Form 6-K ENERGY FUELS INC For: Mar 19

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 6-K

REPORT OF FOREIGN PRIVATE ISSUER PURSUANT TO RULE

13a-16 or 15d-16 UNDER THE

SECURITIES EXCHANGE ACT OF 1934

For the month of March, 2015.

Commission File Number 001-36204

ENERGY FUELS INC.

(Translation of registrant’s name into English)

225 Union Blvd., Suite 600

Lakewood, CO 80228

(Address of principal executive offices)

Indicate by check mark whether the registrant files or will file annual reports under cover Form 20-F or Form 40-F

Form 20-F [ ] Form 40-F [X]

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(1): [ ]

Note: Regulation S-T Rule 101(b)(1) only permits the submission in paper of a Form 6-K if submitted solely to provide an attached annual report to security holders.

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(7): [ ]

Note: Regulation S-T Rule 101(b)(7) only permits the submission in paper of a Form 6-K if submitted to furnish a report or other document that the registrant foreign private issuer must furnish and make public under the laws of the jurisdiction in which the registrant is incorporated, domiciled or legally organized (the registrant’s “home country”), or under the rules of the home country exchange on which the registrant’s securities are traded, as long as the report or other document is not a press release, is not required to be and has not been distributed to the registrant’s security holders, and, if discussing a material event, has already been the subject of a Form 6-K submission or other Commission filing on EDGAR.

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| ENERGY FUELS INC. | |

| /S/ David C. Frydenlund | |

| Date: March 19, 2015 | David C. Frydenlund |

| Senior Vice President, General Counsel & Corporate | |

| Secretary |

-2-

INDEX TO EXHIBITS

-3-

NI 43-101 Technical Report on

Resources Wate Uranium Breccia

Pipe – Northern Arizona, USA.

Report Prepared for

Energy Fuels Resources (USA), Inc.

And

Uranium One Inc.

Report Prepared by

SRK Consulting (U.S.), Inc.

357600.030

March 10, 2015

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page i |

NI 43-101 Technical Report on Resources Wate

Uranium

Breccia Pipe – Northern Arizona, USA

Energy Fuels Resources (USA) Inc.

225 Union Blvd.,

Suite 600

Lakewood, CO., U.S.

And

Uranium One Inc.

25 Adelaide St. E., Suite 1616

Toronto, Ontario, M5C 3A1

SRK Consulting (U.S.), Inc.

3275 West Ina Road,

Suite 240

Tucson, AZ 85741

e-mail: [email protected]

website: www.srk.com

Tel: 1.520 544 3688

Fax: 1.520 544 9853

SRK Project

Number 357600.030

March 10, 2015

Authors and Qualified Persons:

Allan Moran, C.P.G.

AIPG

Associate Principal Consultant (Geology)

Frank A. Daviess, MAusIM, RM SME

Associate Principal

Consultant (Resource Geology)

Peer Reviewed by:

Corolla Hoag, C.P.G. AIPG

Principal Consultant (Geology)

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page ii |

Summary (Item 1)

Energy Fuels Resources (US) Inc. (Energy Fuels) controls the Wate Uranium Breccia Pipe (the Project), located in northern Arizona. The Project is a mid-stage exploration property with established Inferred uranium resources of 71,000 tons grading 0.79% eU3O8 for 1,118,000 contained pounds eU3O8 (Table 20-2). The Wate Pipe is one of several uranium bearing breccia pipe properties held by Energy Fuels in northern Arizona, which include properties in the exploration, development, and active mining stage. The Wate Pipe had historical drilling and resource estimates, and VANE Minerals (US) LLC (VANE) conducted verification drilling and gamma logging to confirm the historical data and allow for resource estimation for the mineralized breccia pipe during the period of 2008 through 2011. Section 16 further describes current resources that are the subject of this report. The Wate Pipe is an attractive high-grade uranium deposit that justifies further exploration and/or pre-development work.

In February of 2015, Energy Fuels, through its wholly-owned subsidiary EFR Arizona Strip LLC, acquired VANE’s 50% interest in the Project. The Project is held by the Wate Mining Company LLC joint venture (the “LLC”) between VANE and Uranium One Americas, Inc. (U1), and U1 continues to own 50% of the LLC. Energy Fuels will assume VANE’s role as Manager of the LLC.

The Wate Uranium Breccia Pipe is located in northwestern Arizona, south of the Grand Canyon National Park in Coconino County. Prior owners advanced the Wate Pipe to the point of internal feasibility study during the 1980’s, although the depressed uranium market at the time resulted in the abandonment of the properties and the dissolution of the companies. The Wate Pipe, acquired through the Agreement with U1, had previously been evaluated with sufficient drill results to be considered by the former owner, Rocky Mountain Energy Partners, L.P. (RME), as a mineral resource (historical term not compliant with current resource classifications) sufficient for internal pre-development consideration. VANE acquired the readily available historical exploration information for the Project in 2008. Uranium mineralization is typical of past producing uranium breccia pipe deposits in Arizona, which had grades near 1.0% U3O8 and from 1 to 6 M lbs. of contained U3O8. Mineralization typically occurs at depths of about 600 ft. to 2,000 ft. in a vertical, narrow, cylindrical breccia body that can have dimensions of 300 ft. across or less.

This report is a NI 43-101 Technical Report on resources for the Wate Uranium Breccia Pipe, for Energy Fuels, specifically to reflect the change in ownership; mineral resources have not changed since reported for VANE in 2011. The mineral resources are still current. VANE confirmed high grade intercepts at Wate by re-entering and re-logging (gamma logs) some of the historical drillholes, and by drilling several new drillholes. VANE confirmed (through re-logging of historical drillholes) an intercept of 34 ft. @ 1.67% eU3O8, from 1,489 to 1,523 ft. in depth in drillhole WT-5 and 10.5 ft. @ 0.40% eU3O8 from 1,244.5 to 1,255.0 ft. in depth in drillhole WT-7. VANE drilling/logging results from eight of eleven new drillholes has defined mineralization of similar grades and thicknesses to that in historical holes. The key drillhole intercepts upon which the current resource for the Wate Pipe is estimated, are listed in Table 20-1:

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page iii |

Table 20-1: Significant Drill intercepts for the Wate Pipe at 0.15% eU3O8 cutoff

| WT-29A

upper |

WT- 29A lower |

WT-33 | WT- 34 | WT-35 (cum) |

WT-37 upper |

WT-37

middle |

WT-37 lower |

WT-39

(un-cut) |

WT-41 | Wt-42 (cum) |

WT-5 | WT-7 | |

| Thickness (ft) | 36.0 | 28.0 | 25.5 | 15.0 | 21.5 | 20.0 | 2.5 | 12.5 | 64.5 | 27 | 35.5 | 32.5 | 9.0 |

| Ave Grade (%U3O8) |

0.69 | 1.60 | 0.45 | 0.30 | 0.33 | 0.37 | 0.19 | 1.29 | 1.45** | 1.45 | 0.25 | 1.52 | 0.47 |

| No 0.5 ft interval |

72 | 56 | 51 | 30 | 31 | 40 | 5 | 25 | 129 | 54 | 71 | 65 | 18 |

| No. > 0.5% eU3O8 |

34 | 49 | 22 | 0 | 6 | 10 | 0 | 20 | 101 | 36 | 4 | 45 | 7 |

| High value (%eU3O8) |

2.47 | 4.61 | 0.97 | 0.48 | 0.69 | 1.39 | 0.25 | 3.18 | 18.35* | 2.92 | 1.12 | 4.38 | 1.21 |

| from (ft) | 1318.0 | 1498.5 | 1421.0 | 1269.5 | 1333.5 | 1299.0 | 1328.0 | 1362.5 | 1448 | 1453.5 | 1246 | 1483.5 | 1242.5 |

| to (ft) | 1354.0 | 1526.5 | 1446.5 | 1284.5 | 1370.0 | 1319.0 | 1330.5 | 1375.0 | 1512.5 | 1480.5 | 1599.5 | 1516.0 | 1251.5 |

| GT (Ft-%) | 24.7 | 44.7 | 11.5 | 4.5 | 7.1 | 7.3 | 0.5 | 16.1 | 93.6 | 39.1 | 8.71 | 49.3 | 4.3 |

Note: WT-35 and WT-42 represent

cumulative intercept intervals; WT-5 and WT-7 are re-logs of historical holes

WT-36 , WT-38, and WT-40 did not encounter +0.15% mineralization

* Two

0.5 ft intervals at 10.3% and 18.4%,

respectively in WT-39

** Two 0.5 ft intervals

capped at 7.0% in WT-39 - results in 1.29%

average grade

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page iv |

History

The Arizona Uranium Breccia Pipe District was prospected for uranium in the 1950s and again in late 1970s, after uranium was discovered in copper bearing breccias, such as those in the Orphan Mine in the Grand Canyon. This region produced approximately 23 M lbs of U3O8 prior to the decline of uranium prices in the late 1980s. Most deposits are small to intermediate in size, with a typical breccia pipe having dimensions of 300 ft. in diameter and 2,000 ft. or more vertically.

The Wate Pipe contains several drill holes with + 0.50%, eU3O8 mineralization grades and an exploration potential (historically estimated resources) of between 70,000 tons grading 0.80% eU3O8 (1.1 million contained pounds eU3O8), and 146,000 tons grading 0.83% eU3O8 (2.4 million contained pounds eU3O8). This exploration potential, or historically reported non-CIM-compliant resources/reserves for the Wate Pipe, cannot be relied upon until adequately demonstrated with sufficient drilling. Historical drilling encountered reported “ore grade” mineralization in 17 of 23 drillholes.

Geology

The high-grade uranium deposits in breccia pipes in northern Arizona were deposited in solution-collapse features that originated in the Mississippian Redwall Limestone and propagated upward through the overlying Pennsylvanian and Permian redbeds and sandstones during several periods of karstification. Uranium was deposited after karstification.

As uranium dissolved in groundwater moved northward from southern Arizona through the sandstones during the early Mesozoic (~200 Ma), it was channeled by the impermeable layers above and below the sandstones. Uranium minerals precipitated in reducing environments influenced by the pre-existing sulfides or hydrocarbon-bearing material present in the limestones, shales, siltstones, and sandstones. This results in concentrations of uranium mineralization in the open space of near vertical sub-cylindrical breccia bodies, which occur in sections of the nearly flat-lying upper Paleozoic sedimentary rocks that comprise the Colorado Plateau on both sides of the Grand Canyon.

Resources – Wate Pipe

The Wate Pipe had an internal company-derived mineral resource completed in the late 1980s, which is not compliant with current CIM standards for reporting mineral resources. VANE gathered the historical information in 2008, conducted drillhole validations through re-entering historical drillholes and re-logging (gamma-logs) in 2009 and 2010, and drilled several new drillholes in 2010. Not all the historical information is available, yet there is sufficient drillhole information to allow for definition of mineralized shapes for the historically defined mineralization. SRK modeled the mineralization in four discrete zones within the Wate Pipe, and completed resource estimation by industry standard procedures that are compliant with CIM definitions for NI 43-101 reporting.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page v |

Table 20-2: Current Inferred Resources for the Wate Pipe at 0.15%eU3O8cutoff

| Wate Breccia Pipe

Inferred Resource 0.15% eU3O8 Cutoff* | |||||

| Zone | Cutoff | U3O8% | Tons (000) | lb-U3O8 (000) | |

| 1 | 0.15 | 0.84 | 58 | 971 | |

| 2 | 0.15 | 0.61 | 11 | 130 | |

| 3 | 0.15 | 0.31 | 2 | 10 | |

| 4 | 0.15 | 0.58 | 1 | 7 | |

| 0.79 | 71 | 1,118 | |||

* Note: Inferred Uranium resources refers to global in-place CIM definitions of resources to which a mine design has not yet been applied; although the above stated resources meet the definition of having the “potential for economic extraction” at the cutoff provided. Resources are current, effective as of March 22, 2011, the date of the most recent drilling information.

A 0.15% eU3O8 cutoff equates to an in-place dollar value per ton, at a $38/lb U3O8 price, of $114/ton; deemed more than sufficient to cover the cost of mining and processing a ton of material. The natural lower threshold of mineralization in the Wate Pipe is approximately 0.15% eU3O8 as well. Both suggest that a 0.15% cutoff grade is acceptable for Wate.

Property, Mining Rights, and Location

Through acquisition of VANE’s interests in Wate Mining LLC, Energy Fuels is the current Manager of the Property. Energy Fuels and joint venture partner U1 hold the Project property through a state mineral exploration permit on Arizona State lands, which is in the process of conversion to a mining lease.

Exploration/Development Potential

The SRK estimate of resources for the Wate Uranium Breccia Pipe is conservative with respect to historical estimates of tonnage, yet similar in grade, in large part due to the minimal amount of historical drilling data available for the Project. VANE acquired historical reports that state the intercepts in all historical drillholes; however, the gamma logs and geological logs that back up the historical intercept data were not available to VANE. Therefore, SRK used the historical intercept data, some of which has been verified by VANE re-logging, to generate the mineralized shapes within which resource estimation was done using only VANE generated data. In SRK’s opinion, further drilling or acquisition (if possible) of the historical data will allow for a better estimate of the in-situ resources and the potential of increasing the total tonnage and contained pounds of uranium mineralization. Section 16 discusses this further.

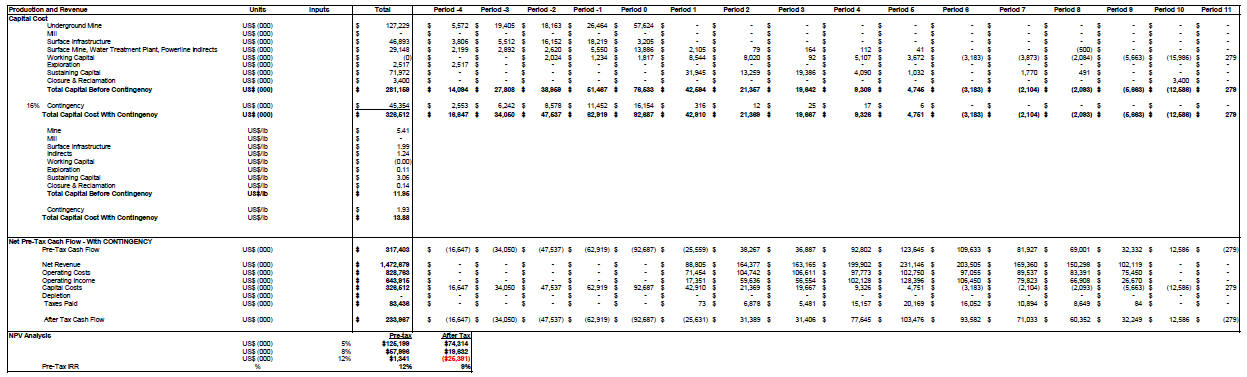

Mining

Underground mining methods are typically used for uranium breccia pipes (Wenrich and others, 1995). Historically mined breccia pipes north of the Grand Canyon were accessed by shaft and decline, and were mined by standard open-stope methods.

The Wate Project is near the stage of mining considerations, as resources are defined; however, drilling confirmation of additional historical drillholes will provide greater confidence in the current resource. SRK understands that Energy Fuels and venture partner U1 may seek to complete additional confirmation drilling. The Wate Pipe could advance rapidly from resource estimate to underground exploration and development planning within a six-to-twelve month period without further confirmation drilling.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page vi |

Metallurgy and Processing

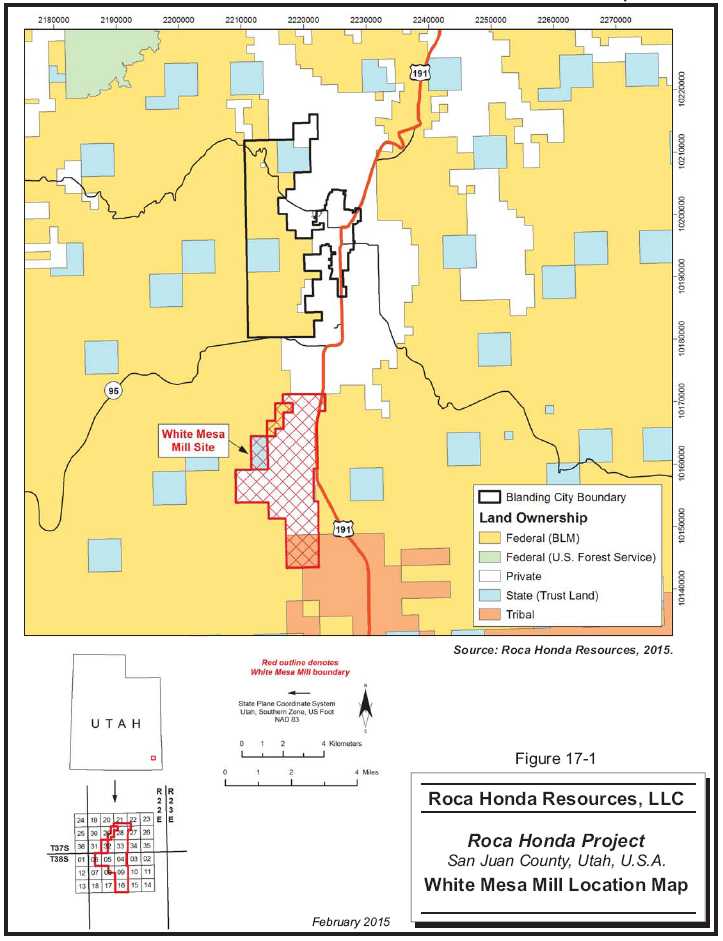

This Project has had no mineral processing or metallurgical testing done, however core samples have been assembled by VANE for this purpose. Historical mining of this deposit type in Arizona developed ores processed by conventional uranium milling technology. Historically, ore was shipped to a mill in Tuba City, AZ, and in the 1980s, uranium ores were shipped to the White Mesa mill in Blanding, Utah. The Shootaring Mill, located in southeastern Utah and owned by Uranium One, was constructed in the 1980s and operated on a test basis. The White Mesa mill, owned and opearated by Energy Fuels is in operation. It is anticipated that future production from the Wate Pipe would be processed at Energy Fuel’s White Mesa mill in Utah; a distance by road for truck-hauling of approximately 390 miles.

Milled uranium ore is processed by either acid or alkaline solutions, and uranium is precipitated by either ion-exchange or solvent extraction – industry standard processes. The product, commonly ammonium diuranate, is called “yellowcake” because of its color (Cooper, 1986).

Infrastructure

The portion of the Colorado Plateau south of the Grand Canyon has excellent infrastructure (roads and power) and an established diverse mining industry with a history of past uranium production.

Environmental/Permitting

SRK is unaware of any environmental liabilities for the Project with respect to additional exploration drilling at the Wate Pipe. The author is not a Qualified Person with respect to environmental issues. However, a brief site visit indicated there was little disturbance to the ground by previous drilling. Drillholes from the 1980s were only discovered because the capped drill casing extended above the soil by at least 6 inches; in other cases, there was no surface sign of drillholes other than scattered drill cuttings. The footprint of the breccia pipe exploration targets and historical mines are quite small, easily being located on about 25 acres. Permitting at this stage of the Project is handled as Plans of Operations through the Arizona State Land Department.

U1 initiated, and VANE completed a Mineral Development Report (MDR) for submission to the Arizona State Land Department. The MDR addresses, at scoping level of study, the mining processing and eventual closure and reclamation of the Project, for the purpose of obtaining a mining lease with an established production royalty rate payable to the state of Arizona. The MDR is reportedly in the final stages of approval (pers. Comm. K. Hefton, 2015) by the Arizona State Land Department. Approval of the MDR will allow for commercial mining, subject to obtaining requires environmental permits.

Conclusions and Recommendations

The VANE-U1 joint venture’s exploration expenditures from November 2008 to the completion of drilling (March 2011) on the Project is approximately US$1,364,000; primarily for drilling.

The Project represents an attractive advanced-stage exploration property with current estimated resources established of over 1.0 million pounds eU3O8, and the potential to increase the total resource tons and contained pounds with additional confirmation drilling. Energy Fuels considers the mineral resources at the Wate Pipe to be sufficiently as a minimum threshold for a decision to proceed underground to allow for detailed drill definition of the resources.

The Project has all the inherent opportunity and/or risk associated with a resource stage property, including quantity and quality of the resource database, commodity price fluctuations, defining metallurgical characteristics, and addressing permitting and potential mining options.

SRK recommends an additional drilling program to advance the Project to a point of maximum resource definition, and the potential for project development. This can best be accomplished by additional drilling from an exploration shaft rather than by drilling from surface.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page vii |

Prior to committing to an exploration shaft, SRK recommends a scoping level study and preliminary economic assessment to determine the potential economic viability of the project and the break-even resource to justify a decision to go underground.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page viii |

Table of Contents

| Summary (Item 1) | ii | |||

| 1 | Introduction (Item 2) | 1 | ||

| 1.1 | Terms of Reference and Purpose of the Report | 1 | ||

| 1.1.1 | Sources of Information | 1 | ||

| 1.1.2 | Terms of Reference | 1 | ||

| 1.1.3 | Definitions of Terms | 2 | ||

| 1.1.4 | Purpose of Report | 2 | ||

| 1.1.5 | Conclusions and Recommendations | 2 | ||

| 1.2 | Sources of Information | 2 | ||

| 1.3 | Mineral Resources Statements | 2 | ||

| 1.4 | Qualifications of Consultants (SRK) and Site Visit | 2 | ||

| 1.5 | Effective Date | 3 | ||

| 2 | Reliance on Other Experts (Item 3) | 4 | ||

| 3 | Property Location and Description (Item 4) | 5 | ||

| 3.1 | Property Location | 5 | ||

| 3.2 | Mineral Titles | 5 | ||

| 3.2.1 | Mineral Rights in Arizona | 5 | ||

| 3.2.2 | Requirements to Maintain the Claims in Good Standings | 5 | ||

| 3.2.3 | Mining Venture Agreement | 6 | ||

| 3.2.4 | Exceptions to Title Option | 6 | ||

| 3.3 | Royalty Agreements and Encumbrance | 6 | ||

| 3.3.1 | Required Permits and Status | 7 | ||

| 3.4 | Environmental Liabilities | 7 | ||

| 4 | Accessibility, Climate, Local Resources, Infrastructure and Physiography (Item 5)10 | |||

| 4.1 | Access to Properties | 10 | ||

| 4.2 | Climate | 10 | ||

| 4.2.1 | Vegetation | 10 | ||

| 4.3 | Physiography | 10 | ||

| 4.4 | Local Resources and Infrastructure | 11 | ||

| 4.4.1 | Access Road | 11 | ||

| 4.4.2 | Water Supply | 11 | ||

| 4.4.3 | Electrical Power Supply | 11 | ||

| 4.4.4 | Buildings and Ancillary Facilities | 11 | ||

| 4.4.5 | Population | 11 | ||

| 4.4.6 | Economy | 11 | ||

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page ix |

| 4.4.7 | Local Resources | 12 | ||

| 4.4.8 | Regional Infrastructure | 12 | ||

| 5 | History (Item 6) | 14 | ||

| 5.1 | Ownership | 14 | ||

| 5.1.1 | Wate Pipe | 14 | ||

| 5.1.2 | Project Expenditures | 15 | ||

| 5.2 | Historic Mineral Resource Estimates | 15 | ||

| 6 | Geologic Setting (Item 7) | 18 | ||

| 6.1 | Regional Geology | 18 | ||

| 6.1.1 | Geology of Breccia Pipes | 18 | ||

| 6.1.2 | Other Productive Uranium Breccia Pipes in the Region | 20 | ||

| 6.2 | Local Geology | 21 | ||

| 6.2.1 | Local Lithology | 21 | ||

| 6.2.2 | Alterations | 23 | ||

| 6.2.3 | Structure | 23 | ||

| 6.2.4 | Mineralization | 23 | ||

| 7 | Deposit Types (Item 8) | 28 | ||

| 8 | Exploration (Item 9) | 29 | ||

| 8.1 | Wate Pipe – VANE Exploration | 29 | ||

| 8.2 | Geophysical Surveys | 29 | ||

| 8.3 | Summary | 30 | ||

| 9 | Drilling (Item 10) | 33 | ||

| 9.1 | Drill Results from Wate Pipe | 34 | ||

| 9.2 | Planned Drilling | 35 | ||

| 9.3 | Recommendations | 35 | ||

| 10 | Sampling Preparation, Analysis and Security (Item 11) | 39 | ||

| 10.1 | RC/Rotary/ Spot Core Drilling | 39 | ||

| 10.2 | Wireline Diamond Core Drilling | 39 | ||

| 10.3 | Gamma Logging | 39 | ||

| 10.4 | Analytical Procedures | 40 | ||

| 10.5 | Sample Preparation and Assaying | 40 | ||

| 10.6 | Quality Controls and Quality Assurance | 40 | ||

| 10.7 | Sample Security | 40 | ||

| 10.8 | Analytical Laboratory Certification | 41 | ||

| 10.9 | Radiometric Analyses | 41 | ||

| 11 | Data Verification (Item 12) | 44 | ||

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page x |

| 12 | Mineral Processing and Metallurgical Testing (Item 13) | 46 | ||

| 13 | Mineral Resource Estimate (Item 14) | 47 | ||

| 13.1 | Drillhole Database | 47 | ||

| 13.2 | Assay Data – Population Domain Analysis | 52 | ||

| 13.3 | Mineralization Envelopes | 54 | ||

| 13.4 | Composition | 59 | ||

| 13.5 | Specific Gravity Measurements (Bulk Density) | 59 | ||

| 13.6 | Block Models | 59 | ||

| 13.7 | Mineralization Zones | 59 | ||

| 13.8 | Dynamic Anisotropy and Search Orientation | 60 | ||

| 13.9 | Mineralization Indicator Assignment, Zones 2-4 | 61 | ||

| 13.10 | Domain Assignment, Zone 1 | 61 | ||

| 13.11 | Grade Estimation and Resource Classification Criteria | 64 | ||

| 13.12 | Block Model Validation & Mineral Resource Sensitivity | 69 | ||

| 13.13 | Resource Statement | 69 | ||

| 13.14 | Sensitivity of the Resource Model | 70 | ||

| 13.15 | Conclusions and Recommendations | 70 | ||

| 14 | Items 15 through 22) | 69 | ||

| 15 | Adjacent Properties (Item 23) | 70 | ||

| 16 | Other Relevant Data and Information (Item 24) | 71 | ||

| 17 | Interpretation and Conclusion (Item 25) | 73 | ||

| 17.1 | Categories of Opportunity and Risk | 73 | ||

| 17.1.1 | Resources | 73 | ||

| 17.1.2 | Commodity Price Fluctuation | 73 | ||

| 17.1.3 | Infrastructure | 73 | ||

| 17.1.4 | Development Decision | 73 | ||

| 17.1.5 | Metallurgical Characteristics | 74 | ||

| 17.1.6 | Environmental/Socio-Economic Considerations | 74 | ||

| 18 | Recommendations (Item 26) | 75 | ||

| 18.1 | Proposed Scoping Study – Phase I | 75 | ||

| 18.2 | Phase II | 75 | ||

| 19 | References (Item 27) | 77 | ||

| 20 | Glossary (Item 27) | 79 | ||

| List of Abbreviations | 80 | |||

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page xi |

List of Tables

| Table 1-1: | Significant Drill intercepts for the Wate Pipe at 0.15% eU3O8 cutoff | iii |

| Table 1-2: | Current Inferred Resources for the Wate Pipe at 0.15% eU3O8 cutoff | v |

| Table 4-1: | Physiography of Wate Pipe Area | 11 |

| Table 5-1: | May 2010 Inferred Resources for the Wate Pipe at 0.15% eU3O8 cutoff | 16 |

| Table 5-2: | May 2010 Inferred Resources for the Wate Pipe at 0.15% eU3O8 cutoff | 16 |

| Table 9-1: | Summary of VANE Drilling Wate Breccia Pipe | 34 |

| Table 9-2: | Summary of VANE Drilling (including washouts of historical holes) | 35 |

| Table 11-1: | Comparison of Historical and VANE re-logs for WT-5 and WT-7 | 45 |

| Table 13-1: | Selected Historical Drillhole Intercepts – Wate Pipe | 50 |

| Table 3-2: | Drillhole Database Statistics – VANE Drillholes (SRK, April 2011) | 51 |

| Table 13-3: | Wate Pipe Zone 1 Grade Population Cutoff Thresholds | 54 |

| Table 13-4: | Zone 1 Composite Summary Statistics | 59 |

| Table 13-5: | Wate Pipe Model Limits | 59 |

| Table 13-6: | Estimation Parameters (Domain 0) | 64 |

| Table 13-7: | Estimation Parameters (Domain 1) | 66 |

| Table 13-8: | Contiguous 0.5ft Higher-Grade intercepts WT-05 & WT-29A | 69 |

| Table 13-9: | Inferred Resource by Zone & Total | 69 |

List of Figures

| Figure 3-1: | Energy Fuels Uranium Breccia Pipe Project Location Map | 8 |

| Figure 3-2: | Location of Wate Pipe. Section 32, T31N R5W (SRK 2010) | 9 |

| Figure 4-1: | Regional Access Roads and Surface Land Ownership in Vicinity of the Wate Pipe | 13 |

| Figure 5-1: | Plan Map and Drillhole traces of Historic Drillholes at the Wate Breccia Pipe (2008) | 17 |

| Figure 6-1: | Geologic Map of Arizona | 25 |

| Figure 6-2: | Stratigraphic Position of Ore in Uranium Breccia Pipes | 26 |

| Figure 6-3: | Characteristics of Uranium Breccia Pipes, Northern Arizona | 27 |

| Figure 8-1: | Wate Pipe Looking Southwest (January 2009) | 31 |

| Figure 8-2: | Typical Breccia Pipe Surface Expression - Miller Pipe Looking Southwest | 32 |

| Figure 9-1: | Locations of VANE and Historic Drillholes at the Wate Breccia Pipe | 37 |

| Figure 9-2: | Sketch Cross Section – Wate Pipe Historical Drillholes | 38 |

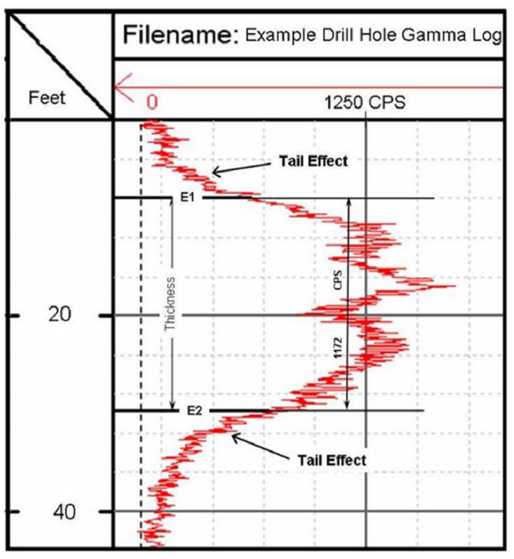

| Figure 10-1: | Example Gamma Log -- Half-Amplitude Method | 43 |

| Figure 13-1: | Cross Section of Historical and VANE drillholes (SRK 2011 | 48 |

| Figure 13-2: | Cross Section of Historical and VANE drillholes (SRK 2011) | 49 |

| Figure 13-3: | Wate Pipe Cumulative Relative Frequency Distribution (SRK 2011) | 52 |

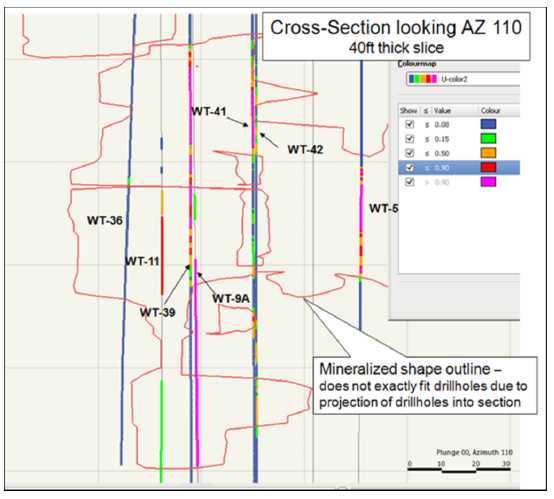

| Figure 13-4: | Cross-Section of Mineralized Drillholes and 2-D strings (SRK 2010) | 55 |

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page xii |

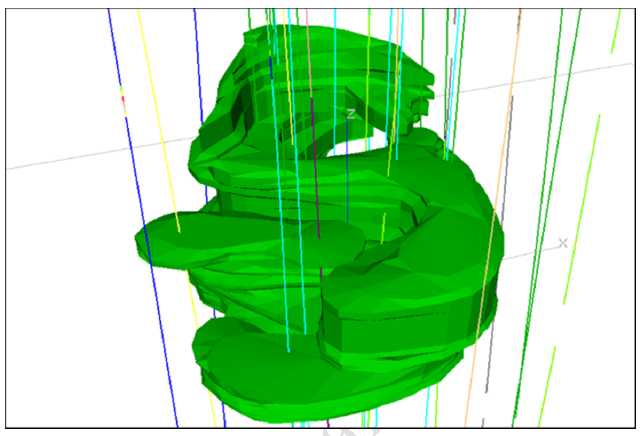

| Figure 13-5: | Oblique View of 2010 Mineralized Shape (SRK 2010) | 56 |

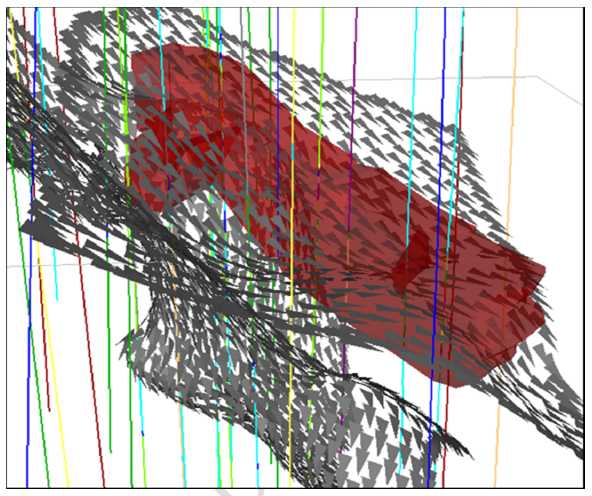

| Figure 13-6: | Oblique View of 2010 Mineralized Shape (SRK 2010) | 57 |

| Figure 13-7: | Plan View delineation (SRK 2011) | 57 |

| Figure 13-8: | Zone 1 Grade shell (SRK 2011) | 58 |

| Figure 13-9: | Wate Breccia Pipe and Mineralized Zones (SRK 2011) | 60 |

| Figure 13-10: | Wate Pipe Mineralized Zone 1 and Anisotropy Points (SRK 2011) | 61 |

| Figure 13-11: | Wate Pipe and Domains 1(Red) 0 (Green) (SRK 2011) | 63 |

| Figure 13-12: | Wate Pipe Anisotropy Points and Domain 1 (SRK 2011) | 64 |

| Figure 13-13: | Wate Pipe Estimated Blocks and Anisotropy Points (SRK 2011) | 67 |

| Figure 13-14: | Wate Pipe Estimated Blocks and Domain 1 Shell (SRK 2011) | 68 |

| Figure 13-15: | Wate Pipe Estimated Blocks, Drillholes WT-05 & WT-29A (SRK 2011) | 68 |

Appendices

Appendix A: Author Certificates

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 1 |

| 1 |

Introduction (Item 2) |

| 1.1 |

Terms of Reference and Purpose of the Report |

| 1.1.1 |

Sources of Information |

In 2007, VANE entered into a Letter of Intent with Uranium One Exploration U.S.A. Inc. (U1), and subsequently signed a Mining Venture Agreement (the Agreement or the “JV”) with U1 effective September 01, 2008, covering approximately 30 breccia pipe targets controlled by U1. The JV subsequently acquired 16 breccia pipe properties from Neutron Energy Inc. through an agreement signed June 3, 2009. The collective properties are either drill discovery stage projects with known mineralized intercepts, or are prospects not yet evaluated by drilling that exhibit surface features similar to known breccia pipes. One property in the portfolio, the Wate Pipe, has current mineral resources. The Wate Pipe, upon completion of current resource estimation in 2011, was spun off into Wate Mining LLC (the “LLC”), a joint operating company for which initially U1 was Manager, and subsequently VANE became Manager. In February 2015, VANE sold its 50% Interest in the LLC to Energy Fuels.

The Arizona Uranium Breccia Pipe District is located in northern Arizona on extensive, nearly flat plateaus dissected by canyons. The breccia pipes are nearly cylindrical collapse features up to 300 ft. in diameter or greater, and as much as 3,000 ft in vertical extent. Past producing mines in the region contained the highest-grade uranium deposits in the U.S. The uranium is concentrated in ring dikes, fractures, and coatings on the pipe infill breccia material, which consists of fragments of Mississippian through Triassic sedimentary rock formations.

This report is prepared for Energy Fuels, and includes discussion of the change of owners, and work completed on the project since resource were reported in a NI-43-101 technical report for VANE and U1 in May 2011.The report includes discussion of VANE’s exploration information gathered since the formation of the JV in September 2008, including information on the Project acquired through the Agreement with U1, and presentation of the current mineral resource estimate for the Wate Pipe, dated 2011. This Technical Report uses currently available project information, as of the effective date this report. This report has been prepared at the request of Energy Fuels Resources (US) Inc., with offices at 225 Union Blvd., Suite 600, Lakewood, CO, 80228. Energy Fuels is listed on the NYSE MKT under the symbol “UUUU, and on the Toronto Stock Exchange under the symbol “EFR” (web site: www.energyfuels.com). This report is prepared for the benefit of Energy Fuels.

| 1.1.2 |

Terms of Reference |

VANE initially commissioned SRK Consulting (U.S.), Inc. (SRK) in January 2010 to prepare a report compliant with the Canadian National Instrument 43-101 (NI 43-101) requirements on the Wate Uranium Breccia Pipe. The report titled “NI 43-101 Technical Report on Resources, Wate Uranium Breccia Pipe” and dated May 19, 2010, describes the initial resource estimate. That report was updated on November 04, 2010 with additional drillhole information, and again in 2011 with information from the most current drilling, VANE drillhole WT-42, as of March 22, 2011. This technical report on mineral resources is prepared according to NI 43-101 guidelines for the benefit of Energy Fuels, based on the current mineral resources (2011). NI 43-101 regulations, as revised in 2011, have been used as the format for this report.

This report is prepared using the industry accepted CIM “Best Practices and Reporting Guidelines” for disclosing mineral exploration information, and the Canadian Securities Administrators revised regulations in NI 43-101 (Standards of Disclosure For Mineral Projects), and Companion Policy 43-101CP. This report on resources is compliant with “CIM Standards on Mineral Resources and Reserves: Definitions and Guidelines” (November 2010).

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 2 |

| 1.1.3 |

Definitions of Terms |

This report generally uses American units of measure, as these are the commonly used units of measure in the United States. Analytical results are reported as parts per million (ppm) contained for uranium (the element U, often analyzed for and expressed as U3O8). This report will state uranium determinations by the equivalent of chemical analyses as percent (%) U3O8. This report will state uranium determinations by conversion of radiometric probe measurements (gamma logs) as percent (%) eU3O8 (“e” for equivalent). Uranium and some elements may be reported as percent (%), and trace elements are commonly reported in parts per million (ppm).

Tables and Figures are numbered consecutively and referenced in the major sections of the report.

Market prices are reported in US$ per pound of U3O8. Tons are short tons of 2,000 lbs.

Energy Fuel’s Wate Uranium Breccia Pipe (the Project) is here referring to the U1 held property contributed to the Mining Venture Agreement dated September 01, 2008 (the Agreement or the “JV” with VANE Minerals (US) LLC), and subsequently transferred to the Operating Agreement for Wate Mining Company LLC, dated February 23, 2011.

| 1.1.4 |

Purpose of Report |

The purpose of this report is to provide the reader with a review of the exploration activities conducted on the Wate Uranium Breccia Pipe, a discussion of the geology of the exploration targets, known deposits and the deposit model, a discussion of historical and current exploration results, and presentation of current mineral resource estimates for the Wate Pipe.

| 1.1.5 |

Conclusions and Recommendations |

SRK concurs that the geological evidence, historical exploration, evidence of uranium mineralization, and VANE’s exploration results from 2009 through 2011 support the Project as a viable exploration program for breccia pipe-hosted uranium mineralization, and support the resources stated for the Wate Pipe. SRK recommends that Energy Fuels continue confirmation drilling on the Wate Pipe with the goal of further defining the uranium resources, preferably through underground exploration and fan drilling from an exploration shaft.

| 1.2 |

Sources of Information |

The authors reviewed data provided by VANE and from publicly available sources, and conducted field investigations to confirm the data. Those data sources include hard copy data and files and digital files located in the offices of VANE in Tucson, Arizona. VANE’s geologist and Chief Operating Officer, Kris Hefton, facilitated the data review and onsite investigations, and provided historical and Project information. The Atomic Energy Commission and the U.S. Geological Survey generated publicly available data on the district. Private exploration data for the Project was derived from the exploration activities of prior historical mining and exploration companies.

| 1.3 |

Mineral Resources Statements |

Mineral resources, as estimated by SRK for the Wate Pipe, are stated in Section 16 of this report.

| 1.4 |

Qualifications of Consultants (SRK) and Site Visit |

Allan V. Moran, R.G., C.P.G.

Allan Moran conducted a site review of the Project on January 07, 2009; and conducted a review of data and maps in the offices of VANE Tucson, Arizona, on December 10, 2008 and reviewed additional information in August of 2010, in January and February of 2011, and in March of 2015. Mr. Moran is a “Qualified Person” as defined by NI 43-101, is the primary author, and is the Qualified Person responsible for all sections of this report.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 3 |

Frank A. Daviess, MAusIMM., Resource Geologist

Frank Daviess is a “Qualified Person” as defined by NI 43-101, and is the Qualified Person responsible for the resources reported for the Wate Pipe in Section 16 of this report. He has not visited the Wate Pipe.

| 1.5 |

Effective Date |

The effective date of this report, March 22, 2011, is the date SRK received the most current drillhole database information for the Wate Uranium Breccia Pipe, through VANE’s drillhole WT-42. There has been no additional drilling since 2011. The updated resource estimation presented in this report is based on data received as of that date. All other information is current as of the report date of March 10, 2015.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 4 |

| 2 |

Reliance on Other Experts (Item 3) |

The author, as a Qualified Person, has relied upon VANE for the basic data that supports the Project exploration results. SRK has examined the project data and in the opinion of the authors, that information is both credible and verifiable in the field. It is also the opinion of the author that no material information relative to the Project has been purposely neglected or omitted from the database. Sufficient information is available to prepare this report, and any statements in this report related to deficiency of information are directed at historical information that is missing or information which, in the opinion of the authors, has not yet been gathered, is intended to be gathered, or is recommended information to be collected as the project moves forward.

The Authors have relied on the work of others (VANE) to describe the land tenure and land title in Arizona (Section 3.2 – Mineral Titles); and the data appear credible. The author is not qualified with respect to environmental laws in Arizona, as regarding issues addressed in Section 3.4 of this report – Environmental Liabilities; however, the environmental issues noted are considered minimal.

This report includes technical information, which requires subsequent calculations to derive subtotals, totals, and weighted averages. Such calculations inherently involve a degree of rounding and consequently can introduce a margin of error. Where these rounding errors occur, SRK does not consider them material.

The author’s statements and conclusions in this report are based upon the information at the time of the property visits, and the exploration database as of the effective date of this report. Surface exploration has ceased as of the date of this report while the next phase of the Project is determined. It is to be expected that new data and exploration results may change some interpretations, conclusions, and recommendations going forward.

The author and SRK are not insiders, associates, or affiliates of Energy Fuels, VANE or its parent company, or of U1. The results of this Technical Report are not dependent upon any prior agreements concerning the conclusions to be reached, nor are there any undisclosed understandings concerning any future business dealings between Energy Fuels, VANE, U1, and the authors or SRK. SRK will be paid a fee for its work in accordance with normal professional consulting practice.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 5 |

| 3 |

Property Location and Description (Item 4) |

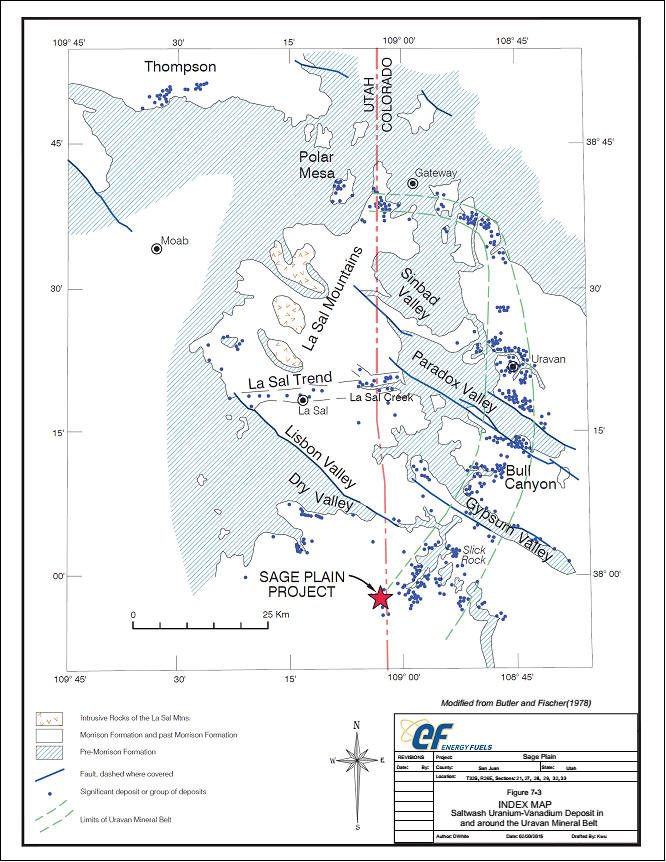

The Wate Project is located in the northwestern part of Arizona in the Colorado Plateau physiographic province. The breccia pipe uranium district of northern Arizona produced approximately 23 Mlbs of U3O8 prior to the decline of uranium prices in the mid-1980s. Existing resources of about 13 Mlbs of U3O8 have been reported to be contained in several breccia pipes, and the rise in uranium prices since 2005 has spurred exploration activity and plans by some companies to reactivate existing mines. Most breccia pipe deposits are small to intermediate in size (1 to 6 million contained pounds U3O8).

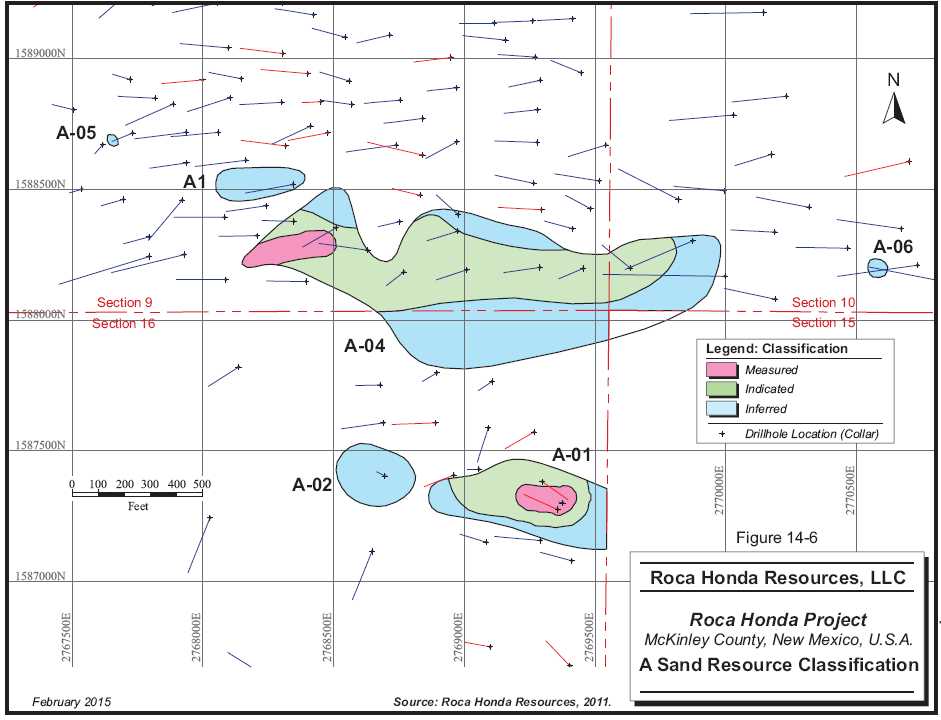

The Wate Pipe has uranium mineralization verified by VANE drilling, and a historically determined potential of 1.1 to 2.4 million contained pounds eU3O8. Current Inferred resources for the Wate Pipe stand at 71,000 tons grading 0.79% eU3O8, for 1,118,000 contained in-situ pounds U3O8. The Wate Pipe is similar to breccia pipes that have been historically mined.

The Wate Pipe is located on 160 acres in a single square parcel, which is the subject of a Mineral Lease application, described as the S ½ of the NE ¼ and the N ½ of the SE ¼ of Section 32, Township 31 North, Range 5 West. All of Section 32 is State of Arizona land; surface and mineral ownership, held by Energy Fuels under Prospecting Permit until approval of the Mineral Lease is finalized.

| 3.1 |

Property Location |

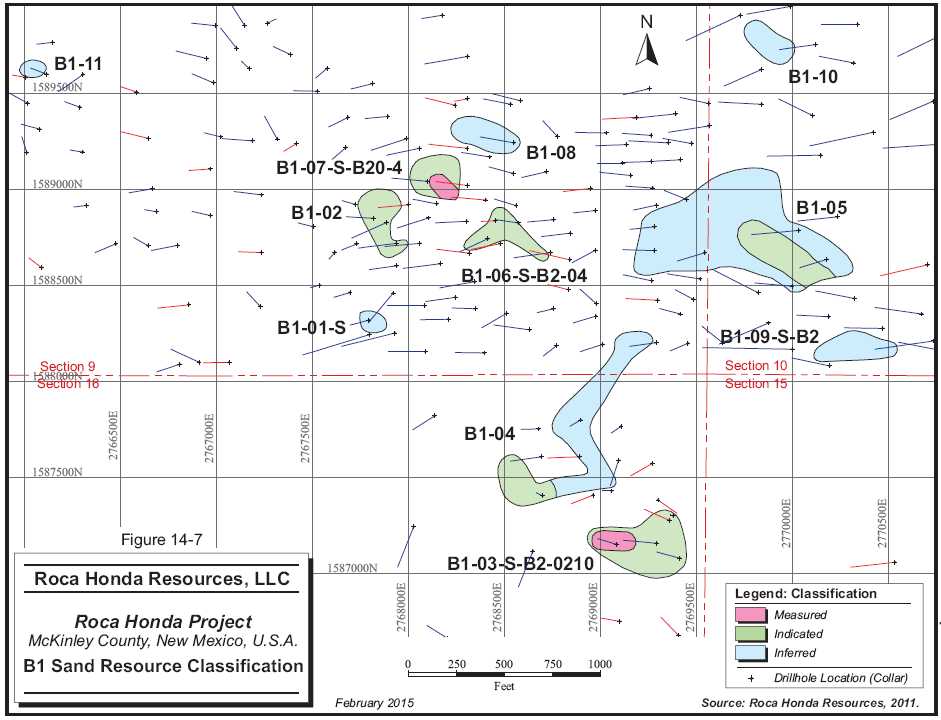

The Wate Uranium Breccia Pipe is shown with respect to other uranium breccia pipe occurrences in the Colorado Plateau of Arizona in Figure 3-1.

The Wate Pipe is located approximately 5 mi NW of Indian Route 18 (to Hualapai Hilltop), which runs NE from Route 66 approximately 5 miles west from Grand Canyon Caverns. The Wate Pipe is located on State Land and is located approximately 9 mi south of the Grand Canyon National Park boundary. The Wate Pipe is held by VANE under Arizona State Land Exploration Permit No. 08-113503, renewed July 9, 2010), and is part of the Agreement between VANE and U1, now U1 and Energy Fuels. The Wate Pipe is located in the southeast quarter of Section 32, T31N, R5W (Figure 3-2. The former owner (Rocky Mountain Energy) completed a minimum of 23 historical drillholes at Wate. They encountered significant uranium mineralization from 1,300 to 1,600 feet in depth in 17 of the 23 drillholes, with a reported average grade to the mineralization of +0.80% eU3O8.

| 3.2 |

Mineral Titles |

Information relating to the exploration permit on State Land is on file with the Arizona State Land Department.

| 3.2.1 |

Mineral Rights in Arizona |

State Mineral Exploration Permits are issued by the Arizona State Land Department, 1616 W. Adams Street, Phoenix, Arizona, 85007, USA, and use the specified “ ¼ ¼ ¼ Section” designator for township/range/section system that conforms to the original General Land Office cadastral survey in use in the western states since the late 1800s.

SRK did not verify land ownership, but did examine evidence of the Arizona State Mineral Exploration Permit; and, SRK did verify the project lands as Arizona State lands.

A 2012 U.S. Department of Interior Record of Decision to withdraw approximately 1 million acres of U.S. Forest Service lands around the Grand Canyon National Park from mineral exploration and development activity, as further describes in Section 17 of this report, does not affect private or Arizona State Lands, including the Wate Pipe.

| 3.2.2 |

Requirements to Maintain the Claims in Good Standings |

State Mineral Exploration Permits have a life of 5 years and require annual combined payments and expenditures of $11 per acre for years 1 and 2, $21 per acre for years 3 and 4, and require conversion to a Mineral Lease prior to development. The Mineral Exploration Permit is in the process of being converted to a Mineral Lease.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 6 |

| 3.2.3 |

Mining Venture Agreement |

A Mining Venture Agreement between VANE Minerals (US) LLC and Uranium One Exploration U.S.A. Inc. (U1) dated September 01, 2008 (Agreement or the “JV”) applies to the Wate Uranium Breccia Pipe property position. The Agreement between VANE and U1 (now Energy Fuels and U1) has the following general provisions:

| • |

Each party to the Agreement has a vested 50% interest; | |

| • |

VANE shall be the Manager of the project operations and shall have a 51% vote on the Management Committee during Exploration Evaluations; | |

| • |

At such time as the Manager or the Management Committee determine or recommend that a property or target undertake a Prefeasibility Evaluation or a Production Feasibility Study, the property shall be conveyed into a Target LLC (limited liability company) that will function independently from the Agreement; | |

| • |

U1 shall be the Manager of the Project operations and shall have a 51% vote on the Management Committee relating to Prefeasibility Evaluations, Productions Feasibility Studies, all mining and milling operations, and all feasibility, development, and mining conducted after formation of a Target LLC; | |

| • |

The Term of the Agreement is until December 31, 2012 unless sooner terminated or the parties mutually agree to an extension; | |

| • |

There is an Area of Interest that encompasses all the existing properties, and allows for inclusion of additional properties at each participants percentage interest; | |

| • |

There are provisions for annual Work Plans and Budgets to be determined by the Management Committee; | |

| • |

Expenditures will be shared according to the participant’s ongoing interest in the Agreement, beginning at 50% each; with allowance for dilution; and | |

| • |

The Agreement includes the form and general content of a Target LLC agreement, including accounting principles, calculation of royalty interest, and transfers of interest. The Wate Mining Company LLC has been organized and registered with the Arizona Corporation Commission. |

The Agreement does not include VANE or U1 properties on the north rim of the Grand Canyon.

On February 23, 2011, VANE and U1 signed the Operating Agreement for Wate Mining Company LLC (the Operating Agreement), which segregated the Wate Pipe from the exploration JV. Initially U1 was the Manager of the Operating Agreement.

On April 15, 2011, Uranium One Exploration U.S.A. Inc. was merged into Uranium One Americas, Inc. (U1).

On May 25, 2012, VANE became Manager of the Operating Agreement.

On February 17, 2015, Energy Fuels announced in a press release (Energy Fuels In, Feb. 2015) the purchase of VANE’s rights and interests in the Operating Agreement, through its wholly-owned subsidiary EFR Arizona Strip LLC, and assumed VANE’s position as Manager of the Operating Agreement.

| 3.2.4 | Exceptions to Title Option |

There are no known exceptions to title known to the authors, or identified by Energy Fuels for the Wate Uranium Breccia Pipe.

| 3.3 |

Royalty Agreements and Encumbrance |

Application for conversion to a Mineral Lease has been completed. When converted to a state mining lease (Mineral Lease), a royalty is assigned by the State of Arizona – Energy Fuels has no State Mineral Lease for the Project presently. The assigned royalty is based on a valuation of the proposed mining project.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 7 |

To convert a State Mineral Prospecting Permit to a Mineral Lease, requires the submission of a Mineral Development Report (MDR) to the Arizona State Land Department. Work toward that end was the only significant work conducted on the Project since the mineral resources were estimated in 2011. Initiated by U1, and subsequently completed and filed with the Arizona State Land Department by VANE, the MDR is a comprehensive report that examines the potential for economic development, in order for the State to issue a Mineral Lease and assign a royalty rate.

The MDR was filed on November 19, 2012, and following public comment was revised on October 27, 20014. The process to convert to a Mineral Lease is well advanced, and in the final stages of State approval (pers. Comm., K.Hefton, 2015).

| 3.3.1 |

Required Permits and Status |

The state lands are covered by Arizona State Mineral Exploration Permits, which are administered by the Arizona State Land Department, and allow for exploration drilling once a Plan of Operations detailing the drilling program and including an archaeological and plant report, is submitted and approved.

Permits to conduct drilling on all lands in Arizona are further administered by the Arizona Department of Water Resources (ADWR). For exploration drilling, ADWR requires a Notice of Intent to Drill and Abandon an Exploratory/Specialty Well be filed with the ADWR. No other permits are required for exploration drilling.

Upon approval of a Mineral Lease, Energy Fuels will have State approval to mine, subject to receipt of operational Air Quality and Aquafer Protection Permits.

| 3.4 |

Environmental Liabilities |

SRK is unaware of any environmental liabilities for the Project, and no potential liabilities that would affect additional exploration drilling. Existing environmental liabilities are not described in any of the project files. The author is not a Qualified Person with respect to environmental issues. However, a brief site visit indicates there was little disturbance to the native ground by previous drilling. Drillholes from the 1980s were only discovered because, in some cases, the drill collar extended above the soil by at least 6 inches. The previous owner reclaimed all drill sites and many of the historical drillhole collars for the Wate Pipe have not been located.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 8 |

Figure 3-1: Energy Fuels Uranium Breccia Pipe Project Location Map

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 9 |

Figure 3-2: Location of Wate Pipe. Section 32, T31N R5W (SRK 2010)

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 10 |

| 4 |

Accessibility, Climate, Local Resources, Infrastructure and Physiography (Item 5) |

The Arizona Breccia Pipe District is located on the Colorado Plateau physiographic province. The portion of the Arizona Breccia Pipe District south of the Grand Canyon has excellent infrastructure including road networks, rail access, power, and proximity to population centers such as Flagstaff and Kingman for staging, services, and labor. An established diverse mining industry with a history of past production for uranium has been active in the Arizona Breccia Pipe District. Several uranium breccia pipe projects are being considered for development or re-activation. Energy Fuels currently mines uranium ores from the Pinenut mine, north of the Grand Canyon,; they are trucking ore to their White Mesa Mill near Blanding, Utah, approximately 310 miles.

| 4.1 |

Access to Properties |

Access to the Wate Pipe, as shown on Figure 3-2, is approximately 70 miles west on US Highway 40 from Flagstaff, Arizona to Seligman, then approximately 25 miles northwest on US Highway 66 to the community of Grand Canyon Caverns, continuing 45 miles via paved road Indian Route 18 northeast from 5 miles west of Grand Canyon Caverns, Arizona, then approximately 4.5 miles to the northwest on mostly unimproved dirt access roads to the southeast quarter of Section 32, T31N, R5W. Access is available year-round; a site visit was conducted in January 2009.

| 4.2 |

Climate |

The regional climate is semiarid, with hot, relatively dry summers and cold winters. According to the Western Regional Climate Center ([email protected]), the average annual precipitation at Flagstaff, Arizona, for 45 years was 22.7 in, with most of the precipitation occurring as rain during July and August with another minor maximum as snow in December and January. The average maximum temperature at the Flagstaff station during the winter months was between 42 and 49F and during the summer months was between 78 and 82F. The average minimum temperature at the Flagstaff station during the winter months was between 15 and 22F and during the summer months was between 41 and 51F (www.climate-zone/climate/united-states/arizona/flagstaff/). Flagstaff is approximately 100 miles in a straight-line distance southeast of the Wate Uranium Breccia Pipe, and at a slightly higher elevation.

| 4.2.1 |

Vegetation |

Range grasses and sagebrush cover the flat areas near the Wate Pipe. There are only limited commercial woodlands in the Kaibab National Forest, and none near the Wate Pipe.

| 4.3 |

Physiography |

The physiography of the Project area is characterized by a relatively flat plateau that is part of the Grand Canyon subsection of the Colorado Plateau physiographic province. The topography is determined by the resistance to erosion of the Kaibab Limestone of Permian age; therefore, the Kaibab limestone is the dominant lithology in outcrop in the area. When streams cut through the plateau cap rock, canyons are developed as the ephemeral streams cut down into the less resistant underlying formations. The area is drained through north- and northwestward-flowing creeks, such as Cataract Creek in Cataract Canyon, which flow down the dip-slope of the strata into the Colorado River and the Grand Canyon to the north of the Project area.

Surface water is scarce and ground water supplies are deep and limited. Summer rainstorms cause flash flooding in some of the areas. Few lakes or reservoirs are present. Grazing for sheep and cattle is the major land use, and the major support to the economy is tourism to the Grand Canyon, which is nearby. The Wate Uranium Breccia Pipe is on Arizona State lands outside the Grand Canyon National Park.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 11 |

Total relief of the Project topographic map quadrangle is approximately 200 ft. Altitudes range from 5,900 to 6,100 ft amsl.

Table 4-1: Physiography of Wate Pipe Area

Exploration Target |

1:24,000 Scale

Quadrangle Name |

Latitude of SE Corner |

Longitude of SE Corner |

Approximate Highest Elevation (ft) |

Approximate Lowest Elevation (ft) |

Approximate Amount of Relief (ft) |

| Wate Pipe | Higgins Tank | 3600’N | 11245’W | 6,100 | 5,900 | 200 |

| 4.4 |

Local Resources and Infrastructure |

Grand Canyon Caverns is a very small community of several families located on U.S. Highway 66, and is a local tourist stop en-route to the Hualapai Reservation, and is the nearest seasonal community to the Wate Pipe. Peach Springs, the largest town of the Hualapai Tribe, is located 6 miles west on U.S. Highway 66 from the Route 18 turn-off to the Wate Pipe

| 4.4.1 |

Access Road |

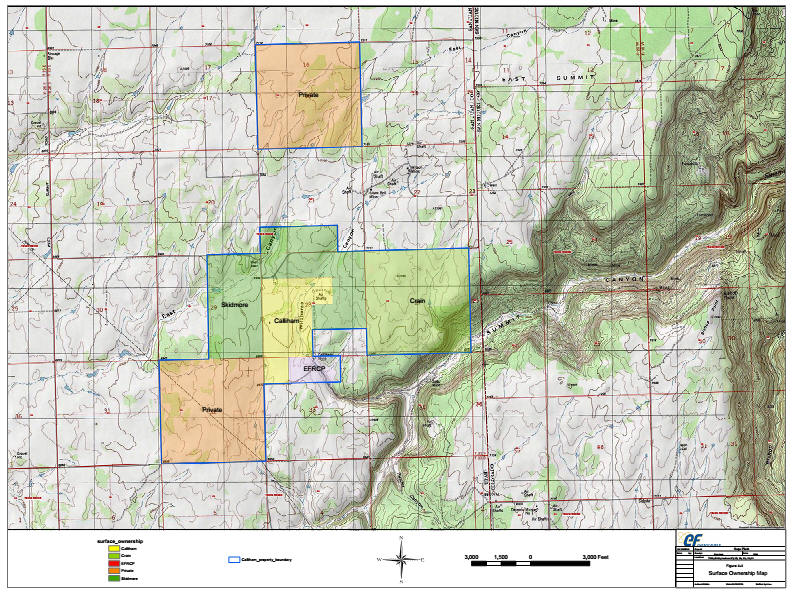

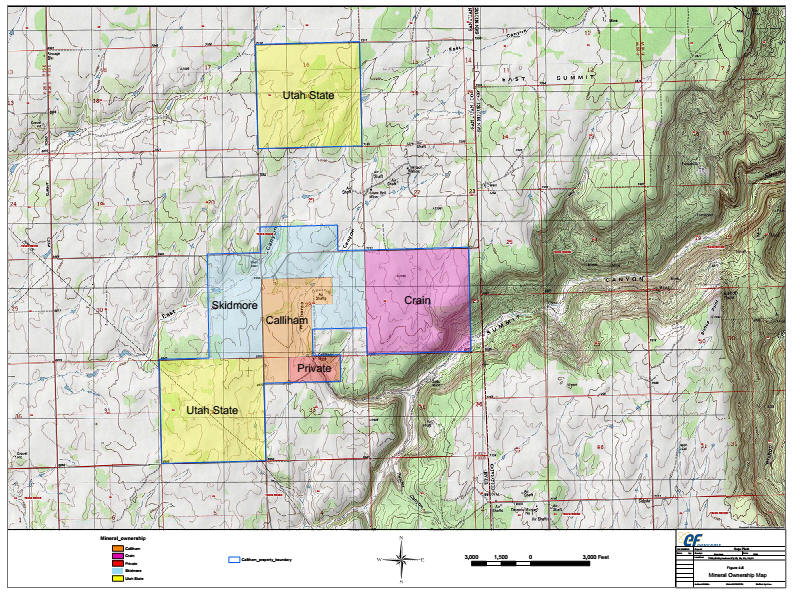

The access from Interstate 40 and Flagstaff gives way to two-lane paved Highway 66 and Indian Route 18 to within five miles of the Project, and then on maintained, graded gravel roads that are part of the public access for the region of local ranches (Figure 4-1).

| 4.4.2 |

Water Supply |

There is currently no readily available water supply for the Project. Nearby ranch wells intersect water at approximately 2,500 to 3,000 ft below the surface in the Redwall aquifer, as the mile-deep Grand Canyon nearby is the natural water table in the region. Surface ponds (tanks) are used to collect surface water run-off for cattle ranching. Ranches in the area have constructed a network of water pipelines and tanks for a stable water supply for cattle. Water for drilling is obtained from this network by agreement with the ranches. Potable water is currently hauled from local ranches or from the town of Grand Canyon Caverns There are no flowing surface waters in the immediate area of the Project, as creeks are ephemeral. Groundwater, while likely to be present in deep drillholes, is not sufficiently defined as to quantity or quality.

| 4.4.3 |

Electrical Power Supply |

There is a high-voltage regional electrical grid in the region, extending across northern Arizona from the various power plants in the greater region. There is local power to nearby ranches and rail stations.

| 4.4.4 |

Buildings and Ancillary Facilities |

There are no buildings or ancillary facilities on the Project. Scattered local ranch houses and outbuildings are present in the general region.

| 4.4.5 |

Population |

The sparse population in the region is scattered between a few local ranches and the towns and communities of Peach Springs, Grand Canyon Caverns, and Seligman.

| 4.4.6 |

Economy |

The economy is heavily dependent on tourism, as the nearby Grand Canyon is one of the most visited national parks in the U.S.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 12 |

| 4.4.7 |

Local Resources |

The population of Coconino County is approximately 125,000, of which 60,000 live in Flagstaff. With an area of 18,617 mi2 for Coconino County, the population density outside of Flagstaff is approximately 3.8 people/mi2. Flagstaff and Kingman are the nearest towns to provide services to support exploration in the region.

| 4.4.8 |

Regional Infrastructure |

The Grand Canyon rail system from Williams to Grand Canyon Village is nearby, with a crossroads at Anita Station; however, it is primarily a tourist attraction. There is a major east-west railroad accessible in Flagstaff that is sub-parallel to US Highways 40 and 66.

Power for the project would be tied into the existing national power grid.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 13 |

Figure 4-1: Regional Access Roads and Surface Land Ownership in Vicinity of the Wate Pipe

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 14 |

| 5 |

History (Item 6) |

Breccia pipes are the highest-grade uranium deposit types in the United States, with average grades of 0.5 to 1.0% U3O8 and with total production from 1 million to more than 6 Mlbs of U3O8. The breccia pipe district of northern Arizona produced approximately 23 Mlbs of U3O8 prior to the decline of uranium prices in the mid 1980s. Individual pipes have been known to contain more than 6 Mlbs of U3O8 at an average grade of about 1% U3O8. Ore is mined from open stopes that are usually accessed by vertical shafts or declines. Most of the uranium ore that was produced from the breccia pipes was trucked from the mine sites to the White Mesa Mill located in Blanding, Utah. On March 21, 2005, Denison Mines announced their intention to resume processing at the White Mesa Mill, now owned by Energy Fuels. There is currently an estimated combined resource of 13 Mlbs of U3O8 in several breccia pipes in northern Arizona that are awaiting production decisions. On June 14, 2006, Denison announced plans to reopen the Arizona 1 breccia pipe mine north of the Grand Canyon. Production from the Arizona 1 mine commenced in late 2009, with ore being trucked to their White Mesa mill near Blanding, Utah; Energy Fuels completed mining of the Arizona 1 pipe in 2014, and is currently mining the Pinenut pipe..

Breccia pipes occupy relatively small surface areas and in most cases can be covered by one to four 20-acre mining claims. Thus, land acquisition costs and surface environmental disturbance related to exploration and mining are minimal.

| 5.1 |

Ownership |

The most prevalent player in the 1970s to 1990s uranium exploration and production from the Arizona breccia pipes was Energy Fuels Nuclear, Inc. (EFNI), which ceased all activity in the region in the early 1990s, and many of the exploration properties were dropped.

Much of the historical exploration information generated by EFNI and other companies is not available; however, some information has been acquired by VANE and/or was available from Arizona State Land Department files. Rocky Mountain Energy explored the Wate Pipe during the same period.

| 5.1.1 |

Wate Pipe |

Rocky Mountain Energy (RME), a subsidiary of Union Pacific Railroad, discovered the Wate Breccia Pipe in the mid 1980s. Twenty-three drillholes to depths up to 2,000 feet were drilled. All were mineralized, and 17 holes were mineralized with reported “ore grades” (SRK notes that the term “ore” is a historically used term, and is not appropriate at this stage of the project). RME Partners, L.P. and limited partnership between RME and Overseas Resource U.S.A., a subsidiary of Taiwan Power Co., a nuclear utility company, completed most of the work. The work on the Wate pipe progressed to internal studies on reserve estimation and potential project development. In 1991, an internal reserve estimate was completed. In 1992, an internal evaluation was completed by RME Partners in support of their plan to convert the State Land Mineral Exploration Permit to a Mineral Lease, The conceptual evaluation examined reserves (resources by current reporting definitions), a preliminary mine plan, and surface site facilities. In 1998, The Arizona State Land Department conducted an independent evaluation of the Wate breccia pipe uranium mineralization and an appraisal of Arizona State Mineral Lease 11-52290 (lease covering the property at that time). That study was undertaken in order to provide the State of Arizona with a break-even uranium price for the project’s possible development, a valuation of the lease, and a market study of similar project royalty rates.

Summary reports of some of the work programs at the Wate pipe are available, but much of the detailed project information, including drillhole data, is not yet available to VANE. VANE has been in contact with Taiwan Power Co., and has ascertained that copies of all the detailed project data are in their possession; However, VANE has been unable to secure copies of the information.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 15 |

The Wate Pipe is a nearly vertical circular to elliptical column of brecciated rock that has a slight plunge to the north with a diameter of 170 ft at 1,200 ft in depth, narrows to 60 ft in diameter at 1,600 ft depth, and expands to 160 ft diameter at 1,700 ft depth and below. The Hermit shale/Esplanade sandstone contact is at about 1,500 ft in depth, which is approximately the location of the best thickness and grade of mineralization. Details of the mineralized intercepts for each drillhole are not available, merely the figures from historical reports. VANE started a program of re-entering the historical drill holes with rotary and core rigs, cleaning out the holes to depth, and then re-logging the drillholes for confirmation of hole deviations indicated on maps and for confirmation of grades. The reported average grade for uranium mineralization is +0.80% eU3O8, and VANE’s confirmation logging of historical drillholes has confirmed high grades (see Section Section 9).

| 5.1.2 |

Project Expenditures |

Total project expenditures by Energy Fuels Nuclear Inc. and Rocky Mountain Energy Partners LP (RME) for the exploration properties are unknown. Approximately US$500,000 to $1,000,000 in historical exploration dollars are estimated to have been spent on the various properties by EFNI, based on the number and depth of drillholes (±1,500 ft). The historical expenditures by RME for the U1 breccia pipe properties, in particular the Wate Pipe, are estimated at +$2,000,000.

| 5.2 |

Historic Mineral Resource Estimates |

The Wate Pipe has historically reported resources/reserves. The details of the methodology used to define the historical mineral resources/reserves that were estimated by RME Partners LP for the Wate Pipe have not been reviewed by a Qualified Person or reconciled with CIM definitions of resource classification, and are therefore not relied upon by Energy Fuels. However, those historical resource/reserve numbers are relevant and important to Energy Fuels, and considered material to the project and are thus presented here as exploration potential to be verified by confirmation drilling and gamma logging of historical drillhole intercepts.

Based on historical drillhole intercepts, the Wate Pipe has mineral exploration potential between 70,000 and146,000 tons grading from 0.80% to 0.83% eU3O8, for 1.1 to 2.4 million contained pounds eU3O8. Some, but not all, of the details supporting that estimate are documented in a historical internal document by RME Partners LP. (Anonymous)

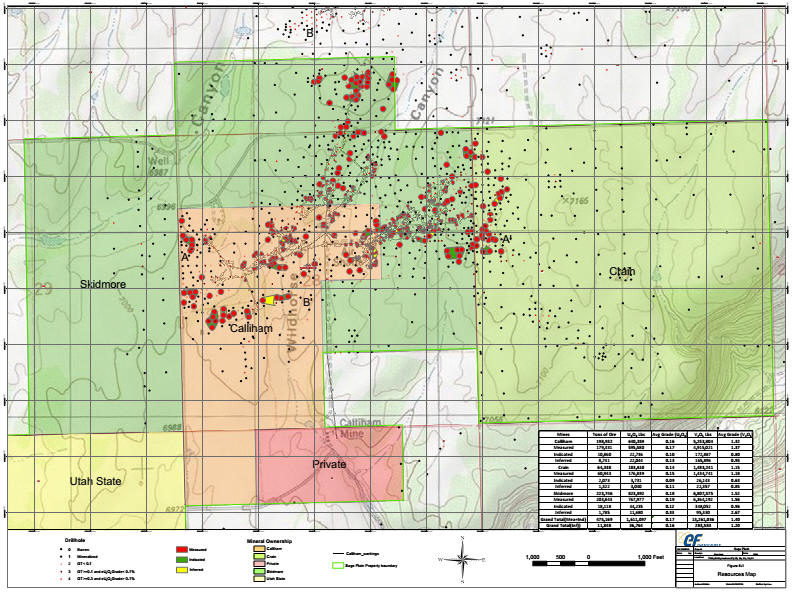

In May 2010, SRK, completed a NI 43-101 technical report on resources for the Wate Pipe, for a portion of the mineralization. That report entitled “NI 43-101 technical Report on Resources, Wate Uranium Breccia Pipe, Northern Arizona, USA”, and dated May 19, 2010, presented the initial resource estimate for the Wate Pipe by current CIM compliant standards for resource classification and reporting. The Qualified Person’s responsible for that initial resource are the same as the authors of this report. That initial resource estimate used similar procedures to that reported in Section 16 of this report, but with two fewer VANE drillholes and with no information on the grade of historical intercepts; therefore, was a preliminary estimate of only part of the historically defined mineralization as determined from VANE information. SRK reported in May 2010 the resources, stated in Table 5-1 below, as then current and CIM compliant Inferred mineral resources. It should be noted that the zone designation in Table 5.1 is not the same as used for current resources stated in Section 16.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 16 |

Table 5-1: May 2010 Inferred Resources for the Wate Pipe at 0.15% eU3O8 cutoff

| Wate Breccia Pipe Inferred

Resource, 0.15% eU3O8* cutoff. | ||||

| Zone | eU3O8% | Tons | Tons eU3O8 | Pounds eU3O8 |

| 1 | 0.38 | 11,000 | 43 | 87,000 |

| 2 | 0.72 | 4,000 | 28 | 57,000 |

| 3 | 1.11 | 4,000 | 45 | 89,000 |

| 4 | 0.95 | 24,000 | 232 | 463,000 |

| Total | 0.80 | 44,000 | 348 | 696,000 |

* Note: Inferred Uranium resources refers to global in-place CIM definitions of resources to which a mine design has not yet been applied; although the above stated resources meet the definition of having the “potential for economic extraction” at the cutoff provided.

In July and August 2010, VANE acquired historical reports that provide the mineralized intercept information previously lacking for most of the historical drillholes. While the back-up gamma and geological logs were not in VANE’s possession, that historical information has been used by SRK for an updated resource estimate as presented in the updated technical report dated November 04, 2010 – resources stated in Table 5-2 below. Note that the numbering of the mineralized zones changed from top down to bottom up; such that the Table 5-2 Zone 1 corresponds to Zone 4 on the initial resource in Table 5-1.

Table 5-2: May 2010 Inferred Resources for the Wate Pipe at 0.15% eU3O8 cutoff

| Wate Breccia Pipe Inferred

Resource 0.15% eU3O8 Cutoff* | ||||

| Zone | Cutoff | U3O8% | Tons (000) | Pounds U3O8 |

| 1 | 0.15 | 0.82 | 45,000 | 739,000 |

| 2 | 0.15 | 0.61 | 11,000 | 130,000 |

| 3 | 0.15 | 0.31 | 2,000 | 10,000 |

| 4 | 0.15 | 0.58 | 1,000 | 7,000 |

| Total | 0.76 | 58,000 | 886,000 | |

* Note: Inferred Uranium resources refers to global in-place CIM definitions of resources to which a mine design has not yet been applied; although the above stated resources meet the definition of having the “potential for economic extraction” at the cutoff provided.

SRK is reporting current resources in Section 16 of this report, which supersedes the resources stated in Tables 5-1 and 5-2.

The above reported historical resources for VANE, and the current mineral resources stated in Section 16, were reported in NI 43-101 technical report format, using CIM compliant resource classifications; however, it is important to note that VANE is not a Canadian listed company, so the reports were not filed on SEDAR, but were made public by VANE on their corporate website.

The current mineral resources reported in Section 16, are effective as of March 22, 2011, the date of the most current drilling information for the Project.

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 17 |

Figure 5-1: Plan Map and Drillhole traces of Historic Drillholes at the Wate Breccia Pipe (2008)

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 18 |

| 6 |

Geologic Setting (Item 7) |

A breccia consists of coarse-grained angular fragments surrounded by finer-grained silt and sand particles and cemented by calcite or other minerals. A breccia pipe is a vertical cylindrical shape of broken rock and is usually caused by collapse of overlying rock into a cave, such as caves in the Redwall Limestone.

The high-grade uranium deposits in breccia pipes in northern Arizona were deposited in solution-collapse features that originated in the Mississippian Redwall Limestone and propagated upward during several periods of karstification. Uranium was deposited during a later period, with and without other minerals, but commonly with minor amounts of copper.

| 6.1 |

Regional Geology |

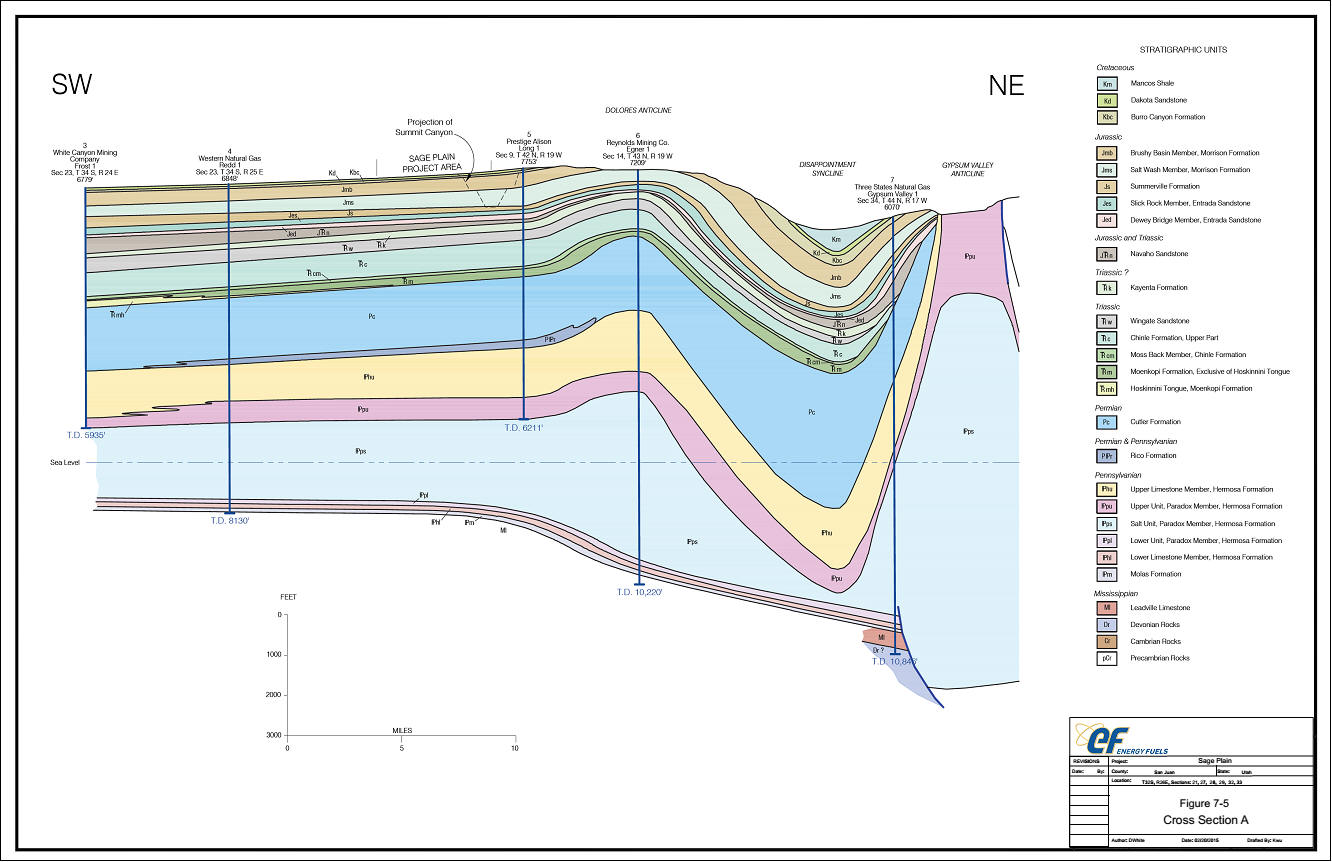

The geologic formation present at the surface across most of the Kaibab Plateau of northern Arizona is the Kaibab Limestone of Permian age (shown in blue on the Arizona geologic map; Arizona geology map from Arizona Geological Survey; Kaibab formation shown in Blue (Pm)

(Figure 6-1). The Kaibab is overlain by a few outlier hills of Triassic-age Moenkopi Formation. The Kaibab plateau is underlain by a thick sequence of Paleozoic sedimentary rocks that crops out in the Grand Canyon (Arizona geology map from Arizona Geological Survey; Kaibab formation shown in Blue (Pm)

(Figure 6-1), which are ultimately underlain by Precambrian granitic and gneissic rocks in the bottom of the Grand Canyon. The plateau-forming Kaibab limestone has gentle southerly dips of a few degrees, other strata have only minor deformation in broad regional folds with nearly horizontal dips. Nearly all of the breccia pipes have their bases in the lower part of the Redwall Limestone, approximately 3,000 ft below the Kaibab plateau. It is unlikely that any breccia pipes will be found where a thick Redwall Limestone section is absent, since karsting in the Redwall is believed to cause the overlying brecciation. The Redwall Limestone regionally pinches out between Holbrook and the Four Corners area, at least 100 mi to the east of the project area.

Many of the breccia pipes in northern Arizona are aligned along northwest- and northeast-trending zones (N45W and N50E) which are likely areas of increased fracture density overlying Precambrian faults and zones of weakness (Wenrich and Sutphin, 1989). These northwest- and northeast-trending joints, as well as the ring fracture system surrounding each breccia pipe, were imposed on the Mississippian Redwall Limestone prior to the deposition of the overlying Pennsylvanian and Permian Supai Group rocks, and later propagated upward through these units. The fracture systems apparently localized groundwater movement during Mississippian time and controlled the development of the karst and cave systems in the Redwall Limestone. The larger caves probably coincide with the intersection of the northwest-trending faults with the northeast-trending fractures, as these intersections would have localized the groundwater flow. The later north-south fabric observed in the Permian sandstones does not appear to be related to breccia pipe distribution (Wenrich and Sutphin, 1989).

| 6.1.1 |

Geology of Breccia Pipes |

Thousands of breccia pipes occur in northern Arizona, although it has been estimated that only about 8% are mineralized and less than 1% contain economic concentrations of uranium (Wenrich and Sutphin, 1988) [SRK note: This estimate is apparently based solely upon surface evaluations of mineralization, not on the results of industry drilling of breccia pipe targets]. Many of these breccia pipes have been dissected by canyons, such as the Grand Canyon, which provide cross-sectional views to clarify the stratigraphic relationships (Figure 6-2).

Physical Characteristics

The breccia pipes average approximately 300 ft in diameter and range from 130 ft (40 m) to 650 ft (200 m) in diameter in the subsurface. Some breccia pipes are as much as 0.5 mi in diameter in surface expression. Part of the larger footprint of the breccia pipes derives from dissolution of carbonate cement or gypsum beds in Permian-age Toroweap Formation and Kaibab Limestone.

The breccia pipes cut vertically through more than 800 ft of the rock column in various areas north of the Grand Canyon. The total stratigraphic section affected by breccia pipes throughout the district consists of the Mississippian Redwall Limestone and Surprise Canyon Formation; the Pennsylvanian and Permian Supai Group, the Permian Esplanade Sandstone of the Supai Group, Hermit Shale, Coconino Sandstone, Toroweap Formation, and Kaibab Limestone; and the Triassic Moenkopi Formation and Chinle Formation (Figure 6-2 and Figure 6-3). The total section affected by the brecciation could total 3,000 vertical feet (900 m).

| FD/AVM/CKH | March 2015 |

| SRK Consulting | |

| NI 43-101 Technical Report on Resources Wate Uranium Breccia Pipe – Northern Arizona, USA. | Page 19 |

The surface expression of a breccia pipe is frequently a cone-shaped depression in the Kaibab Limestone surface that is filled with redbeds of the Moenkopi Formation that have collapsed into the pipe, leaving a “bulls-eye” target with red Moenkopi in the center and light brown Kaibab on the periphery. Moenkopi Formation does not occur in all pipes. Surface expressions of breccia pipes, in the field and in air-photographs, can be subtle and easily overlooked.

Origin of Breccia Pipes

Dissolution of the Redwall Limestone during the Late Mississippian (approximately 330 million years ago [Ma]) created extensive karst topography and formed numerous caves in the thick Redwall Limestone. Only two known breccia pipes extend down to the underlying Temple Butte Formation, and these occur in the western part of the region where the Temple Butte Formation is a thicker limestone; it thins regionally to the east. Karstification occurred soon after formation of the Redwall Limestone, as evidenced by the deposition of the overlying Late Mississippian-age Surprise Canyon Formation in erosion channels and sinkholes on the upper surface of the Redwall. When the cave roof collapsed, overlying formations were deposited or subsided into the resulting sinkhole. After later formations were deposited, later periods of cave formation and limestone dissolution renewed the collapse features, such that later formations collapsed into the breccia pipe. No fragments of formations younger than the Chinle Formation have been found in the breccia pipes.

This gravitational collapse produced steep-sided, pipe-like bodies that are filled with angular to rounded fragments of overlying formations that range in size from finely ground material to large house-sized boulders.

Origin of Uranium Mineralization

Two separate mineralizing events may be responsible for the metallic minerals in the breccia pipes. The early metallic mineralization deposited cobalt, copper, iron, lead, nickel, and zinc. The later uranium-mineralizing event occurred after deposition of the Triassic Chinle Formation at about 200 Ma, based on U-Pb analyses from the Hack, Kanab North, EZ-1, EZ-2, and Canyon pipe deposits (Ludwig and others, 1986).

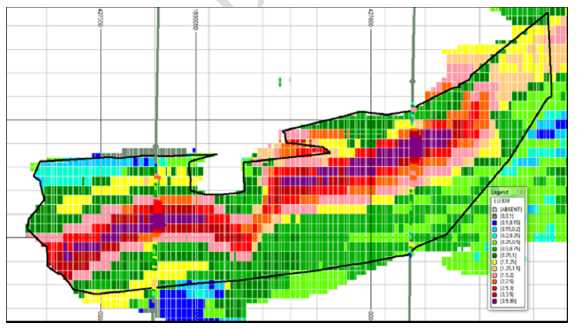

The source of the uranium is not known, although there are several hypotheses pertaining to the source of the mineralizing fluids. Some call for rising fluids, some for descending fluids, some for groundwater, and some for hydrothermal fluids.