Form 6-K Piedmont Lithium Ltd For: Jun 25

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

_______________________

FORM 6-K

_______________________

REPORT OF FOREIGN PRIVATE ISSUER PURSUANT TO RULE 13A-16 OR 15D-16 OF THE SECURITIES EXCHANGE ACT OF

1934

For the month of May, 2019

Commission File Number: 001-38427

_______________________

Piedmont Lithium Limited

(Translation of registrant’s name into English)

_______________________

Level 9, BGC Centre, 28 The Esplanade

Perth, WA, 6000 Australia

(Address of principal executive offices)

_______________________

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40‑F.

Form 20-F ☒ Form 40-F

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(1): □

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(7): □

EXHIBIT INDEX

The following exhibits are filed as part of this Form 6-K:

|

Exhibit

|

Description

|

|

Press Release

|

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by

the undersigned, thereunto duly authorized.

|

|

Piedmont Lithium Limited

|

|

|

(registrant)

|

|

|

|

|

Date: June 25, 2019

|

By: /s/ Bruce Czachor

|

|

|

Name: Bruce Czachor

|

|

|

Title: Vice President and General Counsel

|

ASX RELEASE | June 25, 2019 | ASX:PLL; NASDAQ:PLL

PIEDMONT INCREASES LITHIUM RESOURCE BY 47%

TO 27.9 MILLION TONNES

TO 27.9 MILLION TONNES

|

·

|

47% increase in Piedmont Project-wide Mineral Resource estimate to 27.9 Mt @ 1.11% Li2O

|

|

·

|

55% increase in Mineral Resource estimate on Core property to 25.1 Mt @ 1.09% Li2O

|

|

·

|

74% of the Core property resource is within 100m of surface and 97% is within 150m of

surface

|

|

·

|

100% of the lithium resource is attributed to spodumene mineralization

|

|

·

|

Core property Resource is based on 326 diamond core holes totalling over 51,000 meters

|

|

·

|

9,450 meters of drilling remain in Phase 4 drill campaign with numerous highly prospective

targets

|

Piedmont

Lithium Limited (“Piedmont” or “Company”) is pleased to announce a major update to the Mineral Resource estimate for the Company’s wholly-owned Piedmont Lithium Project (“Project”) located within the world-class Carolina Tin-Spodumene Belt

(“TSB”) in North Carolina, USA (Table 1).

The Mineral Resource for the Core property has increased to 25.1 million tonnes (“Mt”) at a grade of

1.09% Li2O, bringing the Project’s total Mineral Resources to 27.9 Mt at a grade of 1.11% Li2O, containing 309,000 tonnes of lithium oxide (“Li2O”) or 764,000 tonnes of lithium carbonate equivalent (“LCE”) (the

benchmark used in the lithium industry).

|

Table 1: Project Wide Mineral Resource

Estimate for the Piedmont Lithium Project (0.4% cut-off)

|

||||||||

|

Resource Category

|

Core property

|

Central property

|

Total

|

|||||

|

Tonnes (Mt)

|

Grade (Li2O%)

|

Tonnes (Mt)

|

Grade (Li2O%)

|

Tonnes (Mt)

|

Grade (Li2O%)

|

Li2O

(t)

|

LCE

(t)

|

|

|

Indicated

|

12.5

|

1.13

|

1.41

|

1.38

|

13.9

|

1.16

|

161,000

|

398,000

|

|

Inferred

|

12.6

|

1.04

|

1.39

|

1.29

|

14.0

|

1.06

|

148,000

|

366,000

|

|

Total

|

25.1

|

1.09

|

2.80

|

1.34

|

27.9

|

1.11

|

309,000

|

764,000

|

Importantly, 74% of the Core Mineral Resource is within 100m of surface and 97% is within 150m of

surface (Table 2). Approximately 50%; or 12.5 million tonnes of the Mineral Resource is classified in the Indicated Resource category. All of the Mineral Resource tonnes at both Core and Central properties are attributable to spodumene

mineralization.

The Company expects to complete a pre-feasibility level metallurgical testwork program followed by a

Scoping Study update in July 2019.

Keith D. Phillips, President and Chief Executive Officer, commented: “We are very pleased with the resource update at our Core property, bringing our total project-wide resources to 27.9Mt at 1.11% Li2O. As we expand our land holdings and drill out other highly prospective targets, we are optimistic that we will ultimately identify North America’s

largest spodumene ore body. This scale, combined with high grade, strong mineralogy and metallurgy, and our superior location in North Carolina, all support the unique strategic nature of the Piedmont Lithium Project.

For further information, contact:

|

Keith D. Phillips

|

Anastasios (Taso) Arima

|

|

|

President & CEO

|

Executive Director

|

|

|

T: +1 973 809 0505

|

+1 347 899 1522

|

|

1

Core Property Mineral Resource Estimate

The Mineral Resource estimate (“MRE”) for Piedmont’s wholly owned Piedmont Lithium Project in North

Carolina, USA was prepared by independent consultants, CSA Global Pty Ltd (“CSA Global”) in accordance with the JORC Code (2012 Edition).

An important feature of the Core MRE, is that 74% or 18.6 Mt is located within 100 meters of surface. Table 2 shows the

details of the MRE with regards to depth from surface.

|

Table 2: Depth from Surface for the

Core Mineral Resource Estimate (25.1Mt @ 1.09% Li2O)

|

||||

|

Depth (from surface) (m)

|

Tonnes (Mt)

|

Percentage of Resource (%)

|

Cumulative Tonnes (Mt)

|

Cumulative % of Resource

|

|

0 - 50

|

8.7

|

35

|

8.7

|

35

|

|

50 - 100

|

9.9

|

39

|

18.6

|

74

|

|

100 - 150

|

5.7

|

23

|

24.3

|

97

|

|

150 +

|

0.8

|

3

|

25.1

|

100

|

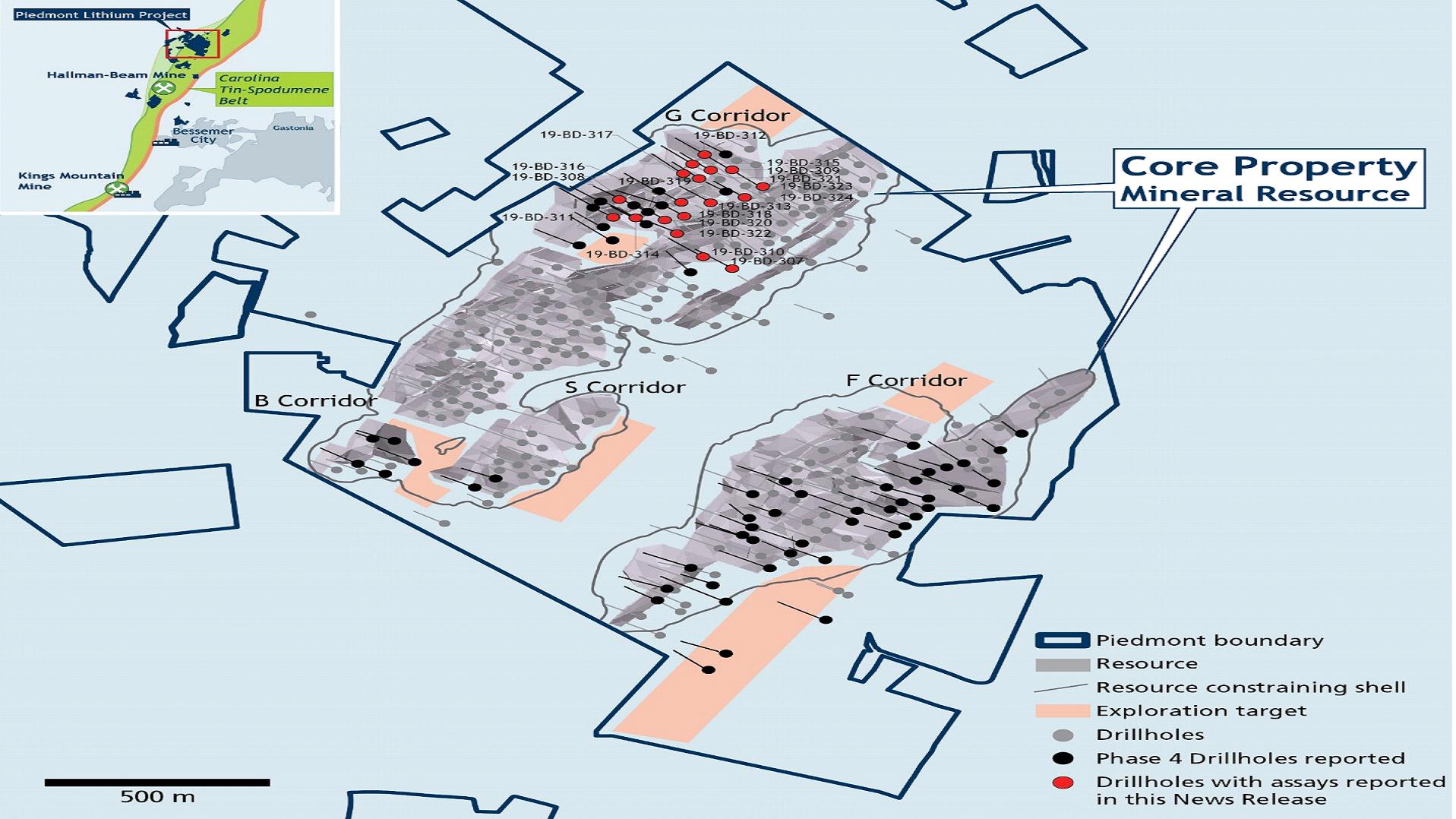

Figure 1: Piedmont Lithium Project Showing Resource, Resource Shells and

New Exploration Target Areas

2

In addition to the updated Core Mineral Resource estimate, a new Exploration Target has been estimated

by CSA Global within the Core Property. This is in addition to the Exploration Target released in April 2019 for the Central property. Table 3 summarizes the Exploration Target potential of the Piedmont Lithium Project. Table 4 and Figure 2

below show the grade-tonnage cut-off values for the Core Property Mineral Resource estimate.

|

Table 3: Project Wide Exploration

Target for the Piedmont Lithium Project

|

||||||

|

Exploration Target

|

Core Property

|

Central Property

|

Total

|

|||

|

Tonnes (Mt)

|

Grade (Li2O%)

|

Tonnes (Mt)

|

Grade (Li2O%)

|

Tonnes (Mt)

|

Grade (Li2O%)

|

|

|

Exploration Target*

|

4.0-4.5

|

1.0-1.2

|

2.0-2.5

|

1.1-1.3

|

6.0-7.0

|

1.0-1.3

|

|

*The potential quantity and grade of the Exploration Targets is conceptual in nature. There has been insufficient exploration to

estimate a Mineral Resource and it is uncertain if further exploration will result in the estimation of a Mineral Resource.

|

||||||

|

Table 4: Core Property Mineral Resource

Estimate Grade / Tonnage Table

|

|||||

|

Cut-Off Grade (Li2O%)

|

Resource Tonnes (Mt)

|

Grade (Li2O%)

|

Cut-Off Grade (Li2O%)

|

Resource Tonnes (Mt)

|

Grade (Li2O%)

|

|

1.30

|

6.00

|

1.50

|

0.60

|

23.50

|

1.12

|

|

1.00

|

15.10

|

1.29

|

0.50

|

24.40

|

1.10

|

|

0.90

|

18.00

|

1.23

|

0.40

|

25.10

|

1.09

|

|

0.80

|

20.30

|

1.19

|

0.20

|

25.60

|

1.07

|

|

0.70

|

22.30

|

1.15

|

0.10

|

25.60

|

1.07

|

Figure 2: Grade Cut-off v. Tonnage Curve for Core Property

3

To date, drilling on the project’s 1,004-acre Core property consists of 326 holes totalling 51,047

meters. The MRE utilizes all 326 holes. In general, drill spacing ranges between 40 – 80m. Dike areas tested by drilling at 40m lateral and downdip spacings were eligible to receive an Indicated resource classification, whereas areas with wider

spacings received an Inferred resource classification. Figure 3 is a plan view showing the Indicated and Inferred classification areas.

Figure 3: Core MRE – Map Showing Areas of Indicated and Inferred Resource Classifications

4

Figure 4 shows a view (looking northeast) of the MRE block model at various grade cut-offs.

Figure 4: Core Block Model - Isometric Views Toward the Northeast at Various Grade Cut-Offs (Li2O)

5

Summary of Resource Estimate and Reporting Criteria

This ASX announcement has been prepared in compliance with JORC Code (2012 Edition) and the ASX

Listing Rules. The Company has included in Appendix 2 the Table Checklist of Assessment and Reporting Criteria for the Piedmont Lithium Project as prescribed by the JORC Code (2012 Edition) and the ASX Listing Rules. The following is a summary of

the pertinent information used in the MRE with the full details provided in Appendix 2: JORC Table 1.

Geology, Mineralogy and Geological Interpretation

Regionally, the Carolina Tin-Spodumene belt extends for 40km along the litho-tectonic boundary between

the inner Piedmont and Kings Mountain belts. The mineralized pegmatites are thought to be concurrent and cross-cutting dike swarms extending from the Cherryville granite, as the dikes progressed further from their sources, they became increasingly

enriched in incompatible elements such as Li, tin (Sn). The dikes are considered to be unzoned.

Within the Project, spodumene pegmatites range from 1- 20+ meters thick and are hosted in a fine to

medium grained, weakly to moderately foliated, biotite, hornblende, quartz feldspar gneiss, commonly referred to as amphibolite. The spodumene pegmatites range from fine grained (aplite) to very coarse-grained pegmatite with primary mineralogy

consisting of spodumene, quartz, plagioclase, potassium-feldspar and muscovite. X-Ray Diffraction analysis has confirmed spodumene as the only lithium bearing ore mineral in the mineralized pegmatites, whereas varying amounts of, holmquistite,

lepidolite and petalite have been identified in the amphibolite host rock alteration zones immediately adjacent to the mineralized pegmatites and outside of the MRE.

To date over 100 spodumene pegmatite bodies have been identified and/or modeled on the property. The

mineralized dikes predominantly strike northeast and dip southeast. Some dikes have impressive lateral extent in which they can be traced for 500+ meters, whereas vertically, the steep dipping dikes extend 150 -200m down-dip. In addition, a

series of flat to shallowly dipping dikes have been defined. Both sets of dikes have similar grade, however, grades and thicknesses increase when two sets of dikes intersect.

A highly variable, low temperature clay/mica alteration has been Identified on the property, locally

and more commonly at depth, it has overprinted the spodumene mineralization resulting in spodumene pseudomorphs that range from partial to complete replacement. This alteration is easily identified in core by the difference in hardness between the

spodumene and the much softer pseudomorphs. This alteration is not to be confused with highly weathered pegmatite commonly encountered at surface.

Drilling and Sampling Techniques

To date total of 326 diamond core holes have been drilled totalling 51,047m. The table below includes

a breakdown of Piedmont Lithium’s four phases of drilling.

|

Table 5: Core Property - Drilling

Program Details

|

||

|

Phase

|

No. Holes

|

Total Length Drilled (m)

|

|

Historical

|

19

|

2,544

|

|

Phase 1

|

12

|

1,667

|

|

Phase 2

|

93

|

12,263

|

|

Phase 3

|

124

|

21,363

|

|

Phase 4

|

78

|

13,210

|

|

Total

|

326

|

51,047

|

6

Of the 78 core holes drilled as part of the Phase 4 drilling program, drill results for 60 holes have

been previously released (refer announcements dated March 14, 2019 and May 29, 2019) and drill results for the remaining 18 holes are reported herein (refer Appendix 1).

Figure 5: Core Phase 4 Drillhole Location Map

All diamond drill holes were collared with HQ and were transitioned to NQ once non-weathered and

unoxidized bedrock was encountered. Drill core was recovered from surface.

Oriented core was collected on select drill holes using the REFLEX ACT III tool by a qualified

geologist at the drill rig. This data was highly beneficial in the interpretation of the pegmatite dikes.

Spacing of drill holes varied for each drilling phase. The historic and Phase 1 drilling were

exploratory in nature where Phase 2 drilling started to identify the mineralized trend at 80m by 40m spacing. The infill drilling of Phases 3 and 4 targeted a 40m by 40m grid spacing.

Drill collars were located with the differential global positioning system (DGPS) with the Trimble Geo

7 unit which resulted in accuracies <1m. All coordinates were collected in State Plane and re-projected to Nad83 zone17 in which they are reported.

7

Down hole surveying was performed on each hole using a REFLEX EZ-Trac multi-shot instrument. Readings

were taken approx. every 15m (50 ft.) and recorded depth, azimuth, and inclination. All holes were geologically and geotechnically logged. All holes were photographed prior to sampling. Sampled zones were subsequently photographed a second time

after the samples had been marked.

The Core was cut in half with a diamond saw with one half submitted as the sample and the other half

retained for reference. Standard sample intervals were a minimum of 0.35m and a maximum of 1.5m for HQ or NQ drill core, taking into account lithological boundaries (i.e. sample to, and not across, major contacts). A CRM or coarse blank was

included at the rate of one for every 20 drill core samples (i.e. 5%). Sampling precision is monitored by selecting a sample interval likely to be mineralized and splitting the sample into two ¼ core duplicate samples over the same sample interval.

These samples are consecutively numbered after the primary sample and recorded in the sample database as “field duplicates” and the primary sample number recorded. Field duplicates were collected at the rate of 1 in 20 samples when sampling

mineralized drill core intervals.

Samples were numbered sequentially with no duplicates and no missing numbers. Triple tag books using

9-digit numbers were used, with one tag inserted into the sample bag and one tag stapled or otherwise affixed into the core tray at the interval the sample was collected. Samples were placed inside pre-numbered sample bags with numbers coinciding

to the sample tag. Quality control (QC) samples, consisting of certified reference materials (CRMs), were given sample numbers within the sample stream so that they are masked from the laboratory after sample preparation and to avoid any

duplication of sample numbers.

Sample Analysis Method

All samples from Phases 2, 3 and 4 drilling were shipped to the SGS laboratory in Lakefield, Ontario.

The preparation code was CRU21 (crush to 75% of sample <2mm) and PUL45 (pulverize 250g to 85% <75 microns). The analyses code was GE ICM40B (multi-acid digestion with either an ICP-ES or ICP-MS finish), which has a range for Li of 1 to

10,000 (1%) ppm Li. The over-range method code for Li >5,000 ppm is GE ICP90A, which uses a peroxide fusion with an ICP finish, and has lower and upper detection limits of 0.001 and 5% respectively. Starting in August 2017, samples were

switched to being analysed using GE ICP90A Li only and then to GE ICP91A Li only. Table 6 is a summary of lab and analysis used for the historical and the different Phases of drilling.

|

Table 6: Laboratories and Analysis Used

|

|||

|

Phase

|

Laboratory

|

Prep Codes

|

Analytical Codes

|

|

Historical

|

ACME Labs

|

-

|

7TX, 7PF-Li

|

|

Phase 1

|

Bureau Veritas (Reno, NV)

|

PRP 70-250

|

MA270, PF370

|

|

Phase 2

|

SGS (Lakefield, ONT)

|

CRU21, PUL45

|

GE ICM40B, GE ICP90A

|

|

Phase 3

|

SGS (Lakefield, ONT)

|

CRU26, PUL45

|

GE ICP91A

|

|

Phase 4

|

SGS (Lakefield, ONT)

|

CRU26, PUL45

|

GE ICP91A

|

Bulk Densities for phase 2 -4 were analyzed by SGS and in house by Piedmont Lithium’s geologist.

Resource Estimation Methodology

Lithological and structural features were defined based upon geological knowledge of the deposit

derived from drill core logs and geological observations on surface. Wireframe models of 95 pegmatite dikes, a diabase dike and one fault were created in Micromine 2014® by joining polygon interpretations made on cross sections and level

plans spaced at 40m. Weathering profiles representing the base of saprolite and overburden were modelled based upon drill hole geological

8

logging. A topographic digital terrain model was derived from a 2003 North Carolina State Lidar survey

with a lateral resolution of 5m and an accuracy of +/-2 m.

A rotated block model orientated to 35 degrees was constructed in Datamine StudioRM® that

encompasses all modelled dikes using a parent cell size of 6 m (E) by 12 m (N) by 6 m (Z). The drill hole files were flagged by the pegmatite and weathering domains they intersected. Statistical analysis of the domained data was undertaken in

SuperVisor®. Samples were regularised to 1m composite lengths and a review of high-grade outliers was undertaken. Regularised sample grades that fell within the pegmatite model were analysed for directional dependence in order to develop

parameters for Li2O grade interpolation by Ordinary Kriging and Inverse Distance Weighting methods. For each modelled pegmatite, regularised sample grades were interpolated into the corresponding pegmatite block model.

Block grade interpolation was validated by means of swath plots, comparison of mean sample and block

model Li2O grades and overlapping Li2O grade distribution charts for sample and block model data. Cross sections of the block model with drill hole data superimposed were also reviewed.

Dry bulk density determinations were statistically analysed to determine an appropriate value to

assign to each modelled rock type. Pegmatites within saprolitized rock received a density value of 2.04 t/m3 and those within fresh rock received a density of 2.72 t/m3. Saprolitized waste rock received a density value of 1.27

t/m3 and fresh waste rock received a density of 2.81 t/m3.

Classification Criteria

Resource classification parameters are based on the validity and robustness of input data and the

estimator’s judgment with respect to the proximity of resource blocks to sample locations and confidence with respect to the geological continuity of the pegmatite interpretations and grade estimates.

All blocks captured in pegmatite dike interpretation wireframes below the topography surface are

classified as Inferred.

Indicated classification boundaries that define a region of blocks that, overall, meet the following

criteria: Within major pegmatite dikes with along strike and down dip continuity greater than 200m and 50m respectively and with a true thickness greater than 2m; and are informed by at least two drill holes and eight samples within a range of

approximately 20m to the nearest drill hole in the along strike or strike and downdip directions.

No Measured category resources are estimated.

Cut-Off Grades

The Mineral Resource Estimate is reported at a 0.4% Li2O cut-off grade, in line with cut

off grades utilized at comparable deposits.

Mining and Metallurgical methods and parameters

The depth, geometry and grade of pegmatites at the property make them amenable to exploitation by open

cut mining methods. Inspection of drill cores and the close proximity of open pit mines in similar rock formations indicate that ground conditions are suitable for this mining method.

The resource is constrained by a conceptual pit shell derived from a Whittle optimisation using a

revenue factor (USD$750/t for a nominal 6% Li2O concentrate). Material falling outside of this shell is considered to not meet reasonable prospects for eventual economic extraction.

9

Reasonable prospects for metallurgical recovery are supported by the results of the bulk sampling and

metallurgical test work program undertaken by Piedmont Lithium in 2018 at North Carolina State University’s Minerals Research Laboratory.

Exploration to date has identified the potential for additional dikes outside of the current Mineral

Resource area that warrant further exploration.

Corridor Extensions: A 700m southward extension of the F-Corridor is modelled that encompasses

mineralised intercepts encountered in holes 19-BD-300, 19-BD-258 and 262. At the north end of the F-Corridor, where mineralization is open, a north-eastward continuation of the trend is modelled over a 250m strike length. An eastward extension of

the S-Corridor is modelled over a strike length of 350m. At the north end of the G-Corridor, where mineralization is not closed off by drilling, trend extensions to the northeast and east are each modelled over strike extents of 100m.

Infill Areas: Between the B and S corridors continuation of mineralized pegmatite is modelled over a

total strike length of 300 m. Between the B and G corridors a continuation of mineralized pegmatite is modelled over a total strike length of 150 m.

Modelled extensions and infill areas for the F, B, G and S Corridors have a total strike length of

1,950m. After consideration of modelled pegmatite continuity, the potential downdip extents and accumulated true thicknesses were estimated. These average 125m down dip extent and 8.5m in true thickness and generate a total volume of approximately

2 million cubic meters (“m3”).

To determine potential tonnage and grade ranges at the deposit, Li2O assay values and density values from drilling have been applied to the volume estimates. For the 80% of assays within pegmatite models that are above a 0.4% Li2O cut off, an average grade of 1.10% Li2O is estimated. For the 70% of assays that are above a 0.6% Li2O cut off, an average grade of 1.20% Li2O is estimated. Applying these assay

frequency proportions to the modelled volumes outside the Mineral Resource results in estimated volume ranges from 1.4 million m3 to 1.6 million m3 for spodumene bearing pegmatite with economically interesting grades. A

density value of 2.7 g/cm3 is applied to derive tonnage values.

Using the above methodology an Exploration Target of between 4 to 4.5 million tonnes at a grade of

between 1.0% and 1.2% Li2O is approximated for the Core deposit. The potential quantity and grade of this Exploration Target is conceptual in nature, there has been

insufficient exploration to estimate a Mineral Resource and it is uncertain if further exploration will result in the estimation of a Mineral Resource.

This Exploration Target is based on the actual results of Piedmont’s previous drill programs. To

further develop this deposit and develop the Mineral Resource, the Company will complete additional step out and infill drilling to establish geological and grade continuity within the Corridor Extensions aiming for a drill spacing of 40m × 40m.

In addition, an Exploration Target was reported on April 23, 2019 for Piedmont’s Central Property.

The Exploration Target is approximated between 2.0 to 2.5 million tonnes at a grade of between 1.1% and 1.3% Li2O. The potential quantity and grade of this

Exploration Target is conceptual in nature, there has been insufficient exploration to estimate a Mineral Resource and it is uncertain if further exploration will result in the estimation of a Mineral Resource.

10

About Piedmont Lithium

Piedmont Lithium Limited (ASX: PLL; Nasdaq: PLL) holds a 100% interest in the Piedmont Lithium Project (“Project”)

located within the world-class Carolina Tin-Spodumene Belt (“TSB”) and along trend to the Hallman Beam and Kings Mountain mines, historically providing most of the western world’s lithium between the 1950s and the 1980s. The TSB has been described

as one of the largest lithium provinces in the world and is located approximately 25 miles west of Charlotte, North Carolina. It is a premier location for development of an integrated lithium business based on its favorable geology, proven

metallurgy and easy access to infrastructure, power, R&D centers for lithium and battery storage, major high-tech population centers and downstream lithium processing facilities.

Forward Looking Statements

This announcement may include forward-looking statements. These forward-looking statements are based

on Piedmont’s expectations and beliefs concerning future events. Forward looking statements are necessarily subject to risks, uncertainties and other factors, many of which are outside the control of Piedmont, which could cause actual results to

differ materially from such statements. Piedmont makes no undertaking to subsequently update or revise the forward-looking statements made in this announcement, to reflect the circumstances or events after the date of that announcement.

Cautionary Note to United States Investors Concerning Estimates of Measured,

Indicated and Inferred Resources

The information contained in this announcement has been prepared in accordance with the requirements

of the securities laws in effect in Australia, which differ from the requirements of U.S. securities laws. The terms "mineral resource", "measured mineral resource", "indicated mineral resource" and "inferred mineral resource" are Australian terms

defined in accordance with the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (the “JORC Code”). However, these terms are not defined in Industry Guide 7 ("SEC Industry Guide 7")

under the U.S. Securities Act of 1933, as amended (the "U.S. Securities Act"), and are normally not permitted to be used in reports and filings with the U.S. Securities and Exchange Commission (“SEC”). Accordingly, information contained herein that

describes Piedmont’s mineral deposits may not be comparable to similar information made public by U.S. companies subject to reporting and disclosure requirements under the U.S. federal securities laws and the rules and regulations thereunder. U.S.

investors are urged to consider closely the disclosure in Piedmont’s Form 20-F, a copy of which may be obtained from Piedmont or from the EDGAR system on the SEC’s website at http://www.sec.gov/.

Competent Persons Statement

The information in this announcement that relates to Exploration Results is based on, and fairly

represents, information compiled or reviewed by Mr. Lamont Leatherman, a Competent Person who is a Registered Member of the ‘Society for Mining, Metallurgy and Exploration’, a ‘Recognized Professional Organization’ (RPO). Mr. Leatherman is a holder

of stock options in, and is a key consultant of, the Company. Mr. Leatherman has sufficient experience that is relevant to the style of mineralization and type of deposit under consideration and to the activity being undertaken to qualify as a

Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’. Mr. Leatherman consents to the inclusion in the report of the matters based on his information in

the form and context in which it appears.

The information in this report that relates to Exploration Targets and Mineral Resources is based on,

and fairly represents, information compiled or reviewed by Mr. Leon McGarry, a Competent Person who is a Professional Geoscientist (P.Geo.) and registered member of the ‘Association of Professional Geoscientists of Ontario’ (APGO no. 2348), a

‘Recognized Professional Organization’ (RPO). Mr. McGarry is a Senior Resource Geologist and full-time employee at CSA Global Geoscience Canada Ltd. Mr. McGarry has sufficient experience which is relevant to the style of mineralisation and type of

deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Mineral Resources and Ore Reserves’. Mr. McGarry consents to the

inclusion in this report of the results of the matters based on his information in the form and context in which it appears.

11

Appendix 1- Drill Core Assay Data

|

Easting

|

Northing

|

Elev.

(m) |

Az.

(o) |

Dip

(o) |

Depth

(m) |

From

(m) |

To

(m) |

Intercept

(m) |

Li2O

(%) |

||

|

19-BD-307

|

473984.2

|

3916538.9

|

243.5

|

308.0

|

-50.5

|

171.0

|

101.76

|

103.3

|

1.54

|

1.00

|

|

|

and

|

153.4

|

163.67

|

10.27

|

1.15

|

|||||||

|

including

|

153.4

|

155.9

|

2.5

|

1.47

|

|||||||

|

19-BD-308

|

473731.1

|

3916807.3

|

254.5

|

307.0

|

-59.6

|

149.0

|

21.25

|

29.23

|

7.98

|

0.92

|

|

|

including

|

21.25

|

24.18

|

2.93

|

1.86

|

|||||||

|

and

|

120.96

|

129

|

8.04

|

1.34

|

|||||||

|

19-BD-309

|

473977.1

|

3916915.9

|

252.6

|

310.0

|

-57.1

|

191.0

|

15.17

|

18.65

|

3.48

|

1.68

|

|

|

and

|

21.22

|

22.56

|

1.34

|

1.08

|

|||||||

|

and

|

31.9

|

32.92

|

1.02

|

1.77

|

|||||||

|

and

|

68.5

|

72.42

|

3.92

|

0.79

|

|||||||

|

and

|

81.46

|

86.3

|

4.84

|

0.86

|

|||||||

|

including

|

82.44

|

85.2

|

2.76

|

1.21

|

|||||||

|

and

|

98.74

|

102.45

|

3.71

|

0.72

|

|||||||

|

including

|

98.74

|

100.14

|

1.4

|

1.27

|

|||||||

|

and

|

111.18

|

112.4

|

1.22

|

0.90

|

|||||||

|

19-BD-310

|

473920.8

|

3916582.0

|

253.2

|

309.0

|

-50.1

|

179.0

|

58.9

|

59.91

|

1.01

|

1.1

|

|

|

and

|

107.4

|

110.84

|

3.44

|

1.08

|

|||||||

|

and

|

149.88

|

152.44

|

2.56

|

0.96

|

|||||||

|

19-BD-311

|

473719.1

|

3916731.7

|

259.0

|

310.0

|

-54.5

|

155.0

|

36.28

|

40.58

|

4.3

|

1.47

|

|

|

and

|

71

|

76.22

|

5.22

|

1.13

|

|||||||

|

and

|

104.38

|

105.43

|

1.05

|

1.38

|

|||||||

|

and

|

138.16

|

140.34

|

2.18

|

1.61

|

|||||||

|

19-BD-312

|

473920.2

|

3916974.2

|

268.2

|

309.0

|

-57.2

|

191.0

|

27.16

|

29.16

|

2

|

0.71

|

|

|

and

|

43.08

|

45.55

|

2.47

|

0.81

|

|||||||

|

and

|

57.98

|

61.28

|

3.3

|

1.23

|

|||||||

|

and

|

97.85

|

100.42

|

2.57

|

1.69

|

|||||||

|

19-BD-313

|

473868.8

|

3916783.0

|

255.5

|

310.0

|

-54.3

|

145.0

|

61.44

|

65.98

|

4.54

|

0.89

|

|

|

and

|

95.4

|

99.85

|

4.45

|

0.61

|

|||||||

|

and

|

121.21

|

122.71

|

1.5

|

0.68

|

|||||||

|

and

|

130.93

|

136.37

|

5.44

|

1.00

|

|||||||

|

including

|

134

|

136.37

|

2.37

|

1.63

|

|||||||

|

19-BD-314

|

473766.0

|

3916729.5

|

255.6

|

308.0

|

-51.0

|

185.0

|

43.96

|

45.97

|

2.01

|

1.13

|

|

|

and

|

49.76

|

54.2

|

4.44

|

1.70

|

|||||||

|

and

|

96.4

|

102.06

|

5.66

|

1.19

|

|||||||

|

including

|

96.4

|

98.54

|

2.14

|

1.91

|

|||||||

|

and

|

113.61

|

114.97

|

2.39

|

1.19

|

|||||||

|

and

|

156.89

|

158.74

|

1.85

|

0.70

|

|||||||

|

and

|

169.16

|

172.1

|

2.94

|

0.75

|

|||||||

|

19-BD-315

|

476892.6

|

3916940.4

|

260.3

|

312.0

|

-56.1

|

176.0

|

7.63

|

10.5

|

2.87

|

0.66

|

|

|

and

|

61.82

|

65

|

3.18

|

1.41

|

|||||||

|

and

|

81.61

|

84.37

|

2.76

|

0.55

|

|||||||

|

and

|

101.84

|

104.5

|

2.66

|

1.32

|

|||||||

|

and

|

135.57

|

137.76

|

2.19

|

0.90

|

|||||||

|

and

|

150.64

|

152.03

|

1.39

|

1.11

|

|||||||

|

19-BD-316

|

473872.3

|

3916743.0

|

259.8

|

306.0

|

-54.2

|

164.0

|

42.48

|

43.52

|

1.04

|

0.70

|

|

|

and

|

49.34

|

53.88

|

4.54

|

0.98

|

|||||||

|

including

|

51.6

|

53

|

1.4

|

1.86

|

|||||||

|

and

|

93.49

|

97

|

3.51

|

1.6

|

|||||||

|

and

|

102.6

|

104

|

1.4

|

0.91

|

|||||||

|

and

|

123.26

|

130.76

|

7.5

|

0.87

|

|||||||

|

including

|

124.26

|

127.26

|

3

|

1.42

|

|||||||

|

and

|

135.1

|

138.06

|

2.96

|

0.73

|

12

|

Hole

|

Easting

|

Northing

|

Elev.

(m) |

Az.

(o) |

Dip

(o) |

Depth

(m) |

From

(m) |

To

(m) |

Intercept

(m) |

Li2O

(%) |

|

|

19-BD-317

|

473876.5

|

3916902.1

|

260.1

|

313.0

|

-53.4

|

161.0

|

3.21

|

4.5

|

1.29

|

1.85

|

|

|

and

|

16.5

|

18.52

|

2.02

|

0.70

|

|||||||

|

and

|

34.47

|

36.92

|

2.45

|

1.09

|

|||||||

|

and

|

66.38

|

69.04

|

2.66

|

1.07

|

|||||||

|

and

|

103.84

|

108.6

|

4.76

|

1.18

|

|||||||

|

including

|

103.84

|

106.22

|

2.38

|

1.62

|

|||||||

|

and

|

126.08

|

127.3

|

1.22

|

1.51

|

|||||||

|

19-BD-318

|

473929.7

|

3916786.7

|

250.1

|

309.0

|

-54.1

|

153.0

|

49.85

|

53.17

|

3.32

|

0.67

|

|

|

and

|

125.24

|

126.51

|

1.27

|

1.22

|

|||||||

|

and

|

133

|

134.88

|

1.88

|

0.51

|

|||||||

|

and

|

149

|

151.85

|

2.85

|

1.7

|

|||||||

|

19-BD-319

|

473912.8

|

3916876.6

|

249.1

|

311.0

|

-54.6

|

140.0

|

19.2

|

22.57

|

3.37

|

0.60

|

|

|

and

|

69.75

|

71

|

1.25

|

1.30

|

|||||||

|

and

|

97.21

|

98.64

|

1.43

|

1.16

|

|||||||

|

and

|

111.57

|

116

|

4.43

|

0.53

|

|||||||

|

and

|

121.42

|

123.33

|

1.91

|

0.94

|

|||||||

|

19-BD-320

|

473827.2

|

3916723.3

|

254.8

|

308.0

|

-59.9

|

146.0

|

61.55

|

65.09

|

3.54

|

1.29

|

|

|

and

|

71.76

|

74.98

|

3.22

|

1.20

|

|||||||

|

and

|

104.25

|

105.93

|

1.68

|

0.93

|

|||||||

|

and

|

115.5

|

123.08

|

7.58

|

1.53

|

|||||||

|

including

|

115.5

|

119.5

|

4

|

1.96

|

|||||||

|

19-BD-321

|

473935.0

|

3916911.8

|

253.1

|

310.0

|

-51.9

|

158.0

|

0.46

|

7.5

|

7.04

|

0.43

|

|

|

including

|

0.46

|

1.5

|

1.04

|

1.60

|

|||||||

|

and

|

37.38

|

38.3

|

1.12

|

2.02

|

|||||||

|

and

|

46.35

|

48.87

|

2.52

|

0.68

|

|||||||

|

and

|

60.96

|

65.72

|

4.76

|

1.15

|

|||||||

|

and

|

71

|

74.6

|

3.6

|

1.14

|

|||||||

|

and

|

93.4

|

94.86

|

1.46

|

0.61

|

|||||||

|

and

|

115.1

|

118.32

|

3.22

|

1.17

|

|||||||

|

and

|

151.58

|

153.24

|

1.66

|

0.85

|

|||||||

|

19-BD-322

|

473864.5

|

3916678.9

|

258.6

|

300.0

|

-51.3

|

173.0

|

17.1

|

23.48

|

6.38

|

1.04

|

|

|

and

|

31.58

|

33.76

|

2.18

|

0.66

|

|||||||

|

and

|

95.82

|

97.75

|

1.93

|

1.15

|

|||||||

|

and

|

103.6

|

105.58

|

1.98

|

1.15

|

|||||||

|

and

|

131.77

|

136.68

|

4.91

|

0.79

|

|||||||

|

19-BD-323

|

474048.7

|

3916851.4

|

259.9

|

309.0

|

-54.2

|

152.0

|

9.37

|

11.17

|

1.8

|

0.79

|

|

|

and

|

29.94

|

35.16

|

5.22

|

1.12

|

|||||||

|

and

|

38.88

|

40.48

|

1.6

|

1.05

|

|||||||

|

and

|

76.97

|

78.45

|

1.48

|

0.83

|

|||||||

|

and

|

83.11

|

85.56

|

3.45

|

1.1

|

|||||||

|

including

|

83.11

|

84.64

|

1.53

|

2.04

|

|||||||

|

and

|

105.98

|

107.43

|

1.45

|

1.33

|

|||||||

|

and

|

109.52

|

111.54

|

2.02

|

0.96

|

|||||||

|

and

|

139.75

|

141.47

|

1.72

|

0.82

|

|||||||

|

19-BD-324

|

474010.0

|

3916804.5

|

238.3

|

313.0

|

-55.7

|

160.0

|

0

|

7.5

|

7.5

|

0.89

|

|

|

including

|

0

|

5.3

|

5.3

|

1.23

|

|||||||

|

and

|

10.65

|

13.5

|

2.85

|

0.77

|

|||||||

|

and

|

24.94

|

26

|

1.06

|

1.53

|

|||||||

|

and

|

30.62

|

32.75

|

2.13

|

1.82

|

|||||||

|

and

|

86.09

|

87.28

|

1.19

|

1.26

|

|||||||

|

and

|

107

|

108.88

|

1.88

|

1.28

|

|||||||

|

and

|

122.4

|

123.61

|

1.21

|

1.24

|

|||||||

|

and

|

142

|

143.06

|

1.06

|

0.55

|

|||||||

|

and

|

146.3

|

149.14

|

2.84

|

1.26

|

13

Appendix 2: JORC Table 1 Checklist of Assessment and Reporting Criteria

Section

1 Sampling Techniques and Data

|

Criteria

|

JORC Code explanation

|

Commentary

|

|

Sampling techniques

|

>Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as downhole gamma sondes, or handheld

XRF instruments, etc.). These examples should not be taken as limiting the broad meaning of sampling.

>Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used.

>Aspects

of the determination of mineralisation that are Material to the Public Report. In cases where ‘industry standard’ work has been done this would be relatively simple (e.g. ‘reverse circulation drilling was used to obtain 1 m samples from

which 3 kg was pulverised to produce a 30 g charge for fire assay’). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g.

submarine nodules) may warrant disclosure of detailed information.

|

All results reported are from diamond core samples. The core was sawn at an orientation not influenced by the distribution of

mineralization within the drill core (i.e. bisecting mineralized veins or cut perpendicular to a fabric in the rock that is independent of mineralization, such as foliation). Diamond drilling provided continuous core which allowed

continuous sampling of mineralized zones. The core sample intervals were a minimum of 0.35m and a maximum of 1.5m for HQ or NQ drill core (except in saprolitic areas of poor recovery where sample intervals may exceed 1.5m in length) and

took into account lithological boundaries (i.e. sample was to, and not across, major contacts).

Standards and blanks were inserted into the sample stream to assess the accuracy, precision and methodology of the external

laboratories used. In addition, field duplicate samples were inserted to assess the variability of the mineralisation., The laboratories undertake their own duplicate sampling as part of their internal QA/QC processes. Examination of the

QA/QC sample data indicates satisfactory performance of field sampling protocols and assay laboratories providing acceptable levels of precision and accuracy.

|

|

Drilling techniques

|

>Drill

type (e.g. core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc.) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is

oriented and if so, by what method, etc.).

|

All diamond drill holes were collared with HQ and were transitioned to NQ once non-weathered and unoxidized bedrock was encountered.

Drill core was recovered from surface.

Oriented core was collected on select drill holes using the REFLEX ACT III tool by a qualified geologist at the drill rig. The

orientation data is currently being evaluated.

|

|

Drill sample recovery

|

>Method of recording and assessing core and chip sample recoveries and results assessed.

>Measures taken to maximise sample recovery and ensure representative nature of the samples.

>Whether a

relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material.

|

The core was transported from the drill site to the logging facility in covered boxes with the utmost care. Once at the logging

facility, the following procedures were carried out on the core:

1.Re-aligning

the broken core in its original position as closely as possible.

2.The length

of recovered core was measured, and meter marks clearly placed on the core to indicate depth to the nearest centimetre.

3.The length

of core recovered was used to determine the core recovery, which is the length of core recovered divided by the interval drilled (as indicated by the footage marks which was converted to meter marks), expressed as a percentage. This data

was recorded in the database. The core was photographed wet before logged.

4.The core was

photographed again immediately before sampling with the sample numbers visible.

Sample recovery was consistently good except for zones within the oxidized clay and saprolite zones. These zones were generally

within the top 20m of the hole. No relationship is recognized between recovery and grade. The drill holes were designed to intersect the targeted pegmatite below the oxidized zone.

|

|

Logging

|

>Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies.

>Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc.) photography.

>The total

length and percentage of the relevant intersections logged.

|

Geologically, data was collected in detail, sufficient to aid in Mineral Resource estimation.

Core logging consisted of marking the core, describing lithologies, geologic features, percentage of spodumene and structural

features measured to core axis.

The core was photographed wet before logging and again immediately before sampling with the sample numbers visible.

All the core from the 326 holes was logged.

|

14

|

Criteria

|

JORC Code explanation

|

Commentary

|

|||

|

Sub-sampling techniques and sample preparation

|

>If core, whether cut or sawn and whether quarter, half or all core taken.

>If non-core, whether riffled, tube sampled, rotary split, etc. and whether sampled wet or dry.

>For all sample types, the nature, quality and appropriateness of the sample preparation technique.

>Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples.

>Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling.

>Whether

sample sizes are appropriate to the grain size of the material being sampled.

|

Core was cut in half with a diamond saw.

Standard sample intervals were a minimum of 0.35m and a maximum of 1.5m for HQ or NQ drill core, taking into account lithological

boundaries (i.e. sample to, and not across, major contacts).

The preparation code is CRU21 (crush to 75% of sample <2mm) and PUL45 (pulverize 250g to 85% <75 microns).

A CRM or coarse blank was included at the rate of one for every 20 drill core samples (i.e. 5%).

Sampling precision is monitored by selecting a sample interval likely to be mineralized and splitting the sample into two ¼ core

duplicate samples over the same sample interval. These samples are consecutively numbered after the primary sample and recorded in the sample database as “field duplicates” and the primary sample number recorded. Field duplicates were

collected at the rate of 1 in 20 samples when sampling mineralized drill core intervals.

Samples were numbered sequentially with no duplicates and no missing numbers. Triple tag books using 9-digit numbers were used, with

one tag inserted into the sample bag and one tag stapled or otherwise affixed into the core tray at the interval the sample was collected. Samples were placed inside pre-numbered sample bags with numbers coinciding to the sample tag.

Quality control (QC) samples, consisting of certified reference materials (CRMs), were given sample numbers within the sample stream so that they are masked from the laboratory after sample preparation and to avoid any duplication of sample

numbers.

|

|||

|

Quality of assay data and laboratory tests

|

>The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total.

>For geophysical tools, spectrometers, handheld XRF instruments, etc., the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their

derivation, etc.

>Nature of quality control procedures adopted (e.g. standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established.

|

All samples were shipped to the SGS laboratory in Lakefield, Ontario.

The preparation code was CRU21 (crush to 75% of sample <2mm) and PUL45 (pulverize 250g to 85% <75 microns).

The analyses code was GE ICP91A, which uses a peroxide fusion with an ICP finish, and has lower and upper detection limits of 0.001

and 50,000 (5%) ppm respectively.

Selected samples were analyzed using ICM40B (multi-acid digestion with either an ICP-ES or ICP-MS finish), which has a range for Li

of 1 to 10,000 (1%) ppm Li and samples >5,000ppm were run using GE ICP90A.

Accuracy monitoring was achieved through submission and monitoring of certified reference materials (CRMs).

Sample numbering and the inclusion of CRMs was the responsibility of the project geologist submitting the samples. A CRM or coarse

blank was included at the rate of one for every 20 drill core samples (i.e. 5%).

The CRMs used for this program were supplied by Geostats Pty Ltd of Perth, Western Australia. Details of the CRMs are provided

below. A sequence of these CRMs covering a range in Li values and, including blanks, were submitted to the laboratory along with all dispatched samples so as to ensure each run of 100 samples contains the full range of control materials.

The CRMs were submitted as “blind” control samples not identifiable by the laboratory.

Details of CRMs used in the drill program (all values ppm):

|

|||

|

CRM

|

Manufacturer

|

Lithium

|

1 Std Dev

|

||

|

GTA-04

|

Geostats

|

9275

|

213

|

||

|

GTA-08

|

Geostats

|

1102

|

50

|

||

|

GTA-09

|

Geostats

|

4837

|

174

|

||

|

Sampling precision was monitored by selecting a sample interval likely to be mineralized and splitting the sample into two ¼ core

duplicate samples over the same sample interval. These samples were consecutively numbered after the primary sample and recorded in the sample database as “field duplicates” and the primary sample number recorded. Field duplicates were

collected at the rate of 1 in 20 samples when sampling mineralized drill core intervals. Random sampling precision was monitored by splitting samples at the sample crushing stage (coarse crush duplicate) and at the final sub-sampling stage

for analysis (pulp duplicates). The coarse, jaw-crushed, reject material was split into two preparation duplicates, sometimes referred to as second cuts, crusher or preparation duplicates, which were then pulverized and analysed

separately. These duplicate samples were selected randomly by the laboratory. Analytical precision was also monitored using pulp duplicates, sometimes referred to as replicates or repeats. Data from all three types of duplicate analyses was

used to constrain sampling variance at different stages of the sampling and preparation process.

Examination of the QA/QC sample data indicates satisfactory performance of field sampling protocols and assay laboratories providing

acceptable levels of precision and accuracy.

|

|||||

15

|

Criteria

|

JORC Code explanation

|

Commentary

|

|

Verification of sampling and assaying

|

>The verification of significant intersections by either independent or alternative company personnel.

>The use of twinned holes.

>Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols.

>Discuss

any adjustment to assay data.

|

Multiple representatives of Piedmont Lithium, Inc. have inspected and verified the results.

CSA has conducted multiple site visits. Dennis Arne (Managing Director -Principal Consultant) toured the site, facilities and

reviewed core logging and sampling workflow as well as Leon McGarry (Senior Resource Geologist). Each provided comments on how to improve our methods and have been addressed. Verification core samples were collected by Leon McGarry.

No holes were twinned.

Three-meter rods and core barrels were used. Li% was converted to Li2O% by multiplying Li% by 2.153.

|

|

Location of data points

|

>Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation.

>Specification of the grid system used.

>Quality

and adequacy of topographic control.

|

Drill collars were located with the Trimble Geo 7 which resulted in accuracies <1m.

All coordinates were collected in State Plane and re-projected to Nad83 zone17 in which they are reported.

Drill hole surveying was performed on each hole using a REFLEX EZ-Trac multi-shot instrument. Readings were taken approx. every 15

meters and recorded depth, azimuth, and inclination.

|

|

Data spacing and distribution

|

>Data spacing for reporting of Exploration Results.

>Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications

applied.

>Whether

sample compositing has been applied.

|

For selected areas, the drill spacing is approximately 40 to 80 m along strike and down dip. This spacing is sufficient to establish

continuity in geology and grade for this pegmatite system.

Composite samples are reported in Li2O%, this is calculated by multiplying drill length by Li2O for each

sample; then the weighted averages for multiple samples are totalled and divided by the total drill length for the selected samples.

|

|

Orientation of data in relation to geological structure

|

>Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

>If the

relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material.

|

The drill holes were designed and oriented with inclinations ranging from -50 to -60 degrees, to best intersect the pegmatite bodies

as close to perpendicularly as possible.

|

|

Sample security

|

>The

measures taken to ensure sample security.

|

Drill core samples were shipped directly from the core shack by the project geologist in sealed rice bags or similar containers using

a reputable transport company with shipment tracking capability so that a chain of custody can be maintained. Each bag was sealed with a security strap with a unique security number. The containers were locked in a shed if they were stored

overnight at any point during transit, including at the drill site prior to shipping. The laboratory confirmed the integrity of the rice bag seals upon receipt.

|

|

Audits or reviews

|

>The

results of any audits or reviews of sampling techniques and data.

|

CSA Global developed a “Standard Operating Procedures” manual in preparation for the drilling program. CSA global reviews all

logging and assay data, as well as merges all data in to database that is held off site.

CSA has conducted multiple site visits. Dennis Arne (Managing Director -Principal Consultant) toured the site and facilities as well

as Leon McGarry (Senior Resource Geologist). Each provided comments on how to improve our methods and have been addressed. Verification core samples were collected by Leon McGarry.

|

Section 2 Reporting of

Exploration Results

|

JORC Code explanation

|

Commentary

|

|

|

Mineral tenement and land tenure status

|

>Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites,

wilderness or national park and environmental settings.

>The

security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area.

|

Piedmont, through its 100% owned subsidiary, Piedmont Lithium, Inc., has entered into exclusive option agreements with local

landowners, which upon exercise, allows the Company to purchase (or long term lease) approximately 2,105 acres of surface property and the associated mineral rights from the local landowners.

There are no known historical sites, wilderness or national parks located within the Project area and there are no known impediments

to obtaining a licence to operate in this area.

|

16

|

JORC Code explanation

|

Commentary

|

|

|

Exploration done by other parties

|

>Acknowledgment

and appraisal of exploration by other parties.

|

The Project is focused over an area that has been explored for lithium dating back to the 1950’s where it was originally explored by

Lithium Corporation of America which was subsequently acquired by FMC Corporation. Most recently, North Arrow explored the Project in 2009 and 2010. North Arrow conducted surface sampling, field mapping, a ground magnetic survey and two

diamond drilling programs for a total of 19 holes. Piedmont Lithium, Inc. has obtained North Arrow’s exploration data.

|

|

Geology

|

>Deposit

type, geological setting and style of mineralisation.

|

Spodumene pegmatites, located near the litho tectonic boundary between the inner Piedmont and Kings Mountain belt. The

mineralization is thought to be concurrent and cross-cutting dike swarms extending from the Cherryville granite, as the dikes progressed further from their sources, they became increasingly enriched in incompatible elements such as Li, tin

(Sn). The dikes are considered to be unzoned.

Project-wide 45 samples from drill core and 10 composite samples have been analyzed by either Semi-Quantitative or Quantitative X-Ray

Diffraction. The Quantitative X-Ray Diffraction by Rietveld Refinement was performed on the Panalytical X'pert Pro Diffractometer with interpretations by HighScore Plus software using Crystallography Open Database (COD) and Joint Committee

on Powder Diffraction Standards -International Center for Diffraction Data (JCPDS-ICDD). The Semi-Quantitative X-Ray Diffraction was performed on the BRUKER AXS D8 Advance Diffractometer with interpretations by PDF2/PDF4 powder diffraction

databases issued by the International Center for Diffraction Data (ICDD) and DiffracPIus Eva software.

Of the 45 samples, 36 samples were of spodumene bearing pegmatite, 6 samples were barren pegmatites and 3 samples from amphibolite

host rock. More specifically, the 36 samples of spodumene bearing pegmatite and the 10 composite samples only contained spodumene and no other lithium bearing minerals above a trace amount. The amphibolite samples contained varying

amounts of holmquistite, lepidolite and petalite which are outside the reported MRE.

|

|

Drill hole Information

|

>A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes:

>easting and northing of the drill hole collar

>elevation or RL (Reduced Level – elevation above sea level in metres) of the drill hole collar

>dip and azimuth of the hole

>down hole length and interception depth

>hole length.

>If the

exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case.

|

Details of all reported drill holes are provided in Appendix 1 of this report.

|

|

Data aggregation methods

|

>In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (e.g. cutting of high grades) and cut-off grades are usually Material and should be stated.

>Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations

should be shown in detail.

>The

assumptions used for any reporting of metal equivalent values should be clearly stated.

|

All intercepts reported are for down hole thickness not true thickness.

Weighted averaging was used in preparing the intercepts reported.

The drill intercepts were calculated by adding the weighted value (drill length x assay) for each sample across the entire pegmatite

divided by the total drill thickness of the pegmatite. For each mineralized pegmatite, all assays were used in the composite calculations with no upper or lower cut-offs. Mineralized pegmatite is defined as spodumene bearing pegmatite.

Intercepts were reported for entire pegmatites, taking into account lithological boundaries (i.e. sample to, and not across, major

contacts), with additional high-grade sub intervals reported from the same pegmatite. In the case where thin wall rock intervals were included, a value of 0% Li2O was inserted for the assay value, thus giving that individual

sample a weighted value of 0% Li2O.

Cumulative thicknesses are reported for select drill holes. These cumulative thicknesses do not represent continuous mineralized

intercepts. The cumulative thickness for a drill hole is calculated by adding the drill widths of two or more mineralized pegmatites encountered in the drill hole, all other intervals are omitted from the calculation.

Li% was converted to Li2O% by multiplying Li% by 2.153.

|

17

|

Criteria

|

JORC Code explanation

|

Commentary

|

|

Relationship between mineralisation widths and intercept lengths

|

>These relationships are particularly important in the reporting of Exploration Results.

>If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported.

>If it is

not known and only the down hole lengths are reported, there should be a clear statement to this effect (e.g. ‘down hole length, true width not known’).

|

Drill intercepts are reported as Li2O% over the drill length, not true thickness. The pegmatites targeted strike

northeast-southwest and dip moderately to the southeast. All holes were drilled to the northwest and with inclinations ranging between -45 and -70 degrees.

|

|

Diagrams

|

>Appropriate

maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional

views.

|

Appropriate diagrams, including a drill plan map are included in the main body of this report.

|

|

Balanced reporting

|

>Where

comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results.

|

All of the relevant exploration data for the Exploration Results available at this time has been provided in this report.

|

|

Other substantive exploration data

|

>Other

exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples – size and method of treatment; metallurgical

test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances.

|

Soil sampling and walking magnetometer geophysical surveys have been completed on the Core and Central property.

|

|

Further work

|

>The nature and scale of planned further work (e.g. tests for lateral extensions or depth extensions or large-scale step-out drilling).

>Diagrams

clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive.

|

Piedmont plans to release the results of a metallurgical testwork program on composite samples currently in process at SGS Lakefield

in the upcoming months.

Piedmont plans to release an updated Project wide

Scoping Study update in the upcoming months.

|

Section

3 Estimation and Reporting of Mineral Resources

|

Criteria

|

JORC Code explanation

|

Commentary

|

|

Database integrity

|

>Measures

taken to ensure that data has not been corrupted by, for example, transcription or keying errors, between its initial collection and its use for Mineral Resource estimation purposes.

|

Geological and geotechnical observations are recorded digitally in Microsoft Excel logging templates using standardized logging codes

developed for the project. Populated templates are imported into a central SQL database by a CSA Global database specialist via Datashed® import and validation functions to minimise risk of transcription errors. Likewise, sample

data and analytical results are imported directly into the central database from the independent laboratory.

|

|

>Data

validation procedures used.

|

An extract of the central database was validated by the Competent Person for internal integrity via Micromine ®

validation functions. This includes logical integrity checks of drill hole deviation rates, presence of data beyond the hole depth maximum, and overlapping from-to errors within interval data. Visual validation checks were also made for

obviously spurious collar co-ordinates or downhole survey values.

|

|

|

Site visits

|

>Comment

on any site visits undertaken by the Competent Person and the outcome of those visits.

|

CSA Global Competent Person; Leon McGarry P.Geo, has undertaken multiple personal inspections of the property during 2017, 2018 and

2019 to review exploration sites, drill core and work practices. The site geology, sample collection, and logging data collection procedures were reviewed. A semi-random selection of drill collar locations at the Core, Central and Sunnyside

properties was verified.. The presence of spodumene hosted lithium mineralisation was verified by the collection of independent check samples from drill core and outcrop. The outcome of the site visit was that data has been collected in a

manner that supports reporting a Mineral Resource estimate in accordance with the JORC Code, and controls to the mineralisation are well-understood.

|

|

>If no

site visits have been undertaken indicate why this is the case.

|

Site visits have been conducted.

|

18

19

|

Criteria

|

JORC Code explanation

|

Commentary

|

|

>The

availability of check estimates, previous estimates and/or mine production records and whether the Mineral Resource estimate takes appropriate account of such data.

|

This Mineral Resource estimate is an update to the maiden Mineral Resource Estimate for the Core Property reported on June 14, 2018.

Estimates Li2O grades and tonnages show good agreement with previous estimates. The resource estimate interpolation was checked using an Inverse Distance Weighted (IDW3) estimate and visually.

|

|

|

>The

assumptions made regarding recovery of by-products.

|

Bench-scale metallurgical test work undertaken at NCSU-MRL announced on September 4, 2018, recovered quartz, feldspar and mica

concentrates as by-products to spodumene. These products were recovered at sufficient amounts and qualities to support the by-product Mineral Resource Estimate for the Core Property reported on September 6, 2018. This updated Mineral Resource Estimate is for spodumene hosted Li2O only.

|

|

|

>Estimation

of deleterious elements or other non-grade variables of economic significance (e.g. sulphur for acid mine drainage characterisation).

|

Within the resource model, deleterious elements, such as iron are reported to be at acceptably to low levels. Metallurgical testwork

demonstrates that deleterious elements will not impede the economic extraction of the modelled grade element (Li) and no estimates for other elements were generated.

|

|

|

>In the

case of block model interpolation, the block size in relation to the average sample spacing and the search employed.

|

A rotated block model orientated at 35 degrees was generated. Given the variable orientation and the thickness the domains, a block

size of 6 mE × 12 mN × 6 mRL, sub-celled to a minimum resolution of 2 mE × 4 mN × 1 mRL, was selected to honour moderately dipping pegmatites in the across strike dimension, and the shallow dipping pegmatites in the vertical dimension. This

compares to an average drill hole spacing of 40 m within the more densely informed areas of the deposit, that increases up to an 80 m spacing in less well-informed portions of the deposit. Blocks fit within all search ellipse volumes and