Form 6-K PLATINUM GROUP METALS For: Nov 25

�

�

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

�

FORM�6-K

�

Report of Foreign Private Issuer

Pursuant to Rule�13a-16 or 15d-16

of the Securities Exchange Act of 1934

�

Commission File Number: 001-33562

�

For the month of: November, 2014

�

PLATINUM GROUP METALS LTD.

�

Suite�788 � 550 Burrard Street, Vancouver BC, V6C 2B5, CANADA

Address of Principal Executive Office

�

Indicate by check mark whether the registrant files or will file annual reports under cover:

�

Form�20-F o �Form�40-F x

�

Indicate by check mark if the registrant is submitting the Form�6-K in paper as permitted by Regulation S-T Rule�101(b)(1): o

�

Indicate by check mark if the registrant is submitting the Form�6-K in paper as permitted by Regulation S-T Rule�101(b)(7): o

�

�

�

�

SIGNATURE

�

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

�

|

Date: |

November�25, 2014 |

� |

�R. Michael Jones� |

|

� |

R. MICHAEL JONES | ||

|

� |

DIRECTOR�& CEO | ||

�

�

EXHIBIT�INDEX

�

|

Exhibit |

� |

Description |

|

� |

� |

� |

|

99.1 |

� |

Technical Report for the Update on Exploration Drilling at the Waterberg Joint Venture and Waterberg Extension Projects, South Africa (Latitude 23� 14� 11�S, Longitude 28� 54� 42�E) with an exploration drilling update effective date of October�21, 2014 and a mineral resource estimate effective date of June�12, 2014* |

|

99.2 |

� |

Consent of Qualified Person dated November�24, 2014 |

|

99.3 |

� |

Consent of Qualified Person dated November�24, 2014 |

�

* Incorporated by reference into the Company�s preliminary offering circular dated November�3, 2014.

�

Exhibit�99.1

�

�

Platinum Group Metals Ltd

�

Technical Report for the Update on Exploration

Drilling at the Waterberg Joint Venture and

Waterberg Extension Projects, South Africa

(Latitude 23� 14� 11�S, Longitude 28� 54� 42�E)

�

Report Date:������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 24 November�2014

Exploration Drilling Update Effective Date:����������������������������� 21 October�2014

Mineral Resource Estimate Effective Date:������������������������������� 12 June�2014

�

Qualified Person:�������������������������������������������������� Kenneth Lomberg (Pr.Sci.Nat.)

����������������������������������������������������������������������������������������������������������������������������������������������� Alan Goldschmidt (Pr.Sci.Nat.)

�

�

�

Coffey Mining South Africa (Pty) Ltd

�

|

Author(s): |

� |

� |

|

� |

� |

� |

|

Kenneth Lomberg |

Senior Principal |

B.Sc. (Hons) Geology, B.Com. M.Eng. Pr.Sci.Nat., FGSSA |

|

� |

� |

� |

|

Alan Goldschmidt |

Senior Consultant |

B.Sc.(Hons) Geology, GDE, Pr.Sci.Nat., MGSSA |

|

� |

� |

� |

|

Date: |

24 November�2014 |

� |

|

� |

� |

� |

|

Project Number: |

JWAT05 |

� |

�

Document Review and Sign Off

�

|

|

� |

|

|

Alan Goldschmidt |

� |

Kenneth Lomberg |

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

Date and Signature Page

�

This report titled �Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and Waterberg Extension Projects, South Africa� with an effective date of 21 October 2014 was prepared on behalf of Platinum Group Metals (Pty) Ltd by Kenneth Lomberg and Alan Goldschmidt and signed:

�

Dated at Roodepoort, South Africa, this 24 November�2014

�

|

|

� |

|

Kenneth Lomberg, B.Sc.(Hons) Geology, B.Com., M.Eng., Pr.Sci.Nat., FGSSA. |

� |

|

� |

� |

|

|

� |

|

Alan Goldschmidt, B.Sc.(Hone) Geology, Pr.Sci.Nat., MGSSA |

� |

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

Table of Contents

�

|

1 |

Summary |

1 | ||

|

� |

� |

� |

� | |

|

� |

1.1 |

Introduction |

1 | |

|

� |

� |

� |

� | |

|

� |

1.2 |

Project Area and Location |

1 | |

|

� |

� |

� |

� | |

|

� |

1.3 |

Geological Setting, Deposit Type and Mineralization |

2 | |

|

� |

� |

� |

� | |

|

� |

1.4 |

Local Geology |

3 | |

|

� |

� |

� |

� | |

|

� |

1.5 |

Exploration Status |

4 | |

|

� |

� |

� |

� | |

|

� |

� |

1.5.1 |

Drilling |

7 |

|

� |

� |

� |

� |

� |

|

� |

� |

1.5.2 |

Sample Preparation |

8 |

|

� |

� |

� |

� |

� |

|

� |

� |

1.5.3 |

Analysis |

8 |

|

� |

� |

� |

� |

� |

|

� |

� |

1.5.4 |

Quality Control and Quality Assurance |

9 |

|

� |

� |

� |

� | |

|

� |

1.6 |

Mineral Resources |

9 | |

|

� |

� |

� |

� | |

|

� |

1.7 |

Interpretation and Conclusions |

12 | |

|

� |

� |

� |

� | |

|

2 |

Introduction |

15 | ||

|

� |

� |

� |

� | |

|

� |

2.1 |

Scope of the Report |

15 | |

|

� |

� |

� |

� | |

|

� |

2.2 |

Principal Sources of Information |

15 | |

|

� |

� |

� |

� | |

|

� |

2.3 |

Qualifications and Experience |

15 | |

|

� |

� |

� |

� | |

|

� |

2.4 |

Independence |

16 | |

|

� |

� |

� |

� | |

|

3 |

Reliance on Other Experts |

17 | ||

|

� |

� |

� | ||

|

4 |

Property Description and Location |

18 | ||

|

� |

� |

� |

� | |

|

� |

4.1 |

Property Description and Location |

18 | |

|

� |

� |

� |

� | |

|

� |

4.2 |

Mining Tenure |

20 | |

|

� |

� |

� |

� | |

|

� |

4.3 |

Licence Status |

21 | |

|

� |

� |

� |

� | |

|

� |

4.4 |

Holdings Structure |

25 | |

|

� |

� |

� |

� | |

|

� |

4.5 |

Royalties and Agreements |

26 | |

|

� |

� |

� |

� | |

|

� |

4.6 |

Environmental Liabilities |

26 | |

|

� |

� |

� |

� | |

|

� |

4.7 |

Legal Access |

26 | |

|

� |

� |

� |

� | |

|

5 |

Accessibility, Climate, Local Resources,�Infrastructure and Physiography |

27 | ||

|

� |

� |

� |

� | |

|

� |

5.1 |

Access |

27 | |

|

� |

� |

� |

� | |

|

� |

5.2 |

Climate |

27 | |

|

� |

� |

� |

� | |

|

� |

5.3 |

Physiography |

27 | |

|

� |

� |

� |

� | |

|

� |

5.4 |

Local Resources and Infrastructure |

28 | |

|

� |

� |

� |

� | |

|

6 |

History |

29 | ||

|

� |

� |

� |

� | |

|

� |

6.1 |

Ownership History |

29 | |

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

|

� |

6.2 |

Exploration History |

29 | |

|

� |

� |

� |

� | |

|

� |

6.3 |

Mineral Resource History � Waterberg JV Project |

30 | |

|

� |

� |

� |

� | |

|

� |

� |

6.3.1 |

September�2012 |

30 |

|

� |

� |

� |

� |

� |

|

� |

� |

6.3.2 |

February�2013 |

31 |

|

� |

� |

� |

� |

� |

|

� |

� |

6.3.3 |

September�2013 |

32 |

|

� |

� |

� |

� | |

|

� |

6.4 |

Production History |

33 | |

|

� |

� |

� |

� | |

|

7 |

Geological Setting and Mineralization |

34 | ||

|

� |

� |

� |

� | |

|

� |

7.1 |

Regional and Local Setting |

34 | |

|

� |

� |

� |

� | |

|

� |

� |

7.1.1 |

Bushveld Complex Stratigraphy |

35 |

|

� |

� |

� |

� |

� |

|

� |

� |

7.1.2 |

The Northern Limb |

37 |

|

� |

� |

� |

� |

� |

|

� |

� |

7.1.3 |

The Platreef and its Mineralization |

40 |

|

� |

� |

� |

� | |

|

� |

7.2 |

Waterberg Group /Bushveld Complex Age Relationship |

41 | |

|

� |

� |

� |

� | |

|

� |

7.3 |

Project Geology |

42 | |

|

� |

� |

� |

� | |

|

� |

� |

7.3.1 |

Stratigraphy |

48 |

|

� |

� |

� |

� |

� |

|

� |

� |

7.3.2 |

Structure |

50 |

|

� |

� |

� |

� | |

|

� |

7.4 |

Mineralized Zones |

50 | |

|

� |

� |

� |

� | |

|

8 |

Deposit Types |

54 | ||

|

� |

� |

� | ||

|

9 |

Exploration |

55 | ||

|

� |

� |

� |

� | |

|

� |

9.1 |

Current Exploration |

55 | |

|

� |

� |

� |

� | |

|

� |

� |

9.1.1 |

Surface Mapping |

55 |

|

� |

� |

� |

� |

� |

|

� |

� |

9.1.2 |

Geochemical Soil Sampling |

56 |

|

� |

� |

� |

� | |

|

� |

9.2 |

Geophysical Surveys |

56 | |

|

� |

� |

� |

� | |

|

� |

� |

9.2.1 |

Waterberg JV Project � Initial survey |

56 |

|

� |

� |

� |

� |

� |

|

� |

� |

9.2.2 |

Extended Airborne Gravity Gradient and Magnetics |

57 |

|

� |

� |

� |

� |

� |

|

� |

� |

9.2.3 |

Ground Gravity |

62 |

|

� |

� |

� |

� | |

|

� |

9.3 |

Coffey: Technical Review |

62 | |

|

� |

� |

� |

� | |

|

10 |

Drilling |

63 | ||

|

� |

� |

� |

� | |

|

� |

10.1 |

Drilling in 2010 |

63 | |

|

� |

� |

� |

� | |

|

� |

10.2 |

Drilling in 2011 to 2013 |

63 | |

|

� |

� |

� |

� | |

|

� |

10.3 |

Exploration Drilling Status 21 October�2014 |

63 | |

|

� |

� |

� |

� | |

|

� |

10.4 |

Drilling Quality |

67 | |

|

� |

� |

� |

� | |

|

� |

10.5 |

Diamond Core Sampling |

67 | |

|

� |

� |

� |

� | |

|

� |

10.6 |

Sample Recovery |

67 | |

|

� |

� |

� |

� | |

|

� |

10.7 |

Sample Quality |

67 | |

|

� |

� |

� |

� | |

|

� |

10.8 |

Interpretation of Results |

67 | |

|

� |

� |

� |

� | |

|

� |

10.9 |

Coffey: Technical Review |

72 | |

|

� |

� |

� |

� | |

|

11 |

Sample Preparation, Analyses and Security |

73 | ||

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

|

� |

11.1 |

Core Handling |

73 | |

|

� |

� |

� |

� | |

|

� |

11.2 |

Core Logging and Identification of Mineralized Layers |

73 | |

|

� |

� |

� |

� | |

|

� |

11.3 |

Sampling Methodology |

74 | |

|

� |

� |

� |

� | |

|

� |

11.4 |

Sample Quality and Sample Bias |

76 | |

|

� |

� |

� |

� | |

|

� |

11.5 |

Supervision of Sample Preparation |

76 | |

|

� |

� |

� |

� | |

|

� |

11.6 |

Sample Preparation |

77 | |

|

� |

� |

� |

� | |

|

� |

11.7 |

Sample Security |

77 | |

|

� |

� |

� |

� | |

|

� |

11.8 |

Chain of Custody |

78 | |

|

� |

� |

� |

� | |

|

� |

11.9 |

Analytical Procedure |

78 | |

|

� |

� |

� |

� | |

|

� |

11.10 |

Sample Preparation |

78 | |

|

� |

� |

� |

� | |

|

� |

11.11 |

Precious Metal Determination |

78 | |

|

� |

� |

� |

� | |

|

� |

11.12 |

Base metals Determination |

79 | |

|

� |

� |

� |

� | |

|

� |

11.13 |

Laboratory QA/QC |

79 | |

|

� |

� |

� |

� | |

|

� |

11.14 |

Quality Assurance and Quality Control (QA/QC) Procedures and Results |

79 | |

|

� |

� |

� |

� | |

|

� |

11.15 |

Analytical Quality Assurance and Quality Control Data |

80 | |

|

� |

� |

� |

� | |

|

� |

11.16 |

Waterberg JV Project Area |

83 | |

|

� |

� |

� |

� | |

|

� |

11.17 |

Waterberg Extension Project Area |

86 | |

|

� |

� |

� |

� | |

|

� |

11.18 |

Recommendations and Conclusion |

88 | |

|

� |

� |

� |

� | |

|

� |

11.19 |

Adequacy of Procedures |

89 | |

|

� |

� |

� |

� | |

|

� |

11.20 |

Coffey: Technical Review |

89 | |

|

� |

� |

� |

� | |

|

12 |

Data Verification |

90 | ||

|

� |

� |

� |

� | |

|

� |

12.1 |

Accurate Placement and Survey of Borehole Collars |

90 | |

|

� |

� |

� |

� | |

|

� |

12.2 |

Downhole Surveys |

91 | |

|

� |

� |

� |

� | |

|

13 |

Mineral Processing and Metallurgical Testing |

92 | ||

|

� |

� |

� | ||

|

14 |

Mineral Resource Estimates |

94 | ||

|

� |

� |

� |

� | |

|

� |

14.1 |

Methodology |

95 | |

|

� |

� |

� |

� | |

|

� |

� |

14.1.1 |

T - Zone Estimation |

95 |

|

� |

� |

� |

� |

� |

|

� |

� |

14.1.2 |

F - Zone Estimation |

96 |

|

� |

� |

� |

� | |

|

� |

14.2 |

Density |

101 | |

|

� |

� |

� |

� | |

|

� |

14.3 |

Compositing |

101 | |

|

� |

� |

� |

� | |

|

� |

14.4 |

Descriptive Statistics: Composites |

101 | |

|

� |

� |

� |

� | |

|

� |

14.5 |

Rhodium Analysis |

102 | |

|

� |

� |

� |

� | |

|

� |

14.6 |

Outlier Analysis |

104 | |

|

� |

� |

� |

� | |

|

� |

14.7 |

Block Model Development |

104 | |

|

� |

� |

� |

� | |

|

� |

� |

14.7.1 |

T - Zone |

104 |

|

� |

� |

� |

� |

� |

|

� |

� |

14.7.2 |

F � Zone Units |

104 |

|

� |

� |

� |

� | |

|

� |

14.8 |

Mineral Resource Estimate |

105 | |

|

� |

� |

� |

� | |

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

|

� |

� |

14.8.1 |

T � Zone |

105 |

|

� |

� |

� |

� |

� |

|

� |

� |

14.8.2 |

F � Zone |

106 |

|

� |

� |

� |

� | |

|

� |

14.9 |

Search Criteria |

107 | |

|

� |

� |

� |

� | |

|

� |

14.10 |

Cut-off Grades |

107 | |

|

� |

� |

� |

� | |

|

� |

14.11 |

Geological Loss |

108 | |

|

� |

� |

� |

� | |

|

� |

14.12 |

Classification |

110 | |

|

� |

� |

� |

� | |

|

� |

14.13 |

Mineral Resource Reporting |

111 | |

|

� |

� |

� |

� | |

|

15 |

Adjacent Properties |

114 | ||

|

� |

� |

� |

� | |

|

� |

15.1 |

The Pan Palladium/Impala Platinum JV |

114 | |

|

� |

� |

� |

� | |

|

� |

15.2 |

Mogalakwena Mine |

114 | |

|

� |

� |

� |

� | |

|

� |

15.3 |

Akanani Project |

114 | |

|

� |

� |

� |

� | |

|

� |

15.4 |

Boikgantsho Project |

114 | |

|

� |

� |

� |

� | |

|

� |

15.5 |

Harriet�s Wish and Aurora Projects |

115 | |

|

� |

� |

� |

� | |

|

� |

15.6 |

Platreef Project (Ivanplats) |

115 | |

|

� |

� |

� |

� | |

|

16 |

Other Relevant Data and Information |

116 | ||

|

� |

� |

� | ||

|

17 |

Interpretation and Conclusions |

117 | ||

|

� |

� |

� | ||

|

18 |

Recommendations |

119 | ||

|

� |

� |

� | ||

|

19 |

References |

120 | ||

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

List of Tables

�

|

Table 1.6_1 � Waterberg Project Mineral Resource Estimate (12 June�2014) |

11 |

|

� |

� |

|

Table 4.2_1 � Summary of Mineral Exploration and Mining Rights (South Africa) |

20 |

|

� |

� |

|

Table 4.3_1 � Summary of Waterberg Extension Project Prospecting Rights |

22 |

|

� |

� |

|

Table 6.3.1_1 � Waterberg Project Mineral Resource Estimate (1 September�2012) |

31 |

|

� |

� |

|

Table 6.3.2_1 � Waterberg Project Mineral Resource Estimate (1 February�2013) |

32 |

|

� |

� |

|

Table 6.3.3_1 � Waterberg Project Mineral Resource Estimate (2 September�2013) |

33 |

|

� |

� |

|

Table 10.8_1 � Recent T-Zone intercepts for the Waterberg JV Project Area |

68 |

|

� |

� |

|

Table 10.8_2 � Recent F-Zone intercepts for the Waterberg JV Project Area |

69 |

|

� |

� |

|

Table 10.8_3 � Recent F-Zone intercepts for the Waterberg Extension Project Area |

71 |

|

� |

� |

|

Table 11.15_1 � Summary of the Number of Control Samples Used in the Waterberg JV Project Area |

82 |

|

� |

� |

|

Table 11.15_2 � Summary of the Number of Control Samples Used in the Extension Project Area |

82 |

|

� |

� |

|

Table 11.15_3 � Summary of Certified Reference Standards Used |

83 |

|

� |

� |

|

Table 14_1 � Summary of the Mineral Resource Estimate Data |

94 |

|

� |

� |

|

Table 14.5_1 � Correlation Coefficient for Rh against other assayed elements |

102 |

|

� |

� |

|

Table 14.5_2 � Correlation Factors for Rh |

104 |

|

� |

� |

|

Table 14.7.1_1 � Summary of the Block Model details |

104 |

|

� |

� |

|

Table 14.7.2_1 � Summary of Block Model Details |

105 |

|

� |

� |

|

Table 14.9_1 � Estimation search parameters (F � Layers) |

107 |

|

� |

� |

|

Table 14.12_1 � Confidence Levels of Key Criteria |

110 |

|

� |

� |

|

Table 14.13_1 � Waterberg Project Mineral Resource Estimate F - Zone (12 June�2014) |

112 |

|

� |

� |

|

Table 14.13_2 � Waterberg Project Mineral Resource Estimate (12 June�2014) |

113 |

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

List of Figures

�

|

Figure 1.5_1 � Borehole Location and Geology of the Waterberg JV and Extension Projects |

6 |

|

� |

� |

|

Figure 4.1_1 � Location of the Waterberg Project Properties on the Bushveld Complex |

19 |

|

� |

� |

|

Figure 4.3_1 � Locations of the Waterberg Project Properties |

23 |

|

� |

� |

|

Figure 4.3_2 � Location of the Waterberg Project Prospecting Rights |

24 |

|

� |

� |

|

Figure 4.4_1 � Schematic Diagram of the Holdings of the Waterberg Project |

25 |

|

� |

� |

|

Figure 5.3_1 � Photograph looking towards the Eastern side of the Waterberg Project |

28 |

|

� |

� |

|

Figure 7.1_1 � Geological map of the Bushveld Complex showing the location of the Waterberg Projects |

35 |

|

� |

� |

|

Figure 7.1.1_1 � Generalised Stratigraphic Column of Rustenburg Layered Suite |

37 |

|

� |

� |

|

Figure 7.1.2_1 � General Geology of the northern limb of the Bushveld Complex |

38 |

|

� |

� |

|

Figure 7.1.2_2 �Geology of the northern limb showing the Various Footwall Lithologies |

39 |

|

� |

� |

|

Figure 7.3_1 � Geology of the Waterberg Project |

43 |

|

� |

� |

|

Figure 7.3_2 � Section�Showing Geology at Waterberg Project |

44 |

|

� |

� |

|

Figure 7.3_3 � Geology of the Waterberg Extension Project |

47 |

|

� |

� |

|

Figure 7.3.1_1 � General Stratigraphy of the Waterberg Projects |

49 |

|

� |

� |

|

Figure 7.4_1 � Stratigraphy of the Mineralised Layers |

51 |

|

� |

� |

|

Figure 7.4_2 � Individual Units of the F - Zone |

53 |

|

� |

� |

|

Figure 9.1.2_1 � Locations of Geochemical Sampling and Geophysical Traverses |

58 |

|

� |

� |

|

Figure 9.2.2_1 � Airborne Gradient Gravity and Magnetic Survey Flight Lines |

59 |

|

� |

� |

|

Figure 9.2.2_2 �Airborne Gradient Gravity Plot with Interpreted Bushveld Complex Edge |

60 |

|

� |

� |

|

Figure 9.2.2_3 � Airborne Total Field Magnetics Plot with Interpreted Bushveld Complex Edge |

61 |

|

� |

� |

|

Figure 10.3_1 � Location of Boreholes on the Waterberg JV Project |

65 |

|

� |

� |

|

Figure 10.3_2 � Location of Boreholes on the Waterberg Extension Project |

66 |

|

� |

� |

|

Figure 11.1_1 � Photograph of an Example of Borehole Marking |

74 |

|

� |

� |

|

Figure 11.3_1 � Photograph of Core Cutting |

75 |

|

� |

� |

|

Figure 11.3_2 � Photograph of an Example of Sampling Methodology |

76 |

|

� |

� |

|

Figure 12.1_1 � Permanent Borehole Beacon |

90 |

|

� |

� |

|

Figure 14.1.1_1 � A Geological Interpretation for the T - Zone |

96 |

|

� |

� |

|

Figure 14.1_1 � Area Underlain by the T- Layer and F - Zone |

98 |

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

|

Figure 14.1_2 � Isometric views of the Structural Model for the T- Layer and F - Zone |

100 |

|

� |

� |

|

Figure 14.4_1 � Summary of Statistics for the Composites of Each Layer |

102 |

|

� |

� |

|

Figure 14.4_2 � Summary of Statistics for the Composites of Each Layer |

102 |

|

� |

� |

|

Figure 14.5_1 � Correlation of Rh against Pt and Pd |

103 |

|

� |

� |

|

Figure 14.11_1 � Area of Geological Loss for the T- Zone and F - Zones |

109 |

�

List of Appendices

�

|

Appendix A � Authors Certificate |

1 |

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

1������������������������������������������������� SUMMARY

�

1.1��������������������������������������� Introduction

�

Coffey Mining (South Africa) Pty Limited (Coffey) has been requested by Platinum Group Metals� (Pty) Ltd (PTM), on behalf of Platinum Group Metals Ltd, the issuer, to complete an Independent Technical Report on the Exploration Drilling supporting the October�21, 2014 public disclosure of the Updated drilling results for the at the Waterberg Joint Venture (JV) Project and the Waterberg Extension Project.� These are two adjoining projects targeting a previously unknown extension to the northern limb of the Bushveld Complex that may have the potential for Platinum Group Metals (PGMs), gold and base metals (Cu, Ni).� This report complies with disclosure and reporting requirements set forth in the Toronto Stock Exchange Manual, National Instrument 43-101 Standards of Disclosure for Mineral Project (NI 43-101), Companion Policy 43-101CP to NI 43-101, and Form�43-101F1 of NI 43-101.

�

This report reviews the geology, the exploration activities and states the most recent mineral resource estimation on the Waterberg JV Project and Waterberg Extension Project (Effective Date: 12 June-2014).� The report provides an update of the exploration activities completed subsequent to the last filed technical report on the resource estimate dated 12 June-2014 up to the effective date of 21 October- 2014 to correspond to the public disclosure up to that date.

�

1.2��������������������������������������� Project Area and Location

�

The Waterberg JV Project and Waterberg Extension Project are adjoining Projects that cover an area along the strike length of the previously unknown northward extension of the Bushveld Complex.

�

Waterberg JV Project

�

The Waterberg Project is the result of a regional target initiative of PTM.� The area was targeted based on detailed geophysical, geochemical and geological work that indicated potential for a package of Bushveld Complex rocks under the Waterberg Group cover rocks.� The project area is along trend, off the northern end of the mapped northern limb of the Bushveld Complex in South Africa that indicated potential for a package of Bushveld Complex rocks under the Waterberg formation cover rocks.

�

The Waterberg JV Project is made up of four prospecting rights covering an area of 25,465ha.� PTM has prospecting rights which allow it to apply for the conversion of the prospecting right into a mining right within the renewal period of three years.

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

Waterberg Extension Project

�

The southern boundary of the Waterberg Extension Project is located some 85km north of the town of Mokopane, Limpopo Province.� The project currently consists of five prospecting rights.� The area of the prospecting rights covers 86,417ha and extends some 42km from north to south and 42km from east to west.

�

1.3��������������������������������������� Geological Setting, Deposit Type and Mineralization

�

PGM-dominated deposits occur in large layered intrusions, such as the Bushveld Complex (South Africa), the Stillwater Complex (Montana) and the Great Dyke (Zimbabwe).� The Waterberg JV and Extension Projects are located on the northern limb of the Bushveld Complex.� The 2,060�million year old Bushveld Complex, with a total extent of approximately 66,000km2, is the world�s largest zoned mafic intrusions.� The mafic rocks of the Bushveld Complex host zones rich in PGMs, chromium and vanadium, and constitute the largest known resource of these metals.� In addition, nickel and copper are generally associated with the PGMs and are significant by-products.

�

The mafic rocks are collectively termed the Rustenburg Layered Suite�(RLS) and have been divided into five zones known as the Marginal, Lower, Critical, Main and Upper Zones.

�

The Critical Zone is characterised by regular rhythmic layering of cumulus chromite within pyroxenites, anorthosites, norites and olivine-rich rocks.� It hosts virtually all the economic mineralization encountered in the Bushveld Complex.

�

The first economically significant cycle from a PGM perspective is the UG2 Chromitite Layer.� The two uppermost cycles of the Critical Zone are the Merensky and Bastard cycles.� The former is of great economic importance as it contains at its base the PGM-bearing Merensky Reef.� In the western part of the Bushveld Complex, several metres below the Merensky Reef, a unit known as the Pseudo Reef occurs that is known to be mineralized with PGMs.

�

In the northern limb, the Platreef mineralization occurs proximal to the basal contact of the Bushveld Complex with the country rock, typically as a thicker zone (up to 30m thick) containing disseminated sulphides.� Where the Bushveld Complex is in contact with the Archaean granite and sediments of the Transvaal Supergroup floor rocks, the Platreef is developed.� The contact between the RLS and footwall rocks in the northern limb is transgressive, with the Platreef in contact with progressively older rocks of different lithologies from south to north.

�

The Platreef is a series of pyroxenites and norites, containing xenoliths/rafts of footwall rocks.� It is irregularly mineralized with PGM, Cu and Ni.� The Platreef (senso stricto) has a strike extent of some 30km, whereas Platreef-style mineralization occurs over the 110km strike length of the northern limb (Kinnaird et al, 2005).� The Platreef varies from 400m thick in the south of the

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

northern limb to <50m in the north.� The overall strike is northwest or north, with dips 40��45� to the west at surface with the dip becoming shallower down dip.� The overall geometry of the southern Platreef appears to have been controlled by irregular floor topography.

�

The Waterberg JV Project and Waterberg Extension Project appear to be on strike along an extension of the Bushveld Complex.� The mineralization has a different setting and metal ratio to the Platreef.

�

1.4��������������������������������������� Local Geology

�

The drilling programmes undertaken by PTM on the Waterberg JV Project and Waterberg Extension Project have identified an extension to the Bushveld Complex beneath the sedimentary rocks of the Proterozoic Waterberg Group which in areas is covered by a veneer of Quaternary sand.� Further west, the Waterberg Group thickens to more than 760m and typically displays a downward coarsening with pebble beds and conglomerates towards the base.

�

The PGM mineralization at the Waterberg JV Project and the Waterberg Extension Project is hosted in modified felsic rocks: gabbros and anorthosites as well as in pyroxenites, troctolites, harzburgites and gabbronorites of the Bushveld Complex.� Layers of PGM mineralization are generally accompanied by significant concentrations of base metal sulphides, with pyrrhotite and chalcopyrite being dominant over pentlandite.

�

A geological model was developed for the project area based on the data from the various boreholes, structural interpretation from aerial photographs and geophysics.� A general dip of 34��-�38� towards the northwest is observed from borehole core for the layered units intersected on the Waterberg property within the Bushveld Package.� However, some blocks may be tilted at different angles depending on structural and /or tectonic controls.� Generally the Bushveld package strikes southwest to northeast.

�

The field relationships in the vicinity of the Waterberg JV Project and Waterberg Extension Project were noted to indicate that the Bushveld Complex is unconformably overlain by the sandstones of the Setlaole Formation of the Waterberg Group, which is post-Bushveld in age.� The core drilling undertaken by PTM shows that an angular unconformity exists between the Waterberg Group and underlying Bushveld Complex.� The nature of the relationship between the Waterberg Group and the Bushveld Complex is confirmed as having no bearing on the presence of mineralization in Bushveld Complex.� The mineralization in the Waterberg Project area generally comprises sulphide blebs, net-textured to interstitial sulphides and disseminated sulphides within gabbronorite and norite, pyroxenite, troctolite, harzburgite.

�

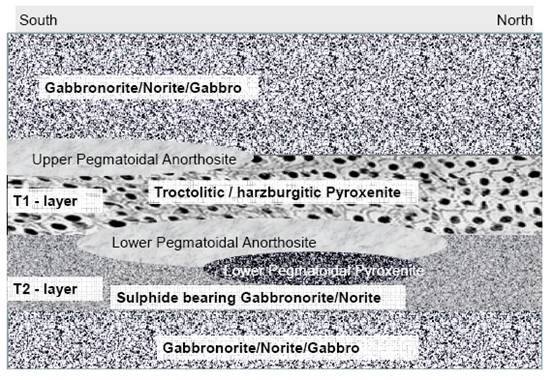

The T - Zone occurs within the Main Zone just beneath the contact of the overlaying Upper Zone.� Although the T � Zone consists of numerous mineralized layers, two potential economical layers

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

have been identified, T1- and T2 - Layers.� They are composed mainly of anorthosite, pegmatoidal gabbros, pyroxenite, troctolite, harzburgite, gabbronorite and norite.

�

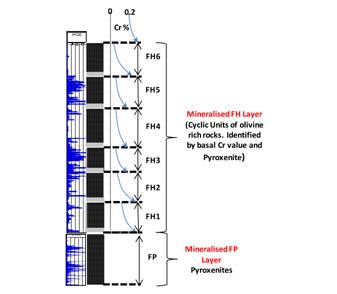

The F - Zone occurs towards the bottom of the Bushveld Complex in a cyclic unit of olivine rich lithologies.� T his zone consists of alternating units of harzburgite, troctolite and pyroxenites.� The F - Zone has been sub divided into the FH and FP layers.� The FH layer has significantly higher volumes of olivine in contrast with the lower lying FP layer, which is predominately pyroxenite.� The FH layer is further subdivided into six cyclic units chemically identified by their geochemical signature, especially chrome.� The base of these units can also be lithologically identified by a pyroxenite layer.

�

The base of the Bushveld Complex is a mix of the Archaean age Hout River Gneiss Suite�and fine grained pyroxenitic bands.

�

1.5��������������������������������������� Exploration Status

�

The Waterberg JV Project is more advanced in terms of the exploration status and includes an Inferred Mineral Resource estimate.� The majority of the Waterberg Extension Project is at an advanced exploration stage.� However recent drilling on the property Early Dawn, just north of the Waterberg JV Project has established sufficient surface drilling information to confirm continuity of mineralization, hence areas can be classified as an Inferred Mineral Resource.

�

Waterberg JV Project

�

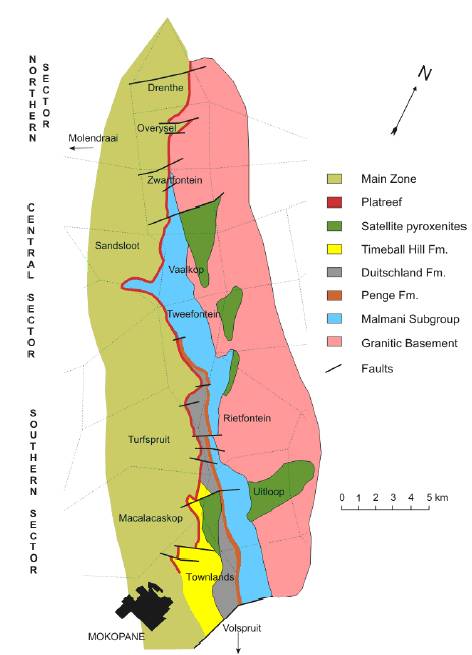

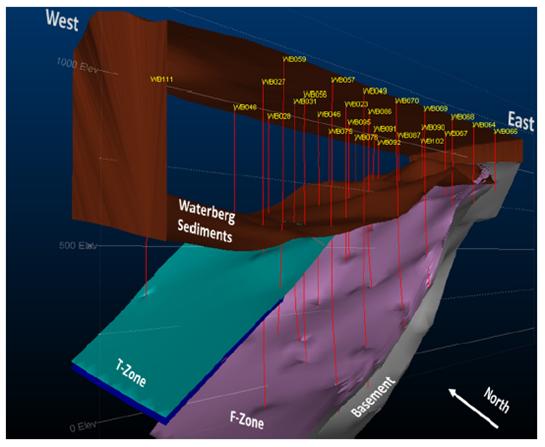

Previous mineral exploration activities were limited due to the extensive sand cover and the understanding that the area was underlain by the Waterberg Group.� Surface mapping has been undertaken but it is noted that most of the area surrounding the Waterberg Mountains is covered by Waterberg sands (Figure 1.5_1).� Mapping in these areas has provided no additional information as the Bushveld Complex is sub outcropped below Waterberg sediments.

�

In March�2010 (two north-south sampling lines) and later during December�2011 and January�2012 (two additional north-south lines), geochemical soil sampling was undertaken.� A total of 601 samples, of which 255 were soil samples, 277 stream sediment samples and 79 rock chip samples, were collected.

�

Approximately 60 lines of geophysical survey for 488 line km using gravity and magnetics were traversed in March�2010.� A second phase of Geophysical Survey was also conducted on the farm Ketting 368LR from August�2011 to September�2011.

�

Anomalous soil results in platinum group metals in areas that were thought, in the regional mapping, to be covered by thick sediments younger than the Bushveld Complex, provided initial interest in the property.� The geochemistry added to the geophysical results which suggested a

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

Bushveld Complex extension in the property area, potentially at reasonable depth.� Based on the exploration combined with the target generation, diamond drilling commenced in 2010.� The drilling confirmed the presence of the rocks of the Bushveld Complex.� Exploration has thus been largely driven by drilling.� The relationship between the Bushveld Complex and Waterberg Group is the subject of discussion between PTM and geologists from various universities.� The age of the rocks of the Bushveld rocks relative to the sedimentary cover is not considered critical to the geological model of the mineralized rocks in the Bushveld Complex.

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

Figure 1.5_1

Borehole Location and Geology of the Waterberg JV and Extension Projects

�

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

Waterberg Extension Project

�

PTM contracted FUGRO Airborne Surveys (Pty) Ltd.� to conduct airborne FALCON� gravity gradiometry and a total field magnetic survey in April�2013.� The target for the surveys was the interpreted edge sub-outcropping of the denser Bushveld Complex to which the Waterberg Group sediments form the regional hanging wall.� The survey was flown on 100m and 200m line spacing and was comprised of 2306.16 line kilometres of Airborne Gravity Gradiometry (AGG) data and 2469.35 line kilometres of magnetic and radiometric data.� The total extent of the survey covered approximately 30km2�of interpreted Bushveld Complex edge within the Waterberg JV Project and Waterberg Extension Project areas.� Modelling of the data suggests that there may be a northeast and north trending continuity to the Bushveld Complex rocks on the Waterberg Extension Project which may have the potential to host PGM mineralization.

�

Later in September�2013 nine ground gravity traverses were completed by Geospec Instruments (Pty) Ltd along roads and tracks.� The survey lines were designed to traverse across the projected edge of the Bushveld Complex on the Waterberg Extension Project in the same area covered by the airborne survey as ground confirmation of the airborne results.� The two surveys were compared and there was acceptable correlation between gravity data sets.� In planning the ground survey, one control line over the known Bushveld Complex edge, at the point where it projected from the adjacent Waterberg JV Project was completed in order to acquire a signature profile over a known source with which to compare the remaining regional lines. �The interpretation of the linked ground gravity profiles suggests that there may be a northeast trending continuity to the Bushveld Complex rocks.� The drilling confirmed the presence of the rocks of the Bushveld Complex.

�

Ground exploration work undertaken includes geological mapping and ground verification of the geology presented in various government and academic papers.� The major faults and South Marginal Zone (SMZ) geology described was confirmed to exist within the property.� Contact relations with the Bushveld Complex were not seen due to the Waterberg cover rock and quaternary sand deposits.

�

1.5.1����������������������������� Drilling

�

Since the declaration of the mineral resource (12June�2014), an additional 71,459m of diamond drilling have been completed at the Waterberg JV and Waterberg Extension combined.� This report updates the technical disclosure of that drilling.

�

The management of the drilling programmes, logging and sampling have been undertaken from the same facility at the town of Marken in Limpopo Province, South Africa.

�

Drilled core is cleaned, de-greased and packed into metal core boxes by the drilling company.� The core is collected from the drilling site on a daily basis by a PTM geologist and transported to

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

the coreyard by PTM personnel.� Before the core is taken off the drilling site, core recovery and the depths are checked.� Core logging is done by hand on a pro-forma sheet by qualified geologists under supervision of the Project Geologist.

�

Waterberg JV Project

�

Based on the target generation and the results of the geochemical sampling and geochemical surveys, two boreholes were initially drilled between July�and October�2010 on the farm Disseldorp 369LR.� A total of 1934.77m was drilled for the first two boreholes in 2010.� Drilling resumed in 2011 on the farm Ketting.� The geological information revealed by this borehole lead to the extension of the drilling campaign in 2012, 2013 and 2014.

�

Subsequent to the boreholes used for the mineral resource estimate of 12 June-2014, an additional 53,684m representing 56 exploration boreholes and 58 deflections have been completed on the Waterberg JV Project.

�

Waterberg Extension Project

�

Based on the strike projections from the Waterberg JV Project, modelling of regional government data, detailed airborne gradient gravity and total field magnetic responses along with ground gravity confirmation, drill targets were generated and drilling commenced in October�2013 on the farm Early Dawn 369LR.

�

Subsequent to the boreholes used for the mineral resource estimate of 12 June-2014 and additional 17,775,m in 12 exploration boreholes and 26 deflections have been completed on the Waterberg Extension Project.

�

1.5.2����������������������������� Sample Preparation

�

The sampling methodology concurs with PTM protocol based on industry best practice.� The quality of the sampling is monitored and supervised by a qualified geologist.� The sampling is done in a manner that includes the entire potentially economic unit.

�

1.5.3����������������������������� Analysis

�

For the present database, field samples have been analyzed by two different laboratories: the primary laboratory is currently Set Point laboratories (South Africa).� Genalysis (Australia) is used for referee test work to confirm the accuracy of the primary laboratory.

�

Samples are received, sorted, verified and checked for moisture and dried if necessary.� Each sample is weighed and the results are recorded.� Rocks, rock chips or lumps are crushed using a jaw crusher to less than 10mm.� The samples are then milled for 5 minutes in a Labtech Essa

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

LM2 mill to achieve a fineness of 90% less than 106�m, which is the minimum requirement to ensure the best accuracy and precision during analysis.

�

Samples are analysed for Pt (ppm), Pd (ppm) Rh (ppm) and Au (ppm) by standard 25g lead fire-assay using a silver collector.� Rh (ppm) is assayed using the same method but with a palladium collector and only for selected samples.� After pre-concentration by fire assay the resulting solutions are analysed using ICP-OES (Inductively Coupled Plasma�Optical Emission Spectrometry).

�

The base metals (copper, nickel, cobalt and chromium) are analysed using ICP-OES (Inductively Coupled Plasma � Optical Emission Spectrometry) after a four acid digestion.� This technique results in �almost� total digestion.

�

The drilling, sampling and analytical aspects of the project are considered to have been undertaken to industry standards.� The data is considered to be reliable and suitable for mineral resource estimation.

�

1.5.4����������������������������� Quality Control and Quality Assurance

�

PTM have instituted a complete QA/QC programme including the insertion of blanks and certified reference materials as well as referee analyses.� The programme is being followed and is considered to be to industry standard.� The data is as a result, considered reliable.

�

1.6��������������������������������������� Mineral Resources

�

The mineral resource estimate (Effective Date: 12 June�2014) is reported for completeness of this report.� There have been no new mineral resource estimates declared since that date.� The mineral resources reported are located within the Waterberg JV Project Area and in the southern portion of the Waterberg Extension Project Area (Table 1.6_1).� There has been insufficient drilling elsewhere on Waterberg Extension Project to update the mineral resource estimate.

�

Mineral resources have been declared for the T- and F - Zone mineralization on the property Ketting 368LR and Goedetrouw 366LR of the Waterberg JV Project and Early Dawn 361LR of the Waterberg Extension Project.

�

The data that formed the basis of the estimate are the boreholes drilled by PTM which consist of geological logs, the borehole collars, the downhole surveys and the assay data.� The area where each layer was present was delineated after examination of the intersections in the various boreholes.

�

The data was used to define the characteristics of the various layers based on their geochemical signatures.� However, it was necessary to check the procedure against the core.� As a result a

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

validation was undertaken on the core with the intention of finding diagnostic features to identify the layers directly from the core.� This was successfully achieved for the T � Zone.� However, due to pervasive alteration, this proved difficult for the F - Zone.� For estimation of the mineral resources reported in September�2013, modelling of the mineralization within the F - Zone was based on its stratigraphic position at the base of the magmatic sequence and on geochemical data.

�

Seven subunits within the broader F - Zone (FP and FH1 � FH6) have been identified based on their geochemical characteristics.

�

Data from the drilling completed by PTM in the estimate consists of intersections from 138 completed boreholes.� Each borehole was examined for completeness in respect of data (geology, sampling, collar) and sample recovery prior to inclusion in the estimate.

�

Geological models (wireframes) of the seven F - Zone units were modelled by CAE Mining (South Africa) on behalf of PTM, using the Strat 3D module of CAE Mining Studio�.

�

The coded borehole database supplied by PTM was composited for Pt, Pd, Au, Cu, Ni and density.� For each unit a three dimensional block model was modelled and an inverse distance weighted (power 2) estimate was undertaken.

�

Coffey considers that the mineral resource of the various layers should be classified as an Inferred Mineral Resource.� The data is of sufficient quality and the geological understanding and interpretation are considered appropriate for this level of mineral resource classification.

�

Two areas were defined defining areas where geological loss of 25% and 12.5% were applied.� These were based primarily on the spacing of surface boreholes and on the knowledge of this type of deposit.� The geological losses are made up of areas where the Zones may be absent due to faults, dykes and mafic/ultramafic pegmatites.

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

Table 1.6_1

Waterberg Project-

Mineral Resource Estimate (SAMREC Code) (12 June�2014)

�

|

� |

� |

Stratigraphic |

� |

Tonnage |

� |

Pt�(g/t) |

� |

Pd |

� |

Rh |

� |

Au |

� |

PGE+Au |

� |

Pt:Pd:Rh:Au |

� |

PGE+Au |

� |

Cu�(%) |

� |

Ni�(%) |

� |

Cu |

� |

Ni |

|

T1 |

� |

2.44 |

� |

10.49 |

� |

1.02 |

� |

1.52 |

� |

� |

� |

0.47 |

� |

3.01 |

� |

34:50:0:16 |

� |

1,015 |

� |

0.17 |

� |

0.10 |

� |

40 |

� |

23 |

|

T2 |

� |

3.87 |

� |

43.57 |

� |

1.14 |

� |

1.99 |

� |

� |

� |

0.82 |

� |

3.95 |

� |

29:50:0:21 |

� |

5,540 |

� |

0.17 |

� |

0.09 |

� |

167 |

� |

90 |

|

T Total |

� |

3.60 |

� |

54.06 |

� |

1.12 |

� |

1.90 |

� |

� |

� |

0.75 |

� |

3.77 |

� |

30:50:0:20 |

� |

6,555 |

� |

0.17 |

� |

0.10 |

� |

207 |

� |

114 |

|

F |

� |

2.75-60 |

� |

232.82 |

� |

0.90 |

� |

1.93 |

� |

0.05 |

� |

0.14 |

� |

3.01 |

� |

30:64:2:4 |

� |

22,529 |

� |

0.08 |

� |

0.19 |

� |

409 |

� |

994 |

|

Total |

� |

� |

� |

286.88 |

� |

0.94 |

� |

1.92 |

� |

0.04 |

� |

0.25 |

� |

3.15 |

� |

30:61:1:8 |

� |

29,084 |

� |

0.10 |

� |

0.18 |

� |

617 |

� |

1,107 |

|

Content (koz) |

� |

8,652 |

� |

17,741 |

� |

341 |

� |

2,350 |

� |

� |

� |

� |

� |

kt |

� |

280 |

� |

502 |

� |

� |

� |

� | ||||

�

Waterberg Project- (JV)

�

|

� |

� |

Stratigraphic |

� |

Tonnage |

� |

Pt�(g/t) |

� |

Pd |

� |

Rh |

� |

Au |

� |

PGE+Au |

� |

Pt:Pd:Rh:Au |

� |

PGE+Au |

� |

Cu�(%) |

� |

Ni�(%) |

� |

Cu |

� |

Ni |

|

T1 |

� |

2.44 |

� |

10.49 |

� |

1.02 |

� |

1.52 |

� |

� |

� |

0.47 |

� |

3.01 |

� |

34:50:0:16 |

� |

1,015 |

� |

0.17 |

� |

0.10 |

� |

40 |

� |

23 |

|

T2 |

� |

3.87 |

� |

43.57 |

� |

1.14 |

� |

1.99 |

� |

� |

� |

0.82 |

� |

3.95 |

� |

29:50:0:21 |

� |

5,540 |

� |

0.17 |

� |

0.09 |

� |

167 |

� |

90 |

|

T Total |

� |

3.60 |

� |

54.06 |

� |

1.12 |

� |

1.90 |

� |

� |

� |

0.75 |

� |

3.77 |

� |

30:50:0:20 |

� |

6,555 |

� |

0.17 |

� |

0.10 |

� |

207 |

� |

114 |

|

F |

� |

2.75-60 |

� |

164.58 |

� |

0.88 |

� |

1.91 |

� |

0.05 |

� |

0.13 |

� |

2.97 |

� |

30:64:2:4 |

� |

15,713 |

� |

0.07 |

� |

0.18 |

� |

247 |

� |

649 |

|

Total |

� |

� |

� |

218.64 |

� |

0.94 |

� |

1.91 |

� |

0.03 |

� |

0.29 |

� |

3.17 |

� |

30:60:1:9 |

� |

22,268 |

� |

0.09 |

� |

0.16 |

� |

455 |

� |

763 |

|

Content (koz) |

� |

6,605 |

� |

13,407 |

� |

239 |

� |

2,018 |

� |

� |

� |

� |

� |

kt |

� |

207 |

� |

346 |

� |

� |

� |

� | ||||

�

Waterberg Project- (Ext)

�

|

� |

� |

Stratigraphic |

� |

Tonnage |

� |

Pt�(g/t) |

� |

Pd |

� |

Rh |

� |

Au |

� |

PGE+Au |

� |

Pt:Pd:Rh:Au |

� |

PGE+Au |

� |

Cu�(%) |

� |

Ni�(%) |

� |

Cu |

� |

Ni |

|

F |

� |

2.75-60 |

� |

68.04 |

� |

0.93 |

� |

1.98 |

� |

0.05 |

� |

0.15 |

� |

3.11 |

� |

30:64:2:4 |

� |

6,802 |

� |

0.11 |

� |

0.23 |

� |

162 |

� |

344 |

|

Total |

� |

� |

� |

68.04 |

� |

0.93 |

� |

1.98 |

� |

0.05 |

� |

0.15 |

� |

3.11 |

� |

30:64:2:4 |

� |

6,802 |

� |

0.11 |

� |

0.23 |

� |

162 |

� |

344 |

|

Content (koz) |

� |

2,043 |

� |

4,325 |

� |

102 |

� |

331 |

� |

� |

� |

� |

� |

kt |

� |

73 |

� |

156 |

� |

� |

� |

� | ||||

�

The T-Zone cut-off is reported as 2PGE+Au and the F - Zone cut-off is reported as 3PGE+Au grade

Individual numbers may not add up due to rounding

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November 2014 |

�

�

�

Coffey Mining South Africa (Pty) Ltd

�

Mineral resources which are not mineral reserves have demonstrated economic viability.� The estimate of mineral resources may be materially affected by environmental, permitting, legal, marketing, or other relevant issues.

�

The quantity and grade of reported Inferred Mineral Resources in this estimate are conceptual in nature.� There is no guarantee that all or any part of the Mineral Resource will be converted to a Mineral Reserve.

�

The independent Qualified Persons responsible for the mineral resource estimate in this report and summarized in Table 1.6_1 are Kenneth Lomberg and Alan Goldschmidt

�

Kenneth Lomberg, a geologist with some 29 years� experience in mine and exploration geology, resource and reserve estimation and project management in the minerals industry (especially platinum and gold).� He is a practising geologist registered with the South African Council for Natural Scientific Professions (Pr.Sci.Nat.) and is independent of Platinum Group Metals Ltd as that term is defined in Section�1.5 of the Instrument.

�

Alan Goldschmidt, a geologist with some 29 years� experience in minerals industry.� He has been primarily been involved with geological block models and geostatistical resource estimation.� He is a practising geologist registered with the South African Council for Natural Scientific Professions (Pr.Sci.Nat.) and is independent of Platinum Group Metals Ltd as that term is defined in Section�1.5 of the Instrument.

�

1.7��������������������������������������� Interpretation and Conclusions

�

Exploration drilling by PTM has intersected layered magmatic PGM mineralization in what is interpreted to be the northern extension of the northern limb of the Bushveld Complex under the Waterberg Group rocks.

�

Exploration drilling has confirmed the presence of mineralization.� Elevated PGM concentrations have been identified in mineralized zones/layers consistent with layered magmatic sulphide deposits and displays characteristics of a geological setting, including the ratio of precious metals that differs from other locations in the Bushveld Complex.

�

In conclusion, Coffey recommended that drilling continue and that more detailed logging be undertaken to improve the geological understanding and allow for improved layer definition.

�

The scale of the inferred mineral resource and the fact that the mineralization is open to the west would suggest that a drill program be extended into this area.

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

Waterberg JV Project

�

After the mineral resource estimate (Effective Date: 2 September�2013) there was an update (Effective Date 12 June�2104) which is a significant increase in inferred mineral resource.� This is primarily due to extension of the mineral resource further north and to a depth of 1250m from a previous 1,000m depth cut-off.� The delineation of the F - Zone has been advanced due to better understanding of the geology.

�

The mineral resource (Effective Date 12 June�2104) for the identified mineralized layers within this project area, utilised the exploration database that contained 114 boreholes with 307 intersections.�� The mineralization is considered open down-dip and along strike.

�

It is recommended to advance that further detailed logging and refined modelling the geological will advance the geological confidence in the model.�� In addition the infill drilling should continue as it may assist to improve the confidence in determining the grade and geological continuity.

�

Waterberg Extension Project

�

Exploration on the Waterberg Extension Project has confirmed the presence of Bushveld rocks under the Waterberg Group.� Exploration drilling has confirmed the presence of the continuation of the mineralized F - Zone along strike from the adjacent Waterberg JV Project.� Elevated PGM concentrations have been identified in mineralized zones/layers consistent with layered magmatic sulphide deposits and displays characteristics of a geological setting, including the ratio of precious metals that differs from other locations in the Bushveld Complex.

�

An interpretation of the position of the Bushveld Complex was made after modelling of data from airborne gradient gravity and magnetics, regional magnetics and ground gravity surveys.� The three methods of interpretation all indicate that the Bushveld Complex continues in a northeast to northerly arc from the known position from drilling in the southern area of the Project.

�

The continuity of geological features and mineralized layers has been confirmed.� The database for the Waterberg Extension Project used fro the latest mineral resource estimate (Effective Date 12 June�2104) contains 24 boreholes with 56 intersections.� The geophysical data and the new drilling supports the model that the mineralization is open down-dip and along strike.� The new data supports the previous recommendation that further drilling would confirm the location of the northern extension of the Bushveld Complex.

�

It is now recommended that drilling continue on the Waterberg Extension Project on a 250m x 250m grid to support a Mineral Resource Estimate in the areas where mineralization of sufficient grade and width has been intersected.� In addition the infill drilling should continue as it may assist to improve the confidence in determining the grade and geological continuity.

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

It is recommended that consideration be given to the commencement of a Pre-feasibility Study.

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

�

2������������������������������������������������� INTRODUCTION

�

2.1��������������������������������������� Scope of the Report

�

Coffey Mining (South Africa) Pty Limited (Coffey) has been requested by Platinum Group Metals� (Pty) Ltd (PTM), on behalf of Platinum Group Metals Ltd, the issuer, to complete an Independent Technical Report on Exploration Drilling supporting the October�21, 2014 public disclosure of the Updated drilling results for the combined Waterberg Joint Venture (JV) Project and the Waterberg Extension Project, two adjoining projects targeting a previously unknown extension to the northern limb of the Bushveld Complex which may have the potential for Platinum Group Metals (PGMs), gold and base metals (Cu, Ni).� This report complies with disclosure and reporting requirements set forth in the Toronto Stock Exchange Manual, National Instrument 43-101 Standards of Disclosure for Mineral Project (NI 43-101), Companion Policy 43-101CP to NI 43-101, and Form�43-101F1 of NI 43-101.

�

This report reviews and updates the geology, the exploration activities and states the mineral resource estimation (Effective date: 12 June�2014) on the project areas based on documentation related to the project, and discussions with project management up to 21 October�2014.

�

2.2��������������������������������������� Principal Sources of Information

�

The sources of information and data include both public domain data (conventional publications, �Open File� and Internet) and information gathered or otherwise acquired by PTM, which are not generally available in the public domain.� Where possible, published and/or generally available data on �Open File� in the Council of Geoscience, Pretoria, South Africa, was used.

�

The public domain sources and documents that were supplied by PTM are listed in Section�19 - References.

�

2.3��������������������������������������� Qualifications and Experience

�

Coffey is an integrated Australian-based consulting firm, which has been providing services and advice to the international mineral industry and financial institutions since 1987.� Coffey has maintained a fully operational office at Accra in Ghana since 1996, providing an operational base for consulting and contracting assignments throughout the West African region.� An additional African office was established in Johannesburg, South Africa, in 1999 to support expanding activities within southern and eastern portions of the continent.

�

The following persons were nominated to the project team and their specific areas of responsibility are shown below.� The qualifications and appropriate experience of the authors are detailed in the attached Authors� Certificates.� Mr.�K�G�Lomberg visited the Waterberg JV site on 16-18 April�2012, 16�18 August�2012, 21�22 August�2012, 13-15 January�2013 and 24 - 25 July�

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

2013, 24 � 25 March�2014,6 � 7 October�2014 and the Waterberg Extension site on 8 November�2013.� Mr.�Goldschmidt visited site on 24 - 25 July�2013.

�

PTM personnel on site facilitated the technical review by providing documentation, overview presentations, field visits, access to the exploration and drilling already completed, and access to project databases.

�

The overall report was compiled by Mr.�Lomberg and Mr.�Goldschmidt.

�

Kenneth Lomberg, Principal Consultant Resources, Coffey � Southern Africa

Project management, site visits, geological review and interpretation, mineral resource estimation, report preparation.

�

Mr.�Lomberg has the relevant experience to the type of deposit and resource estimation that is the subject of this report.� Mr.�Lomberg has done consultant work on various projects on the Bushveld Complex including Aurora, Kransplaats, Bokoni Mine, Mecklenburg, Smokey Hills, Kalplats, Garatau, Kennedy�s Vale, Kalkfontein, Blue Ridge Mine, Eland Mine, Western Bushveld Joint Venture (WBJV), Palmietfontein, Stellite, Townlands and Tharisa.� Mr.�Lomberg has assisted with approximately 15 of the estimated 20 Junior Platinum Exploration and Mining Companies in South Africa.� These assignments have ranged from listings documents, Due Diligences, CPRs,�ITRs, feasibility studies, NI�43-101 compliant resource estimations and valuations.

�

Alan Goldschmidt, Senior Consultant Resources, Coffey � Southern Africa

Site visit, geological review and interpretation, mineral resource estimation, report preparation.

�

Mr.�Goldschmidt has some 29 years experience in the minerals industry.� He has been involved in exploration and mine geology.� His expertise is project management, reserve, and resource estimation.� Primarily he has been involved with geological block modelling and geostatistical resource estimation, reserve, and resource estimation.

�

2.4�������������������������������������� Independence

�

Neither Coffey, nor the key personnel nominated for the completed and reviewed work, have any material interest in PTM or its mineral properties.� The proposed work, and any other work done by Coffey for PTM, is strictly in return for professional fees.� Payment for the work is not in any way dependent on the outcome of the work or on the success or otherwise of PTM�s own business dealings.� As such there is no conflict of interest in Coffey undertaking the Independent Qualified Person�s Report as contained in this document.

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

3������������������������������������������������� RELIANCE ON OTHER EXPERTS

�

This report was prepared as a National Instrument 43-101 Technical Report, in accordance with Form�43-101F1, for Platinum Group Metals� (Pty) Ltd (PTM), on behalf of Platinum Group Metals Ltd, the issuer, by Coffey Mining (South Africa) Pty Ltd (Coffey).� The quality of information and conclusions contained herein is consistent with the level of effort involved in Coffey�s services and based on:

�

i)���������������������������������������� Information available at the time of preparation by PTM,

�

ii)������������������������������������� Previously completed and filed technical reports on the resource estimate titled: �Revised and Updated Mineral Resource Estimate for the Waterberg Platinum Project, South Africa� dated 2 September�2013 and �Amended and Combined Technical Report, Waterberg Joint Venture and Waterberg Extension projects, South Africa�� dated� 9th�December�2013.

�

iii)���������������������������������� Third party technical reports prepared by Government agencies and previous tenement holders, along with other relevant published and unpublished third party information.

�

iv)��������������������������������� This report is intended to be used by PTM, subject to the terms and conditions of its contract with Coffey.� This contract permits PTM to file this report as a Technical Report with Canadian Securities Regulatory Authorities pursuant to National Instrument 43-101, Standards of Disclosure for Mineral Projects.� Any other use of this report by any third party is at that party�s sole risk.

�

A final draft of this report was provided to PTM, along with a written request to identify any material errors or omissions, prior to lodgement.

�

Neither Coffey, nor the authors of this report, are qualified to provide extensive comment on legal facets associated with ownership and other rights pertaining to PTM�s mineral properties described in Section�4.� Coffey did not see or carry out any legal due diligence confirming the legal title of PTM to the properties.

�

Similarly, neither Coffey nor the authors of this report are qualified to provide extensive comment on environmental issues associated with PTM�s mineral properties, as discussed in Section�4.

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

4������������������������������������������������� PROPERTY DESCRIPTION AND LOCATION

�

4.1��������������������������������������� Property Description and Location

�

The Waterberg Project (PTM and JOGMEC Joint venture) is some 85km north of the town of Mokopane (formerly Potgietersrus) (Figure 4.1_1).� The exploration area comprises a number of prospecting rights.� Their status is tabled in Table 4.3_1.

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

Figure 4.1_1

Location of the Waterberg JV and Waterberg Extension Project Properties on the Bushveld Complex

�

�

|

Technical Report for the Update on Exploration Drilling at the for Waterberg Joint Venture and |

� |

|

Waterberg Extension Projects South Africa � 24 November�2014 |

� |

�

�

Coffey Mining South Africa (Pty) Ltd

�

4.2��������������������������������������� Mining Tenure

�

A summary of the mineral exploration and mining rights regime for South Africa is provided in Table�4.2_1.� It should be noted that PTM have a Prospecting Right which allows them should they meet the requirements in the required time, to have the sole mandate to file an application for the conversion of the registered Prospecting Right to a Mining Right.

�

Table 4.2_1

Summary of Mineral Exploration and Mining Rights

(South Africa)

�

|

South Africa |

� |

Mineral Exploration and Mining Rights |

|

Mining Act |

: |

Mineral and Petroleum Resources Development Act, No.� 28 of 2002 (Implemented 1 May�2004) |

|

State Ownership of Minerals |

: |

State custodianship |

|

Negotiated Agreement |

: |

In part, related to work programmes and expenditure commitments. |

|

� |

� |

� |

|

Mining Title/Licence Types |

� |

� |

|

Reconnaissance Permission |

: |

Yes |

|

Prospecting Right |

: |

Yes |

|

Mining Right |

: |

Yes |

|

Retention Permit |

: |

Yes |

|

Special Purpose Permit/Right |

: |

Yes |

|