‘000 t) |

Gold Grade (g/t) |

Contained Gold (‘000 oz) |

|||||||||

| Proven |

||||||||||||

| Santoy Mine |

380 | 7.41 | 90 | |||||||||

| Seabee Mine |

82 | 6.98 | 18 | |||||||||

| Broken (Underground and Stockpile) |

56 | 4.04 | 7 | |||||||||

|

|

|

|

|

|

|

|||||||

| Total Proven |

518 | 6.97 | 116 | |||||||||

|

|

|

|

|

|

|

|||||||

| Probable |

||||||||||||

| Santoy Mine |

805 | 9.03 | 234 | |||||||||

| Seabee Mine |

48 | 7.37 | 11 | |||||||||

|

|

|

|

|

|

|

|||||||

| Total Probable |

854 | 8.93 | 245 | |||||||||

|

|

|

|

|

|

|

|||||||

| Total Proven and Probable |

1,371 | 8.19 | 361 | |||||||||

|

|

|

|

|

|

|

|||||||

Notes: Mineral Reserves are included in Mineral Resources. All figures have been rounded to reflect the relative accuracy of the estimate. Mineral Reserves are based on a cut-off value of 4.92 g/t gold for the Seabee mine and 3.65 g/t gold for the Santoy mine assuming: a gold price of US$1,250/oz; a C$:US$ exchange rate of 1.25; milling recoveries of 96.5%; royalty of 3.0%; and operating cost of C$231/t at the Seabee mine and C$172/t at the Santoy mine. Mineral Reserves are stated at a mill feed reference point and include for diluting materials and mining losses.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page x |

SSR Mining has successfully completed three environmental assessments for the Seabee Gold Operation to date. The site is regulated by both the Saskatchewan Ministry of Environment and Environment and Climate Change Canada. In accordance with provincial environmental legislation and regulations, the operation must adhere to the terms and conditions of an Approval to Operate a Pollutant Control Facility (Approval to Operate). The Seabee Gold Operation is in compliance with all the terms and conditions of its current Approval to Operate number PO16-002, issued in January 2016 with an expiry date of September 2019. SSR Mining is responsible to submit an application to renew this Approval to Operate a minimum of 90 days prior to the expiry date.

The dominant environmental liability at the Seabee Gold Operation is the management of the mill tailings and associated tailings effluent. Appropriate infrastructure and operational plans are in place to reduce operational and closure risks associated with these liabilities to acceptable levels.

SSR Mining has initiated a thorough stakeholder engagement plan designed to strengthen its relationship with communities impacted by the Seabee Gold Operation, and the existing social license to continue operations of the facility. No significant public concern with the Seabee Gold Operation was expressed during stakeholder engagement meetings held in 2016 and 2017.

There are no known environmental concerns at the Seabee Gold Operation that cannot be successfully mitigated through the implementation of the various approved management plans that have been developed based on accepted scientific and engineering practices.

In accordance with provincial regulations, SSR Mining has submitted an updated decommissioning and reclamation plan and cost estimate every five years, since 1996. Following initial regulatory review and subsequent edits by SSR Mining, the 2016 revision to the preliminary decommissioning and reclamation plan is under final review by the Ministry of Environment. The total cost to implement the closure plan through the use of a third party contractor is C$7.2 million. This cost estimate incorporates costs to cover release of the property, following the successful implementation of the closure plan, back to the province by way of Saskatchewan’s Institutional Control Program.

The PEA is preliminary in nature and includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that the PEA will be realized.

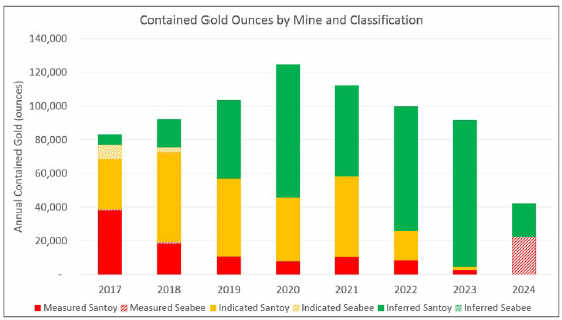

Based on SSR Mining’s operating experience and investment in exploration to increase Mineral Resources at the Seabee Gold Operation since its acquisition in May 2016, the PEA contemplates the technical and investment requirements for and demonstrates the economics of a potential expansion to a sustained mining and milling rate of 1,050 tonnes per day. This results in increased gold production and decreased cash costs, over a seven-year operating period. Developing and evaluating this production plan assists SSR Mining in identifying potential strategic, long term direction for Seabee Gold Operation.

By including the Inferred Mineral Resource in the PEA production plan, a production rate of 1,050 tonnes per day can be sustained until 2024. Overall, the life of mine plan, commencing July 1, 2017, includes 2.654 million tonnes at an average grade of 8.30 g/t gold (including dilution). The total gold delivered to the mill under the PEA would be 708,000 ounces.

Mining would occur at both the Seabee mine and Santoy mine in 2017 and 2018. After 2018, the Santoy mine would be the only source of feed until 2024, when the known Mineral Resource is exhausted and some lower value remnant mining is completed back at the Seabee mine. The production rate would ramp up gradually from 920 tonnes per day in 2017 to 1,050 tonnes per day in 2019 as additional mining fronts are established at the Santoy mine. To achieve the production plan under the PEA, 28,900 metres of capital and operating development would be required.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xi |

At the Santoy mine, the footprint expands from that of the Mineral Reserve. Access underground from surface is still maintained via the Santoy portal and main ramp. Stoping would take place from 2 Level to as deep as 74 Level. The stopes would be mined via longhole mining methods. Mining at the Seabee mine is identical to that included in the current production plan for the Seabee Gold Operation.

Additional site infrastructure improvements are included in the PEA for the camp accommodation, the diesel storage, the Santoy mine electrical distribution, and a tailings management facility expansion.

The capital costs required to achieve the PEA life of mine are summarized in Table iii.

The operating expense estimated for the PEA is summarized in Table iv. On inclusion of royalties and treatment and refining charges, and sustaining capital costs, the operating cost translates into a cash cost of US$548 per payable ounce of gold and an all-in sustaining cost (AISC) of US$682 per payable ounce of gold.

Cash costs and AISC per payable ounce of gold sold are non-GAAP financial measures. Please see “Cautionary Note Regarding Forward-Looking Statements” in this Report.

Table iii: Summary of PEA Capital Costs

| Cost Component |

Value US$ MM |

|||

| Infrastructure capital |

50.2 | |||

| Capital development |

23.4 | |||

| Capitalized exploration |

15.9 | |||

|

|

|

|||

| Total Capital Cost |

89.6 | |||

|

|

|

|||

Note: Sum of individual values may not match total due to rounding.

Table iv: Summary of PEA Operating Costs

| Cost Component |

Value US$/t milled |

|||

| Mining |

58 | |||

| Processing |

20 | |||

| General and Administrative |

52 | |||

|

|

|

|||

| Operating Costs |

130 | |||

|

|

|

|||

The estimated post-tax net present value of the Seabee Gold Operation PEA using a discount rate of 5 percent, generated on July 1, 2017 is US$292.0 million. The corresponding pre-tax net present value is US$363.5 million. A summary of key operating and financial estimates is provided in Table v.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xii |

Table v: Key PEA Operating and Financial Estimates

| Item |

Unit of Measure | Value | ||||

| Tonnes milled |

‘000 tonnes | 2,654 | ||||

| Milled grade |

g/t | 8.30 | ||||

| Mine plan |

years | 7 | ||||

| Daily mill production |

tonnes/day | 1,050 | ||||

| Gold milled |

‘000 oz | 708 | ||||

| Gold recovery |

% | 96.5 | ||||

| Gold produced |

‘000 oz | 683 | ||||

| Average annual gold production (2018-2023) |

‘000 oz | 100 | ||||

| Gold price |

US$/oz | 1,300 | ||||

| Exchange rate (2019-2026) |

C$:US$ | 1.25 | ||||

| Cash costs |

US$/payable ounce | 548 | ||||

| Capital costs |

US$ MM | 89.6 | ||||

| AISC |

US$/payable ounce | 682 | ||||

| Cumulative post-tax cash flow |

US$ MM | 346.7 | ||||

| NPV5% (pre-tax) |

US$ MM | 363.5 | ||||

| NPV5% (post-tax) |

US$ MM | 292.0 | ||||

Conclusion and Recommendations

In the opinion of SSR Mining and SRK, the Mineral Resource and Mineral Reserve estimates and the PEA summarized herein have received appropriate geological and engineering consideration to be included in this Report in accordance with NI 43-101. Thus, Mineral Resources and Mineral Reserves can be declared and the PEA can be used as a guide to consider an expansion case for the Seabee Gold Operation.

SRK is not aware of any significant risks and uncertainties that could be expected to affect the reliability or confidence in the information discussed herein.

The current Mineral Reserve life of mine plan extends to the first quarter of 2021. The average production rate is planned to achieve 920 tonnes per day. The Mineral Reserve includes 1.371 million tonnes at an average grade 8.19 g/t gold, for a total of 361,000 contained gold ounces.

In comparison, under the PEA, which includes a portion of the Inferred Mineral Resource, 2.654 million tonnes at an average grade of 8.30 g/t gold are considered, for a total of 708,000 contained gold ounces. At the peak production rate of 1,050 tonnes per day, the PEA estimates a seven-year operating period, concluding in 2024.

SSR Mining has proposed a five-year exploration program at the Seabee Gold Operation that includes 80,000 metres of surface diamond drilling at an estimated cost of US$11 million. This program intends to test various greenfield targets such as the Carr trend and brownfield targets such as those near Munro Lake that also exhibit stratigraphy, alteration, and mineralization similar to the Santoy deposits.

In addition, SSR Mining has proposed an additional infill surface and underground drilling program of 300,000 metres between 2018 and 2022 at an estimated cost of C$16.2 million. The surface drilling will focus on targets between the Santoy mine and Seabee mine that are in proximity to the haulage road and have either limited, but notable historic drilling or surface showings with strong soil sample anomalies; the concept being that production from these targets, if proven, could be achieved within a three to five-year timeline. A total of 210,000 metres included in the underground drilling program is intended to improve the confidence in the Inferred Mineral Resource included in the PEA production profile. Based on the results of the audit of the Mineral Resource and Mineral Reserve estimates and the PEA, SRK recommends executing the exploration and infill diamond drilling programs proposed by SSR Mining to potentially expand and improve the level of confidence in the Mineral Resource estimate. The cost of the underground drilling program has been included in the PEA economic analysis. Structural geology investigations on the property should be ongoing as new drilling data is generated and these should be integrated into regular Mineral Resource model updates.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xiii |

As the geological understanding of the Seabee Gold Operation improves, SRK recommends refining the PEA at least annually to determine modifications to the production plan and provide guidance for further exploration and mining focus. This is current practice for the technical department at the Seabee Gold Operation for the current Mineral Reserve life of mine plan and is covered within normal operating costs.

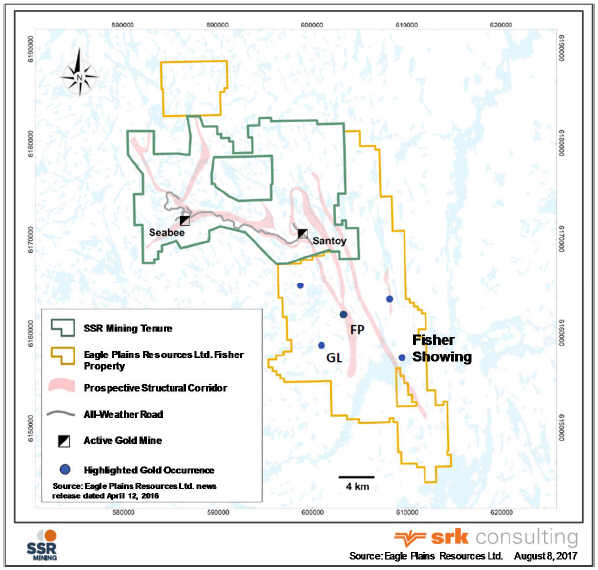

Regional exploration activities should continue, particularly evaluating the southern extension of the Santoy shear zone toward the adjacent Fisher property, which SRK considers having sufficient merit to justify additional exploration expenditures.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xiv |

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xv |

| 8 | Deposit Types | 25 | ||||||||

| 9 |

26 | |||||||||

| 9.1 |

26 | |||||||||

| 9.2 |

28 | |||||||||

| 9.2.1 |

28 | |||||||||

| 9.2.2 |

28 | |||||||||

| 9.2.3 |

29 | |||||||||

| 10 |

30 | |||||||||

| 10.1 |

Drilling by Cominco, Claude Resources, and Placer 1947 – 1988 |

30 | ||||||||

| 10.2 |

31 | |||||||||

| 10.2.1 |

31 | |||||||||

| 10.2.2 |

32 | |||||||||

| 10.3 |

33 | |||||||||

| 10.4 |

33 | |||||||||

| 10.4.1 |

33 | |||||||||

| 10.4.2 |

34 | |||||||||

| 10.5 |

35 | |||||||||

| 10.6 |

35 | |||||||||

| 10.6.1 |

35 | |||||||||

| 10.6.2 |

Drill Core Sampling by Claude Resources and SSR Mining 2009 – 2017 |

35 | ||||||||

| 10.6.3 |

37 | |||||||||

| 10.7 |

37 | |||||||||

| 10.8 |

38 | |||||||||

| 11 |

39 | |||||||||

| 11.1 |

39 | |||||||||

| 11.2 |

39 | |||||||||

| 11.3 |

39 | |||||||||

| 11.4 |

40 | |||||||||

| 11.5 |

40 | |||||||||

| 12 |

41 | |||||||||

| 12.1 |

41 | |||||||||

| 12.2 |

44 | |||||||||

| 12.2.1 |

44 | |||||||||

| 12.2.2 |

44 | |||||||||

| 12.2.3 |

44 | |||||||||

| 13 |

47 | |||||||||

| 13.1 |

47 | |||||||||

| 13.2 |

47 | |||||||||

| 13.3 |

48 | |||||||||

| 14 |

49 | |||||||||

| 14.1 |

49 | |||||||||

| 14.2 |

50 | |||||||||

| 14.2.1 |

50 | |||||||||

| 14.2.2 |

51 | |||||||||

| 14.2.3 |

52 | |||||||||

| 14.3 |

52 | |||||||||

| 14.4 |

52 | |||||||||

| 14.5 |

54 | |||||||||

| 14.6 |

55 | |||||||||

| 14.7 |

56 | |||||||||

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xvi |

| 15 |

57 | |||||||||

| 15.1 |

58 | |||||||||

| 15.2 |

58 | |||||||||

| 15.2.1 |

58 | |||||||||

| 15.2.2 |

59 | |||||||||

| 15.2.3 |

59 | |||||||||

| 15.2.4 |

59 | |||||||||

| 15.3 |

59 | |||||||||

| 16 |

60 | |||||||||

| 16.1 |

60 | |||||||||

| 16.2 |

62 | |||||||||

| 16.3 |

62 | |||||||||

| 16.4 |

62 | |||||||||

| 16.5 |

63 | |||||||||

| 16.6 |

63 | |||||||||

| 16.7 |

63 | |||||||||

| 16.8 |

64 | |||||||||

| 16.9 |

64 | |||||||||

| 16.10 |

64 | |||||||||

| 16.10.1 |

64 | |||||||||

| 16.10.2 |

65 | |||||||||

| 16.10.3 |

65 | |||||||||

| 16.10.4 |

Current Mitigation Measures Used to Minimize the Geotechnical Risk |

66 | ||||||||

| 16.11 |

67 | |||||||||

| 16.12 |

68 | |||||||||

| 17 |

70 | |||||||||

| 17.1 |

70 | |||||||||

| 17.2 |

71 | |||||||||

| 17.3 |

72 | |||||||||

| 17.4 |

72 | |||||||||

| 17.5 |

72 | |||||||||

| 17.6 |

72 | |||||||||

| 17.7 |

72 | |||||||||

| 17.8 |

73 | |||||||||

| 17.9 |

73 | |||||||||

| 17.10 |

73 | |||||||||

| 17.11 |

73 | |||||||||

| 18 |

74 | |||||||||

| 18.1 |

78 | |||||||||

| 18.2 |

78 | |||||||||

| 18.3 |

79 | |||||||||

| 18.3.1 |

79 | |||||||||

| 18.3.2 |

79 | |||||||||

| 18.3.3 |

79 | |||||||||

| 18.3.4 |

79 | |||||||||

| 18.3.5 |

79 | |||||||||

| 18.4 |

80 | |||||||||

| 18.4.1 |

80 | |||||||||

| 18.4.2 |

81 | |||||||||

| 18.5 |

83 | |||||||||

| 18.6 |

83 | |||||||||

| 18.7 | Water Facilities | 83 | ||||||||

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xvii |

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xviii |

| 122 | ||||

| 127 | ||||

| 128 | ||||

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xix |

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xx |

| Table 26: |

PEA Development, Waste Rock, and Backfill Summary | 103 | ||||

| Table 27: |

PEA Peak Mining Mobile Equipment Fleet | 104 | ||||

| Table 28: |

Summary of PEA Capital Costs | 108 | ||||

| Table 29: |

Summary of PEA Operating Costs | 108 | ||||

| Table 30: |

PEA Annual Cash Flow | 109 | ||||

| Table 31: |

Key PEA Operation and Financial Estimates | 110 | ||||

| Table 32: |

NPV Sensitivity Analysis: Gold Price and Canadian Exchange Rate | 111 | ||||

| Table 33: |

NPV Sensitivity Analysis: Site Costs and Infrastructure Capital | 111 | ||||

| Table 34: |

Mineral Resource Statement, Seabee Gold Operation, Saskatchewan, SSR Mining Inc., December 31, 2016 | 115 | ||||

| Table 35: |

Mineral Reserve Statement, Seabee Gold Operation, Saskatchewan, Canada SRK Consulting (Canada) Inc., December 31, 2016 | 116 | ||||

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page xxi |

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page 1 |

| 2 | Introduction and Terms of Reference |

The Seabee Gold Operation is an underground gold mining and milling operation, located in Saskatchewan, Canada, approximately 125 kilometres northeast of the town of La Ronge. SSR Mining Inc. (SSR Mining) holds a 100 percent interest in the property through its wholly-owned subsidiary, SGO Mining Inc. (formerly Claude Resources Inc. (Claude Resources)) (SGO Mining).

SSR Mining, formerly Silver Standard Resources Inc., is a Vancouver-based mining company focused on the operation, development, exploration and acquisition of precious metal projects. It is listed under the ticker symbol SSRM on the NASDAQ Capital Markets and the Toronto Stock Exchange. SSR Mining is a precious metals producer with three operations, including the Seabee Gold Operation, the Marigold gold mine in Nevada, U.S., and the 75% owned and operated Puna Operations joint venture in Jujuy Province, Argentina. Puna Operations consists of the Pirquitas operation and the Chinchillas project.

In May 2017, SSR Mining commissioned SRK Consulting (Canada) Inc. (SRK) to visit the property to audit its Mineral Resource models, Mineral Reserve estimate, and preliminary economic assessment (PEA) that considers an expansion scenario and includes Inferred Mineral Resource in respect of such proposed expansion scenario. The services were rendered between May 2017 and August 2017 leading to the preparation of the Mineral Resource Statement and Mineral Reserve Statement reported herein and the PEA summarized herein that were disclosed publicly by SSR Mining in a news release on September 7, 2017.

The last NI 43-101 technical report for the Seabee Gold Operation was generated by Claude Resources and filed on December 23, 2013, documenting Mineral Resources and Mineral Reserves as of December 31, 2012. This NI 43-101 technical report (Report) documents the Mineral Resource Statement, Mineral Reserve Statement and PEA of an expansion scenario for the Seabee Gold Operation as of December 31, 2016, prepared by SSR Mining and audited by SRK. It was prepared following the guidelines of the Canadian Securities Administrators’ National Instrument 43-101– Standards of Disclosure for Mineral Projects (NI 43-101) and Form 43-101F1. The Mineral Resource Statement and the Mineral Reserve Statement reported herein were prepared in conformity with generally accepted Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines.

This Report provides a summary of the current Seabee Gold Operation, including the current Mineral Resource and Mineral Reserve estimates for such operation, as at the effective date of this Report. In addition, this Report summarizes, in Section 24, a PEA of an expansion scenario being considered by SSR Mining. Unless specified otherwise, disclosure outside of Section 24 of this Report describes the Seabee Gold Operation as presently conducted and not as contemplated under the PEA.

| 2.1 | Scope of Work |

The scope of work, as defined in a letter of engagement, executed on May 18, 2017 between SSR Mining and SRK, includes: (1) the review and audit of the Mineral Resource models for the gold mineralization delineated by drilling on the Seabee Gold Operation; (2) the review and audit of the Mineral Reserve estimate; (3) the review and audit of the PEA and the supporting aspects of the associated production plans; and, (4) the preparation of an independent technical report in compliance with NI 43-101 and Form 43-101F1 guidelines. This work typically involves the assessment of the following aspects of a project:

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page 2 |

| • | Topography, landscape, access |

| • | Regional and local geology |

| • | Exploration history |

| • | Audit of exploration work |

| • | Geological modelling |

| • | Metallurgical work |

| • | Mineral Resource estimation and validation |

| • | Preparation of a Mineral Resource Statement |

| • | Preparation of a Mineral Reserve Statement |

| • | Mine design and schedule |

| • | Rock geotechnical assessment |

| • | Mineral processing |

| • | Tailings management facility assessment |

| • | Environment and social impact |

| • | Cost estimation |

| • | Recommendations for additional work |

| 2.2 | Work Program |

The Mineral Resource Statement, Mineral Reserve Statement, and PEA reported herein represent a collaborative effort between SSR Mining and SRK personnel. The exploration database was compiled and maintained by SSR Mining, and was audited by SRK. The geological model and outlines for the gold mineralization were constructed by SSR Mining, and were audited by SRK. In the opinion of SRK, the geological model is a reasonable representation of the distribution of the targeted mineralization at the current level of sampling. The geostatistical analysis, variography and grade models were completed by SSR Mining, and audited by SRK. The life of mine plans supporting the Mineral Reserve estimate and PEA were generated by SSR Mining, and audited and modified where appropriate by SRK. The Mineral Resource Statement and Mineral Reserve Statement as of December 31, 2016 reported herein with minor modifications were disclosed publicly by SSR Mining within their fourth quarter and year-end 2016 results news release dated February 23, 2017.

The Porky Main deposit included in the Mineral Resource Statement disclosed in SSR Mining’s news release dated February 23, 2017 was estimated using polygonal methods by Claude Resources in 2005. However, SSR Mining has not been able to verify the results of this polygonal estimate, therefore Porky Main is not included in the Mineral Resource Statement contained herein, but may be included in the future pending additional drilling and modelling.

This Report was assembled in the SRK Sudbury, Toronto, and Saskatoon offices during the months of May to October 2017.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page 3 |

| 2.3 | Basis of NI 43-101 Technical Report |

This Report is based on information collected by SRK during a site visit performed between May 29 and 31, 2017 and on additional information provided by SSR Mining throughout the course of SRK’s analysis. SRK conducted certain verifications to ensure the reliability of data collected by SSR Mining and has no reason to doubt the reliability of the information provided. Other information was obtained from the public domain. This Report is based on the following sources of information:

| • | Discussions with SSR Mining personnel. |

| • | Inspection of the Seabee Gold Operation area, including outcrop, drill core, and underground exposures. |

| • | Review of exploration data collected by SSR Mining. |

| • | Review of actual operations data provided by SSR Mining. |

| • | Additional information from public domain sources. |

The Mineral Resource Statement disclosed publicly in the news release dated February 23, 2017 was prepared by SSR Mining under the supervision of Jeffrey Kulas, PGeo (APEGS#12374), a Qualified Person and Manager Geology, Mining Operations at the Seabee Gold Operation. The Mineral Reserve Statement disclosed publicly in the news release dated February 23, 2017 was prepared by SSR Mining under the supervision of Kevin Fitzpatrick, PEng (APEGS#26974), a Qualified Person and Engineering Supervisor at the Seabee Gold Operation.

| 2.4 | Qualifications of SRK and NI 43-101 Technical Report Team |

The SRK Group comprises of more than 1,400 professionals, offering expertise in a wide range of resource engineering disciplines. The independence of the SRK Group is ensured by the fact that it holds no equity in any project it investigates and that its ownership rests solely with its staff. These facts permit SRK to provide its clients with conflict-free and objective recommendations. SRK has a proven track record in undertaking independent assessments of Mineral Resource and Mineral Reserve estimates, project evaluations and audits, technical reports and independent feasibility evaluations to bankable standards on behalf of exploration and mining companies, and financial institutions worldwide. Through its work with a large number of major international mining companies, the SRK Group has established a reputation for providing valuable consultancy services to the global mining industry.

The Mineral Resource and Mineral Reserve estimates and PEA audit work, and the compilation of this Report were completed by Mr. Michael Selby, PEng (APEGS#30781), Mr. Dominic Chartier, PGeo (APEGS#39656), Mr. Mark Liskowich, PGeo (APEGS#10005) and Mr. Jeffrey Kulas, PGeo (APEGS#12374). By virtue of their education, membership to a recognized professional association and relevant work experience, Messrs. Selby, Chartier, Liskowich, and Kulas are Qualified Persons as this term is defined by NI 43-101. Additional contributions were provided by Ms. Caitlyn Adams, GIT (APGO#10520), Mr. Ross MacFarlane, PEng (PEO#28062503), and Mr. Trevor Podaima, PEng (APGO#20380).

Mr. Michael Selby, PEng is a Principal Consultant (Mining) with SRK and has been practicing in the field of underground mining continuously since 2001 in operating, engineering, and consultancy roles. He completed the audit of the Mineral Reserve estimate and PEA summarized within this Report. He is the Qualified Person for Sections 1, 2, 3, 13, 15, 16, 17, 18, 19, 21, 22, 24, 25, 26, and 27. Mr. Selby visited the Seabee Gold Operation between May 29 and 31, 2017.

Mr. Dominic Chartier, PGeo is a Senior Consultant (Geology) with SRK and has been practicing his profession continuously in field exploration and consultancy since 2002. He completed the audit of the Mineral Resource estimate and supervised the compilation of the historical, geological, and exploration information in this Report. He is the Qualified Person for Sections 4.1, 4.2, 5, 6, 7, 8, 9, 10, 11, 12, 14.1, 14.7, and 23. Mr. Chartier visited the Seabee Gold Operation between May 29 and 31, 2017.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page 4 |

Mr. Mark Liskowich, PGeo is a Principal Consultant (Environmental Management) with SRK. He has been practicing his profession within the mineral exploration and mining industry continuously since 1989. His expertise is in the environmental, permitting, and social management of mineral exploration and mining projects. He is the Qualified Person for Sections 4.3, 4.4, and 20. Mr. Liskowich has visited the Seabee Gold Operation on numerous occasions since 1992 and most recently in March 2016.

Mr. Jeffrey Kulas, PGeo, is Manager Geology, Mining Operations at the Seabee Gold Operation with SSR Mining. The Mineral Resource estimation work was completed by the mine geology department under the supervision of Mr. Kulas. He is the Qualified Person for Sections 14.1 to 14.6. Mr. Kulas has been employed at the Seabee Gold Operation since October 2000.

Ms. Caitlyn Adams, GIT is a Staff Consultant (Geology) with SRK. She has been involved in field exploration and consultancy since 2012. She assisted with compiling the historical, geological, and exploration information in this Report. Ms. Adams has not visited the Seabee Gold Operation.

Mr. G. Ross MacFarlane, PEng is an Associate (Metallurgist) with SRK and has been involved in mining and metallurgy since 1973. He assisted with the review and summary of the mineral processing aspects of this Report. He visited the Seabee Gold Operation in 2010 and relied on the status update provided by SSR Mining and observed by Mr. Selby during his site visit.

Mr. Trevor Podaima, PEng is a Senior Consultant (Geotechnical Engineering) with SRK. He has been practicing continuously in his field of tailings management facility and water management consultancy since 2004. He assisted with the review and summary of the site infrastructure portion of this Report. He has visited the Seabee Gold Operation on numerous occasions since 2008, and most recently on August 8 to 10, 2017.

Mr. Glen Cole, PGeo (APGO#1416), is a Principal Consultant (Resource Geology) with SRK. He reviewed a draft of this Report prior to delivery to SSR Mining as per SRK internal quality management procedures. Although Mr. Cole has not personally visited the Seabee Gold Operation, he has contributed to previous Mineral Resource models and audits of Mineral Resource and Mineral Reserve estimates at the Seabee Gold Operation.

Mr. Gary Poxleitner, PEng (PEO#100059860), is a Principal Consultant (Mining) with SRK. He reviewed the draft mining, site infrastructure, and cost estimation portions of this Report prior to their delivery to SSR Mining as per SRK internal quality management procedures. Mr. Poxleitner has not visited the Seabee Gold Operation.

| 2.5 | Site Visit |

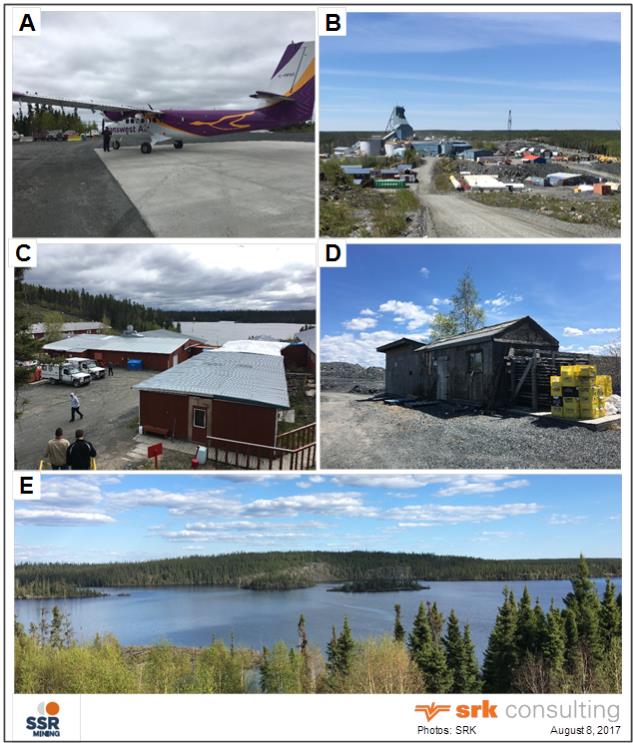

In accordance with NI 43-101 guidelines, Mr. Dominic Chartier and Mr. Michael Selby visited the Seabee Gold Operation on May 29 to 31, 2017 accompanied by Ms. Vicky Bleppony, Mr. Cameron Chapman, Mr. Kevin Fitzgerald, Mr. Jeffery Kulas, and Mr. Kyle MacLintock of SSR Mining.

The purpose of the site visit was to review the digitalization of the exploration database and validation procedures, review exploration procedures, define geological modelling procedures, examine drill core, review mine design and scheduling processes, examine underground workplaces, gain an understating of the status of the mill and other site infrastructure, interview project personnel, and collect all relevant information for the audit of the Mineral Resource and Mineral Reserve estimates and PEA, and the compilation of this Report.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page 5 |

SRK was given full access to relevant data and conducted interviews with SSR Mining personnel to obtain information on the past exploration work, and to understand procedures used to collect, record, store and analyze historical and current exploration data.

| 2.6 | Acknowledgement |

SRK would like to acknowledge the support and collaboration provided by SSR Mining personnel for this assignment. Their collaboration was greatly appreciated and instrumental to the success of this project. Mr. Bruce Butcher, Director, Mine Planning and Ms. Victoria Bleppony, Senior Planning Engineer, Technical Services, for SSR Mining provided invaluable guidance and direction to the project.

| 2.7 | Declaration |

SRK’s opinion contained herein and effective December 31, 2016 is based on information collected by SRK throughout the course of SRK’s investigations. The information in turn reflects various technical and economic conditions at the time of writing this Report. Given the nature of the mining business, these conditions can change significantly over relatively short periods of time. Consequently, actual results may be significantly more or less favourable.

This Report may include technical information that requires subsequent calculations to derive subtotals, totals, and weighted averages. Such calculations inherently involve a degree of rounding and consequently introduce a margin of error. Where these occur, SRK does not consider them to be material.

SRK is not an insider, associate or an affiliate of SSR Mining, and neither SRK nor any affiliate has acted as advisor to SSR Mining, its subsidiaries or its affiliates in connection with this project. The results of the technical review by SRK are not dependent on any prior agreements concerning the conclusions to be reached, nor are there any undisclosed understandings concerning any future business dealings.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page 6 |

| 3 | Reliance on Other Experts |

SRK has not performed an independent verification of land title and tenure information as summarized in Section 4 of this Report. SRK did not verify the legality of any underlying agreement(s) that may exist concerning the permits or other agreement(s) between third parties. For certain matters related to mineral tenure, including for example, the legal status of the rights disclosed in Section 4.1 and the recorded notices relating to Section 4.2, SRK relied on an opinion letter provided by MLT Aikins LLP of Winnipeg, Manitoba, Canada to SSR Mining dated July 30, 2017.

Several mineral dispositions have “Good Standing To” dates between July 30, 2017 and the signature date of this Report. These mineral dispositions include MC00003517, MC00003518, MC00003532, MC00003551, MC00003552, MC00003564, MC00003571, MC00003573, MC00003593, MC00003594, MC00003631, MC00003716, and MC00003717. SSR Mining has provided SRK with the disposition abstracts from the Saskatchewan Ministry of the Economy that indicate work filings have been submitted in respect of each of these mineral dispositions and are pending review.

SRK was informed by SSR Mining that there is no known litigation potentially affecting the Seabee Gold Operation.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page 7 |

| 4 | Property Description and Location |

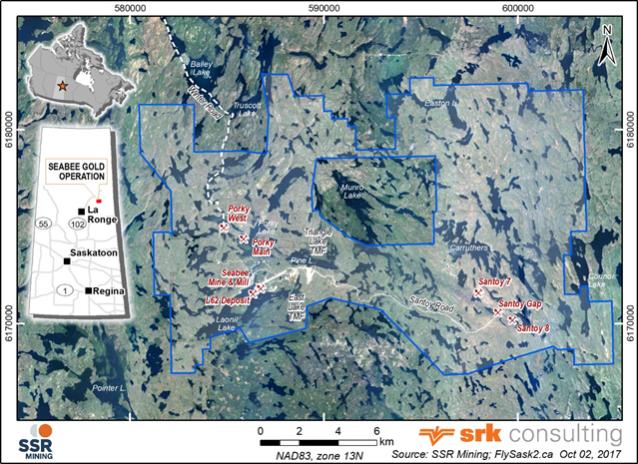

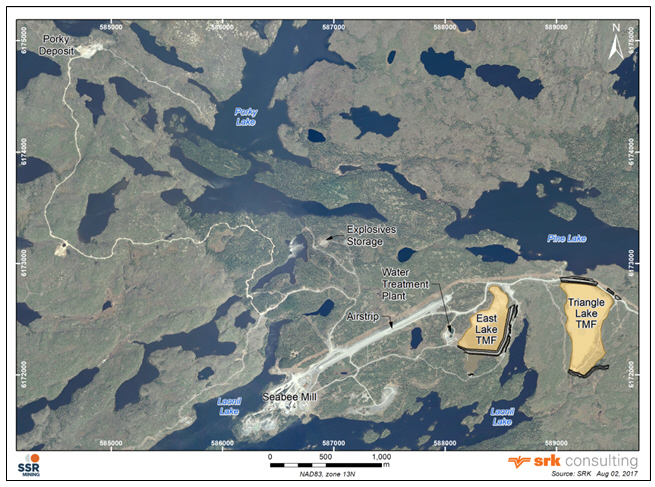

The Seabee Gold Operation is located at the north end of Laonil Lake, approximately 125 kilometres northeast of the town of La Ronge, Saskatchewan, Canada (Figure 1). The property hosts two operating mines – the Seabee mine and the Santoy mine – with the Santoy mine situated approximately 14 kilometres to the east of the Seabee mine. A central milling facility is located on the property near the Seabee mine.

The centre of the property is located at approximately 55.7 degrees latitude north and 103.5 degrees longitude west.

Figure 1: Location of the Seabee Gold Operation

| 4.1 | Mineral Tenure |

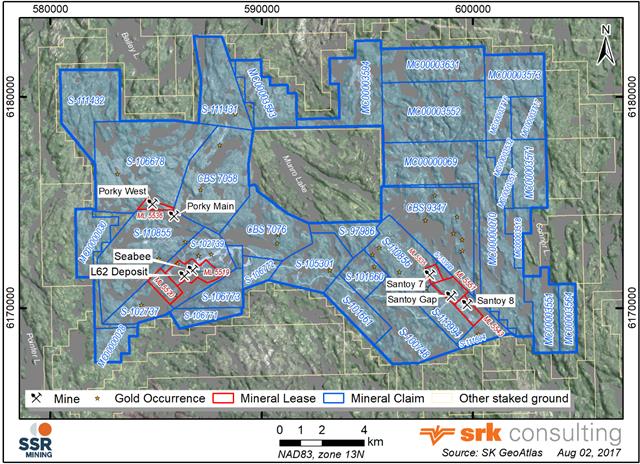

The Seabee Gold Operation is comprised of six mineral leases and 40 mineral claims that cover an area of approximately 23,700 hectares (Table 1 and Figure 2). SSR Mining holds a 100 percent interest in the property through its wholly-owned subsidiary, SGO Mining.

| SRK Team / gmp – gc – vp – ah | SSR_Seabee_TR_5CS010_001_SRKTeam_gmp_gc_vp_ah_20171020.docx | October 20, 2017 |

Table of Contents

| 5CS010.001 – SSR Mining Inc. | ||

| NI 43-101 Technical Report for the Seabee Gold Operation, Saskatchewan, Canada | Page 8 |

Table 1: Mineral Tenure Information

| Tenement Number |

Ownership | Grant Date | Expiry Date | Area (ha) |

||||||||||||

| ML 5519* |

SGO Mining Inc.: 100 | % | 24-Feb-1958 | 23-May-2032 | 201.00 | |||||||||||

| ML 5520 |

SGO Mining Inc.: 100 | % | 9-Mar-1999 | 6-Jun-2018 | 125.00 | |||||||||||

| ML 5535 |

SGO Mining Inc.: 100 | % | 3-Apr-2007 | 1-Jul-2032 | 45.00 | |||||||||||

| ML 5536 |

SGO Mining Inc.: 100 | % | 4-May-2007 | 1-Aug-2023 | 50.00 | |||||||||||

| ML 5543* |

SGO Mining Inc.: 100 | % | 27-Oct-2009 | 24-Jan-2033 | 86.00 | |||||||||||

| ML 5551* |

SGO Mining Inc.: 100 | % | 3-Oct-2013 | 31-Dec-2024 | 114.65 | |||||||||||

| CBS 7058 |

SGO Mining Inc.: 100 | % | 8-Feb-1980 | 8-May-2027 | 1,230.00 | |||||||||||

| CBS 7076 |

SGO Mining Inc.: 100 | % | 3-Mar-1980 | 31-May-2027 | 856.00 | |||||||||||

| CBS 9347 |

SGO Mining Inc.: 100 | % | 29-Jul-1991 | 26-Oct-2026 | 1,369.00 | |||||||||||

| MC00000028 |

SGO Mining Inc.: 100 | % | 14-Dec-2012 | 14-Mar-2018 | 261.92 | |||||||||||

| MC00000030 |

SGO Mining Inc.: 100 | % | 14-Dec-2012 | 14-Mar-2018 | 392.42 | |||||||||||

| MC00000069 |

SGO Mining Inc.: 100 | % | 19-Dec-2012 | 19-Mar-2018 | 904.62 | |||||||||||

| MC00000070 |

SGO Mining Inc.: 100 | % | 19-Dec-2012 | 19-Mar-2018 | 1,226.28 | |||||||||||

| MC00003517 |

SGO Mining Inc.: 100 | % | 1-May-2015 | 30-Jul-2017 | ** | 113.00 | ||||||||||

| MC00003518 |

SGO Mining Inc.: 100 | % | 1-May-2015 | 30-Jul-2017 | ** | 216.46 | ||||||||||

| MC00003532 |

SGO Mining Inc.: 100 | % | 6-May-2015 | 4-Aug-2017 | ** | 162.99 | ||||||||||

| MC00003551 |

SGO Mining Inc.: 100 | % | 7-May-2015 | 5-Aug-2017 | ** | 493.88 | ||||||||||

| MC00003552 |

SGO Mining Inc.: 100 | % | 8-May-2015 | 6-Aug-2017 | ** | 1,381.57 | ||||||||||

| MC00003564 |

SGO Mining Inc.: 100 | % | 11-May-2015 | 9-Aug-2017 | ** | 260.28 | ||||||||||

| MC00003571 |

SGO Mining Inc.: 100 | % | 12-May-2015 | 10-Aug-2017 | ** | 526.23 | ||||||||||

| MC00003573 |

SGO Mining Inc.: 100 | % | 12-May-2015 | 10-Aug-2017 | ** | 568.36 | ||||||||||

| MC00003593 |

SGO Mining Inc.: 100 | % | 15-May-2015 | 13-Aug-2017 | ** | 574.11 | ||||||||||

| MC00003594 |

SGO Mining Inc.: 100 | % | 15-May-2015 | 13-Aug-2017 | ** | 890.16 | ||||||||||

| MC00003631 |

SGO Mining Inc.: 100 | % | 25-May-2015 | 23-Aug-2017 | ** | 783.47 | ||||||||||

| MC00003716 |

SGO Mining Inc.: 100 | % | 12-May-2015 | 10-Aug-2017 | ** | 244.39 | ||||||||||

| MC00003717 |

SGO Mining Inc.: 100 | % | 12-May-2015 | 10-Aug-2017 | ** | 329.92 | ||||||||||

| S- 97986 |

SGO Mining Inc.: 100 | % | 22-Mar-1990 | 19-Jun-2027 | 250.00 | |||||||||||

| S- 99942 |

SGO Mining Inc.: 100 | % | 3-Aug-1988 | 31-Oct-2027 | 65.00 | |||||||||||

| S-100748 |

SGO Mining Inc.: 100 | % | 17-Aug-1990 | 14-Nov-2027 | 930.00 | |||||||||||

| S-101660 |

SGO Mining Inc.: 100 | % | 17-Aug-1990 | 14-Nov-2027 | 280.00 | |||||||||||

| S-101661 |

SGO Mining Inc.: 100 | % | 17-Aug-1990 | 14-Nov-2026 | 425.00 | |||||||||||

| S-102737 |

SGO Mining Inc.: 100 | % | 8-Feb-1980 | 8-May-2027 | 360.00 | |||||||||||

| S-102738 |

SGO Mining Inc.: 100 | % | 8-Feb-1980 | 8-May-2027 | 130.00 | |||||||||||

| S-102739 |

SGO Mining Inc.: 100 | % | 8-Feb-1980 | 8-May-2027 | 380.00 | |||||||||||

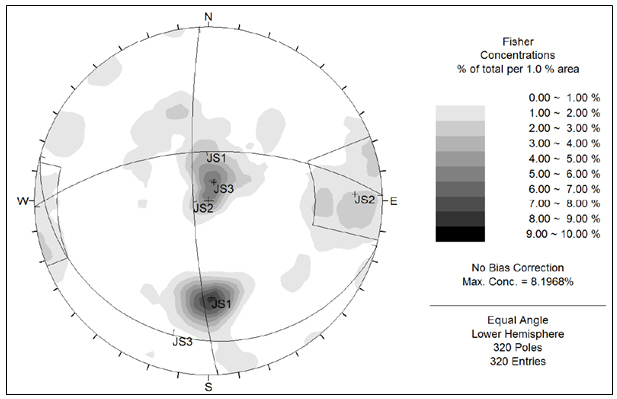

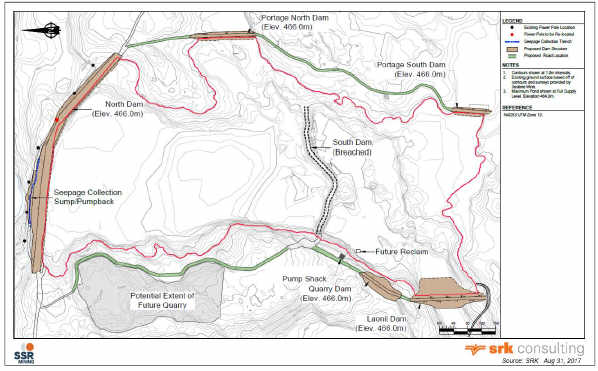

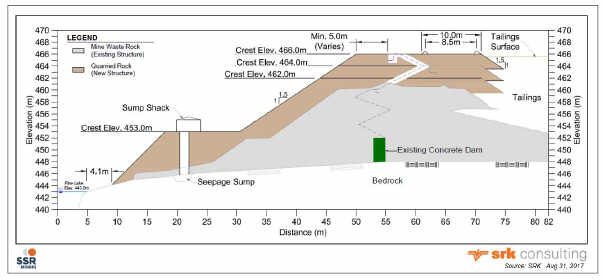

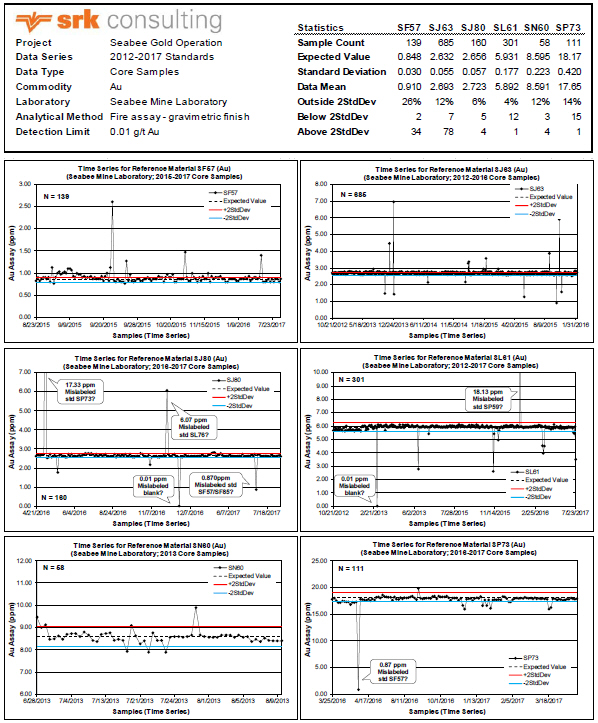

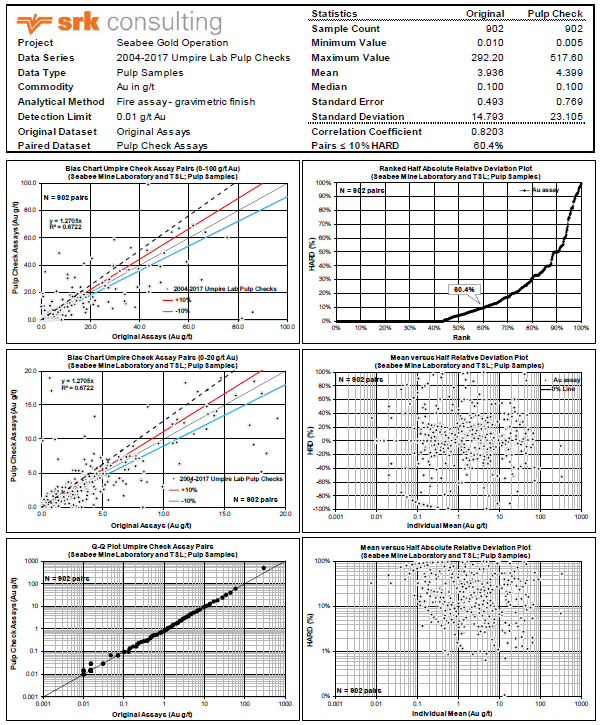

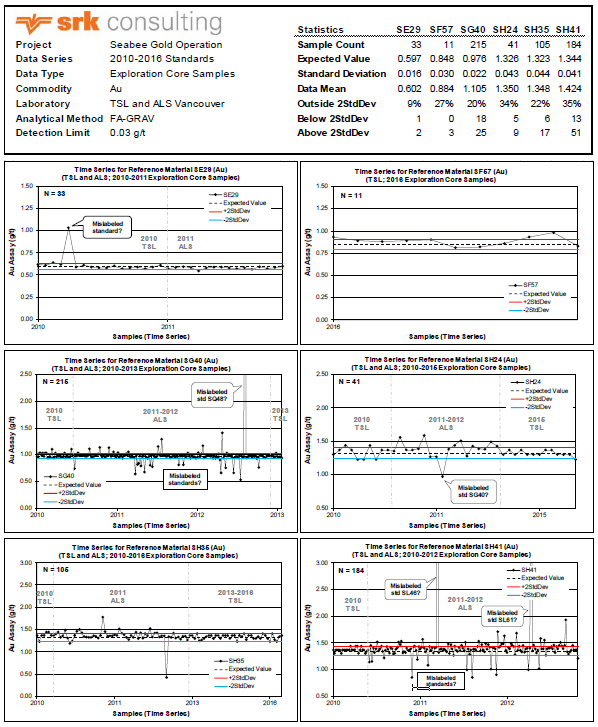

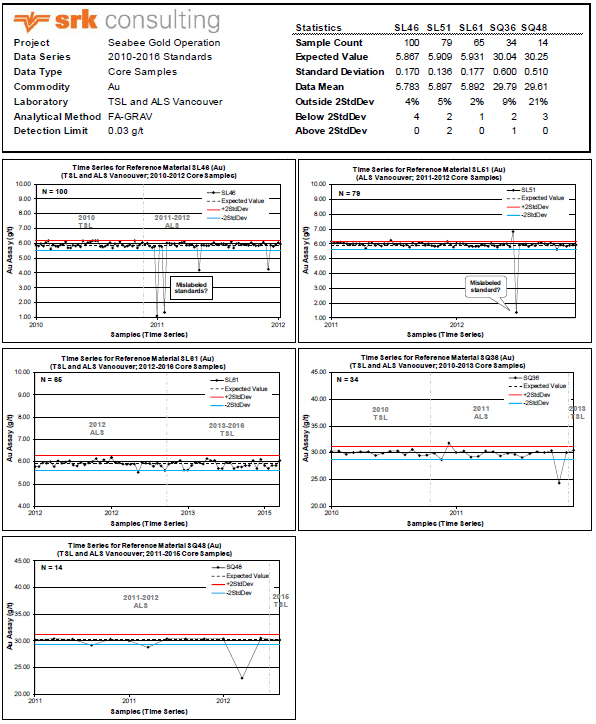

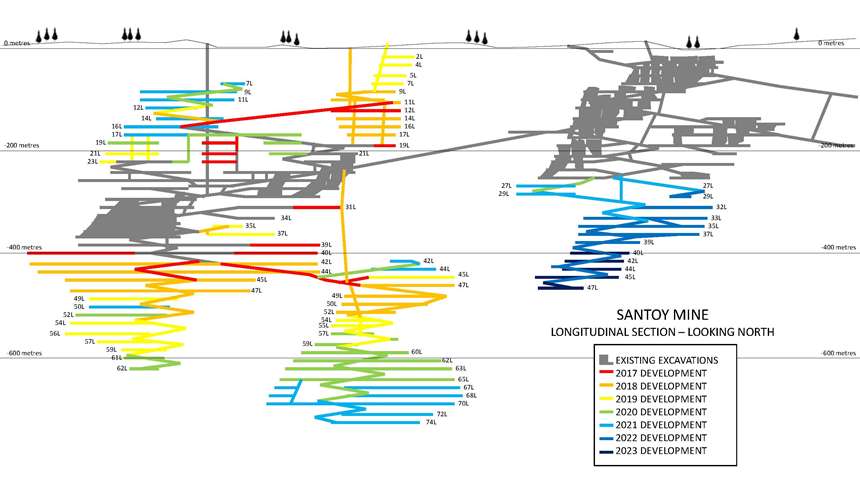

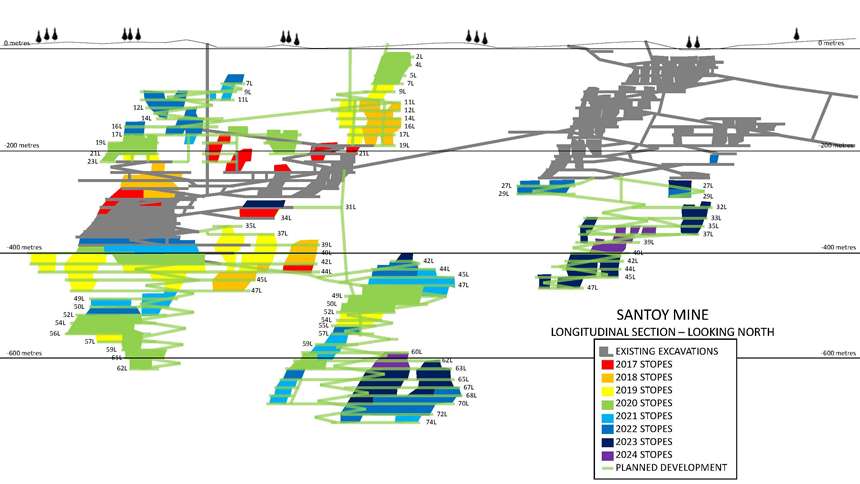

| S-105301 |