Form 6-K ASML HOLDING NV For: Dec 31

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

______________________

______________________

FORM 6-K

REPORT OF A FOREIGN ISSUER

PURSUANT TO RULE 13A-16 OR 15D-16

OF THE SECURITIES EXCHANGE ACT OF 1934

For February 10, 2021

______________________

ASML Holding N.V.

De Run 6501

5504 DR Veldhoven

The Netherlands

(Address of principal executive offices)

______________________

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F.

Form 20-F x Form 40-F ¨

Indicate by check mark whether the registrant by furnishing the information contained in this Form is also thereby furnishing the information to the Commission pursuant to Rule 12g3-2(b) under the Securities Exchange Act of 1934.

Yes ¨ No x

If ‘‘Yes’’ is marked, indicate below the file number assigned to the registrant in connection with Rule 12g3-2(b):

Exhibits

99.1 2020 Integrated Report based on IFRS

99.2 "ASML Publishes 2020 Annual Reports", press release dated February 10, 2021

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

ASML HOLDING N.V. (Registrant)

Date: February 10, 2021 By: /s/ Peter T.F.M. Wennink

Peter T.F.M. Wennink

Chief Executive Officer

ASML ANNUAL REPORT 2020 1 Annual Report 2020 ’ 0 Exhibit 99.1

ASML ANNUAL REPORT 2020 2 Contents A definition or explanation of abbreviations, technical terms and other terms used throughout this Annual Report can be found in the chapter Definitions. In some cases numbers have been rounded for readers' convenience. This report comprises regulated information within the meaning of articles 1:1 and 5:25c of the Dutch Financial Markets Supervision Act (Wet op het Financieel Toezicht). The sections Who we are and what we do, What we achieved in 2020, CFO financial review, How we manage risk, Leadership and governance and Directors’ Responsibility Statement together form the Management Report within the meaning of Section 2:391 of the Dutch Civil Code (and related Decrees). In this report the name ‘ASML’ is sometimes used for convenience in contexts where reference is made to ASML Holding N.V. and/or any of its subsidiaries, as the context may require. © 2021, ASML Holding N.V. All Rights Reserved. 2020 at a glance Interview with our CEO 2020 Highlights Business as (un)usual Who we are and what we do Our company Our products and services Our markets Semiconductor industry trends and opportunities How we create value Our strategy What we achieved in 2020 Technology and innovation ecosystem Our people Our supply chain Circular economy Climate and energy CFO financial review Financial performance Financing policy Tax policy Long-term growth opportunities How we manage risk How we manage risk Risk factors Responsible business Leadership and governance Corporate governance Message from the Chair of our Supervisory Board Supervisory Board report Remuneration report Directors’ Responsibility Statement Consolidated Financial Statements Consolidated Statement of Profit or Loss Consolidated Statement of Comprehensive Income Consolidated Statement of Financial Position Consolidated Statement of Changes in Equity Consolidated Statement of Cash Flows Notes to the Consolidated Financial Statements Company Financial Statements Company Balance Sheet Company Statement of Profit or Loss Notes to the Company Financial Statements Other Information Adoption of Financial Statements Independent auditor’s report Non-financial statements Assurance Report of the Independent Auditor About the non-financial information Non-financial indicators Materiality: assessing our impact Stakeholder engagement Other appendices Definitions 5 7 8 10 14 17 18 22 24 27 39 53 59 65 74 81 83 85 87 92 100 106 119 120 135 147 150 151 152 153 154 155 209 210 211 217 218 225 227 229 244 247 250 253

ASML ANNUAL REPORT 2020 3 Special note regarding forward-looking statements In addition to historical information, this Annual Report contains statements relating to our future business and / or results. These statements include certain projections, business trends and other matters that are "forward- looking" within the meaning of the Private Securities Litigation Reform Act of 1995. You can generally identify these statements by the use of words like "may", "will", "could", "should", "project", "believe", "anticipate", "expect", "plan", "estimate", "forecast", "potential", "intend", "continue" and variations of these words or comparable words. They appear in a number of places throughout this Annual Report and include statements with respect to our expected trends and outlook, strategies, corporate priorities, expected semiconductor industry trends and 2024 market opportunities and roadmap, expected trends in markets served by our customers, expected market growth and drivers of such trends and growth, expected financial results, including expected sales, EUV revenue, service revenue, expected trends in working capital, gross margin, capital expenditures including expected capital expenditures, R&D and SG&A expenses, cash conversion cycle, target and expected effective annualized tax rate, sales targets and outlook for 2021 and other statements under "-Trend Information", annual revenue opportunity and potential and growth outlook for 2025, expected growth in 2021, expected continued growth in free cash flow generation, investments in the future and cash returned to shareholders, our Strengths, Weaknesses, Opportunities and Threats (SWOT), expected demand for upgrades, semiconductor industry dynamics and industry opportunities, expected trends in customer demand and demand for particular systems and upgrades and expected trends in end markets, including Memory, Logic and Foundry, including the continuation of investment by Logic customers in ramping new nodes and stronger lithography demand from memory customers, expected benefits of High-NA and planned target to start shipment of High-NA systems and high-volume production of systems using High-NA by 2025, 2024 market opportunities for semiconductor industry end markets, expected innovation drivers, expected drivers of long-term stakeholder value, expected trends in DUV systems revenue, expected DUV sales and the expectation that DUV will continue to drive value for our customers and be used in production in most layers of their chips, expected benefits of Holistic Lithography and expected installed based management revenues, our supply chain strategies and goals, customer, partner and industry roadmaps, ASML’s applications business, expected development of High-NA and its benefits, including the expected timing for development of future generation EUV systems, expected growth in EUV revenue the expected benefits of the indirect interest in Carl Zeiss SMT GmbH and the acquisition of Berliner Glas, expected EUV margins and margin improvement in our systems and service via cost reduction and value delivery, expected productivity and benefits of our tools, systems, and projects, EUV productivity targets and goals, potential future innovations and system performance, expected shipments of our tools and systems, including demand for and timing of shipments, statements with respect to DUV and EUV competitiveness, the development of EUV technology and EUV industrialization, expected productivity upgrade releases, enabling high-volume production of next generation chips and expected designs of such chips and their benefits, and revenue recognition, predicted growth in wafer production, sustainability targets, goals and strategies, shrink being a key driver supporting innovation and providing long-term industry growth, lithography enabling affordable shrink and delivering value to customers, sustainability strategy, goals and targets, including circular procurement goals, targeted greenhouse gas emission and waste reduction and recycling initiatives and investments, repair center expansion and targets, our expectation of the continuation of Moore’s Law and that EUV will continue to enable Moore’s Law and drive long- term value for ASML well beyond the current decade, tax strategy, capital allocation policy, dividend policy, our expectation to continue to return cash to our shareholders through share buybacks and dividends including our proposed dividend for 2020 and statements relating to our share buyback program for 2020-2022, and statements with respect to the expected impact of accounting standards. These forward-looking statements are not historical facts, but rather are based on current expectations, estimates, assumptions and projections about the business and our future financial results and readers should not place undue reliance on them. Forward-looking statements do not guarantee future performance, and actual results may differ materially from projected results as a result of certain risks, and uncertainties. These risks and uncertainties include, without limitation, those described under How we manage risk - Risk factors. These forward-looking statements are made only as of the date of this Annual Report. We do not undertake to update or revise the forward-looking statements, whether as a result of new information, future events or otherwise.

ASML ANNUAL REPORT 2020 4 2020 at a glance

ASML ANNUAL REPORT 2020 5 How do you look back on 2020? It was a year that affected us all due to the global COVID-19 pandemic. The impact has been widely felt across societies and families, as well as in the ASML community. But it was also a year that brought new learnings. For me personally, for instance, if you'd asked me 12 months ago if I could lead a company of over 28,000 people of which over 80% were at home, I would have said: “Are you out of your mind? Of course that won't work!" But this is what happened in 2020 – and it has worked. We even managed to close the acquisition of Berliner Glas Group, and welcomed around 1,600 new colleagues into ASML. While recognizing fully the severity of the pandemic, I also see 2020 as a year that underlined the importance of our work at ASML. Around the world people were abruptly confined to their homes and forced to work from their study, kitchen or bedroom. What was remarkable is that despite this widespread working from home, few companies experienced productivity loss. And let's not forget the many colleagues in our factories, and those who went to customers' factories and worked under very difficult conditions. Those who had to take long- distance trips to serve our customers were quarantined for weeks and forced to stay in their hotel rooms. Their dedication is nothing short of amazing and reflects the true ASML spirit. For those who had to work from home, the trust we put in their hands was returned with incredible flexibility and commitment. We even had to urge our colleagues to take breaks to stay physically and mentally fit. All of this was possible because the digital tools that the high-tech industry has developed over the past two decades proved sufficiently mature to support individuals and, even more importantly, collaboration in virtual teams. ASML systems have contributed significantly to advance and make affordable the necessary electronic building blocks for this digital transformation. During 2020, we collaborated closely with our partners in the supply chain to ensure we could continue to manufacture and ship systems to our customers. The situation was very dynamic and I am impressed with the way that we managed to deal with the many challenges. This is how, collectively, we limited the impact of COVID-19 on our company. We kept up our strong financial performance and we were able to continue to return capital through dividends and share buybacks. What were the main factors behind ASML’s strong performance in such a challenging year? The global economic consequences of COVID-19 had a limited impact on ASML' results. Declining consumer spending on smartphones and automotive was offset by increasing investments in 'working-from-home' electronics, datacenters and the communications network infrastructure needed to support an economy where data is an important driver of economic value and productivity. ASML does not produce these electronic devices or the software and digital services that run over them, but our systems are essential to manufacture the semiconductors that power this ecosystem. ASML and other semiconductor equipment peers are an integral part of this global electronic ecosystem of many dozens of companies that generates $400 billion worth of annual taxable profit. It is the strong performance of our entire ecosystem that powered the demand for our products and services this year, and enabled us to deliver record results. What were your customers' priorities in 2020? We divide our customers into two main market segments. First, the customers who produce Logic chips, who kept their steady pace of increasing investments in new production nodes. This explains the increasing demand for our most-advanced EUV systems, which customers need for the ramp of 5 nm chip production and the preparation for 3 nm chips. These advanced chips, the size of a thumbnail, contain up to a dozen billion transistors, which will power the latest and greatest smartphones, computers and other data-processing devices. Second, the market segment of customers who produce Memory chips, who started the year in a 'wait and see' mode, but showed signs of recovery throughout the year. The Memory segment routinely experiences supply and demand swings, which you need to visualize as a continuously upward swinging trend. The underlying growth in Memory 'bit' demand is the result of continuously rising data traffic that needs to be stored on servers and consumer devices. Our customers can meet this increase largely by shrinking the size of the memory transistors on their chips. They do this by adding more advanced ASML systems to make the smallest features on the chip even smaller. If the global economy is strong or when new data-hungry applications are introduced, the demand for Memory rises even faster. In Interview with our CEO Peter Wennink, Chief Executive Officer

ASML ANNUAL REPORT 2020 6 this case, the Memory makers need to add new production lines or even entirely new fabs. To support the projected bit growth, we expect that customers will need to add more capacity, as observed in our Q4 results. What do you expect for 2021? The digital transformation and wider technology trends significantly shape our roadmap and are driving our industry forward. Our Logic customers are very clear that they will continue their investments in ramping new, more advanced nodes. The pace will depend on the health of the global economy, and even more so on the value provided by the electronics and semiconductor industries, which are enabling the world's digital transformation. For the Memory segment, demand did not outpace supply in 2020, due to COVID-19 uncertainty. Based on our customers’ comments at the end of 2020, and improving market conditions, we expect to see stronger lithography demand from Memory customers in 2021 versus 2020. Another significant revenue stream comes from service and upgrades of ASML systems installed at our customers’ fabs. We expect our service revenue to grow with a growing installed base, whereas our upgrade business is more dependent on the release of new upgrades and the interest and capability of our customers. In summary, although we are currently going through a period of near-term uncertainty, the outlook for 2021 is positive, and the long-term demand drivers have only increased confidence in our future sustainable growth outlook towards 2025. Does anything stand in the way of that optimistic view? When I am asked what the future holds, my first response is that of course there are many uncertainties in today's world. We don't know what the effects of the COVID-19 crisis will be. In addition, geopolitical tensions and export control issues could have a significant impact on our industry. Looking specifically at our company, short-term business cycles and fluctuations in the global economy may have an impact on our business performance, even when the long-term megatrends provide us with a solid foundation. Most important is that we continue to put the customer at the heart of our business. Listening to the customer may sound obvious, but having direct interaction and communication with our customers is no longer possible for all ASML employees. We are making an extra effort to bring the voice of our customers to all ASML employees, through the online and off-line channels at our disposal. Everyone at ASML is constantly reminded of the reality that ASML systems are at the heart of our customers’ fabs, and in many cases our systems are even at the heart of our customers’ business strategies. This is a tremendous responsibility that should weigh heavily on all our shoulders. This feeling of responsibility and humility starts with the people who design and develop new systems and solutions. It continues with the folks who assemble the systems in our factories and our service engineers in the field. It is carried all the way to our office staff who provide support to their colleagues around the world. As long as we cherish this 'customer-centricity', we will continue to deserve the trust that our customers have put in us. How would you describe ASML’s footprint in the broader society? It's clear there is increasing interest in companies’ ecological and social footprints. We continue to apply corporate responsibility standards in the pursuit of our business ambitions. Our innovation ecosystem, energy- efficient products, circular use of materials and a responsible supply chain are our key sustainability priorities. These are vital for the long-term success of our business and long-term value we create for all our stakeholders. “Although we are currently going through a period of near-term uncertainty, the outlook for 2021 is positive.” Please scan the QR-code in order to read more information on our website. We continue to accelerate talent development and we promote a diverse and inclusive workplace that drives creativity and new ideas. We also drive collaborative innovation in environmentally friendly solutions for our customers. We are strongly committed to ethical business behavior, and we play an active role in promoting high standards of business conduct across the value chain. Outside the walls of our organization, we are committed to supporting schools with science, technology, engineering and math (STEM) subjects, particularly among female students, to support children and young adults to unlock their potential. Do ASML’s customers demand different things now than they did in the past? Our customers run very tight operations in gigantic fabs worth tens of billions of euros. A small disruption in the production process can disrupt their supply of chips for weeks. This means that the quality and availability of ASML systems are more important than ever before. In addition, as our industry grows, the impact that we and our customers have on our societies and communities also grows. All our customers have ambitious sustainability targets and they expect ASML to help them achieve those targets by, for instance, reducing energy consumption and also by being a responsible employer and good corporate citizen. We welcome these ambitions, because they align perfectly with our purpose, our vision and our values.

ASML ANNUAL REPORT 2020 7 2020 Highlights Financial Operational Social Governance Total net sales Gross margin Dividend per share Net income per share Net income Free cash ow €14.0bn (€11.8bn in 2019) 45.6% (41.5% in 2019) €3.7bn (€2.6bn in 2019) €3.6bn (€2.4bn in 2019) based on US GAAP €2.75 (€2.40 in 2019) (proposed) €8.84 (€6.13 in 2019) R&D expensesLithography systems sold CO2 emissions footprint Waste intensity Customer support IP portfolio €2.2bn (€2.0bn in 2019) based on US GAAP 258 (229 in 2019) 4.5m hours (3.8m hours in 2019) >14,100 patents (>13,700 patents in 2019) 15.4 kt (22.2 kt in 2019) scope 1 & 2 360 kg (417 kg in 2019) per €m revenue female members compliant average votes Forindependent Material recycling rate Systems refurbished 85% (80% in 2019) 31 (26 in 2019) Total employees Engagement score Community engagement ASML Foundation projects supported Attrition rate Nationalities 28,073 FTE (24,900 FTE in 2019) 80% (77% in 2019) 3.8% (4.3% in 2019) (118 in 2019) 120 €4.0m (€4.9m in 2019) COVID-19 donations €2.7m22 (17 projects in 2019) Startups and scaleups in-kind support 1,550 hours (1,300 hours in 2019) Supervisory Board Supervisory Board diversity Annual General Meeting resolutions 100% (100% in 2019) 33% (38% in 2019) (100% in 2019) (98.6% in 2019) 98.4% Corporate Governance 100%

ASML ANNUAL REPORT 2020 8 In every part of the world, the entire year was dominated by COVID-19, a novel virus that in the blink of an eye changed the world we live in. It affected how we lived, interacted with each other, and worked – in every country, region, village and community. Businesses and entire industries had to adapt to a new situation overnight, and many struggled to stay afloat. Countries came to a complete standstill, and there were uncountable stories of personal tragedy. This was a year where people had to pull together in unprecedented ways to tackle the pandemic. Of course, our company was impacted by the pandemic too, and in this Annual Report, we will describe its effect on our organization, the challenges we faced, and how we overcame these to continue to run our business. Two priorities At ASML, as with many other companies, there was an intense period at the start of the year when we had to introduce, develop and communicate our crisis- management measures. In a very short time, we moved from a policy of 'stay home if you have flu-like symptoms' to 'stay at home, period'. Fortunately, and in accordance with strict safety measures, our colleagues working directly in the production of our scanners, in the clean rooms, logistics or other supporting departments were able to continue their work in otherwise deserted locations. We have two very clear priorities in our crisis response and communications, then and now. Our number one priority is to ensure the health and safety of our people and their families. The second priority is to ensure business continuity: manufacture our products, provide service to our customers, and develop future products according to our roadmap. In all our health and safety measures, we follow the guidelines of the World Health Organization and local health authorities. And although we developed an ASML- specific policy worldwide, we follow national government measures in the regions where we operate. Challenge, Collaborate, Care We know that COVID-19 is not behind us, but looking back on 2020, we can say we have delivered on our priorities. We have also learned how important ASML’s company values are, and why we need them now more than ever. When the future is uncertain and there are no easy answers, these values of Challenge, Collaborate and Care have and will provide a strong foundation for everything we do. In 2020, we really lived our values, and they united us in many ways. They are our DNA. For example: • With every local lockdown and travel restriction that came into effect, we challenged ourselves and others to come up with creative ways to do our work and fulfil our obligations. Our can-do mentality was evident in so many ways. • Our ability to collaborate proved to be extremely valuable in these times. We were not in the crisis alone, and we made sure our partners, customers and colleagues knew we supported them. • We united in our care for our colleagues, suppliers, customers and communities. Colleagues around the world went above and beyond to provide support at all levels. This included voluntarily going into quarantine far from home to support a customer, to delivering critical medical equipment and protective clothing to organizations in need. Prioritizing our colleagues, their families and our business Throughout the year, our people were our top priority: keeping them safe by creating a secure workplace, providing mental and physical health support, and staying in close contact even when working remotely. Undoubtedly, this experience has made us stronger as a global team. Then, although it was not always easy, we were able to continue to run our business and serve our customers. Our operational capabilities returned to normal in the second quarter. We were able to source the modules and parts for our products, complete installs and upgrades, and service our customers across the globe. One of ASML’s strengths as a company has always been that its people pull together when we need to most. The past year certainly stands as testimony to this strength. Business as (un)usual: how COVID-19 shaped 2020

ASML ANNUAL REPORT 2020 9 Who we are and what we do

ASML ANNUAL REPORT 2020 10 Our company 1984 Year founded >60 Locations across 3 continents, headquartered in the Netherlands 28,073 Total employees 12,918 in operations 10,543 in R&D 3,020 in sales and support 1,592 Berliner Glas1 €14.0bn Net sales €11.8bn Asia €1.7bn US €0.5bn EMEA We are a global innovation leader in the chip industry. We provide chipmakers with hardware, software and services to mass produce patterns on silicon through lithography. What we do increases the value and lowers the cost of a chip, which advances us all towards a smarter, more connected world. 1 Berliner Glas Group has been re ected throughout this report, with the exception of our non-

nancial reporting. Our purpose For all the ways we have moved forward as a society, the world faces crucial challenges for the future. We must change how we think and act on themes that impact everyone, like energy use, climate change, mobility and access to healthcare and nutrition. At ASML, we believe that the chip industry is in a unique position to help tackle these challenges. From artificial intelligence (AI) to a vast internet of things (IoT), microchips are at the heart of modern technology. So whether it’s transitioning to sustainable energy, improving global health, increasing the safety and efficiency of transport, tackling pollution, bridging the digital divide, or feeding eight billion people without exhausting the earth’s resources, our vision is that we will enable the groundbreaking technology that will help solve some of humanity’s toughest challenges. As the innovation leader that makes vital systems for chip manufacturing, we are proud to not only be a part of these solutions, but also the ones who are making them possible. We can only play this role if we continue to challenge the status quo, tap into the collective knowledge of our global ecosystem and create an environment where people can contribute, learn and grow. At ASML, we believe our purpose is to unlock the potential of people and society by pushing technology to new limits. The long-term growth of the semiconductor industry is based on the principle that the energy, cost and time required for electronic computations can be reduced by shrinking transistors on microchips. One of the main drivers of shrink is the resolution that systems can achieve, which is mainly determined by the wavelength of the light used and the numerical aperture of the optics. A shorter wavelength – like a finer brush used for painting – can print smaller features. A larger numerical aperture can focus the light more tightly, which also leads to better resolution. To enable shrink, what we do – lithography – is key. As such, we are a focused supplier of holistic lithography solutions to all of the world’s major chipmakers. Our mission, together with our partners, is to provide leading patterning solutions that drive the advancement of microchips. Through our sustained investment in, and dedication to, research and development, we innovate at least at the same pace as our customers. We put our innovations in the hands of chipmakers as quickly as possible by engineering in parallel, not sequentially, while ensuring their quality, reliability, manufacturability, and serviceability. Our core values To help solve humanity’s toughest challenges while at the same time addressing our own, we must continue to amplify ASML's core values that created our success – Challenge, Collaborate, Care. We challenge We challenge boundaries, question the status quo and stand up for the ideas we believe in. We’re comfortable with discussion and debate, because it is often inherent to stress-testing and championing an idea. This is what enables us to push technology forward, keep things simple and do things with care and attention. We always challenge ourselves to add value for our customer, ensuring we continually improve across key aspects, like safety, quality, efficiency and cost. We collaborate As a system architect and system integrator, we collaborate to tap into our collective potential. Together with our partners in our ecosystem, we expand our

ASML ANNUAL REPORT 2020 11 knowledge and skills, learn from each other, and share approaches to deliver the best results. What we do is unique, and we need each other to make it possible. As we continue to grow and our ecosystem of partners expands, this collaborative mindset becomes even more essential to success. We care As we push technology further together, we have to do so with care. As an industry leader, we realize our impact extends from people, to society, to the planet. We care not only for those we work with, but for our customers, suppliers, the world we live in, and the communities where we do business. We believe in integrity and respect for people and their human rights. We take personal responsibility to create a safe, inclusive and trusting environment where people from all backgrounds are encouraged and enabled to speak up, contribute, learn, make mistakes, and grow. We also take care to create clarity in how we organize ourselves to achieve our goals, making sure we have a clear framework for what we do and how we do it. These values will help our company and our employees to make smart decisions that will benefit all stakeholders. Our values and purpose, together with the great responsibility we have as an industry leader, make us keenly optimistic for the future. Where we come from Our company was founded in 1984 in Eindhoven under the name of ASM Lithography, a joint venture between Philips and ASM International. As they moved into their new space near the Philips factories at Strijp-T in Eindhoven, our first employees could never have imagined that in just three decades, ASML would be a global innovation leader. We’ve grown from our humble beginnings to a global force through relentless focus on innovation, sheer customer focus through tough times, and a willingness to rely on others to come to a better result. Our position in the semiconductor industry Although we’re constantly looking to the future, where we have come from is just as important to us as we evolve. These pioneering behaviors have been key to our success over the past 36 years, and they’ve become even more important to us as we continue to define our purpose and articulate the values that underpin everything we do. Understanding what made us successful in the past will help us maintain our success in the future. What guides us Innovation is rarely a straight line. We've always known that it takes laser focus, multidisciplinary teamwork and a keen eye for how we can best help our customers. And even then, we've had to show grit. It took a decade of tenacity to get our technology off the ground. We've cared for this company like it was our own, and are proudly committed to its success. We believed then as we do now that even the biggest challenge can be overcome by chipping away, if necessary with hundreds of people over many years. We also learned to rely on others to come to a better result – without losing focus. That meant expanding our own knowledge and skills by building an ecosystem of expert suppliers, strategic partners, academia and service providers. We also acquired leading companies with unique technologies that strengthened our ability to deliver better solutions to our customers. We started to see ourselves as architects and integrators, inspiring our partners to innovate on the cutting edge of engineering while sharing risk and reward. And like us, some of our earliest customers are now leaders in the chip industry. We are geared towards providing long-term value to our customers and other stakeholders. Our direct value chain consists of our R&D partners, supply chain and customers, as well as our own manufacturing and service activities. Together we enable product and service manufactures, so- called Original Equipment Manufacturers (OEMs), and Original Design Manufacturers (ODMs), to create end-use devices and services for the consumer market. Suppliers ASML Customers Consumers Research partners Development & engineering partners Supply chain (Tier-1) Supply chain (N-tier) Lithography equipment manufacturer Foundries and IDMs (semiconductor manufacturers) Semiconductor design Manufacturers Devices and software (OEMs and ODMs) End-use products and services

ASML ANNUAL REPORT 2020 12 Repeat process to add each additional layer Metrology & inspection Optical E-beam Computational lithography Optical proximity correction Source mask optimization Removing photoresist Ion implantation Embed impurity atoms into areas unprotected by resist, changing parameters of the semiconductor material Etching Remove materials unprotected by the wafer resist mask using chemicals or a plasma Photoresist coating Covering the wafer with unexposed photoresist Deposition Adding a new layer of silicon or other materials over the wafer Baking and developing Leaving the chip pattern as a photoresist mask on the wafer Exposure Using light in lithography systems to make a pattern in the photoresist Lithography The role of lithography Lithography is a driving force in the creation of more powerful, faster and cheaper chips. Today’s most advanced processors, based on the Logic N5 node, contain billions of transistors. But shrinking transistors further is becoming increasingly difficult. We aren’t as close to the fundamental limits of physics as some would think. Next-generation chip designs will include more advanced materials, new packaging technologies, and more complex 3D designs, which will create the electronics of the future. The manufacturing of chips becomes increasingly complex as semiconductor feature sizes shrink, while the imperative to mass produce at the right cost remains. Our holistic lithography product portfolio helps to optimize production and enable affordable shrink by integrating lithography systems with computational modeling, as well as metrology and inspection solutions. Our computational models enable our customers to optimize their mask design and tape-out time. This works through mask-correction software to prepare and modify the design for optimized exposures, while the inspection solutions help in analyzing and controlling the manufacturing process in real time. A lithography system is essentially a projection system. Light is projected through a blueprint of the pattern that will be printed (known as a ‘mask’ or ‘reticle’). With the pattern encoded in the light, the system’s optics shrink and focus the pattern onto a photosensitive silicon wafer. After the pattern is printed, the system moves the wafer slightly and makes another copy on the wafer. This process is repeated until the wafer is covered in patterns, completing one layer of the wafer’s chips. To make an entire microchip, this process is repeated layer after layer, stacking the patterns to create an integrated circuit (IC). The simplest chips have around 10 layers, while the most complex can have over 150 layers. The size of the features to be printed varies depending on the layer, which means that different types of lithography systems are used for different layers – our latest-generation EUV systems for the most critical layers with the smallest features to ArF, KrF, and i-line DUV systems for less critical layers with larger features. Semiconductor manufacturing process

ASML ANNUAL REPORT 2020 13 • CD is the critical dimension, a measure of how small the smallest structures are that the lithography system can print. • λ (lambda) is the wavelength of the light source used and the smaller the wavelength the smaller the structures that can be printed. Our deep ultraviolet (DUV) lithography systems, known as the industry workhorse, dive deep into the UV light spectrum to print the tiny features that form the basis of the microchip. Over the years ASML made several wavelength steps and our DUV lithography systems range from 365 nm (i-line), 248 nm (KrF) to 193 nm (ArF). With the extreme ultraviolet (EUV) systems, we provide highest-resolution lithography in high-volume manufacturing, as these systems make a major step in wavelength as with EUV tin plasma we generate EUV light which has a wavelength of just 13.5 nm. • NA is the numerical aperture, indicating the entrance angle of the light and with larger NA lenses/ mirrors smaller structures can be printed. Besides larger lenses ASML increased the NA of our ArF systems by maintaining a thin film of water between the last lens element and the wafer, using the breaking index of the water to increase the NA (so called immersion systems). After the wavelength step to EUV, ASML is developing the next generation EUV systems, called high-NA where we push the NA from 0.33 to 0.55. • k 1 is a factor relating to optical and process optimizations. Together with our computational lithography and patterning control software solutions we provide the control loops for our customers to optimize their mask designs and illumination conditions. ASML's goal has always been to reduce the critical dimension. By reducing the wavelength and increasing the numerical aperture, our systems can print IC structures in increasingly smaller feature sizes. If our customers can print smaller structures, the chips can be smaller and the cost per transistor become cheaper, which in turn makes it more profitable for our customers. Extending Moore’s Law is becoming increasingly complex and costly. What will always be needed is a way to mass produce IC designs at the right cost. That’s where the full scope of ASML’s product portfolio will continue to play a big role to ensure affordable transistor shrink. We continue to push our entire system portfolio to new productivity levels and imaging performance. Our EUV and High-NA lithography will enable tomorrow’s most advanced chips. In our computational lithography solutions, we’re bringing machine learning and big data to the forefront in predicting both lithography and metrology processes with 100% accuracy. Finally, we have developed an entirely new class of e-beam inspection systems to help our customers control defectivity in manufacturing in next-generation chip nodes, as those smaller structures can hardly be detected with optical inspection. CD = k 1 x λ NA Rayleigh's equation that drives Moore’s Law Moore’s Law, a prediction made over half a century ago, set the pace for our industry. Gordon Moore predicted that computing would dramatically increase in power, and decrease in relative cost, at an exponential pace. In other words, the number of transistors (tiny electrical switches) on an integrated circuit will double every two to three years at the same cost. This opens up two options to make microchips faster and more powerful: by using the same number of transistors on a chip at half the cost, or by doubling the number of transistors at the same cost. Even today the power of this prediction is the fundamental principle of the semiconductor industry and the driving force for innovations that benefit our daily lives. At ASML, our job is to help the industry continue Moore’s Law. Our goal has always been to reduce the critical dimension (CD) – the smallest structure that a lithography system can print. This is defined by Rayleigh’s criterion, the equation on which all our innovation is based:

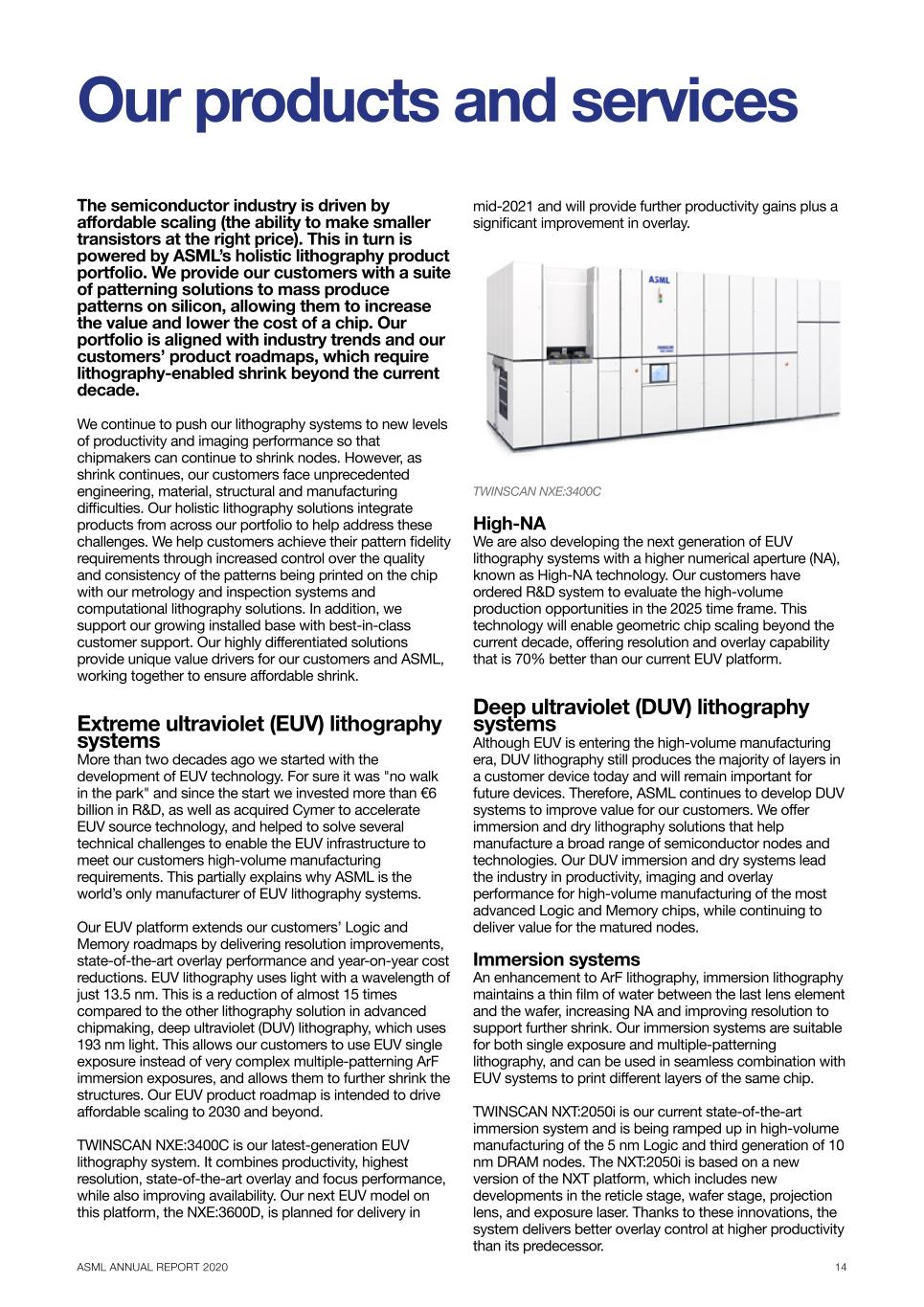

ASML ANNUAL REPORT 2020 14 TWINSCAN NXE:3400C High-NA We are also developing the next generation of EUV lithography systems with a higher numerical aperture (NA), known as High-NA technology. Our customers have ordered R&D system to evaluate the high-volume production opportunities in the 2025 time frame. This technology will enable geometric chip scaling beyond the current decade, offering resolution and overlay capability that is 70% better than our current EUV platform. Deep ultraviolet (DUV) lithography systems Although EUV is entering the high-volume manufacturing era, DUV lithography still produces the majority of layers in a customer device today and will remain important for future devices. Therefore, ASML continues to develop DUV systems to improve value for our customers. We offer immersion and dry lithography solutions that help manufacture a broad range of semiconductor nodes and technologies. Our DUV immersion and dry systems lead the industry in productivity, imaging and overlay performance for high-volume manufacturing of the most advanced Logic and Memory chips, while continuing to deliver value for the matured nodes. Our products and services The semiconductor industry is driven by affordable scaling (the ability to make smaller transistors at the right price). This in turn is powered by ASML’s holistic lithography product portfolio. We provide our customers with a suite of patterning solutions to mass produce patterns on silicon, allowing them to increase the value and lower the cost of a chip. Our portfolio is aligned with industry trends and our customers’ product roadmaps, which require lithography-enabled shrink beyond the current decade. We continue to push our lithography systems to new levels of productivity and imaging performance so that chipmakers can continue to shrink nodes. However, as shrink continues, our customers face unprecedented engineering, material, structural and manufacturing difficulties. Our holistic lithography solutions integrate products from across our portfolio to help address these challenges. We help customers achieve their pattern fidelity requirements through increased control over the quality and consistency of the patterns being printed on the chip with our metrology and inspection systems and computational lithography solutions. In addition, we support our growing installed base with best-in-class customer support. Our highly differentiated solutions provide unique value drivers for our customers and ASML, working together to ensure affordable shrink. Extreme ultraviolet (EUV) lithography systems More than two decades ago we started with the development of EUV technology. For sure it was "no walk in the park" and since the start we invested more than €6 billion in R&D, as well as acquired Cymer to accelerate EUV source technology, and helped to solve several technical challenges to enable the EUV infrastructure to meet our customers high-volume manufacturing requirements. This partially explains why ASML is the world’s only manufacturer of EUV lithography systems. Our EUV platform extends our customers’ Logic and Memory roadmaps by delivering resolution improvements, state-of-the-art overlay performance and year-on-year cost reductions. EUV lithography uses light with a wavelength of just 13.5 nm. This is a reduction of almost 15 times compared to the other lithography solution in advanced chipmaking, deep ultraviolet (DUV) lithography, which uses 193 nm light. This allows our customers to use EUV single exposure instead of very complex multiple-patterning ArF immersion exposures, and allows them to further shrink the structures. Our EUV product roadmap is intended to drive affordable scaling to 2030 and beyond. TWINSCAN NXE:3400C is our latest-generation EUV lithography system. It combines productivity, highest resolution, state-of-the-art overlay and focus performance, while also improving availability. Our next EUV model on this platform, the NXE:3600D, is planned for delivery in mid-2021 and will provide further productivity gains plus a significant improvement in overlay. Immersion systems An enhancement to ArF lithography, immersion lithography maintains a thin film of water between the last lens element and the wafer, increasing NA and improving resolution to support further shrink. Our immersion systems are suitable for both single exposure and multiple-patterning lithography, and can be used in seamless combination with EUV systems to print different layers of the same chip. TWINSCAN NXT:2050i is our current state-of-the-art immersion system and is being ramped up in high-volume manufacturing of the 5 nm Logic and third generation of 10 nm DRAM nodes. The NXT:2050i is based on a new version of the NXT platform, which includes new developments in the reticle stage, wafer stage, projection lens, and exposure laser. Thanks to these innovations, the system delivers better overlay control at higher productivity than its predecessor.

ASML ANNUAL REPORT 2020 15 TWINSCAN NXT:2050i Metrology and inspection systems Delivering speed and accuracy, our metrology and inspection portfolio covers every step of the manufacturing process, from R&D to mass production. The information captured through our metrology and inspections systems helps us to control the thousands of knobs in the scanner to enlarge the process window and improve yield for our customers. Together with our computational lithography and patterning-control software solutions, these systems help chipmakers achieve the highest yield and best performance in mass production. Optical metrology and inspection Our YieldStar optical metrology solutions can quickly and accurately measure the quality of patterns on the wafer. YieldStar 385H offers the latest in-resist post lithography overlay and focus metrology, with enhanced throughput and accuracy. Overlay, how well one layer is aligned to its previous layer, is becoming more important as structures get smaller and error tolerance reduces. Compared to previous systems, key enhancements include a faster stage and faster wavelength changing. This enables highly accurate overlay measurements and tool matching using multiple wavelengths without impacting throughput. YieldStar 385H YieldStar 1375F is the only optical tool on the market for fast, accurate in-device overlay and metrology. Capable of measuring multiple layers at once, it helps customers improve yield through post-etch process control. E-beam metrology and inspection Our HMI e-beam solutions allow customers to locate and analyze individual chip defects amid billions of printed features, extending the possibilities for process control. Historically, e-beam solutions were too slow to monitor volume production processes. However, ASML has made progress in various methods for increasing the throughput of e-beam systems. Our pattern fidelity metrology option draws data from a wide variety of sources, analyzing it using predictive models to identify hotspots where defects are most Dry systems Our portfolio of dry systems offers tool types for all wavelengths currently used in the semiconductor industry, from i-line using 365 nm wavelength, KrF using 248 nm and ArF using light of 193 nm supporting the continued progress to enable shrink. TWINSCAN NXT:1470 is our latest dry ArF lithography system. It is also the first dry NXT system, building on our successful immersion platform, and delivers improvements in matched machine overlay, productivity and its footprint in the fab. TWINSCAN XT:860M is our most popular KrF system, supporting high-volume 200 mm and 300 mm wafer production at and below 110 nm resolution. For more critical KrF layers, the higher-NA TWINSCAN XT:1060K is our most advanced KrF lithography system, and offers best-in-class resolution and overlay. TWINSCAN XT:400L is our latest i-line lithography system, printing features down to a resolution of 220 nm for 200 mm and 300 mm wafer production. TWINSCAN NXT:1470

ASML ANNUAL REPORT 2020 16 probable or most critical. This insight is used to guide the e-beam inspection system and optimize scan strategies, increasing the effective productivity. In addition, in 2020 we shipped the first multiple e-beam (multibeam) inspection system. The HMI eScan 1000 demonstrated successful multibeam operation, simultaneously scanning with nine beams. It increases throughput by up to 600% compared to single e-beam systems, thus reducing the cost of inspection. eScan 1000 Computational lithography Our computational lithography and software solutions revolve around creating applications that enhance the setup of the lithography system so chipmakers can print exactly what they want to print. Accurate simulation models of the lithography process are a foundational element for all these applications. These models represent a wide variety of physical and chemical effects. Machine learning solutions are now broadly used in the simulation models as well as in the applications. Managing our installed base systems The installed base of ASML systems continues to grow, with many systems finding second or even third lives at new owners in new markets and applications. To provide all our customers with the best possible value proposition, we offer an extensive Installed Base Management portfolio, including a wide range of service and upgrade options. We develop and sell product options and enhancements designed to improve throughput, patterning performance and overlay. Through field-upgrade packages, it is possible to upgrade older systems to newer models in the field. This enables customers to optimize their cost of ownership over the system’s lifetime. Meanwhile, our Mature Products and Services (MPS) business refurbishes used lithography equipment and offers associated services. We focus on the refurbishment of three product families: the ‘classic’ PAS 5500, the first generation AT systems, and the early generation NXT and XT systems. We are investing to be able to extend the lifetime of the PAS platform until at least 2030. Customer support We support our customers with a broad range of applications, services, and technical support products to maintain and enhance our systems' performance. We have more than 6,200 customer support employees, including service engineers and applications specialists, who work to ensure the systems in our customers’ fabs run at the highest levels of predictability and availability. We offer 24/7 support, next-day parts delivery, an easy, centralized customer portal, and training for customer engineers. Visit www.asml.com for more product details and specifications.

ASML ANNUAL REPORT 2020 17 Our markets Our customers are the world’s leading microchip manufacturers, and our success is inextricably linked with theirs. We design our machines based on their input, engage in helping them achieve their technology and cost roadmaps, and work together to make sure our machines are running smoothly in their fabs. Our customers can be grouped into Memory and Logic chipmakers. Memory chips can store a large amount of data in a very small area. They are used in an increasing variety of electronic products like servers, data centers, smartphones, high-performance computing, automotive or personal computers, and other communication devices. There are two main classes of Memory: NAND and DRAM. With NAND chips, data can be stored even when a device is powered off. DRAM memory is used to efficiently provide data to the processor. These DRAM and NAND chips are typically made in dedicated Memory-chip factories. Logic chips, which process information in electronic devices, are produced by two groups of manufacturers. The first group, known as integrated device manufacturers (IDM), designs and manufactures Logic chips. The second group comprises contract manufacturers known as foundries. Foundry manufacturers produce chips for ‘fabless’ companies, which focus only on chip design and distribution, but do not manufacture themselves. Both Logic and Memory chips can vary greatly in complexity and capability. For example, the most advanced chips are powering leading-edge technology in artificial intelligence (AI), big data and automotive technology, while the simpler, low-cost chips are integrating sensing capabilities in everyday technology to create a vast IoT. The chip market has grown by 5% per year on average over the past 20 years, but the factors driving this growth have radically changed. In the 1990s, personal computers (PCs), both desktops and later laptops, drove chip demand. In the first decade of this century, the market driver evolved from PCs to smartphones. These in turn produced new market drivers, data centers and cloud solutions, where data from PCs and smartphones is routed, processed and stored with the extensive use of specialized Logic chips, in combination with DRAM, NAND and HDD storage.

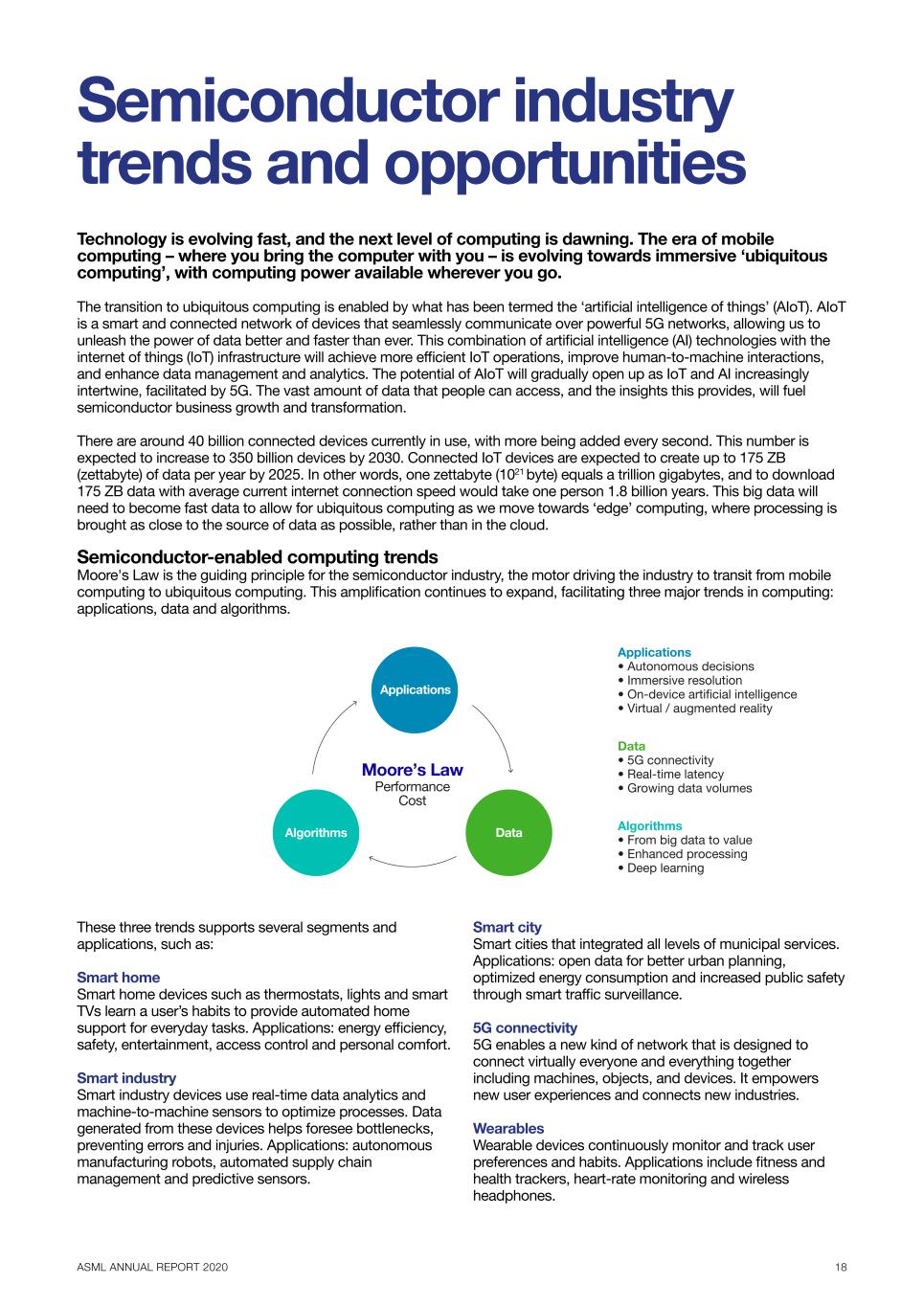

ASML ANNUAL REPORT 2020 18 Semiconductor industry trends and opportunities Technology is evolving fast, and the next level of computing is dawning. The era of mobile computing – where you bring the computer with you – is evolving towards immersive ‘ubiquitous computing’, with computing power available wherever you go. The transition to ubiquitous computing is enabled by what has been termed the ‘artificial intelligence of things’ (AIoT). AIoT is a smart and connected network of devices that seamlessly communicate over powerful 5G networks, allowing us to unleash the power of data better and faster than ever. This combination of artificial intelligence (AI) technologies with the internet of things (IoT) infrastructure will achieve more efficient IoT operations, improve human-to-machine interactions, and enhance data management and analytics. The potential of AIoT will gradually open up as IoT and AI increasingly intertwine, facilitated by 5G. The vast amount of data that people can access, and the insights this provides, will fuel semiconductor business growth and transformation. There are around 40 billion connected devices currently in use, with more being added every second. This number is expected to increase to 350 billion devices by 2030. Connected IoT devices are expected to create up to 175 ZB (zettabyte) of data per year by 2025. In other words, one zettabyte (1021 byte) equals a trillion gigabytes, and to download 175 ZB data with average current internet connection speed would take one person 1.8 billion years. This big data will need to become fast data to allow for ubiquitous computing as we move towards ‘edge’ computing, where processing is brought as close to the source of data as possible, rather than in the cloud. Semiconductor-enabled computing trends Moore's Law is the guiding principle for the semiconductor industry, the motor driving the industry to transit from mobile computing to ubiquitous computing. This amplification continues to expand, facilitating three major trends in computing: applications, data and algorithms. These three trends supports several segments and applications, such as: Smart home Smart home devices such as thermostats, lights and smart TVs learn a user’s habits to provide automated home support for everyday tasks. Applications: energy efficiency, safety, entertainment, access control and personal comfort. Smart industry Smart industry devices use real-time data analytics and machine-to-machine sensors to optimize processes. Data generated from these devices helps foresee bottlenecks, preventing errors and injuries. Applications: autonomous manufacturing robots, automated supply chain management and predictive sensors. Smart city Smart cities that integrated all levels of municipal services. Applications: open data for better urban planning, optimized energy consumption and increased public safety through smart traffic surveillance. 5G connectivity 5G enables a new kind of network that is designed to connect virtually everyone and everything together including machines, objects, and devices. It empowers new user experiences and connects new industries. Wearables Wearable devices continuously monitor and track user preferences and habits. Applications include fitness and health trackers, heart-rate monitoring and wireless headphones. Applications • Autonomous decisions • Immersive resolution • On-device arti cial intelligence • Virtual / augmented reality Data • 5G connectivity • Real-time latency • Growing data volumes Algorithms • From big data to value • Enhanced processing • Deep learning Algorithms Applications Data Moore’s Law Performance Cost

ASML ANNUAL REPORT 2020 19 Self-driving cars These supercomputers on wheels are enabled by electronics and semiconductors. Autonomous vehicles offer ADAS (Advanced Driver Assistance Systems) features that reduce accidents and casualties and allow us to stay connected continuously through infotainment systems. Autonomous robotics A new generation of lightweight robots fitted with smart sensors enables humans and machines to collaborate closely and safely. Smart robots that are connected to a greater network can benefit from big data and collective learning making it possible to reduce manufacturing costs and improve quality of products. Mixed reality Combining augmented reality and virtual reality technology will bring together the real world and digital elements and create the next-level user experience with potential applications in education and training, healthcare, entertainment. For example, imagine you can interact with your teacher and co-students as if you are in the class- room, but this time from your living room. Predictive healthcare Using devices connected to patients (bracelets, watches, and more) allows us to collect data on the health status of patients to diagnose disease in advance, provide treatment (even remotely), and prevent critical situations. When joining forces with AI, machine learning can save lives. Semiconductor industry opportunities Semiconductor technology plays a crucial part in shaping the interconnected and intelligent network future, and end markets continue to grow. The overview below shows the current market size and market opportunity for the entire industry based on external research of market outlook. Market Key driver 2019 market size ($bn) 2024 market opportunity ($bn) CAGR (%) Smartphone Continued refresh of all semiconductor content including image sensors 106 155 7.9% Personal computing High-end compute and Memory, fast conversion to SSD 86 99 2.8% Consumer electronics Legacy products and packaged ICs. Advanced ICs in add-ons 42 61 7.7% Automotive Strong IC content growth: GPU, sensors, V2X communication sensing 41 65 9.5% Industrial electronics High-end compute for AI on big data and sensors 49 71 7.8% Wired and wireless infrastructure Devices for fast data processing, modem, base- station infrastructure refresh 34 45 5.5% Servers, datacenters and storage High processor and Memory growth, hardware accelerations including GPU 61 102 10.6% 419 598 7.3%

ASML ANNUAL REPORT 2020 20 Semiconductor industry dynamics Several factors are shaping the semiconductor industry landscape. These are some of the major trends driving industry development, today and tomorrow. Rising consumer demand The convergence of wireless communication, telecom, media and cloud via connected devices continues to drive demand for advanced semiconductors across the globe. Growing populations and urbanization are creating increasing demand for advanced consumer electronic devices. Microchips are at the heart of these devices. Significant growth drivers of the emerging technologies are demanding new and advanced chips that are specifically designed for a wave of new applications. Read more in: Semiconductor industry trends and opportunities, Customer intimacy Global race for talent Highly skilled people with a technical background are scarce in the labor market and competition is growing. Top-tier talent select their employer of choice, not the other way around. The global race for talent is becoming more crucial as the industry competes for a small pool of scientists, engineers and software developers with the skill set to develop innovative solutions. Companies are trying to staff up for growth, but the high-tech resource pool is shallow. The number of STEM jobs is projected to grow significantly, but it is challenging to fill these given the shortage of qualified candidates. Retaining talent has become crucial for tech companies. Read more in: Our people Global geopolitics The current trade environment presents significant challenges for the global semiconductor industry, and trade tensions and increased protectionism are likely to continue. US authorities took steps that further restrict US chipmakers and other companies from doing business with China. These actions are impacting the semiconductor industry’s ability to conduct business in the global marketplace. The industry is being forced to manage trading costs. Ultimately, this could be passed on to the end-market resulting in an increase of prices of devices. Besides the financial implication, trade tensions and protectionism also introduce significant complexity throughout the supply chain and its processes. This is forcing the industry to relook at its global supply chain. Read more in: Our supply chain, How we manage risk, Risk factors Expanding R&D costs In the rapidly evolving semiconductor industry, access to the latest technologies, chip designs and manufacturing processes is the basis for competition. R&D is an ever bigger priority and expense. Chipmakers are faced with supporting applications and end markets that are becoming increasingly complex. Traditional semiconductor companies are challenged to diversify their portfolio, due to the rise of tech platform companies moving to in-house chip design. In addition, the incremental costs of executing innovation are rising, requiring higher levels of R&D investments to achieve the same goals. Getting products to the market faster is essential – or the chipmakers risk missing the boat. As a result, there is increased pressure to get solutions to the customers early. Read more in: Technology & innovation ecosystem, Risk factors, Financial performance Changing landscape To capitalize the convergence of mega trends such as AI, IoT, 5G and autonomous vehicles, the industry is investing significant amounts in assets that can unlock value across the portfolio. The global semiconductor industry has shown tremendous growth in recent years and this is set to continue. It is refocusing on increasing scale and proficiency in core competences as well as expanding into new capabilities and new markets. Mergers, acquisitions and joint ventures are expected to be key parts of the chip-market strategy, with deals focusing on emerging technologies. Read more in: Semiconductor industry trends and opportunities, Our supply chain and Risk factors Taking action on climate change Climate change is an urgent matter around the world. It is a global challenge that requires global responsibility to limit a temperature rise to well below 2°C. Our industry has a role to play. The semiconductor manufacturing process consumes large volumes of energy and water resources. Driving Moore’s Law in enabling shrink and, at the same time, improving computing power and storage capacity, fuels the demand for these resources. New architectures and a new way of looking at the entire ecosystem will be required to enhance energy and water-resource efficiency. To meet these challenges, the semiconductor industry has to reduce power consumption. With data centers consuming about 10% of the world’s electric power, it touches the boundaries of scale. Taking action on climate change is a moral imperative. Read more in: Climate and energy

ASML ANNUAL REPORT 2020 21 SWOT analysis Acting on the global trends and developments in the semiconductor industry and in society is an important factor in the success of our business, as well as in creating value for our stakeholders. Using these external and internal factors, as well as current and future potential, we have evaluated our company's competitive position in the environment we operate in. The following table provides a brief overview of our strengths, weaknesses, opportunities and threats (SWOT). More information on how we manage the topic can be found in the reference sections. Strengths + Weaknesses — • Technology leadership (Read more in: Our products and services, Technology and innovation ecosystem) • Market leadership (Read more in: Our products and services, Our markets, Customer intimacy) • Collaborative & enduring innovation (Read more in: Technology and innovation ecosystem) • World-class workforce with 'can-do' mentality (Read more in: Our core values, Our people) • Strong financial position (Read more in: 2020 Highlights, Financial performance) • Fast-growing workforce (Read more in: Our people, How we manage risk) • Limited cost leadership advantage (Read more in: Operational excellence, CFO financial review, How we manage risk) • Increasing complexity of our products and technology (Read more in: How we manage risk) Opportunities ä Threats æ • Ride the tech megatrends (Read more in: Semiconductor industry trends and opportunities, Our strategy) • Holistic lithography portfolio expansion (Read more in: Our products and services, Our strategy) • Emergence of new customers in semiconductor industry (Read more in: Semiconductor industry dynamics) • Raising brand awareness (Read more in: Our people) • Increasing sustainability drive (Read more in: Our strategy, Circular economy, Climate and energy) • Geopolitical tensions (Read more in: Semiconductor industry dynamics, How we manage risk) • Supply chain disruption (Read more in: Our supply chain, How we manage risk) • IP Technology leadership pressure (Read more: in How we manage risk) • Competition for market share (Read more in: How we manage risk) • Competition for talent (Read more in: Semiconductor industry dynamics, Our people, How we manage risk) • Narrow customer base (Read more in: Customer intimacy, How we manage risk) • Outbreaks and the consequences of climate change (Read more in: Business as (un)usual, How we manage risk, Climate and energy)

ASML ANNUAL REPORT 2020 22 How we create value The success of our business depends on strong, sustainable relationships with all stakeholders in the value chain to achieve the desired innovations in semiconductor technology. We use input from stakeholders and trends in our industry and society to develop our strategy, our products and services. We define our stakeholders as our shareholders, customers, suppliers, employees and the society we operate in. We use the model of the International Integrated Reporting Council (IIRC) to optimize our long-term stakeholder value and sustainable impact. Below, we have concretized: 1. The capital inputs we use for our products and services; 2. The long-term value we create for our stakeholders; 3. The broader impact we generate towards the United Nations Sustainable Development Goals. Capital inputs We use various forms of capital to manufacture our products, which we define as follows: • Financial capital: these are the funds available to ASML • Manufacturing capital: our human-created and production-oriented equipment and tools • Intellectual capital: our investment in R&D to determine our competitive advantage • Human capital: the capabilities, knowledge, skills and experience of our employees • Social capital: the high-tech ecosystem and partnerships we create • Natural capital: the natural resources we use and energy we consume We aim to use these forms of capital in the most effective way to generate long-term value for all of our stakeholders. Long-term stakeholder value Our core values - Challenge, Collaborate, Care - are a key contributor to our culture aimed at long-term value creation and as such an important enabler in the execution of our strategy. Read more in: Our core values, Our people. We define our long-term value for all our stakeholders as follows: Shareholder value Our large and sustained investments in research and development to execute our business strategy enable us to maintain our position as a leader in holistic lithography. Our innovations contribute to the long-term growth of the semiconductor industry, which benefits our solid financial performance and capital return policy. Customer value As one of the world’s leading manufacturers of chip- making equipment, we invest in innovations that enable the continued shrink of microchips. With EUV and the next generation of EUV, High-NA, we secure the continuation of Moore’s Law. This allows our customers to develop ever- more powerful chips for new applications and devices. At the same time we help our customers to reduce their costs and environmental footprint by embedding circularity principles in our products. Supplier value As we grow and our innovations enter ever-higher levels of complexity, we want our suppliers to grow with us. We innovate together with our supplier network, sharing knowledge and tapping into each other’s technology expertise. Long-term relations, close cooperation and transparency with our suppliers are key to our success. Employee value Our workforce has grown steeply in recent years. In the past five years, we have created around 12,000 jobs in the communities where we operate. For example, with 14,269 employees in Veldhoven (our headquarters) we are a major employer in the community. We are a proud employer of 120 nationalities, allowing for diverse points of view in our quest to develop the best ideas. Developing our people is crucial to the sustained success of our business, so we invest in their career development and well-being. Societal value With our continuous innovations, we enable new technology that supports the growth and transformation of the semiconductor industry, using artificial intelligence to offer new applications and services to address society’s needs. Through our innovation ecosystem we nurture innovation by giving back to society, such as sharing our expertise with universities and research institutes, supporting young tech companies, and promoting STEM education worldwide. We also develop groundbreaking technology to reinforce our innovation footprint and minimize our environmental footprint. We do this by minimizing waste, maximizing the value of material we use, and taking every step possible to lower our carbon footprint. Sustainable impact We believe the chip industry is in a unique position to tackle socioeconomic and environmental challenges. We focus on challenges and sustainability areas most relevant to our stakeholders and on which ASML can have the greatest impact in the long term. (Read more in: Materiality assessment, SWOT analysis). We focus on those United Nations Sustainable Development Goals on which ASML can make a real difference.

ASML ANNUAL REPORT 2020 23 45.6% 2020 outcome Capital resources Our strategy Financial €15.3bn Total shareholders' equity (€13.9bn) (actuals 2019) (actuals 2019) €4.7bn Long-term debt Financial €2.75 Proposed annualized dividend per share €3.7bn Net income €8.84 EPS Holistic lithography and applications Strengthen customer trust DUV competitiveness EUV industrialization High-NA Manufacturing €7.6bn Total cost of sales 8 Manufacturing sites 12,918 FTE Manufacturing €14.0bn Total net sales 258 Lithography systems sold Intellectual €2.2bn R&D expenses 4 R&D sites 10,543 FTE Employees in R&D Intellectual >14,100 Patent portfolio €785m IP & developed technology value Human 28,073 FTE Total employees €12m Training and development 120 Nationalities Human 80% Employee engagement score 22 Projects supported through ASML Foundation 1,550 hrs Startups and scaleups in-kind support 5 Employer brand ranking listing 3.8% Attrition Natural 85% Material recycling rate -30.8% CO2 scope 1 and 2 net footprint decreased 360 kg Waste generated per €m revenue Social Our purpose Unlocking the potential of people and society by pushing technology to new limits Social Promoted STEM education Natural 1,412 TJ Energy consumption Committed to circular economy Employees in operations Gross margin Sustainable impact Value created Employee value Sustainable employment in the community Supplier value Contributing to new technology and circular economy Societal value Enabling new technological advancement Customer value Continuing Moore’s Law and lower energy consumption Shareholder value Long-term organic growth €0.9m ASML Foundation €3.1m Community outreach Nurture high-tech ecosystem (€2.40) (€2.6bn) (€6.13) (€11.8bn) (229) (41.5%) (>13,700) (€843m) (77%) (3) (4.3%) (17) (1,300 hrs) (80%) (-32.5%) (1,367 TJ) (€3.1bn) (€6.9bn) (11,886 FTE) (€2.0bn) (4) (10,166 FTE) (€24,900 FTE) (€19m) (118) (€1.5m) (€3.4m) (7) (417 kg)

ASML ANNUAL REPORT 2020 24 The long-term growth of the semiconductor industry is based on the principle that the power, cost and time required for every computation on a digital electronic device can be reduced by shrinking the density of transistors on microchips. ASML invests in a technology-based innovation roadmap that enables the continued shrink of microchips by enhancing resolution with EUV and High-NA, together with the holistic scaling of overlay and pattern fidelity control. To achieve this we also invest in continuing innovations in DUV, Metrology and Inspection technology, to supplement the power of EUV-led shrink. This is how Our strategy Holistic lithography and application Strengthen our leadership position in in-device metrology, enabling high-order overlay correction. Secure a winning position in pattern delity control and combine this with superior computational lithography. DUV competitiveness Continue our innovation leadership, driving DUV to the highest level of performance by expanding our installed base and through continuous improvement and operational excellence. EUV industrialization Secure high-volume manufacturing and improve cost effectiveness for our customers by enhancing the value of EUV technology for future nodes down to the 2 nm Logic node. High-NA Enable next-generation geometric shrink by extending our 0.33 NA product portfolio to enable High-NA EUV at the 2 nm Logic node, followed by Memory nodes at comparable density. Strengthen customer trust Enhance operational excellence capabilities by focusing on our customers’ needs to improve cost of ownership and deliver future nodes. Deliver on our commitment to accelerate improvements in our sustainability performance. For the next decade, the semiconductor industry roadmap fires on three cylinders: • 3D integrated circuits enabling better performance, power, form factor and functionality • Geometric scaling to reduce cost • Domain-specific architecture driven by energy efficiency Geometric scaling (shrink) is a key industry driver supporting innovation and providing long-term industry growth. Our guiding principle is continuing Moore’s Law towards ever-smaller, cheaper, more powerful and energy- efficient semiconductors. To enable shrink, lithography is key, as the process is used to pattern the structures on a microchip. We innovate across our entire product portfolio at the same pace as our customers through large and sustained investment in research and development. To accelerate our product development, we engineer in parallel, not sequentially, all the while guarding the product’s quality, reliability, manufacturability and serviceability. This enables us to get our innovations into the hands of chipmakers faster. We collaborate with chipmakers to understand how our technology best fits their needs, including their challenges and visions of the future. It is through this collaboration and trust that we can build for today and develop for tomorrow. Five pillars of our core strategy To realize our long-term strategic vision within the semiconductor industry, we continue to drive our core strategy, which we define around five major pillars: Strengthen customer trust, holistic lithography and applications, DUV competitiveness, EUV industrialization and High-NA. we pursue our long-term strategic vision. To enable ‘edge’ – which brings computation and data storage closer to the location where it is needed – our customers continue to invest in developing more advanced semiconductor processes to create more powerful Logic and Memory microchips. At the same time, these also need to be more energy-efficient and cost-effective.

ASML ANNUAL REPORT 2020 25 Five sustainability areas At the same time, we want to ensure a sustainable impact while providing the best value for our stakeholders – today and in the future. Staying focused on what matters for our business and stakeholders is the cornerstone of our strategy. Through a materiality assessment, we identify and assess the topics most relevant to our stakeholders and which sustain ASML's long-term business growth. (Read more in: Materiality - assessing our impact) We are committed to sustainability. To accelerate our sustainability performance, we focus on five strategic areas of sustainability, to create long-term value for our stakeholders, shape a sustainable future, and contribute to the United Nations Sustainable Development Goals. People Empowering individuals for the collective good to ensure our employees are proud to work for us and engaged with our ambitions as a company. Responsible supply chain Setting the bar higher for our world-class supplier network to achieve the innovations we strive for, by ensuring we conduct our business in a sustainable and responsible manner. Climate & energy Taking every step to lower our footprint to achieve zero emissions across our operations. While increasing productivity of our products, we are also working towards enhancing the energy ef ciency of our products. We don't innovate in isolation to ensure the fast pace of innovation in our value chain. We develop technology together with the help of our partners and collaborative knowledge network. Innovation ecosystem Circular economy Minimizing waste, maximizing resources to extract the maximum value from the materials we use and repurpose our products across their life cycles.

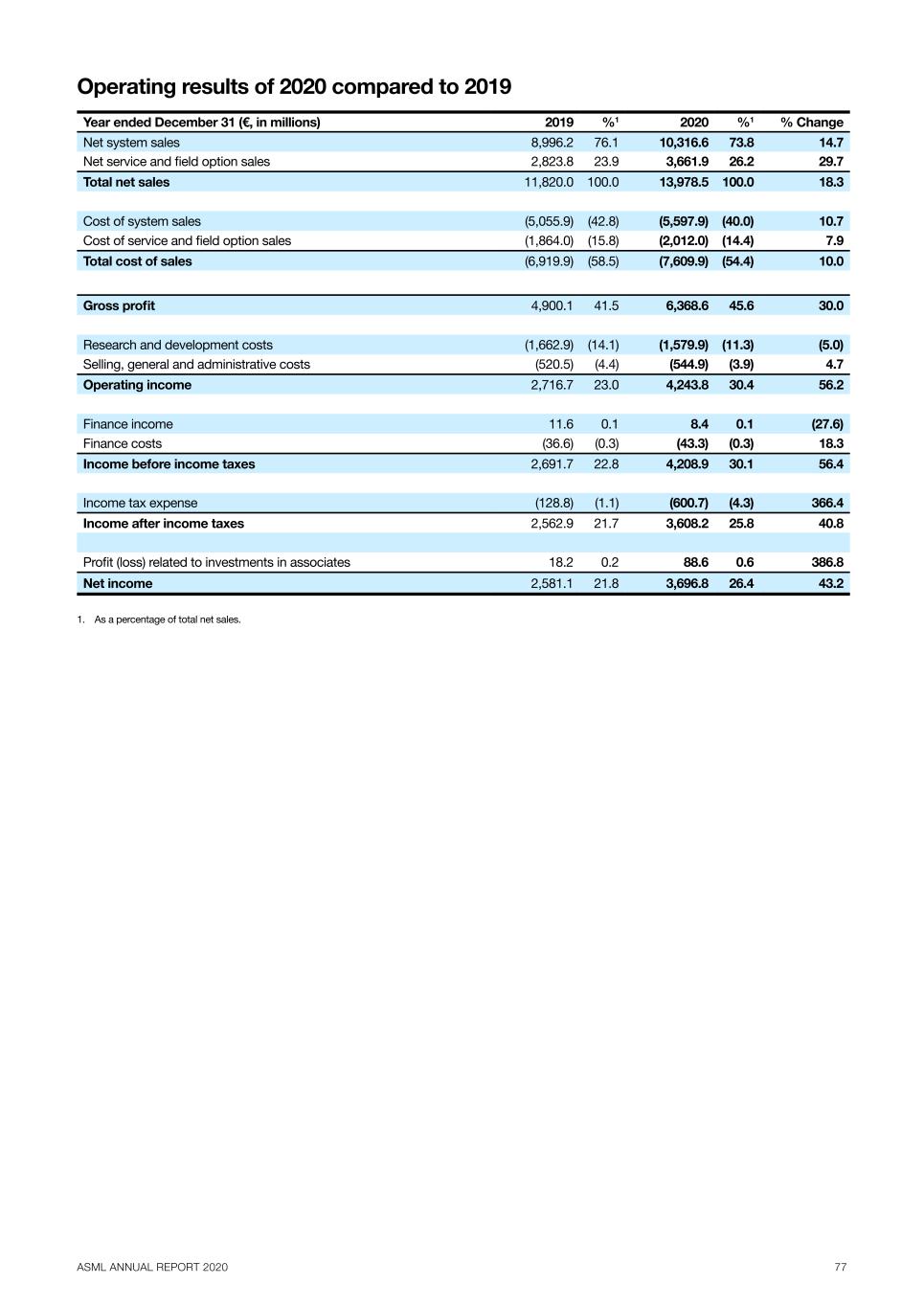

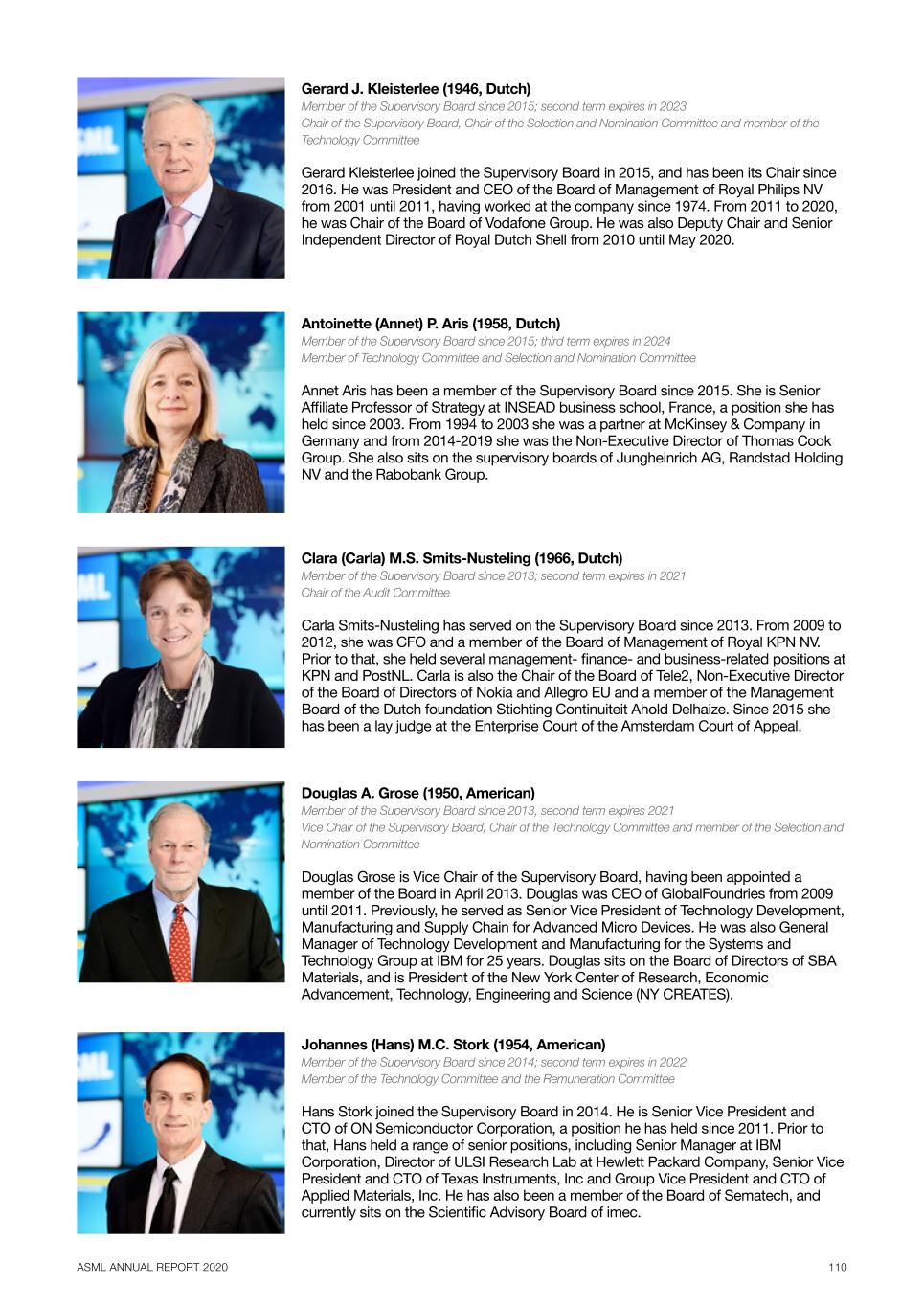

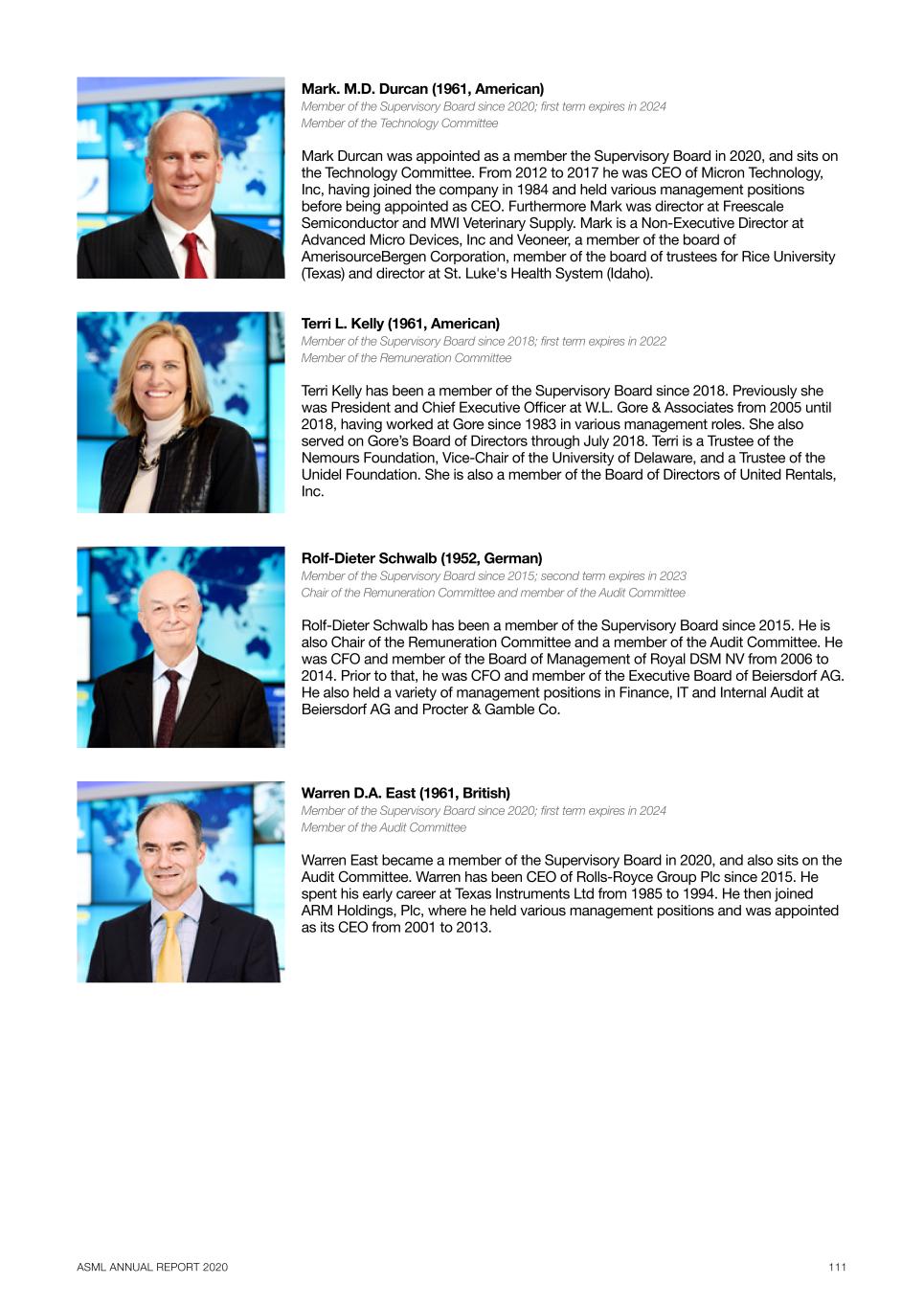

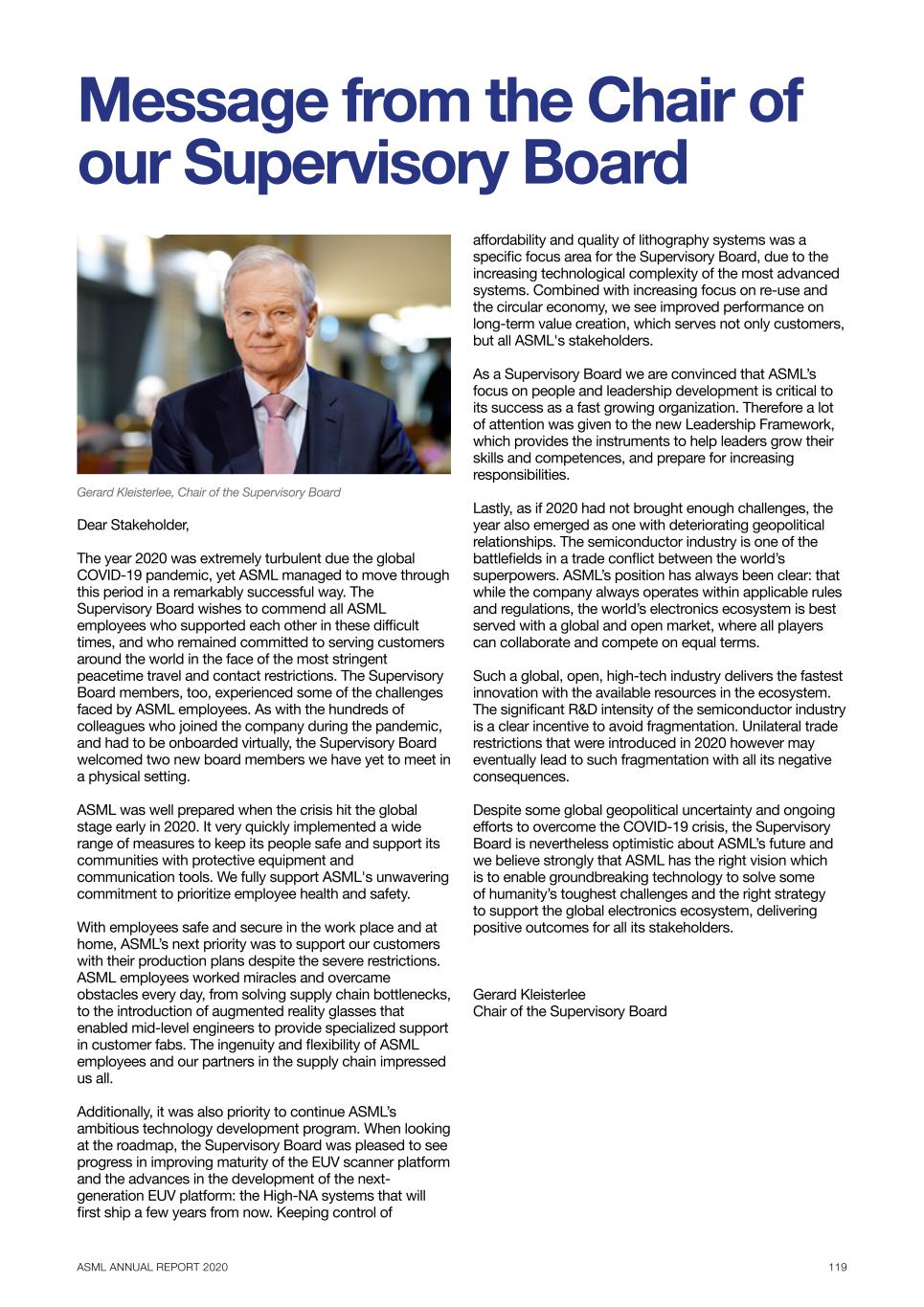

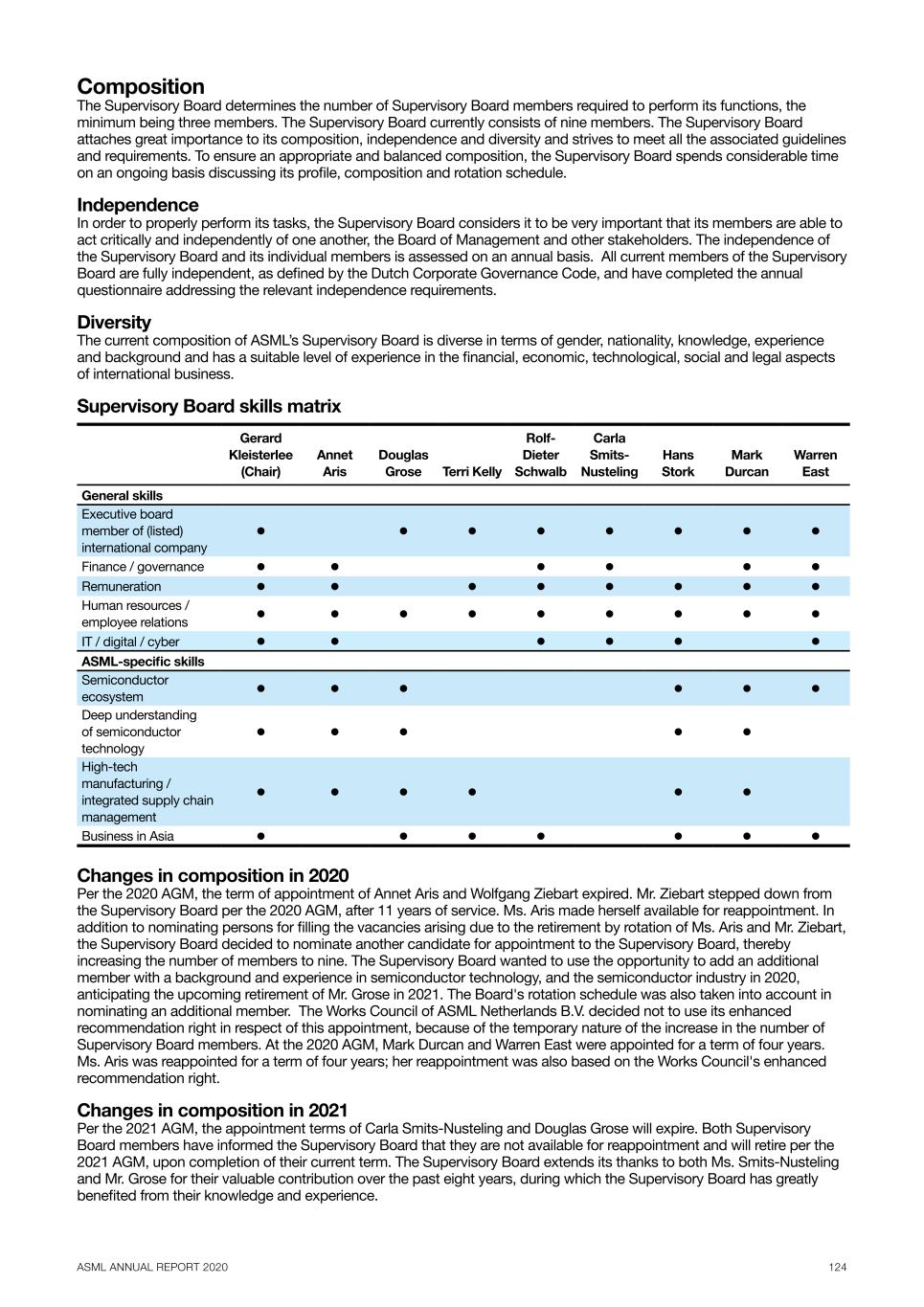

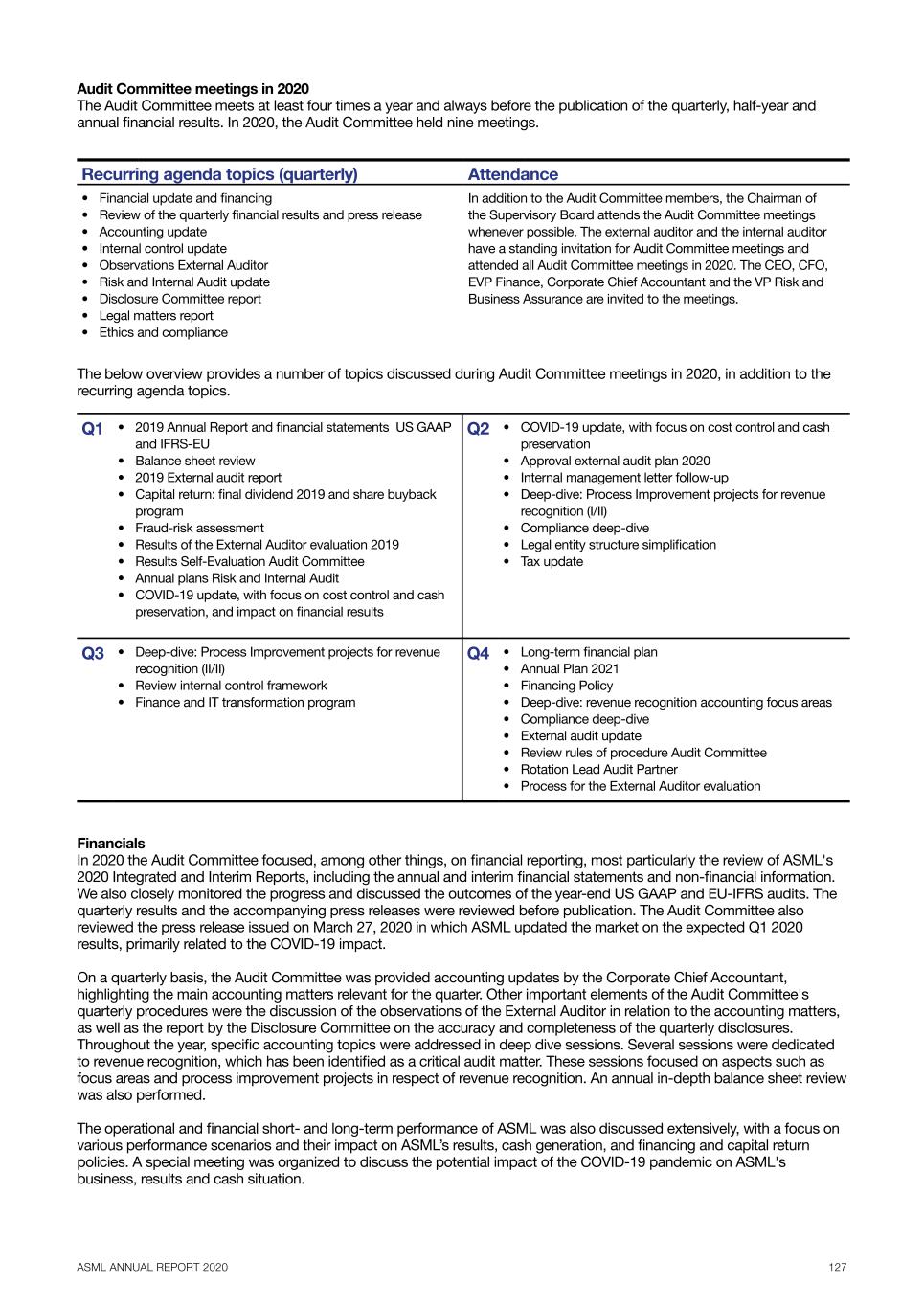

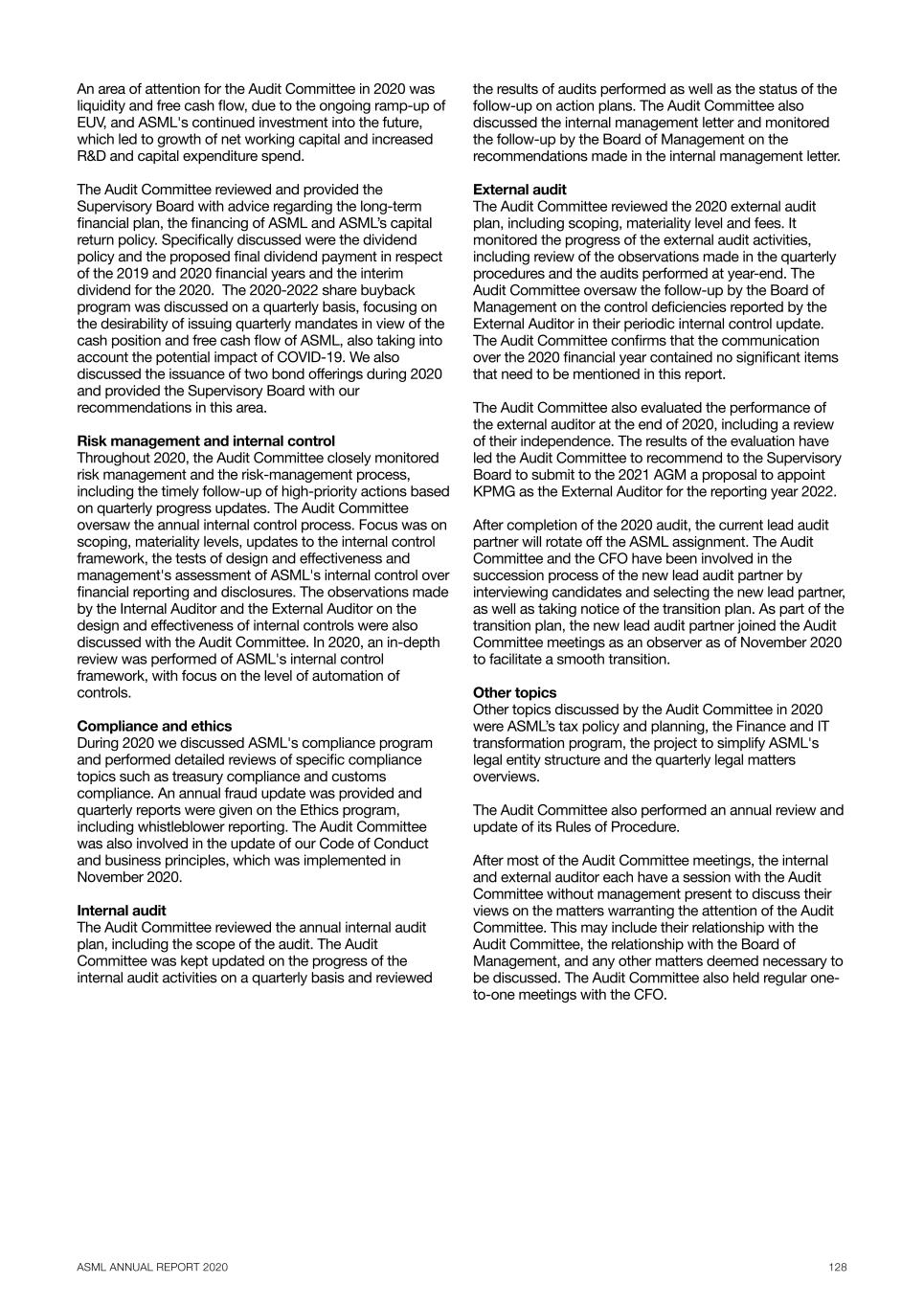

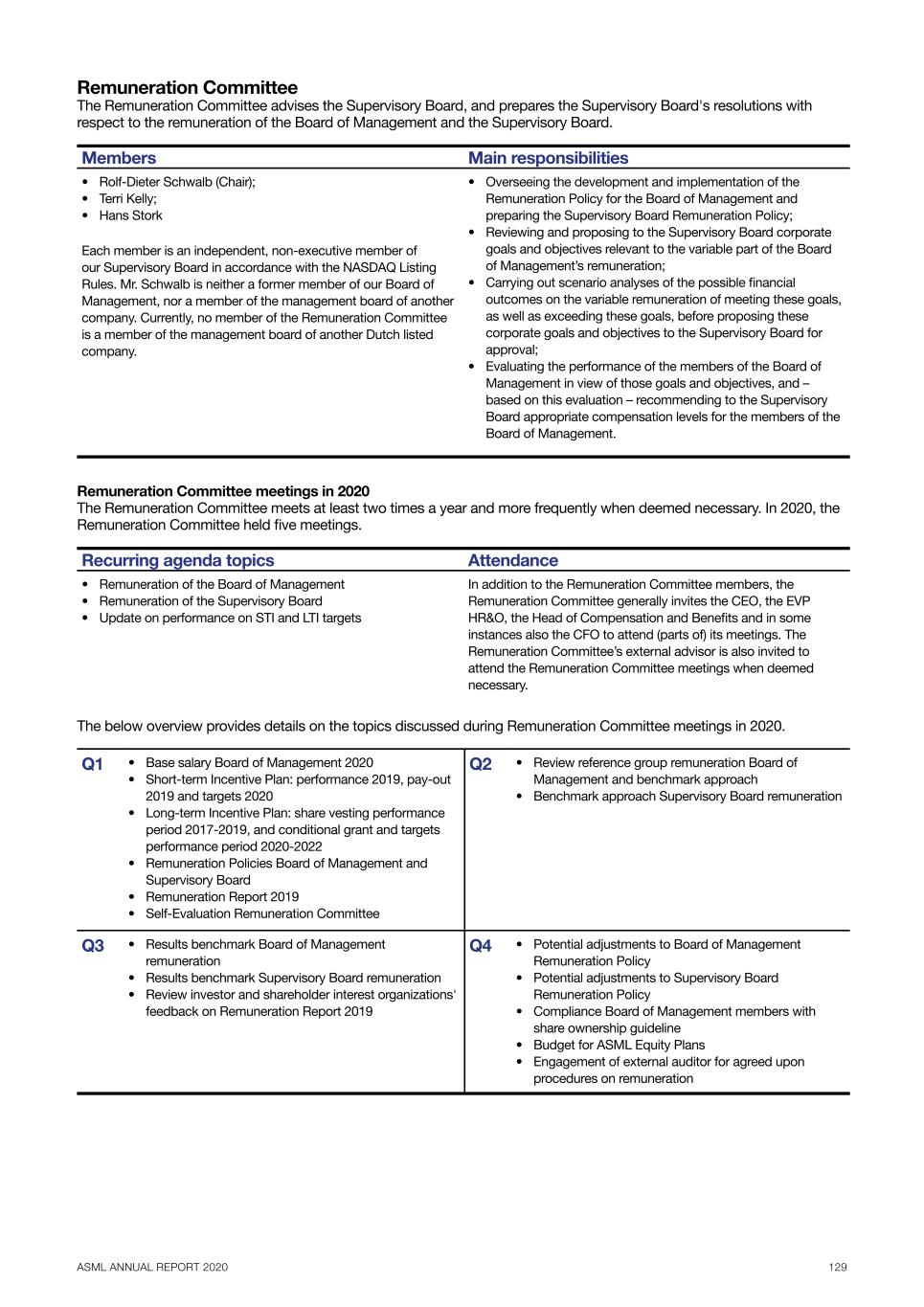

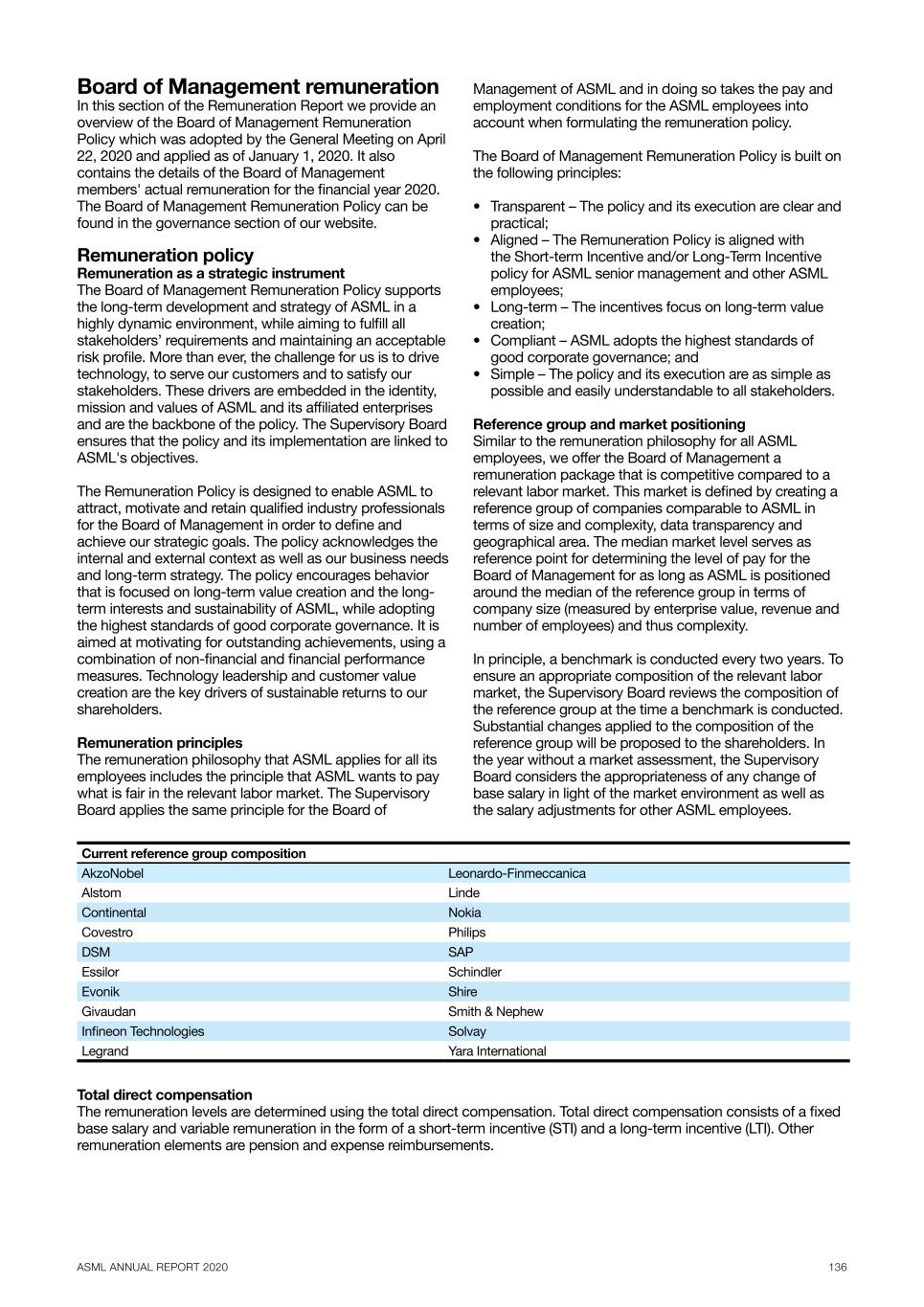

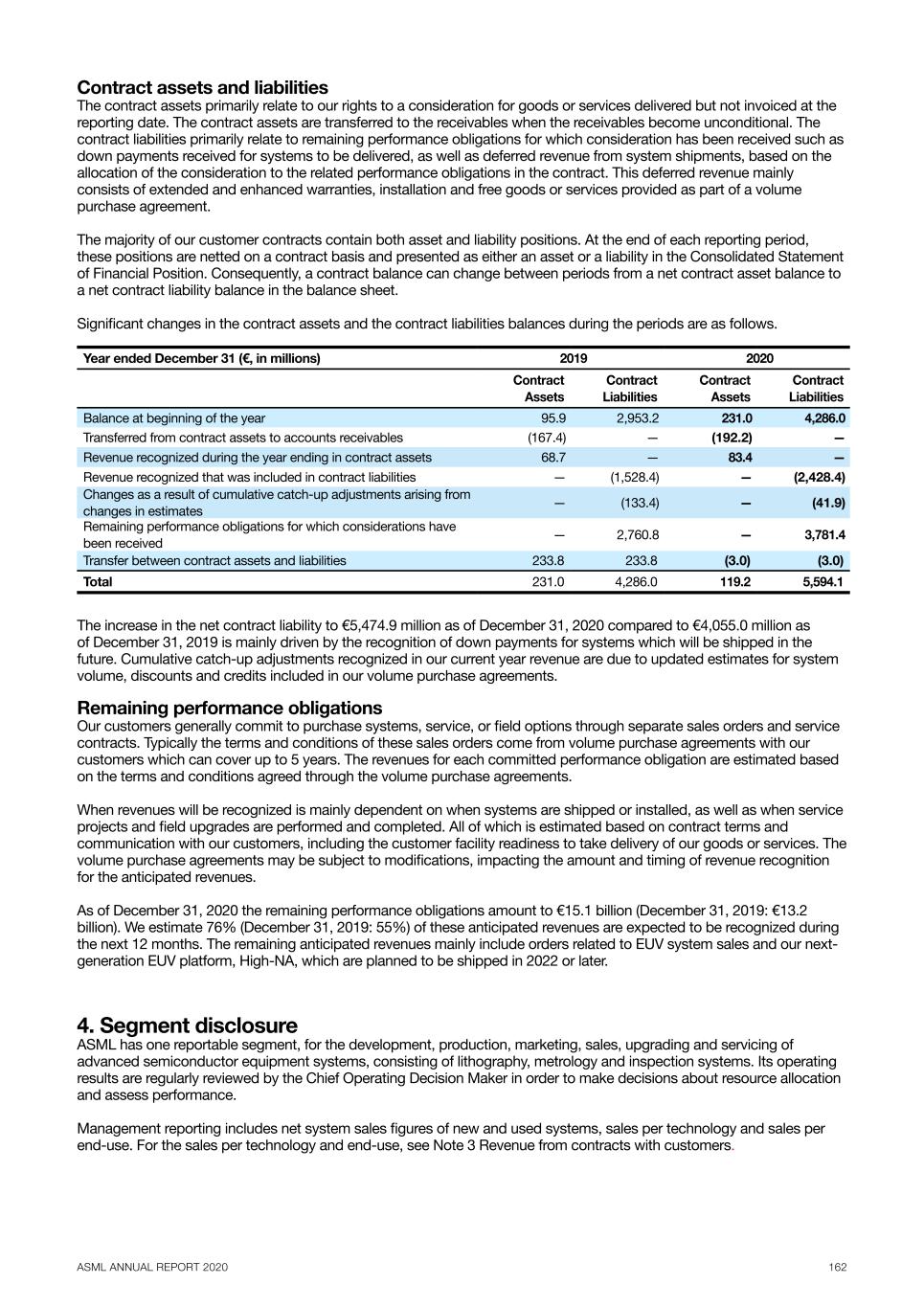

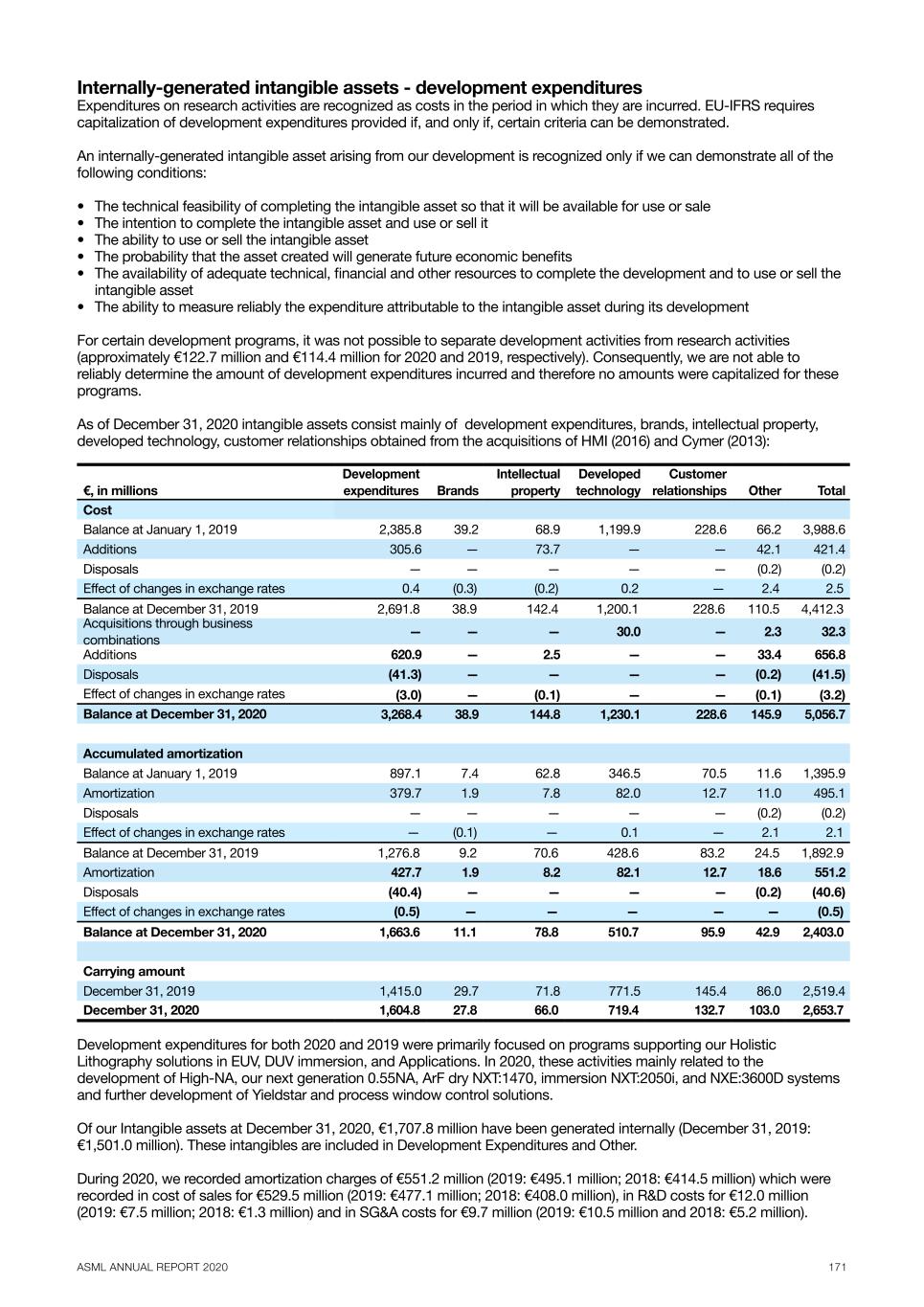

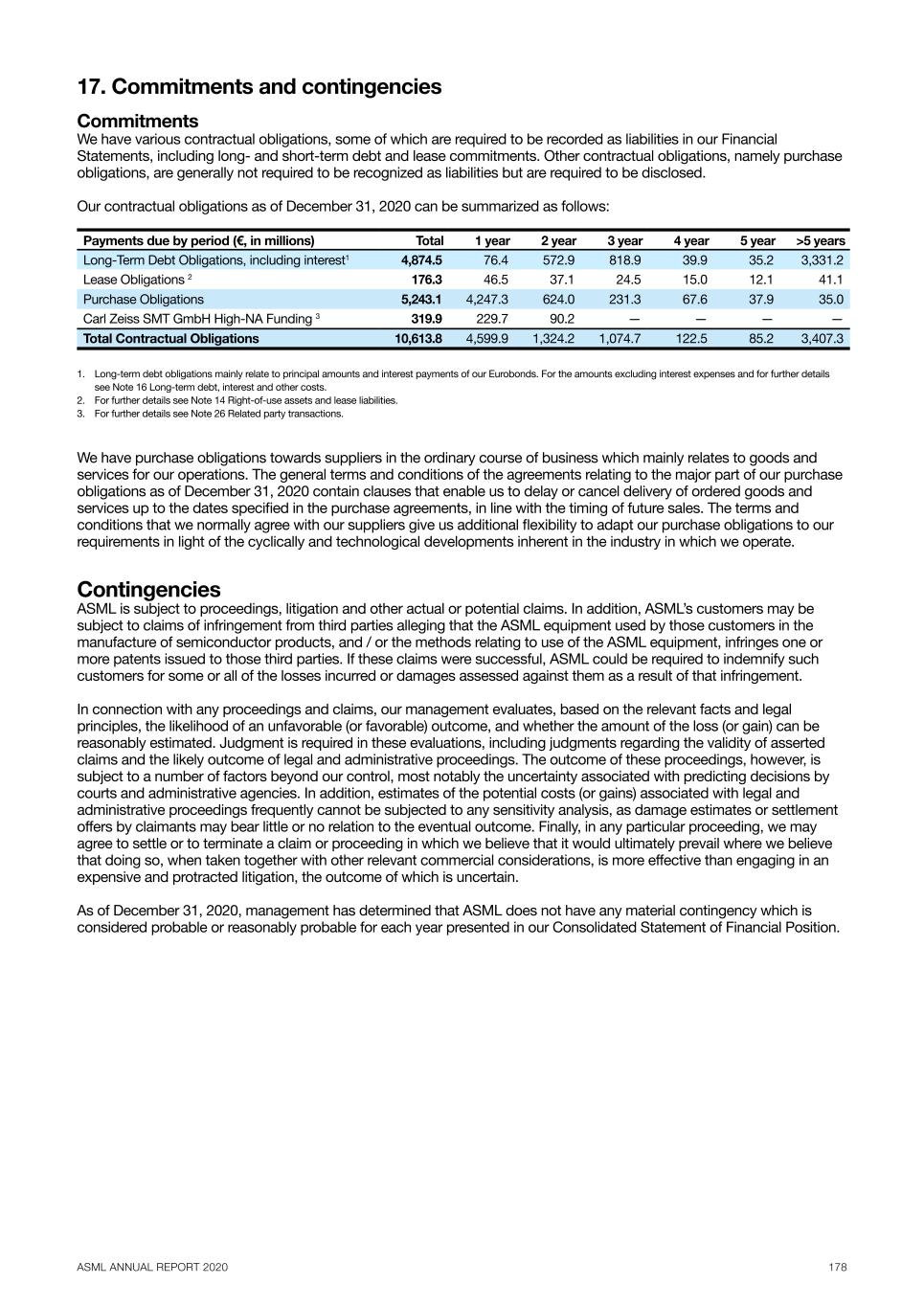

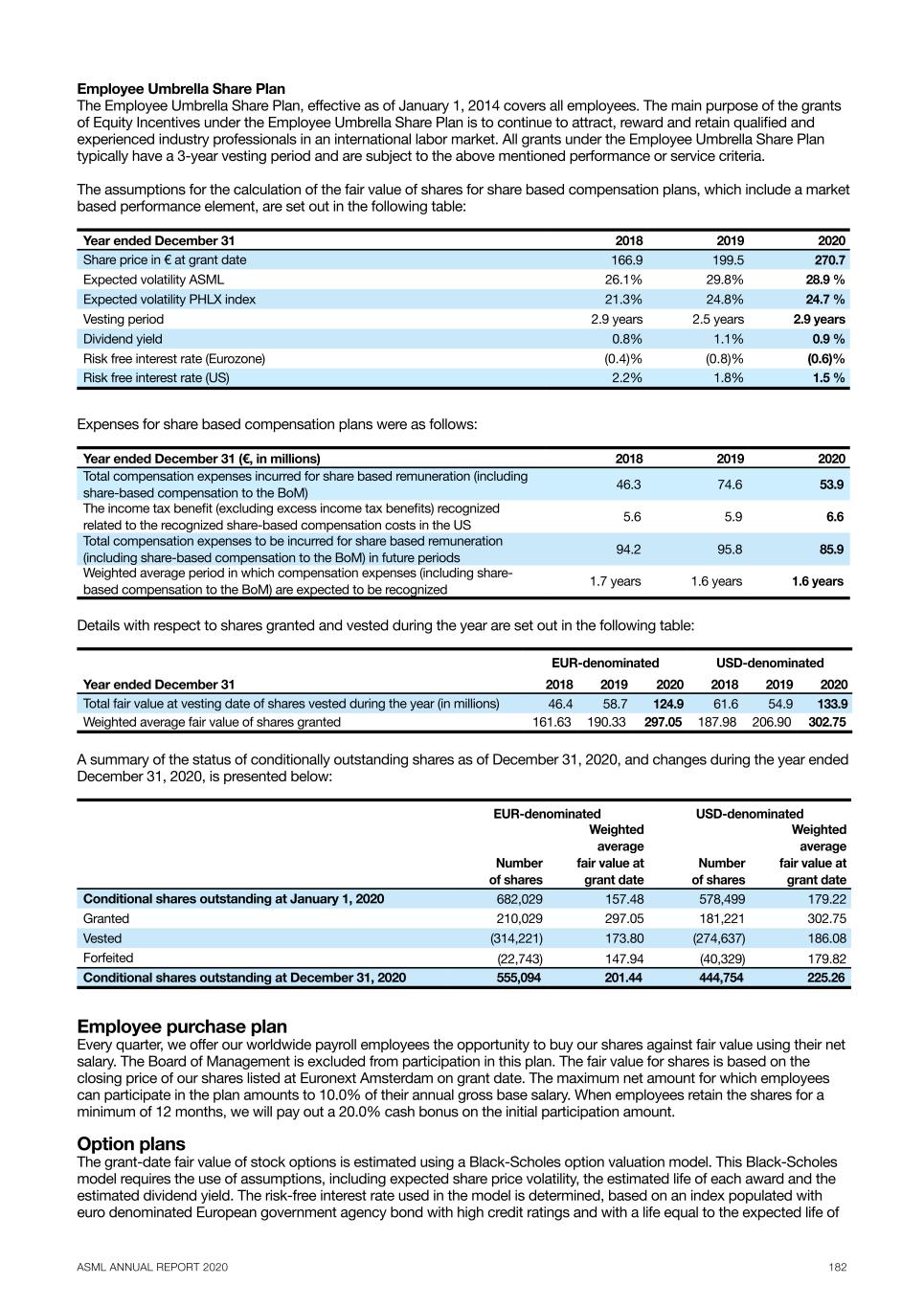

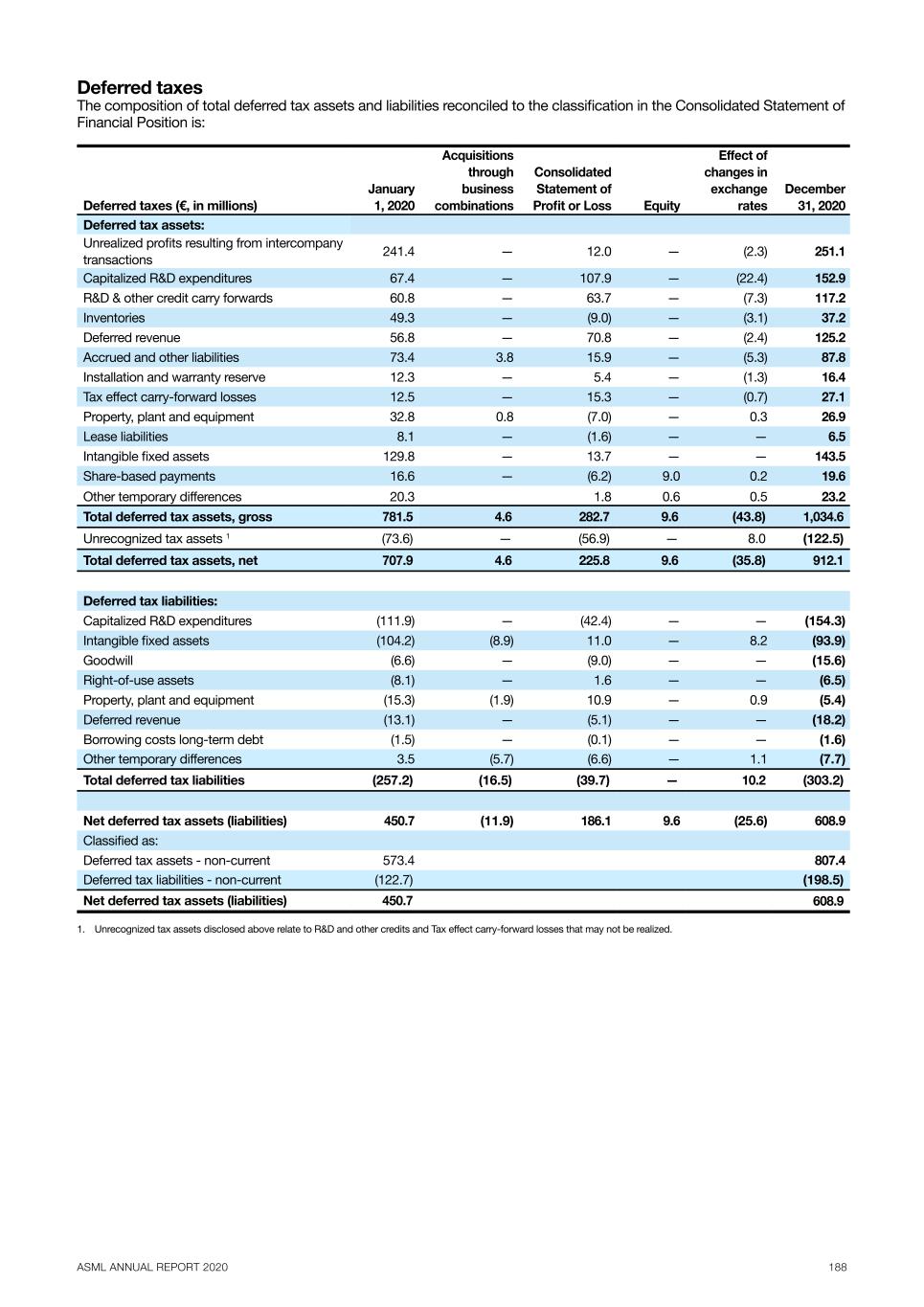

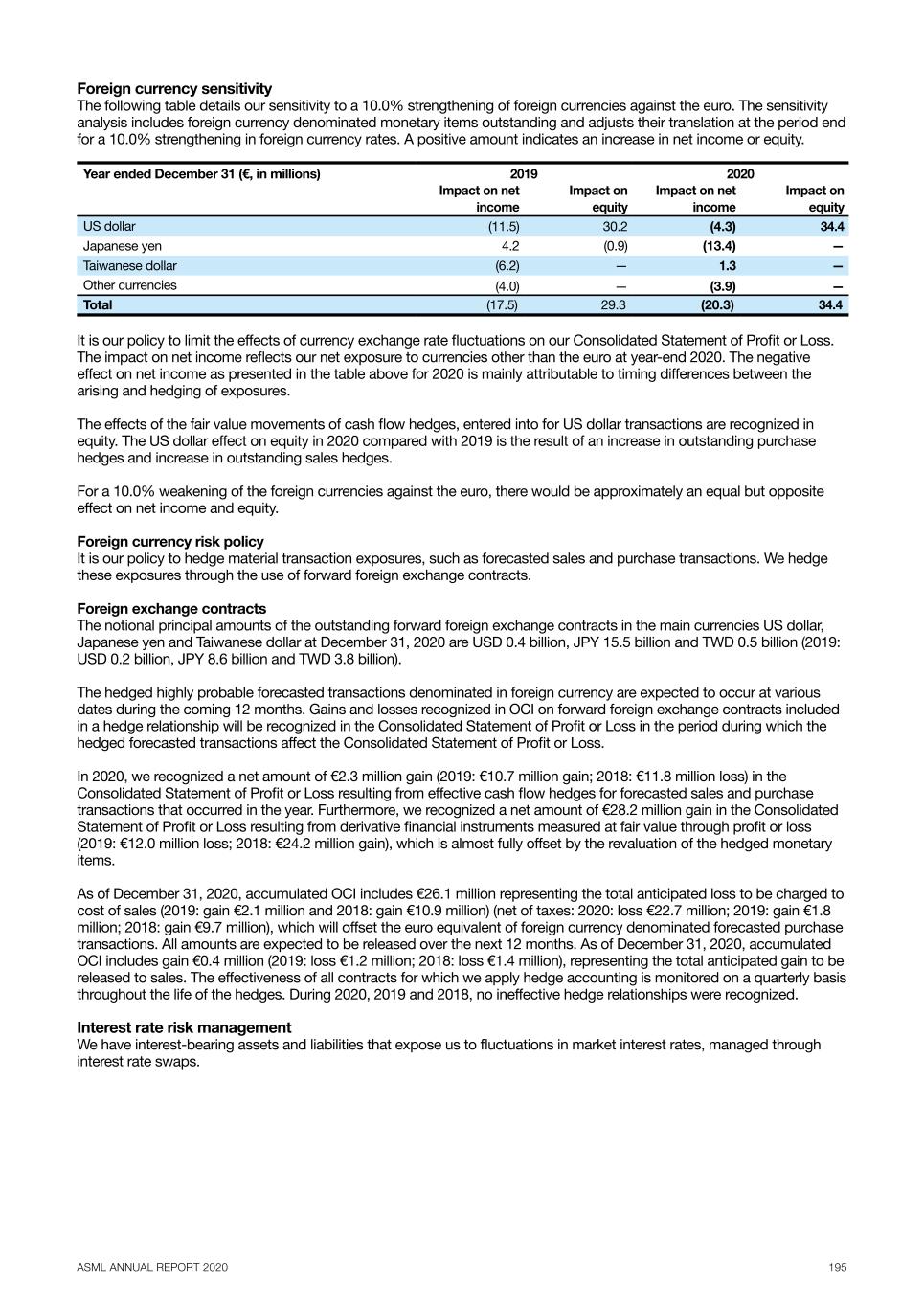

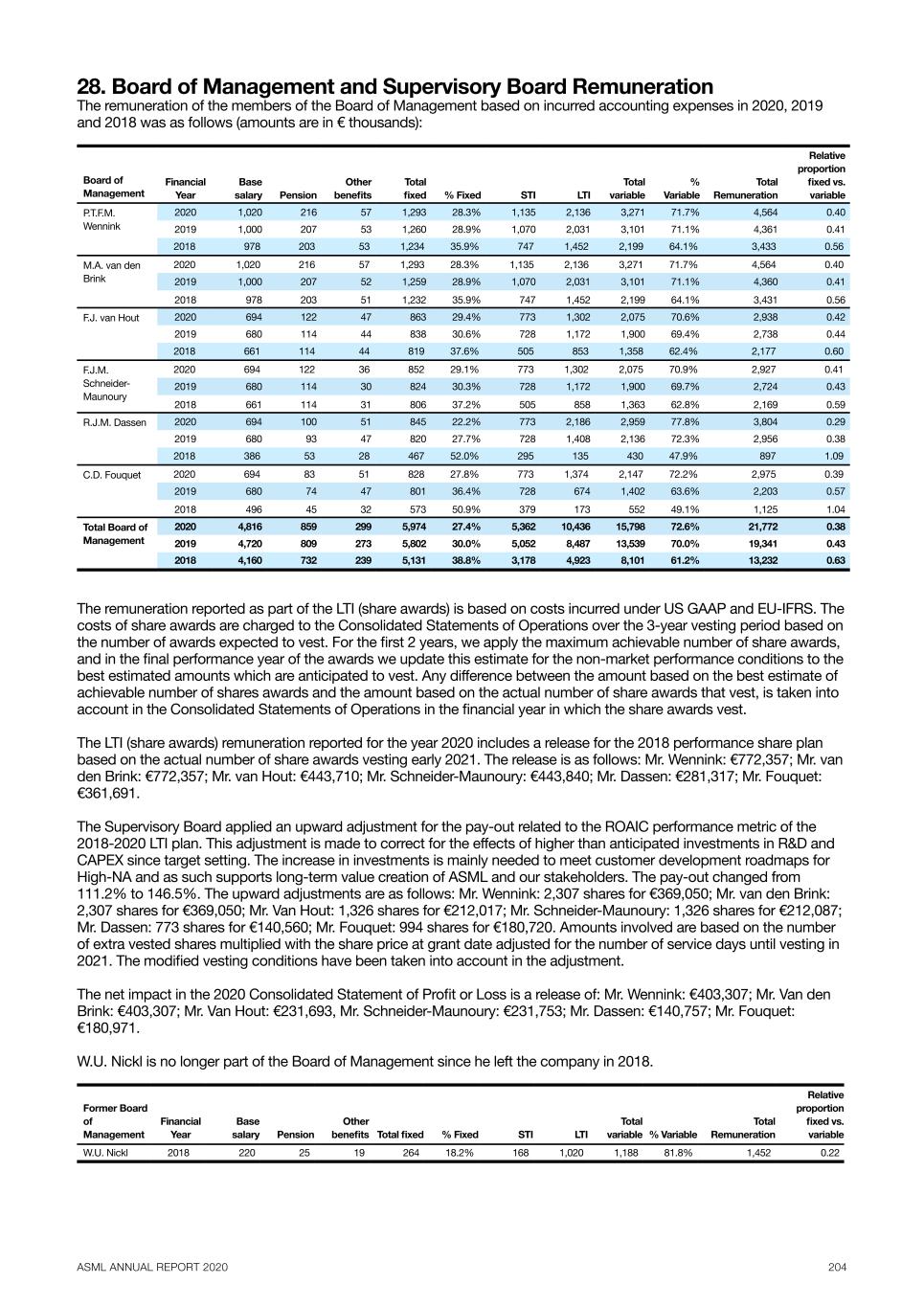

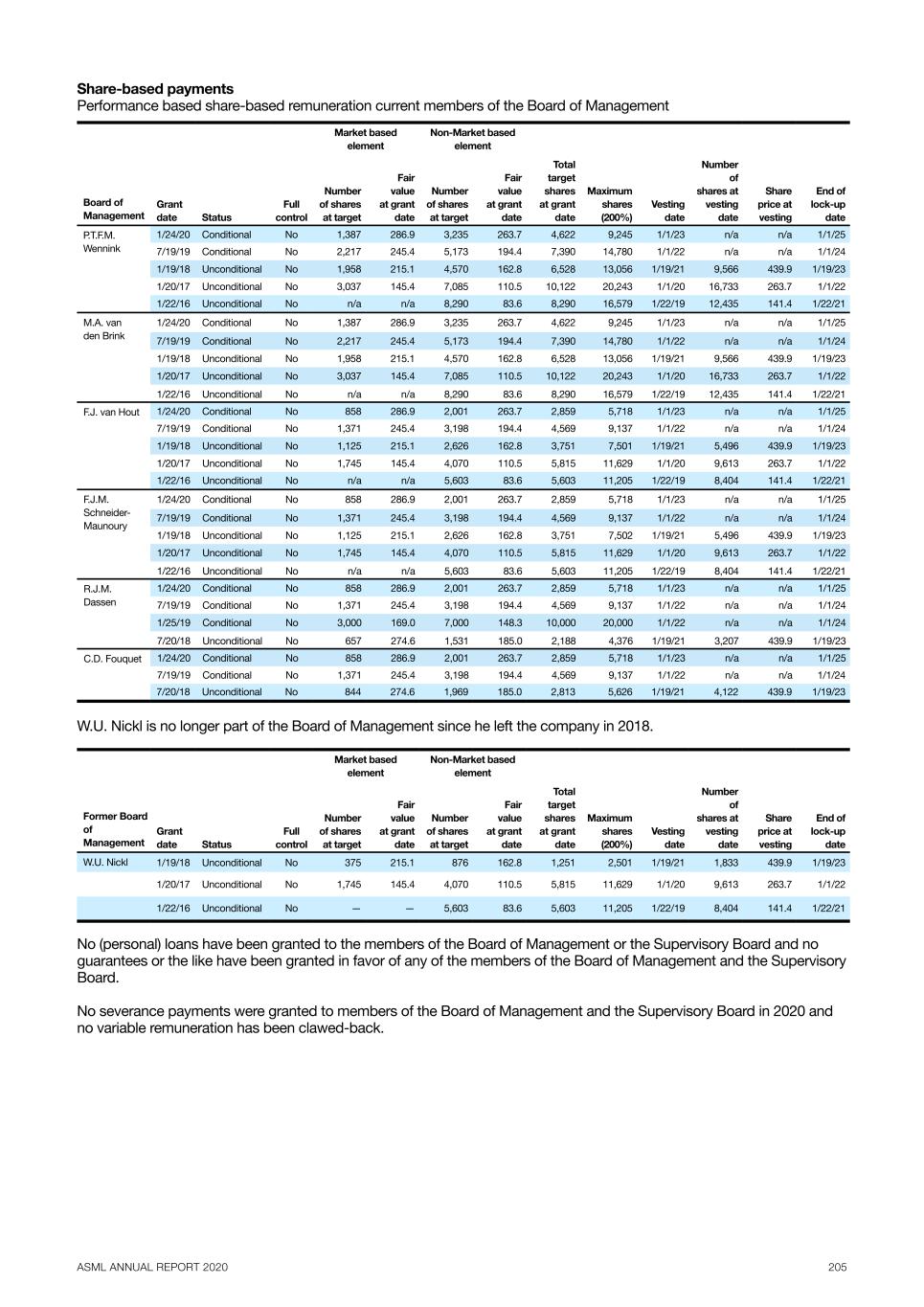

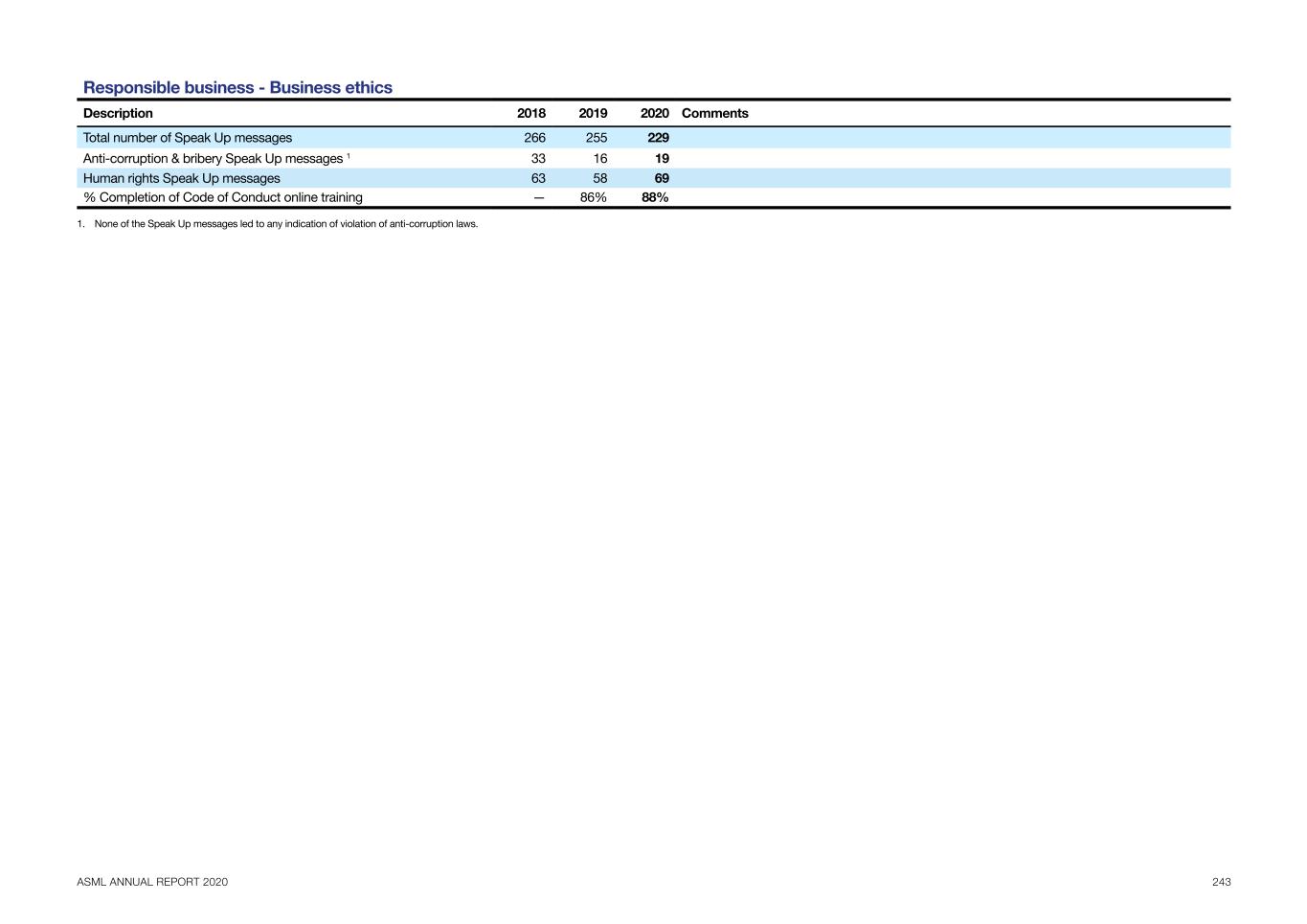

ASML ANNUAL REPORT 2020 26 What we achieved in 2020