Form 6-K ALMADEN MINERALS LTD For: Jan 24

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 6-K

Report of Foreign Private Issuer

Pursuant to Rule 13A-16 or 15D-16

of the Securities Exchange Act of 1934

For the month of January 2019

Commission File Number: 001-32702

Almaden Minerals Ltd.

(Translation of registrant's name into English)

Suite 210 – 1333 Johnston St., Vancouver, B.C. Canada V6H 3R9

(Address of principal executive offices)

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F.

| Form 20-F | ☒ | |

| Form 40-F | ☐ |

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulations S-T Rule 101(b)(1): ☐

Note: Regulation S-T Rule 101(b)(1) only permits the submission in paper of a Form 6-K if submitted solely to provide an attached annual report to security holders.

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulations S-T Rule 101(b)(7): ☐

Note: Regulation S-T Rule 101(b)(7) only permits the submission in paper of a Form 6-K if submitted to furnish a report or other document that the registrant foreign private issuer must furnish and make public under the laws of the jurisdiction in which the registrant is incorporated, domiciled or legally organized (the registrant's "home country"), or under the rules of the home country exchange on which the registrant's securities are traded, as long as the report or other document is not a press release, is not required to be and has not been distributed to the registrant's security holders, and, if discussing a material event, has already been the subject of a Form 6-K submission or other Commission filing on EDGAR.

Indicate by check mark whether by furnishing the information contained in this Form, the registrant is also thereby furnishing the information to the Commission pursuant to Rule 12g3-2(b) under the Securities Exchange Act of 1934.

| Yes | ☐ | |

| No | ☒ |

If "Yes" is marked, indicate below the file number assigned to the registrant in connection with Rule 12g3-2(b): 82-

Signature

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned hereunto duly authorized.

| Almaden Minerals Ltd. | ||

| Dated: January 25, 2019 | ||

| By: | /s/ Douglas McDonald Vice President | |

Exhibit Index

| Exhibit | Description of Exhibit |

| 99.1 | Technical Report |

Exhibit 99.1

|

| ||

Ixtaca Gold-Silver Project Puebla State, Mexico NI 43-101 Technical Report on the Feasibility Study

|

|||

|

| ||

|

Submitted to: Almaden Minerals Ltd.

Effective Date: 24 January 2019

|

|||

Report Authors: Tracey Meintjes, P.Eng. Jesse Aarsen, P.Eng. Kristopher Raffle, P.Geo. G.H. Giroux, P.Eng. Clara Balasko, P.E. Edward Wellman PE, PG, CEG

|

Company: Moose Mountain Technical Services Moose Mountain Technical Services Apex Geoscience Ltd Giroux Consultants Ltd SRK Consulting SRK Consulting |

||

| Page 1 |

|  |

| Ixtaca Feasibility Study – Technical Report |

Certificate Of Qualified Person

I, Tracey Meintjes, P.Eng., of Vancouver B.C. do hereby certify that:

| 1. | I am a Metallurgical Engineer with Moose Mountain Technical Services with a business address at 1975 1st Avenue South, Cranbrook, BC, V1C 6Y3. |

| 2. | This certificate applies to the technical report entitled “Ixtaca Gold-Silver Project, Puebla State, Mexico, NI 43-101 Technical Report on the Feasibility Study” dated 24 January 2019 (the “Technical Report”). |

| 3. | I am a graduate of the Technikon Witwatersrand, (NHD Extraction Metallurgy – 1996) |

| 4. | I am a member in good standing of the Association of Professional Engineers and Geoscientists of British Columbia (#37018). |

| 5. | My relevant experience includes metallurgy and process engineering, and mine planning in South Africa and North America. My experience includes both operations and metallurgical process development including base metals, precious metals, industrial minerals, coal, uranium and rare earth metals. My precious metals project experience includes both operations and metallurgical process development. I have been working in my profession continuously since 1996. |

| 6. | I am a “Qualified Person” for the purposes of National Instrument 43-101 (the “Instrument”). |

| 7. | I visited the Property from on 01 to 02 July 2014, 15 to 16 March 2016, 04 to 05 October 2016, 24 October 2017, 08 December 2017, 12 April 2018, 19 to 20 March 2018, 03 to 04 May 2018, and 01 November 2018. |

| 8. | I am responsible for Sections 1.1, 1.14, 1.15, 1.16, 1.17, 1.18, 1.19, 1.2, 2, 3, 13, 17, 18.1, 18.2, 18.3, 19, 20.1.7, 20.2, 20.3, 22, 24, 25.1, 25.11, 25.12, 25.13, 25.5, 26.4, 26.7, 26.8, 26.9, as well as processing portions of Section 21 of the Technical Report. |

| 9. | I am independent of Almaden Minerals as defined by Section 1.5 of the Instrument. |

| 10. | I have been involved with the Ixtaca Project during the preparation of previous Technical Reports. |

| 11. | I have read the Instrument and the Technical Report has been prepared in compliance with the Instrument. |

| 12. | As of the date of this certificate, to the best of my knowledge, information, and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. |

Dated the 24th day of January 2019

“ORIGINAL SIGNED AND SEALED”

________________________

Signature of Qualified Person

Tracey D. Meintjes, P.Eng.

| Page 2 |

|  |

| Ixtaca Feasibility Study – Technical Report |

Certificate Of Qualified Person

I, Jesse J. Aarsen, B.Sc. Mining Engineering, P.Eng., of Penticton B.C. do hereby certify that:

| 1. | I am an Associate (Mining Engineer) with Moose Mountain Technical Services with a business address of 1975-1st Avenue South, Cranbrook BC, V1C 6Y3. | |

| 2. | This certificate applies to the technical report entitled “Ixtaca Gold-Silver Project, Puebla State, Mexico, NI 43-101 Technical Report on the Feasibility Study” dated 24 January 2019 (the “Technical Report”) | |

| 3. | I graduated with a Bachelor of Science degree in Mining Engineering Co-op from the University of Alberta in April 2002. | |

| 4. | I am a member in good standing of the Association of Professional Engineers and Geoscientists of British Columbia (#38709). | |

| 5. | I have worked as a mining engineer for a total of 14 years since my graduation from university. I have also taken a 2 year period for personal travel throughout the world. My relevant experience for the purpose of the Technical Report includes: | |

| • | 2002 to 2005 – employed at complex coal mine in the Elk Valley working as a short range, long range, dispatch, and pit engineer. Preparation of budget levels mine plans and cost inputs, oversaw operation of personal designs and acting in supervisory-role positions as needed. | |

| • | Since 2007 – Consulting mining engineer specializing in mine planning and project development. Completion of mine plans for complex coal operating mines in north-eastern British Columbia and an open-pit copper/molybdenum mine in central British Columbia. Supervisory role in large multi-disciplinary studies for projects in both coal and hard-rock settings in Canada and Mongolia. Responsible for building several coal geology and block models and calculation of mineral resources under the supervision of a P.Geo. | |

| 6. | I have read the definition of “qualified person” set out in National Instrument 43-101 (“the Instrument”) and certify that by reason of my education, affiliation with a professional associations and past relevant work experience, I am a “Qualified Person” for the purposes of the Instrument. | |

| 7. | I have visited the site on April 30-May 01, 2013, August 27-28, 2014, March 15-16, 2016, Dec 12-16, 2016, and May 16-18, 2018. | |

| 8. | I have prepared and am responsible Sections 1.13, 15, 16.1, 16.2, 16.3, 16.4.1, 16.4.3, 16.4.4, 16.5.1, 16.6, 16.7, 16.8, 16.9, 18.5, 25.7, 25.8, 26.3.1, 26.3.2, as well as the mining components of Section 21 of the Technical Report. | |

| 9. | I am independent of Almaden Minerals applying the tests in Section 1.5 of the Instrument. | |

| 10. | I have been involved with the Ixtaca Project during the preparation of previous Technical Reports. | |

| 11. | I have read the Instrument, and the Technical Report has been prepared in compliance with the Instrument. | |

| 12. | As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. | |

Dated the 24th day of January 2019

“ORIGINAL SIGNED AND SEALED”

________________________

Signature of Qualified Person

Jesse J. Aarsen, B.Sc., P.Eng.

| Page 3 |

|  |

| Ixtaca Feasibility Study – Technical Report |

Certificate Of Qualified Person

I, Kristopher J. Raffle, B.Sc., P.Geo., of Vancouver B.C. do hereby certify that:

| 1. | I am an Associate (Mining Engineer) with Moose Mountain Technical Services with a business address of 1975-1st Avenue South, Cranbrook BC, V1C 6Y3. | |

| 2. | This certificate applies to the technical report entitled “Ixtaca Gold-Silver Project, Puebla State, Mexico, NI 43-101 Technical Report on the Feasibility Study” dated 24 January 2019 (the “Technical Report”) | |

| 3. | I graduated with a Bachelor of Science degree in Mining Engineering Co-op from the University of Alberta in April 2002. | |

| 4. | I am a member in good standing of the Association of Professional Engineers and Geoscientists of British Columbia (#38709). | |

| 5. | I have worked as a mining engineer for a total of 14 years since my graduation from university. I have also taken a 2 year period for personal travel throughout the world. My relevant experience for the purpose of the Technical Report includes: | |

| • | 2002 to 2005 – employed at complex coal mine in the Elk Valley working as a short range, long range, dispatch, and pit engineer. Preparation of budget levels mine plans and cost inputs, oversaw operation of personal designs and acting in supervisory-role positions as needed. | |

| • | Since 2007 – Consulting mining engineer specializing in mine planning and project development. Completion of mine plans for complex coal operating mines in north-eastern British Columbia and an open-pit copper/molybdenum mine in central British Columbia. Supervisory role in large multi-disciplinary studies for projects in both coal and hard-rock settings in Canada and Mongolia. Responsible for building several coal geology and block models and calculation of mineral resources under the supervision of a P.Geo. | |

| 6. | I have read the definition of “qualified person” set out in National Instrument 43-101 (“the Instrument”) and certify that by reason of my education, affiliation with a professional associations and past relevant work experience, I am a “Qualified Person” for the purposes of the Instrument. | |

| 7. | I have visited the site on April 30-May 01, 2013, August 27-28, 2014, March 15-16, 2016, Dec 12-16, 2016, and May 16-18, 2018. | |

| 8. | I have prepared and am responsible Sections 1.13, 15, 16.1, 16.2, 16.3, 16.4.1, 16.4.3, 16.4.4, 16.5.1, 16.6, 16.7, 16.8, 16.9, 18.5, 25.7, 25.8, 26.3.1, 26.3.2, as well as the mining components of Section 21 of the Technical Report. | |

| 9. | I am independent of Almaden Minerals applying the tests in Section 1.5 of the Instrument. | |

| 10. | I have been involved with the Ixtaca Project during the preparation of previous Technical Reports. | |

| 11. | I have read the Instrument, and the Technical Report has been prepared in compliance with the Instrument. | |

| 12. | As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. | |

Dated the 24th day of January 2019

“ORIGINAL SIGNED AND SEALED”

________________________

Signature of Qualified Person

Kristopher J. Raffle, B.Sc., P.Geo.

| Page 4 |

|  |

| Ixtaca Feasibility Study – Technical Report |

Certificate Of Qualified Person

I, G.H. Giroux, P.Eng. MASc, of Vancouver B.C., do hereby certify that:

| 1. | I, G.H. Giroux, of 982 Broadview Drive, North Vancouver, British Columbia, do hereby certify that: |

| 2. | I am a consulting geological engineer with an office 982 Broadview Dr. North Vancouver, British Columbia. |

| 3. | I am a graduate of the University of British Columbia in 1970 with a B.A. Sc. and in 1984 with a M.A. Sc., both in Geological Engineering. |

| 4. | I am a member in good standing of the Association of Professional Engineers and Geoscientists of the Province of British Columbia. |

| 5. | I have practiced my profession continuously since 1970. I have had over 40 years’ experience estimating mineral resources. I have previously completed resource estimations on a wide variety of precious metal deposits both in B.C. and around the world, many similar to the Ixtaca project. |

| 6. | I have read the definition of “qualified person” set out in National Instrument 43-101 (“NI 43-101”) and certify that by reason of my education, past relevant work experience and affiliation with a professional association (as defined in NI 43-101), I fulfill the requirements to be a “qualified person” for the purposes of NI 43-101. |

| 7. | I am responsible for the preparation of Section 1.11, 14, and 25.6 of the Technical Report titled “Ixtaca Gold-Silver Project, Puebla State, Mexico, NI 43-101 Technical Report on the Feasibility Study” dated 24 January 2019 (the “Technical Report”). |

| 8. | I have not visited the Property. |

| 9. | I have completed previous resource estimates on the Property that is the subject of the Technical Reports in 2013, 2014 and 2017. |

| 10. | As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the portions of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

| 11. | I am independent of the issuer applying all of the tests in Section 1.5 of NI 43-101. |

| 12. | I have read NI 43-101, and the portions of the Technical Report for which I am responsible have been prepared in compliance with NI 43-101. |

Dated the 24th day of January 2019

“ORIGINAL SIGNED AND SEALED”

________________________

Signature of Qualified Person

G. H. Giroux, P.Eng., MASc.

| Page 5 |

|  |

| Ixtaca Feasibility Study – Technical Report |

Certificate Of Qualified Person

I, Clara Balasko, MSc, PE of Reno, Nevada do hereby certify that:

| 1. | I am Consultant, Civil Engineer of SRK Consulting (U.S.), Inc., 5250 Neil Road, Suite 300, Reno, NV, USA, 89502. |

| 2. | This certificate applies to the technical report titled “Ixtaca Gold-Silver Project, Puebla State, Mexico, NI 43-101 Technical Report on the Feasibility Study” with an Effective Date of January 24, 2019 (the “Technical Report”). |

| 3. | I graduated with a degree in Bachelors of Science in Geology from Texas A&M University in 2000. In addition, I have obtained a Master’s of Science in Geological Engineering from University of Nevada, Reno in 2003. I am a Professional Engineer in Civil Engineering of the Arizona and Nevada Boards of Technical Registration. I have worked as a Civil Engineer for a total of 15 years since my graduation from university. My relevant experience includes planning and conducting geotechnical investigations for tailings storage facility foundation and embankment design, design for construction, operation and closure of tailings storage facilities, calculating tailings storage facility water balances for operation and closure, and performing slope stability assessments. |

| 4. | I have read the definition of “qualified person” set out in National Instrument 43-101 (NI 43-101) and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purposes of NI 43-101. |

| 5. | I visited the Ixtaca Property on 5 to 13 April, 2018 for 8 days and on 16 to 19 May, 2018 for 3 days. |

| 6. | I am responsible for the preparation of Sections 1.15.1 , 1.15.2 , 16.5.2, 18.4, 18.6, 18.7, 20.1.1, 20.1.2, 20.1.3, 20.1.4, 20.1.5, 20.1.6, 20.4, 25.10, 26.2, 26.5, and tailings/rock Co-disposal facility and rock storage facility foundation preparation, water management, and mine closure portions of 21 and 26.6. of the Technical Report. |

| 7. | I am independent of the issuer applying all the tests in section 1.5 of NI 43-101. |

| 8. | I have not had prior involvement with the property that is the subject of the Technical Report. |

| 9. | I have read NI 43-101 and Form 43-101F1 and the sections of the Technical Report I am responsible for have been prepared in compliance with that instrument and form. |

| 10. | As of the aforementioned Effective Date, to the best of my knowledge, information and belief, the sections of the Technical Report I am responsible for contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. |

Dated this 24th Day of January 2019.

“ORIGINAL SIGNED AND SEALED”

________________________

Clara Balasko, MSc, PE

Civil Engineer #50059 (Arizona exp. 09/30/2021)

| Page 6 |

|  |

| Ixtaca Feasibility Study – Technical Report |

CERTIFICATE OF QUALIFIED PERSON

I, Edward C. Wellman, PE do hereby certify that:

| 1. | I am a Principal Consultant (Rock Mechanics) of SRK Consulting (U.S.), Inc., 1125 Seventeenth Street, Suite 600, Denver, CO, USA, 80202. |

| 2. | This certificate applies to the technical report titled “Ixtaca Gold-Silver Project, Puebla State, Mexico, NI 43-101 Technical Report on the Feasibility Study” with an Effective Date of January 24, 2019 (the “Technical Report”). |

| 3. | I graduated with a Bachelor of Science degree in Geosciences from the University of Arizona in 1994. I graduated with a Master of Science in Geological Engineering from the University of Nevada in 1997. In addition, I have obtained Professional Engineering Licenses in the states of Arizona, California, Colorado, Hawaii, Illinois, Iowa, Maryland, Michigan, Nevada, New Mexico, Utah, and Alaska. I am also a Registered Geologist and Certified Engineering Geologist in the state of California. I am a Member of the Society of Mining, Metallurgy & Exploration, Association of Environmental and Engineering Geologists, and the American Society of Civil Engineers. I have worked as a Geological Engineer for a total of 21 years since my graduation from university. My relevant experience includes over 20 years of experience in mining (base metals, gold, industrial minerals), and civil tunneling for public utilities, wineries and the private sector. My experience includes slope stability analysis of open-pit slopes, waste rock and heap leach piles, and preparation of analysis and technical reports suitable for agency review. My underground areas of expertise include rock mechanics for block cave mining, large excavations and shafts, cavability studies, subsidence including surface and underground interaction. I am also versed in geotechnical instrumentation and monitoring programs, from inception to evaluating excavation performance. My experience includes rock mass characterization and probabilistic analysis for pit slope and ground reinforcement design. I am also experienced in numerical modeling and is a developer of fragmentation analysis codes. |

| 4. | I have read the definition of “qualified person” set out in National Instrument 43-101 (NI 43-101) and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purposes of NI 43-101. |

| 5. | I visited the Ixtaca Project Site located in the Mexico on October 24-25, 2017 for 2 days. |

| 6. | I am responsible for the preparation of Sections 1.12, 16.4.2, 25.9, and 26.3.3 of the Technical Report. |

| 7. | I am independent of the issuer applying all the tests in section 1.5 of NI 43-101. |

| 8. | I have not had prior involvement with the property that is the subject of the Technical Report. |

| 9. | I have read NI 43-101 and Form 43-101F1 and the sections of the Technical Report I am responsible for have been prepared in compliance with that instrument and form. |

| 10. | As of the aforementioned Effective Date, to the best of my knowledge, information and belief, the sections of the Technical Report I am responsible for contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. |

Dated this 24th Day of January, 2019.

“ORIGINAL SIGNED AND SEALED”

________________________________

Edward C. Wellman, PE

Geological Engineer #15318 (Nevada exp. 6/30/2020)

Principal Consultant (Rock Mechanics)

| Page 7 |

|  |

| Ixtaca Feasibility Study – Technical Report |

TABLE OF CONTENTS

| 1.0 | Summary | 21 | ||

| 1.1 | Introduction | 21 | ||

| 1.2 | Property Description and Location | 22 | ||

| 1.3 | Accessibility, Climate, Local Resources, Infrastructure, Physiography | 22 | ||

| 1.4 | History | 22 | ||

| 1.5 | Geological Setting and Mineralization | 23 | ||

| 1.6 | Exploration | 24 | ||

| 1.7 | Drilling | 24 | ||

| 1.8 | Sample Preparation, Analyses and Security | 25 | ||

| 1.9 | Data Verification | 26 | ||

| 1.10 | Metallurgy | 26 | ||

| 1.11 | Resource Estimate | 27 | ||

| 1.12 | Geomechanical | 28 | ||

| 1.12.1 | Ash Tuff and Upper Volcanics | 29 | ||

| 1.12.2 | Rock Units (Limestone, Shale, Dikes) | 29 | ||

| 1.13 | Proposed Development Plan | 29 | ||

| 1.14 | Production and Processing | 32 | ||

| 1.15 | Tailings Co-disposal and Water Management | 33 | ||

| 1.15.1 | West T/RSF | 33 | ||

| 1.15.2 | Water Management | 33 | ||

| 1.16 | Capital and Operating Costs | 34 | ||

| 1.17 | Economic Analysis | 34 | ||

| 1.18 | Environmental and Social Considerations | 37 | ||

| 1.19 | Project Execution Plan | 38 | ||

| 1.20 | Conclusions and Recommendations | 39 | ||

| 2.0 | Introduction | 40 | ||

| 3.0 | Reliance on Other Experts | 42 | ||

| 4.0 | Property Description and Location | 43 | ||

| 5.0 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 47 | ||

| 6.0 | History | 48 | ||

| 7.0 | Geological Setting and Mineralization | 50 | ||

| 7.1 | Regional Geology | 50 | ||

| 7.2 | Property Geology | 52 | ||

| 7.3 | Mineralization | 56 | ||

| 7.3.1 | Steam Heated Alteration, Replacement Silicification and Other Surficial Geothermal Manifestations at Ixtaca | 61 | ||

| 8.0 | Deposit Types | 65 | ||

| 8.1 | Epithermal Gold-Silver Deposits | 65 | ||

| 8.1.1 | The Ixtaca Zone Epithermal System | 68 | ||

| 8.2 | Porphyry Copper-Gold-Molybdenum and Lead-Zinc Skarn Deposits | 70 | ||

| 9.0 | Exploration | 71 | ||

| 9.1 | Rock Geochemistry | 71 | ||

| 9.2 | Soil and Stream Sediment Geochemistry | 71 | ||

| Page 8 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| 9.3 | Ground Geophysics | 74 | ||

| 9.3.1 | Magnetics | 74 | ||

| 9.3.2 | Induced Polarization/Resistivity | 75 | ||

| 9.3.3 | CSAMT/CSIP | 76 | ||

| 9.4 | Exploration Potential | 76 | ||

| 10.0 | Drilling | 82 | ||

| 10.1 | Main Ixtaca and Ixtaca North Zones | 86 | ||

| 10.2 | Chemalaco Zone | 93 | ||

| 11.0 | Sample Preparation, Analyses and Security | 100 | ||

| 11.1 | Sample Preparation and Analyses | 100 | ||

| 11.1.1 | Rock Grab and Soil Geochemical Samples | 100 | ||

| 11.1.2 | Almaden Drill Core | 101 | ||

| 11.1.3 | Author’s Drill Core | 102 | ||

| 11.2 | Quality Assurance / Quality Control Procedures | 103 | ||

| 11.2.1 | Analytical Standards | 103 | ||

| 11.2.2 | Blanks | 111 | ||

| 11.2.3 | Duplicates | 112 | ||

| 11.3 | Independent Audit of Almaden Drillhole Database | 114 | ||

| 11.3.1 | Collar Coordinate and Downhole Survey Databases | 114 | ||

| 11.3.2 | Drill Core Assay Database | 114 | ||

| 12.0 | Data Verification | 115 | ||

| 13.0 | Mineral Processing and Metallurgical Testing | 116 | ||

| 13.1 | Introduction | 116 | ||

| 13.2 | Metallurgical Test Work History | 116 | ||

| 13.3 | Samples | 119 | ||

| 13.4 | Mineralogy | 121 | ||

| 13.4.1 | Limestone | 121 | ||

| 13.4.2 | Volcanic | 122 | ||

| 13.4.3 | Black Shale | 124 | ||

| 13.5 | Diagnostic Leaching | 127 | ||

| 13.5.1 | Limestone | 128 | ||

| 13.5.2 | Volcanic | 128 | ||

| 13.5.3 | Black Shale | 128 | ||

| 13.6 | Comminution Test Work | 129 | ||

| 13.6.1 | Limestone | 130 | ||

| 13.6.2 | Volcanic | 130 | ||

| 13.6.3 | Black Shale | 130 | ||

| 13.7 | Ore Sorting | 130 | ||

| 13.7.1 | How it works | 131 | ||

| 13.7.2 | Limestone Ore Sort Amenability Tests | 132 | ||

| 13.7.3 | Limestone Ore Sort Performance Tests | 133 | ||

| 13.7.4 | Black Shale Ore Sort Performance Tests | 136 | ||

| 13.7.5 | Volcanic Ore Sort Performance Tests | 138 | ||

| 13.8 | Whole Ore Leaching | 140 | ||

| 13.9 | Gravity Concentration | 140 | ||

| 13.9.1 | Limestone | 140 | ||

| Page 9 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| 13.9.2 | Volcanic | 144 | ||

| 13.9.3 | Black Shale | 146 | ||

| 13.10 | Flotation of Gravity Tails | 149 | ||

| 13.10.1 | Flotation Optimization (2016) | 149 | ||

| 13.10.2 | Flotation Variability Test Work (2018) | 150 | ||

| 13.11 | Leaching of gravity concentrate | 153 | ||

| 13.12 | Leaching of flotation concentrate | 154 | ||

| 13.12.1 | Limestone | 154 | ||

| 13.12.2 | Volcanic | 159 | ||

| 13.12.3 | Black Shale | 160 | ||

| 13.13 | Leach Residue Detox | 166 | ||

| 13.14 | Carbon Adsorption and Merrill-Crowe | 166 | ||

| 13.15 | Settling tests and Filtration | 167 | ||

| 13.16 | Recommended Flowsheet | 169 | ||

| 13.17 | Metallurgical Performance Projections | 169 | ||

| 13.18 | Aggregate test work on Ixtaca Limestone Waste Rock | 171 | ||

| 14.0 | Mineral Resource Estimates | 173 | ||

| 14.1 | Data Analysis | 173 | ||

| 14.2 | Composites | 178 | ||

| 14.3 | Variography | 179 | ||

| 14.4 | Block Model | 182 | ||

| 14.5 | Bulk Density | 182 | ||

| 14.6 | Grade Interpolation | 184 | ||

| 14.7 | Classification | 186 | ||

| 14.8 | Block Model Verification | 190 | ||

| 15.0 | Mineral Reserve Estimates | 194 | ||

| 15.1 | Cut-Off Grade | 194 | ||

| 15.2 | Loss and Dilution | 194 | ||

| 15.3 | Mineral Reserves | 195 | ||

| 16.0 | Mining Method | 196 | ||

| 16.1 | Introduction | 196 | ||

| 16.2 | Mining Study Basis | 196 | ||

| 16.2.1 | Mine Planning Datum | 196 | ||

| 16.2.2 | Resource Classes | 196 | ||

| 16.2.3 | Metallurgical Recovery for Mine Planning | 196 | ||

| 16.2.4 | Cut-off Grade | 196 | ||

| 16.2.5 | Mining Dilution and Loss | 197 | ||

| 16.3 | Economic Pit Limits | 197 | ||

| 16.3.1 | LG Cost Inputs | 197 | ||

| 16.3.2 | LG Slope Inputs | 198 | ||

| 16.3.3 | LG Sensitivity Cases | 198 | ||

| 16.4 | Detailed Pit Designs | 201 | ||

| 16.4.1 | Pit Phase Selection | 201 | ||

| 16.4.2 | Pit Design Slope Inputs and Bench Configuration | 201 | ||

| 16.4.3 | Haul Road Design Parameters | 202 | ||

| 16.4.4 | Pit Design Results | 202 | ||

| Page 10 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| 16.5 | Rock Storage Facilities | 206 | ||

| 16.5.1 | RSF Design Inputs | 206 | ||

| 16.5.2 | South RSF Surface Water Management | 207 | ||

| 16.6 | Mine Haul Road Designs | 210 | ||

| 16.7 | Ore Stockpiles | 210 | ||

| 16.8 | Mine Production Schedule | 211 | ||

| 16.8.1 | End of Period Maps | 214 | ||

| 16.8.2 | Pre-Production Mine Operations (Year -1) | 214 | ||

| 16.9 | Mine Operations | 218 | ||

| 16.9.1 | Direct Mining Unit Operations (Contractor) | 219 | ||

| 16.9.2 | GME and Technical (Owner) | 222 | ||

| 16.9.3 | Mine Operations Organizational Chart | 223 | ||

| 17.0 | Recovery Methods | 224 | ||

| 17.1 | Process Flowsheet | 224 | ||

| 17.2 | Acquisition of the Rock Creek Processing Plant | 226 | ||

| 17.3 | Process Design Criteria | 226 | ||

| 17.4 | Process Description | 228 | ||

| 17.4.1 | General | 228 | ||

| 17.4.2 | Crushing and Ore Sorting | 228 | ||

| 17.4.3 | Fine Ore Stockpile | 229 | ||

| 17.4.4 | Processing Plant | 229 | ||

| 17.5 | Reagents and Power Consumption | 236 | ||

| 17.6 | Process Water and Power | 237 | ||

| 18.0 | Project Infrastructure | 238 | ||

| 18.1 | Site Access | 238 | ||

| 18.2 | Power | 238 | ||

| 18.3 | Fuel | 238 | ||

| 18.4 | Water Supply | 240 | ||

| 18.5 | Mine Maintenance Facility | 243 | ||

| 18.6 | Tailings Management | 243 | ||

| 18.6.1 | Tailings Storage Alternatives | 244 | ||

| 18.6.2 | Design Criteria Summary | 244 | ||

| 18.6.3 | Tailings and Rock Storage Design | 247 | ||

| 18.6.4 | West Tailings and Rock Storage Facility Closure | 251 | ||

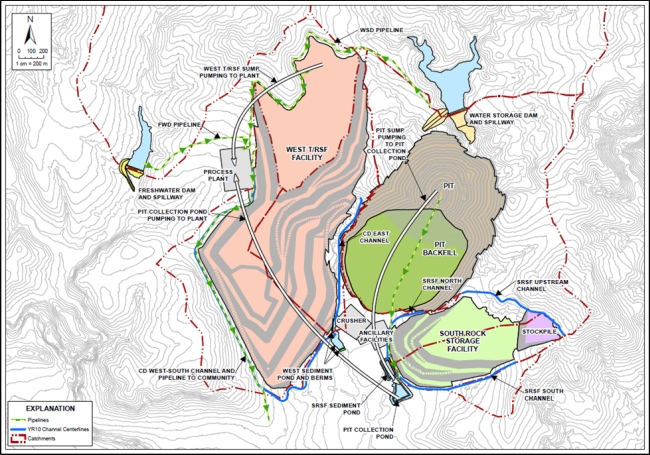

| 18.7 | Site Wide Water Management | 252 | ||

| 19.0 | Market Studies and Contracts | 253 | ||

| 19.1 | Market Studies | 253 | ||

| 19.2 | Commodity Price Projections | 253 | ||

| 19.3 | Comments on Section 19 | 253 | ||

| 20.0 | Environmental Studies, Permitting and Social or Community Impact | 254 | ||

| 20.1 | Environmental Studies | 254 | ||

| 20.1.1 | Meteorology | 254 | ||

| 20.1.2 | Surface Hydrology | 255 | ||

| 20.1.3 | Surface Water Quality | 255 | ||

| 20.1.4 | Groundwater | 258 | ||

| 20.1.5 | Groundwater Quality | 262 | ||

| Page 11 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| 20.1.6 | Geochemistry | 264 | ||

| 20.1.7 | Flora and Fauna | 265 | ||

| 20.2 | Permitting | 267 | ||

| 20.3 | Social and Community Engagement | 268 | ||

| 20.3.1 | Local Communities | 268 | ||

| 20.3.2 | Community Engagement | 268 | ||

| 20.3.3 | Land Acquisition | 270 | ||

| 20.3.4 | Potential Social or Community Requirements and/or Plans | 270 | ||

| 20.4 | Mine Closure | 270 | ||

| 20.4.1 | Open Pit | 270 | ||

| 20.4.2 | West Tailings and Rock Storage Facility | 271 | ||

| 20.4.3 | South Rock Storage Facility | 271 | ||

| 20.4.4 | Water Dams | 271 | ||

| 20.4.5 | Buildings | 271 | ||

| 20.4.6 | Roads | 271 | ||

| 20.4.7 | Diversions | 272 | ||

| 20.4.8 | Wells | 272 | ||

| 20.4.9 | Monitoring | 272 | ||

| 21.0 | Capital and Operating Costs | 273 | ||

| 21.1 | Introduction | 273 | ||

| 21.2 | Capital Costs | 273 | ||

| 21.2.1 | Responsibilities | 274 | ||

| 21.2.2 | Basis of Estimate | 274 | ||

| 21.3 | Operating Cost Estimate | 281 | ||

| 21.3.1 | Operating Cost Summary | 281 | ||

| 21.3.2 | Mining | 281 | ||

| 21.3.3 | Processing | 282 | ||

| 21.3.4 | General & Administration (G&A) | 283 | ||

| 21.4 | Closure Cost Estimate | 283 | ||

| 22.0 | Economic Analysis | 284 | ||

| 22.1 | Cautionary Statement | 284 | ||

| 22.2 | Assumptions | 284 | ||

| 22.3 | Taxes and Mining Duties | 285 | ||

| 22.4 | Analysis | 285 | ||

| 22.5 | Economic Results and Sensitivities | 287 | ||

| 23.0 | Adjacent Properties | 289 | ||

| 23.1 | Cuyoaco Property | 289 | ||

| 23.2 | Minera Frisco S.A. de C.V. Espejeras | 289 | ||

| 24.0 | Other Relevant Data and Information | 290 | ||

| 24.1 | Preliminary Development Schedule | 290 | ||

| 25.0 | Interpretation and Conclusions | 291 | ||

| 25.1 | Introduction | 291 | ||

| 25.2 | Mineral Tenure, Surface Rights | 291 | ||

| 25.3 | Geology and Mineralization | 291 | ||

| 25.4 | Exploration, Drilling and Analytical Data Collection in Support of Mineral Resource Estimation | 291 | ||

| Page 12 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| 25.5 | Metallurgical Testwork | 292 | ||

| 25.6 | Mineral Resource Estimates | 292 | ||

| 25.7 | Mineral Reserves | 293 | ||

| 25.8 | Mine Plan | 293 | ||

| 25.9 | Geomechanical | 293 | ||

| 25.10 | Tailings, Rock, and Water Management | 294 | ||

| 25.11 | Environmental, Permitting and Social Considerations | 296 | ||

| 25.12 | Capital and Operating Cost Estimates | 296 | ||

| 25.13 | Economic Analysis | 296 | ||

| 26.0 | Recommendations | 297 | ||

| 26.1 | Geology and Exploration | 297 | ||

| 26.2 | Tailings, Rock, and Water Management Recommendations | 297 | ||

| 26.3 | Mining Recommendations | 298 | ||

| 26.3.1 | Open Pit Mining | 298 | ||

| 26.3.2 | Underground Mining Potential | 298 | ||

| 26.3.3 | Geomechanical recommendations | 299 | ||

| 26.4 | Metallurgy and Process Recommendations | 300 | ||

| 26.5 | Environmental Recommendations | 300 | ||

| 26.6 | Infrastructure Recommendations | 300 | ||

| 26.7 | Aggregate Potential | 300 | ||

| 26.8 | Cement Potential | 300 | ||

| 26.9 | Risk Assessment | 301 | ||

| 26.10 | Budget | 301 | ||

| 27.0 | References | 303 | ||

| APPENDIX A - | LIST OF DRILL HOLES | 306 | ||

| Page 13 |

|  |

| Ixtaca Feasibility Study – Technical Report |

LIST OF TABLES

| Table 1-1 | Ixtaca Zone Measured, Indicated and Inferred Mineral Resource Statement | 27 |

| Table 1-2 | Recovered In-pit Reserve and Diluted Grade | 30 |

| Table 1-3 | Ore Sort Mill Feed grade improvement | 32 |

| Table 1-4 | Average Life of Mine Process Recoveries from Mill Feed | 33 |

| Table 1-5 | Projected Initial Capital Costs (USD million) | 34 |

| Table 1-6 | Summary of Average LOM Operating Costs ($/tonne mill feed) | 34 |

| Table 1-7 | Revenue before transport, refining, and royalties | 35 |

| Table 1-8 | Summary All-in sustaining cost (exclusive of initial capital) | 35 |

| Table 1-9 | Summary of Ixtaca Economic Sensitivity to Precious Metal Prices (Base Case is Bold) | 35 |

| Table 1-10 | Summary of Economic Results and Sensitivities to Operating Costs ($ Million) | 36 |

| Table 1-11 | Summary of Economic Results and Sensitivities to Exchange Rate ($ Million) | 36 |

| Table 1-12 | Summary of Economic Results and Sensitivities to Capital Cost ($ Million) | 36 |

| Table 2-1 | QPs, Section of Report Responsibility, and Site Visits | 40 |

| Table 4-1 | Tuligtic Property Mineral Claims | 43 |

| Table 4-2 | Exploitation Claim Minimum Expenditure/Production Value Requirements | 46 |

| Table 8-1 | Classification of Epithermal Deposits | 67 |

| Table 10-1 | Tuligtic Property Drilling Summary 2010-2016 | 82 |

| Table 10-2 | Tuligtic Property Down Hole Survey Statistics | 85 |

| Table 10-3 | Section 10+675E Significant Drill Intercepts (Main Ixtaca and Ixtaca North Zones) | 89 |

| Table 10-4 | Section 10+375E Significant Drill intercepts (Main Ixtaca Zone) | 92 |

| Table 10-5 | Section 50+050N Significant Drill intercepts (Chemalaco Zone) | 94 |

| Table 12-1 | Authors Independent Drill Core Sample Assays | 115 |

| Table 13-1 | History of Metallurgical testing campaigns for the Ixtaca Project | 117 |

| Table 13-2 | Variability Samples for Stage 3 Metallurgical Test Work - Limestone Sample Head Assays | 120 |

| Table 13-3 | Limestone Ore Sample Chemical and mineral composition | 121 |

| Table 13-4 | Volcanic Sample Chemical and mineral composition | 123 |

| Table 13-5 | Black Shale Sample Chemical and mineral composition | 125 |

| Table 13-6 | Stage 1 and 2 Comminution Results (2014 and 2016) | 129 |

| Table 13-7 | Limestone Comminution Variability Results (2018) | 129 |

| Table 13-8 | Limestone Ore Sort Test Results Summary | 134 |

| Table 13-9 | Limestone Ore Sort Mass Balance Summary | 135 |

| Table 13-10 | Black Shale Ore Sort Test Results Summary | 136 |

| Table 13-11 | Black Shale Ore Sort Mass Balance Summary | 138 |

| Table 13-12 | Black Shale Ore Sort Test Results Summary | 138 |

| Table 13-13 | Volcanic Ore Sort Mass Balance Summary | 140 |

| Table 13-14 | 2013 Limestone EGRG results | 141 |

| Table 13-15 | 2016 Limestone EGRG results | 141 |

| Table 13-16 | 2013 Volcanic EGRG results | 144 |

| Table 13-17 | 2016 Volcanic EGRG results | 144 |

| Table 13-18 | 2013 Black Shale EGRG results | 146 |

| Table 13-19 | 2016 Blackshale EGRG results | 146 |

| Table 13-20 | Flotation Conditions | 150 |

| Table 13-21 | Ultrafine gravity concentration on flotation rougher concentrate | 165 |

| Table 13-22 | Carbon Loading and Merrill-Crowe tests | 167 |

| Page 14 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| Table 13-23 | Static Thickener Tests | 168 |

| Table 13-24 | Dynamic Thickener Tests | 168 |

| Table 13-25 | Ixtaca ore Ore Sort Performance | 169 |

| Table 13-26 | Limestone Process Plant Metallurgical Projections | 170 |

| Table 13-27 | Volcanic and Black Shale Process Plant Metallurgical Projections | 170 |

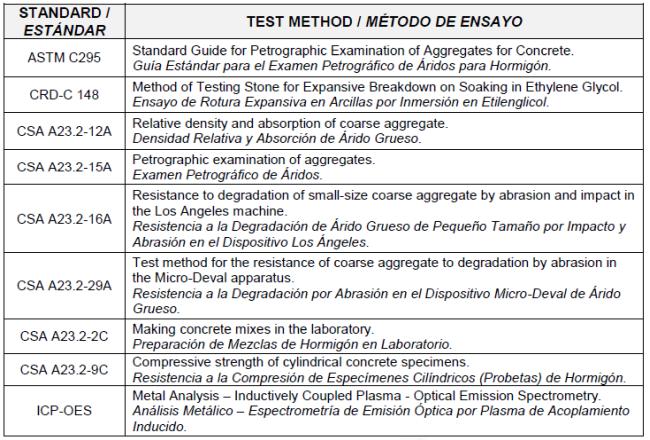

| Table 13-28 | Ixtaca limestone aggregate testing standards | 171 |

| Table 13-29 | Ixtaca limestone testing of aggregate potential | 172 |

| Table 14-1 | Assay Statistics for Gold and Silver Sorted by Mineralized Zone | 177 |

| Table 14-2 | Capped Levels for Gold and Silver | 177 |

| Table 14-3 | Capped Assay Statistics for Gold and Silver Sorted by Domain | 178 |

| Table 14-4 | 3m Composite Statistics for Gold and Silver Sorted by Mineralized Zone | 178 |

| Table 14-5 | Pearson Correlation Coefficients for Au – Ag Geologic Domains | 179 |

| Table 14-6 | Semivariogram Parameters for Gold and Silver | 180 |

| Table 14-7 | Specific Gravity Determinations Sorted by Cross Section | 183 |

| Table 14-8 | Specific Gravity Determinations Sorted by Lithology | 183 |

| Table 14-9 | Kriging Parameters for Gold in Each Domain | 185 |

| Table 14-10 | Measured Resource for Total Blocks | 189 |

| Table 14-11 | Indicated Resource for Total Blocks | 189 |

| Table 14-12 | Inferred Resource for Total Blocks | 189 |

| Table 14-13 | Measured + Indicated Resource for Total Blocks | 190 |

| Table 14-14 | Comparison of Composite Mean Au Grade to Block Mean Au Grade | 190 |

| Table 15-1 | Metal Prices and NSP | 194 |

| Table 15-2 | Process Recoveries for Block Model NSR coding | 194 |

| Table 15-3 | Dilution Grades | 195 |

| Table 15-4 | Mineral Reserves | 195 |

| Table 16-1 | Metallurgical Recovery Assumptions | 196 |

| Table 16-2 | LG Operating Cost Inputs | 198 |

| Table 16-3 | Bench Face Angles | 198 |

| Table 16-4 | Inter-Ramp Angles (Final) | 198 |

| Table 16-5 | Ixtaca Ultimate Pit Limit Contents (NSR>=$12.50) | 200 |

| Table 16-6 | Ixtaca Pit Recommended Slope Angles – Final Walls | 202 |

| Table 16-7 | RSF Capacities | 210 |

| Table 16-8 | Production Schedule Summary | 212 |

| Table 16-9 | Hauler Cycle Time Assumptions | 220 |

| Table 16-10 | Primary Mining Fleet Schedule For Key Periods | 221 |

| Table 16-11 | Mine Operations Support Equipment For Key Periods | 221 |

| Table 17-1 | Summary of Process Initial Design Criteria | 226 |

| Table 17-2 | Reagents and Consumables Summary | 237 |

| Table 18-1 | Regional Rainfall Data | 240 |

| Table 18-2 | Ixtaca West Tailings and Rock Storage Facility Design Criteria Summary | 244 |

| Table 21-1 | Initial Capital Cost Summary | 273 |

| Table 21-2 | Sustaining Capital Cost Summary | 273 |

| Table 21-3 | Expansion Capital Cost Summary | 274 |

| Table 21.4 | Allowances for Contingencies | 279 |

| Table 21-5 | LOM Operating Cost Summary | 281 |

| Table 21-6 | Mining Operating Cost Summary | 282 |

| Page 15 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| Table 21-7 | Process Initial Operating Cost Summary | 282 |

| Table 21-7 | Process Personnel | 283 |

| Table 21-8 | Annual G&A Costs | 283 |

| Table 22-1 | Inputs for Economic Analysis | 285 |

| Table 22-2 | Cash Flow Summary | 286 |

| Table 22-3 | Summary of Ixtaca Economic Sensitivity to Precious Metal Prices (Base Case is Bold) | 287 |

| Table 22-4 | Summary of Economic Results and Sensitivities to Operating Costs ($ Million) | 287 |

| Table 22-5 | Summary of Economic Results and Sensitivities to Exchange Rate ($ Million) | 288 |

| Table 22-6 | Summary of Economic Results and Sensitivities to Capital Cost ($ Million) | 288 |

| Table 26-1 | Recommendations Budget | 302 |

| Page 16 |

|  |

| Ixtaca Feasibility Study – Technical Report |

LIST OF FIGURES

| Figure 1-1 | Ixtaca General Arrangement | 31 |

| Figure 4-1 | General Location | 44 |

| Figure 4-2 | Tuligtic Property Mineral Claims | 45 |

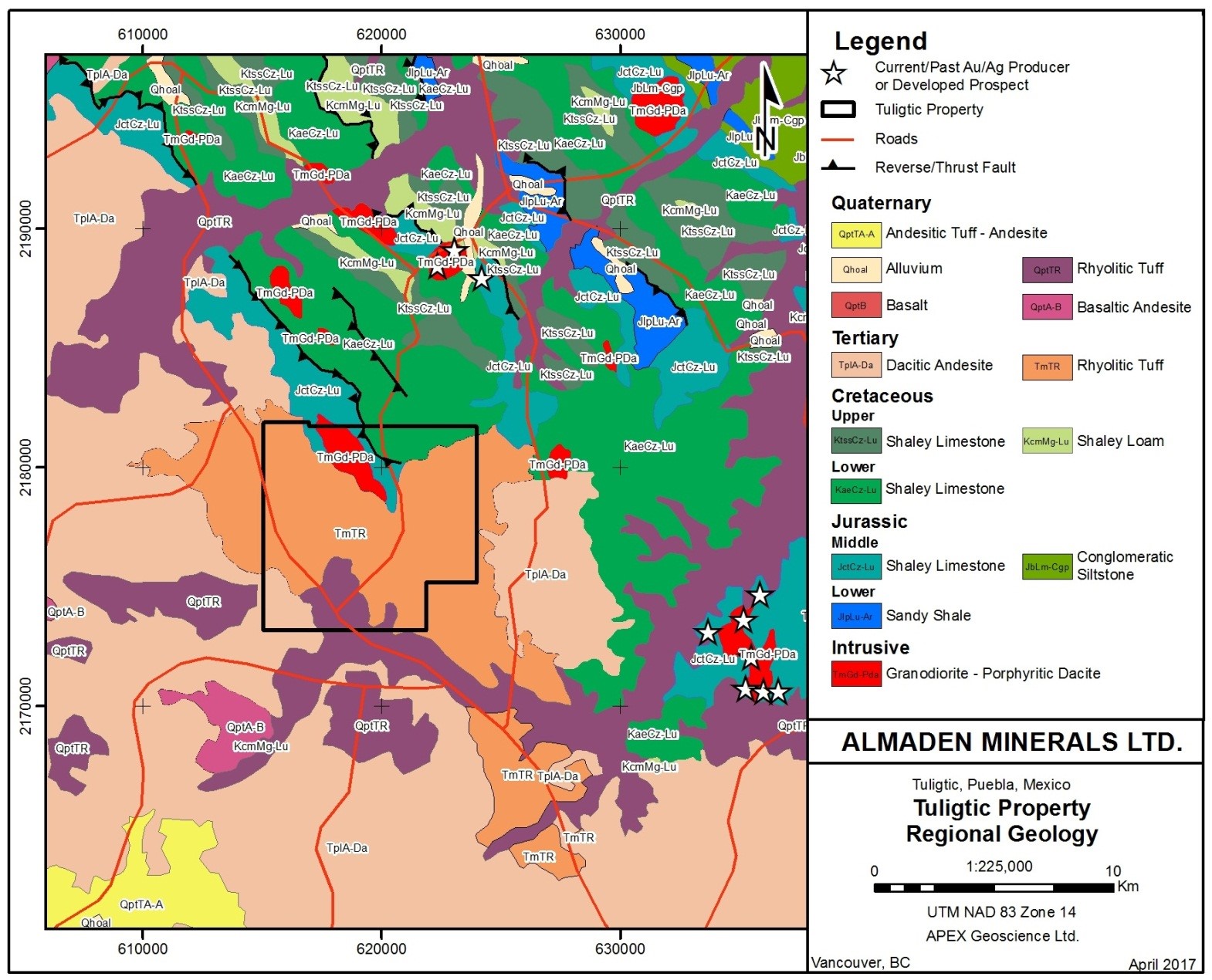

| Figure 7-1 | Regional Geology | 51 |

| Figure 7-2 | Geology of the Ixtaca Area | 53 |

| Figure 7-3 | Chert Limestone | 54 |

| Figure 7-4 | Shale (Calcareous Silstone) from the Chemalaco Zone | 55 |

| Figure 7-5 | Post Mineral Unconsolidated Volcanic Ash Deposits. Generally less than 1m thick | 56 |

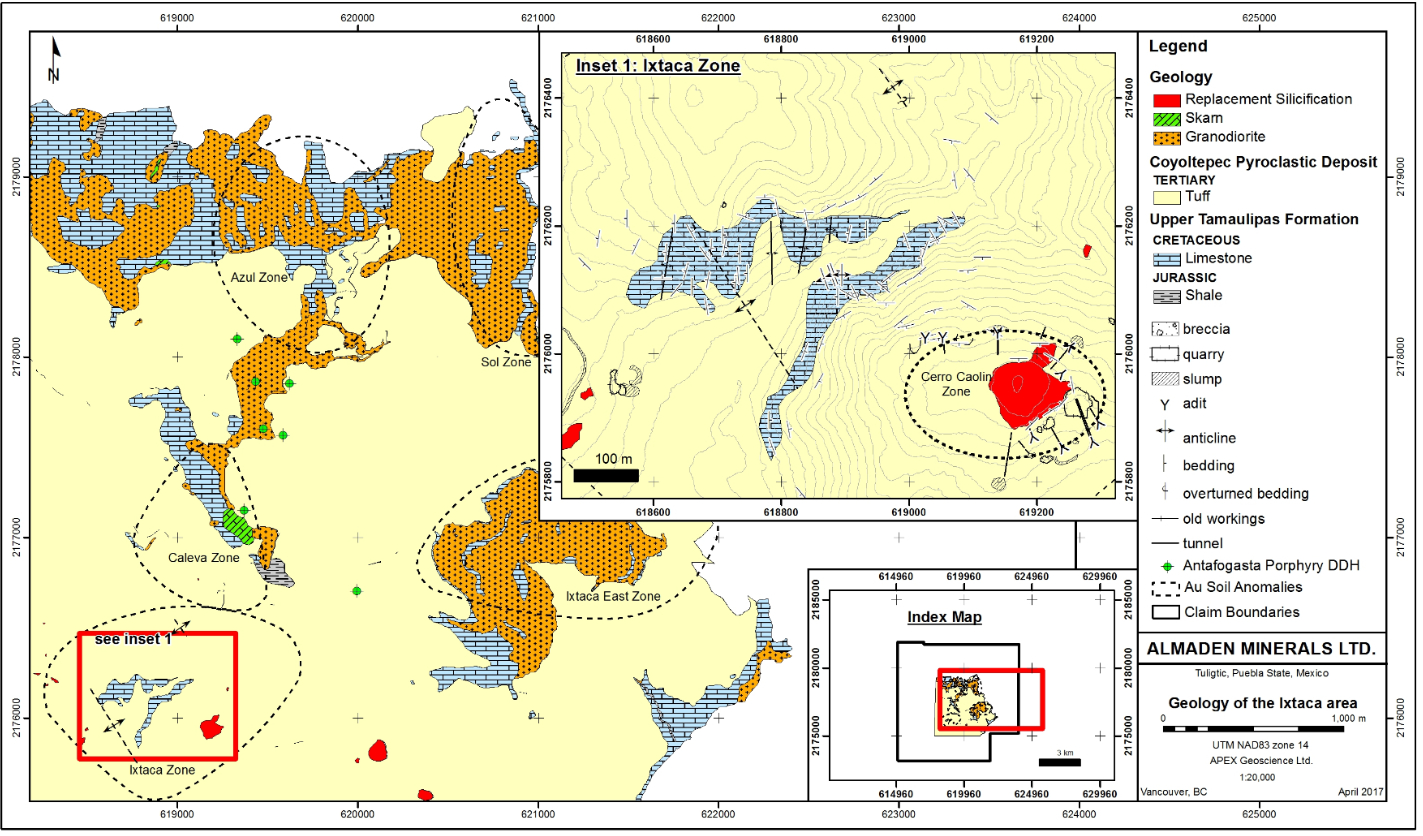

| Figure 7-6 | Looking to the east of Cerro Caolin with Relative positions of Altered Volcanics, Unconformity, Limestone and the Main Ixtaca Vein Swarm | 58 |

| Figure 7-7 | Photo of Cerro Caolin of the Main Ixtaca Vein Swarm From North Looking to the South Showing the Contact between the Clay Altered Volcanic and Limestone Units | 59 |

| Figure 7-8 | Example of Banded Veining of the Main Ixtaca Vein Swarm Zone of | 59 |

| Figure 7-9 | Altered, Veined and Mineralised Volcanics | 61 |

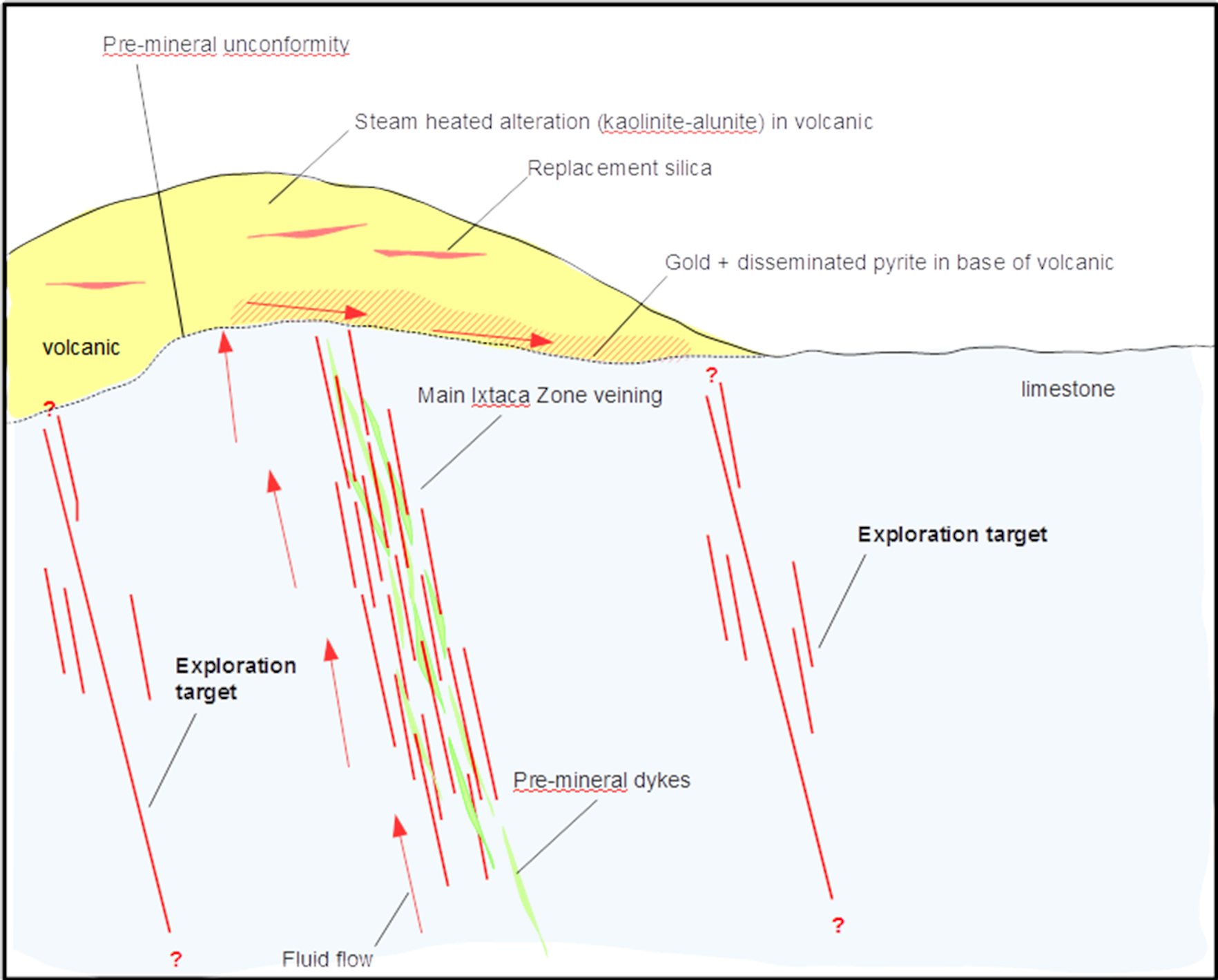

| Figure 7-10 | The Vein System of the Ixtaca Main Zone | 63 |

| Figure 7-11 | Photo (2001) of Historic Clay Exploration Pits in Clay Altered Volcanic Rocks. Looking to West. Photo Taken from near Section 10+300 | 64 |

| Figure 8-1 | Schematic Cross-section of an Epithermal Au-Ag Deposit | 65 |

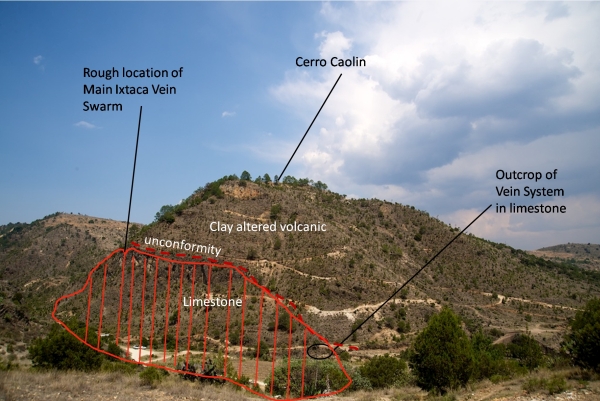

| Figure 8-2 | Photos of Epithernal Veining from Ixtaca, Hishikari Japan and Well Scale from the Active Geothermal System, Broadlands Ohaaki, New Zealand | 66 |

| Figure 8-3 | Selected styles and geometry of epithermal deposits illustrating the structural setting of the limestone hosted veining at Ixtaca, a vein swarm and local stockwork. Taken from Sillitoe (1993). | 70 |

| Figure 9-1 | Exploration Overview Showing Gold in Soil Anomalies and Extent of Geophysical Surveys | 73 |

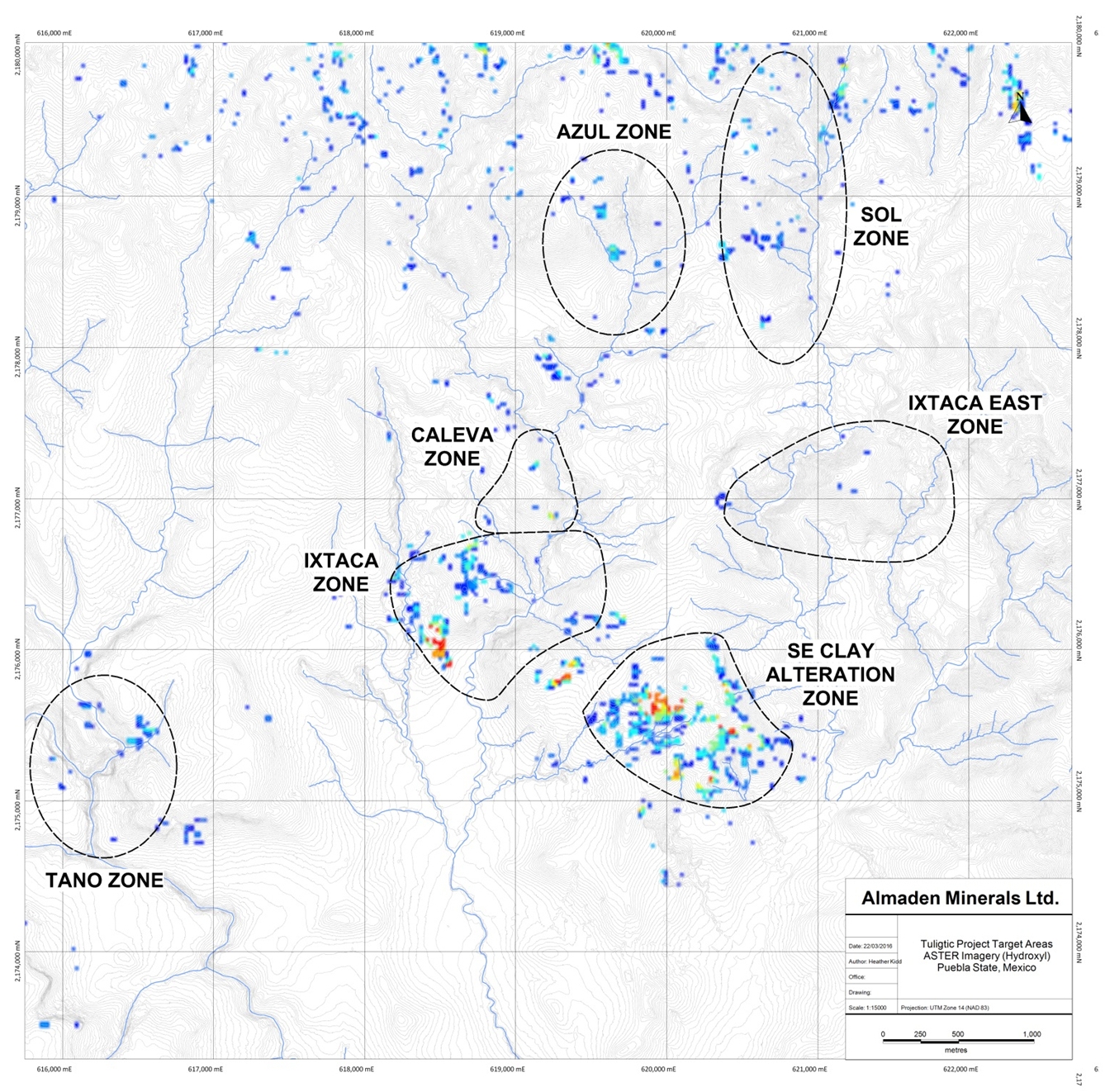

| Figure 9-2 | Gold in Soil Anomalies, ASTER Satellite Hydroxyl responses and Target Areas | 74 |

| Figure 9-3 | IP Chargeability and Resistivity Section Showing Soil Results and Targets. The red target was drill tested with hole TU-10-001 and resulted in the Discovery of the Main Ixtaca Vein Swarm Zone | 75 |

| Figure 9-4 | Exploration Targets on the Tuligtic Project | 77 |

| Figure 9-5 | ASTER Satellite Hydroxyl (Clay) responses Outlining Clay Altered Volanics | 78 |

| Figure 9-6 | Overview Photo of the Waihi Vein Deposit New Zealand. Historic Martha Pit on vein swarm in foreground. Surface projections of the concealed and more recently discovered Favona and Correnso veins also shown. | 80 |

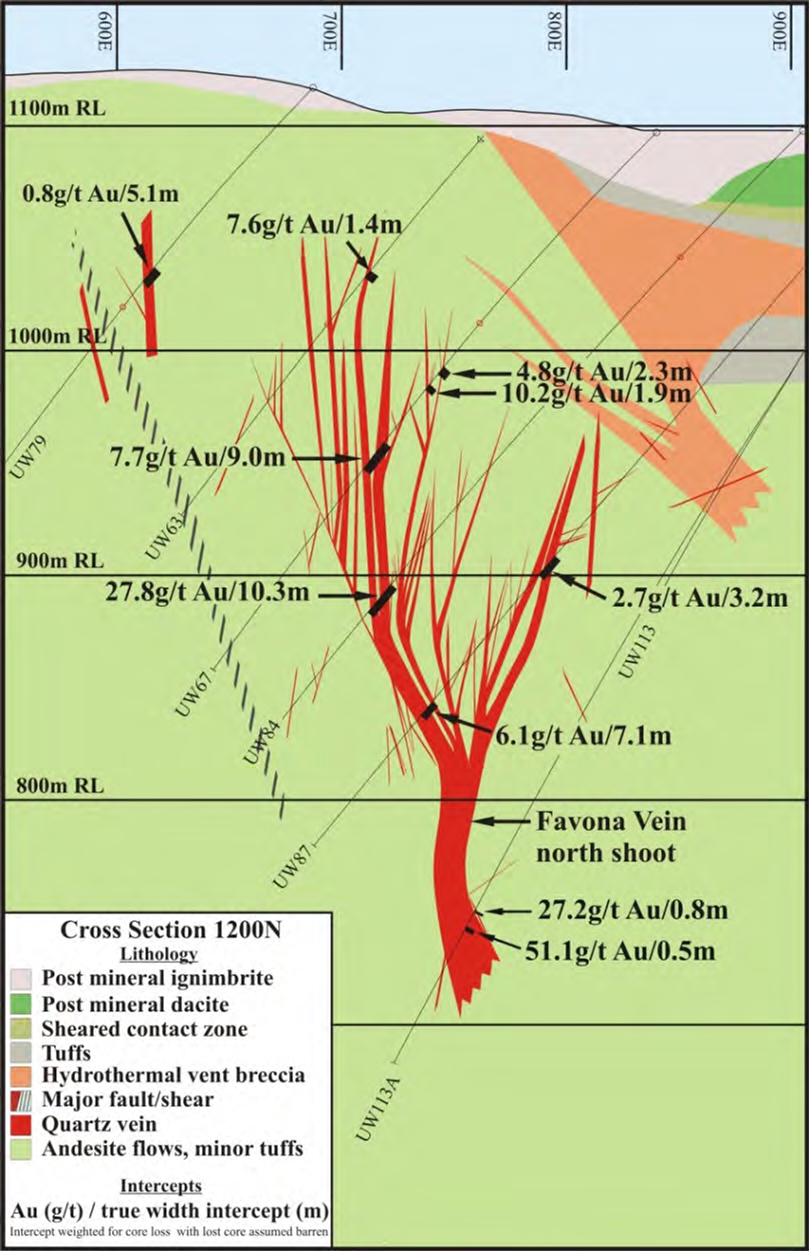

| Figure 9-7 | Cross Section of the Favona Vein Swarm and System, Waihi Deposit New Zealand showing the concealed nature of the deposit | 80 |

| Figure 9-8 | Model for Further Exploration at the Tuligtic Project | 81 |

| Figure 10-1 | 100 Azimuth Section (Looking East) Showing the Assay Results of Discovery hole TU-10-001 which intersected the Main Ixtaca Zone Vein Swarm | 84 |

| Figure 10-2 | Drillhole Locations | 88 |

| Figure 10-3 | Section 10+675E through the Ixtaca Main and North Zones | 97 |

| Figure 10-4 | Section 10+375E through the Ixtaca Main Zone | 98 |

| Figure 10-5 | Section 50+050N through the Chemalaco Zone | 99 |

| Figure 11-1 | QA/QC Analytical Standards | 106 |

| Figure 11-2 | QA/QC Blanks | 112 |

| Page 17 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| Figure 11-3 | QA/QC Duplicates | 113 |

| Figure 13-1 | Ixtaca Metallurgical Domains | 116 |

| Figure 13-2 | Plan View Of Drill holes used for Stage 1 and 2 Metallurgical Test Work | 119 |

| Figure 13-3 | Location of Variability Samples for Stage 3 Metallurgical Test Work – 3D View from NW | 120 |

| Figure 13-4 | Limestone ore: estimated percentage deportment by mineral species | 122 |

| Figure 13-5 | Volcanic: estimated percentage deportment by mineral species | 124 |

| Figure 13-6 | Black Shale: estimated percentage deportment by mineral species | 126 |

| Figure 13-7 | Black Shale: organic carbon mineral distribution | 126 |

| Figure 13-8 | Gold diagnoistic Leach | 127 |

| Figure 13-9 | Silver diagnoistic Leach | 128 |

| Figure 13-10: | Typical Limestone high grade veining (GMET-17-04 at 88 to 89 m depth) | 130 |

| Figure 13-11: | XRT Ore Sorting | 131 |

| Figure 13-12: | Tomra high capacity commercial XRT Ore Sorting Machine | 132 |

| Figure 13-13: | Ixtaca XRT Amenability Test Images | 132 |

| Figure 13-14: | Limestone Ore Sort Mass Balance | 135 |

| Figure 13-15: | Black Shale Concentrate Yield vs Tailings Au Grade | 137 |

| Figure 13-16: | Black Shale Ore Sort Mass Balance | 137 |

| Figure 13-17: | Volcanic Ore Sort Mass Balance | 139 |

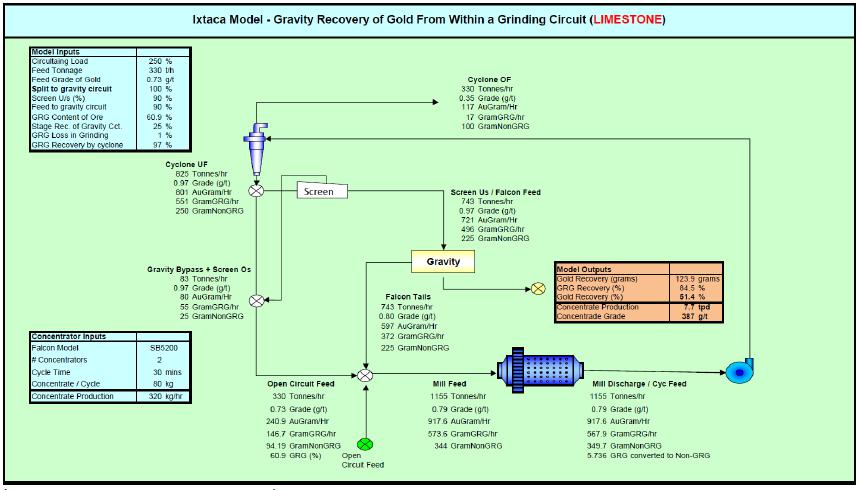

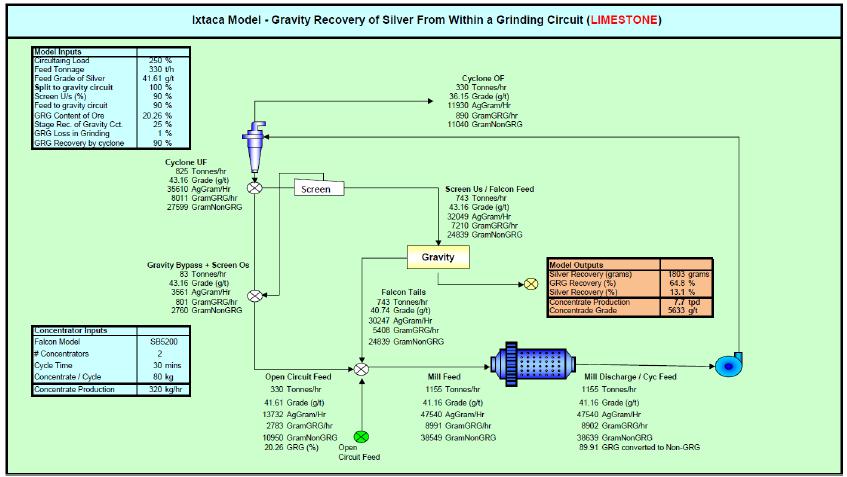

| Figure 13-18: | Limestone gravity recovery vs grind size | 142 |

| Figure 13-19: | 2018 Limestone gravity recovery vs head grade (P80 = 75 µm) | 142 |

| Figure 13-20: | 2018 Limestone Gold - industrial gravity recovery model | 143 |

| Figure 13-21: | 2018 Limestone Silver - industrial gravity recovery model | 143 |

| Figure 13-22: | 2018 Volcanic Gold - industrial gravity recovery model | 145 |

| Figure 13-23: | 2018 Volcanic Silver - industrial gravity recovery model | 145 |

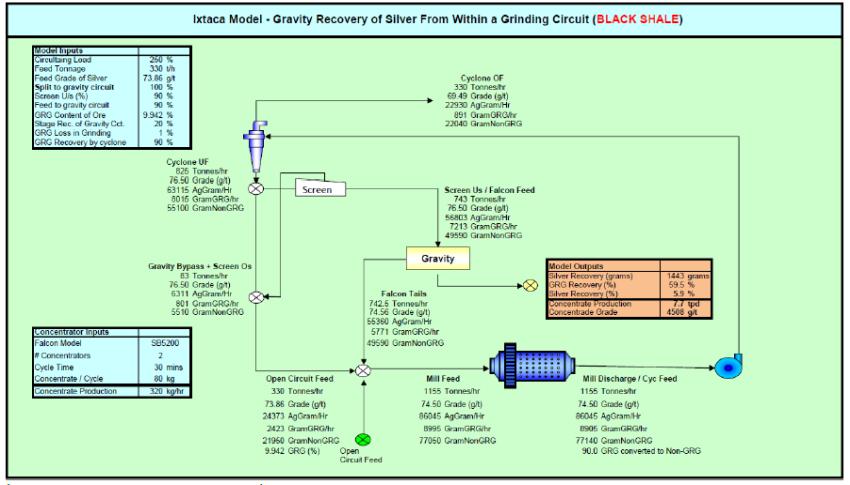

| Figure 13-24: | 2016 Black Shale Gold recovery sensitivty to number of passes | 147 |

| Figure 13-25: | 2018 Black Shale Gold - industrial gravity recovery model | 148 |

| Figure 13-26: | 2018 Black Shale Silver - industrial gravity recovery model | 148 |

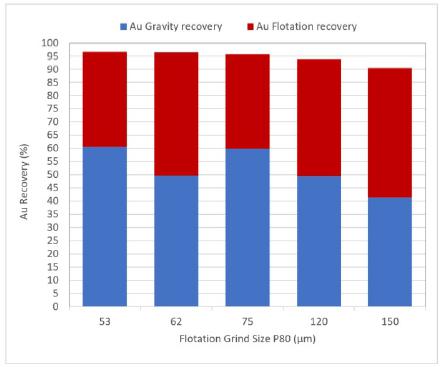

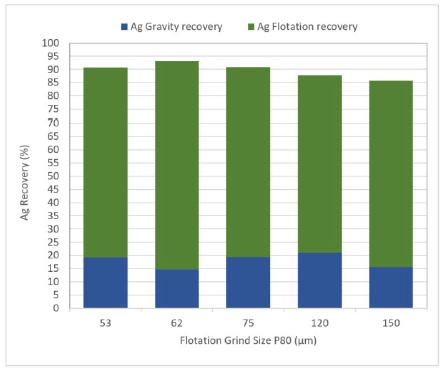

| Figure 13-27: | Summary of Gold recovery by flotation grindsize (2016) | 149 |

| Figure 13-28: | Summary of Silver recovery by flotation grindsize (2016) | 149 |

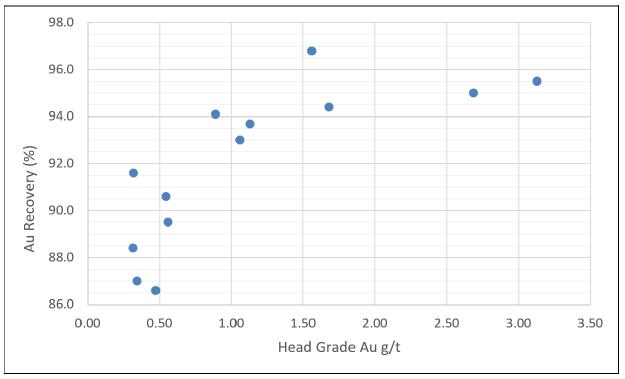

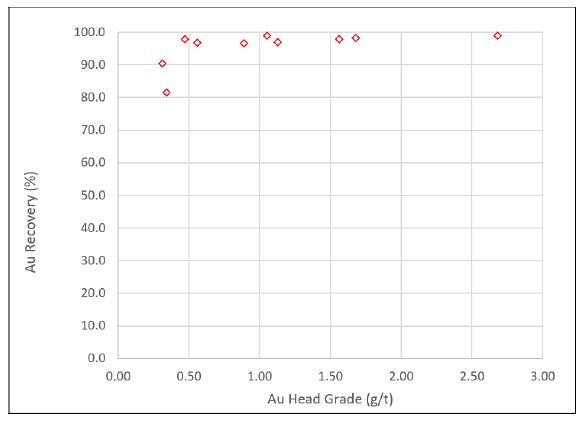

| Figure 13-29: | Gold recovery to combined flotation and gravity concentrate by head grade | 151 |

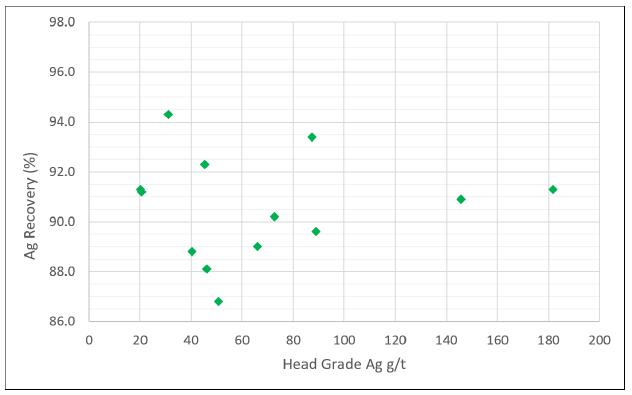

| Figure 13-30: | Silver recovery to combined flotation and gravity concentrate by head grade | 151 |

| Figure 13-31: | Gold flotation recovery sensitivity to flotation reagent | 152 |

| Figure 13-32: | Silver flotation recovery sensitivity to flotation reagent | 152 |

| Figure 13-33: | Gravity concentrate intensitve leach gold recovery | 153 |

| Figure 13-34: | Limestone Gold Leach Rates Limestone (2016) | 155 |

| Figure 13-35: | Limestone Silver Leach Rates Limestone (2016) | 155 |

| Figure 13-36: | Carbon absorption rates | 156 |

| Figure 13-37: | Carbon absorption capacity test – gold loading | 156 |

| Figure 13-38: | Carbon absorption capacity test – silver loading | 157 |

| Figure 13-39: | CIL Gold recovery vs head grade | 157 |

| Figure 13-40: | CIL Silver recovery vs head grade | 158 |

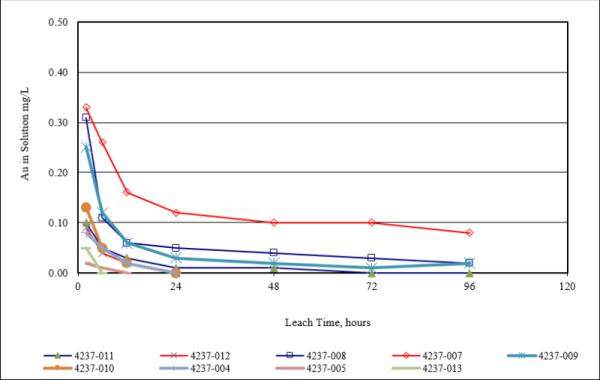

| Figure 13-41: | CIL – Gold in Solution | 158 |

| Figure 13-42: | Volcanic gold leach kinetics at different grind sizes | 159 |

| Figure 13-43: | Volcanic silver leach kinetics at different grind sizes | 159 |

| Figure 13-44: | Black Shale carbon backscatter images | 160 |

| Figure 13-45: | Black Shale carbon rejection exploratory testwork | 161 |

| Page 18 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| Figure 13-46: | Ultrafine gravity concentration of black shale at Metsolve laboratory | 163 |

| Figure 13-47: | Black Shale – gravity concentration of preflotation concentrate | 164 |

| Figure 13-48: | Black Shale – gravity concentration of flotation rougher concentrate | 165 |

| Figure 13-49: | Black Shale impact of organic carbon content on gold recovery | 166 |

| Figure 13-50: | Block Diagram of Recommended Ixtaca Flowsheet | 169 |

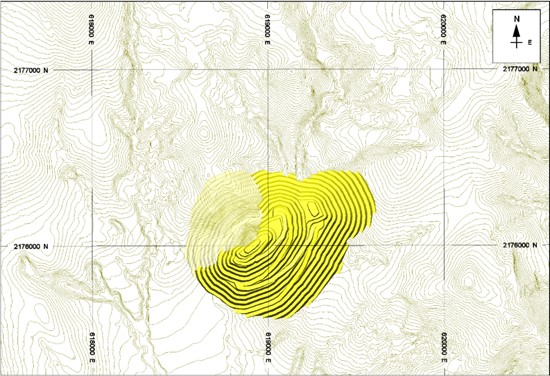

| Figure 14-1 | Plan View Showing the Mineralized Volcanic Ash solid and all drill holes | 174 |

| Figure 14-2 | Plan View Showing the Main HG zone in red, the North Limb HG zone in green and the North East HG zone in magenta. | 175 |

| Figure 14-3 | Plan View Showing Main LG in yellow, North Limb LG in blue and NE LG in grey. | 176 |

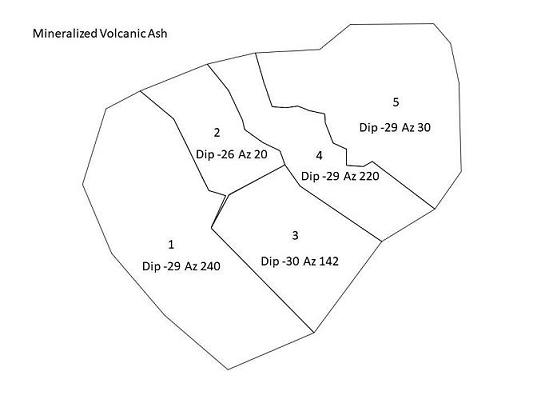

| Figure 14-4 | Plan View of Mineralized Volcanic Ash showing the different quadrants for estimation. | 180 |

| Figure 14-5 | Isometric View Looking NW Showing Mineralized Blocks. | 182 |

| Figure 14-6 | Ixtaca 2202 Level Plan Showing Estimated Gold in Blocks | 192 |

| Figure 14-7 | Ixtaca 2100 Level Plan Showing Estimated Gold in Blocks | 193 |

| Figure 16-1 | Ixtaca Pit Shell Resource Contents by Case | 199 |

| Figure 16-2 | Discounted Cashflow by Price Case | 200 |

| Figure 16-3 | Plan view of selected LG shell (Case 15) | 201 |

| Figure 16-4 | Phase 1 | 203 |

| Figure 16-5 | Phase 2 | 203 |

| Figure 16-6 | Phase 3 | 204 |

| Figure 16-7 | Phase 4 | 204 |

| Figure 16-8 | Phase 5 | 205 |

| Figure 16-9 | Phase 6 | 205 |

| Figure 16-10 | Phase 7 | 206 |

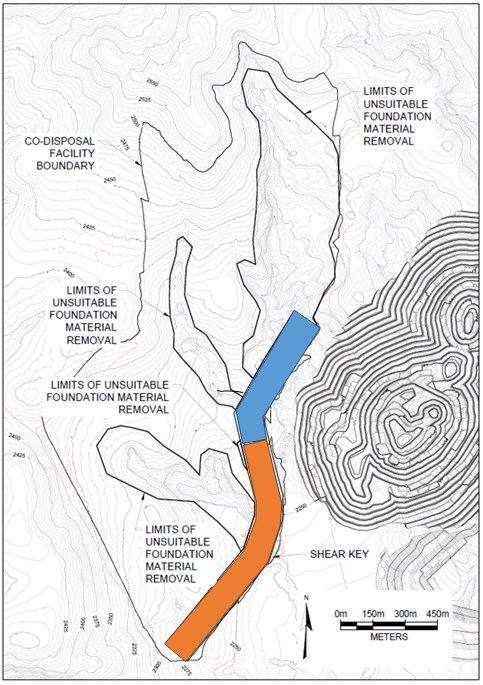

| Figure 16-11 | Extent of South RSF Unsuitable Material Removal | 208 |

| Figure 16-12 | South RSF Underdrainage Collection System | 209 |

| Figure 16-13 | RSF Locations | 210 |

| Figure 16-14 | Crusher Feed Summary by Rock Type | 213 |

| Figure 16-15 | Crusher Feed Gold and Silver Grades by Year | 213 |

| Figure 16-16 | Material Movement by Year | 214 |

| Figure 16-17 | End of Pre-Production Period | 215 |

| Figure 16-18 | End of Year 1 | 216 |

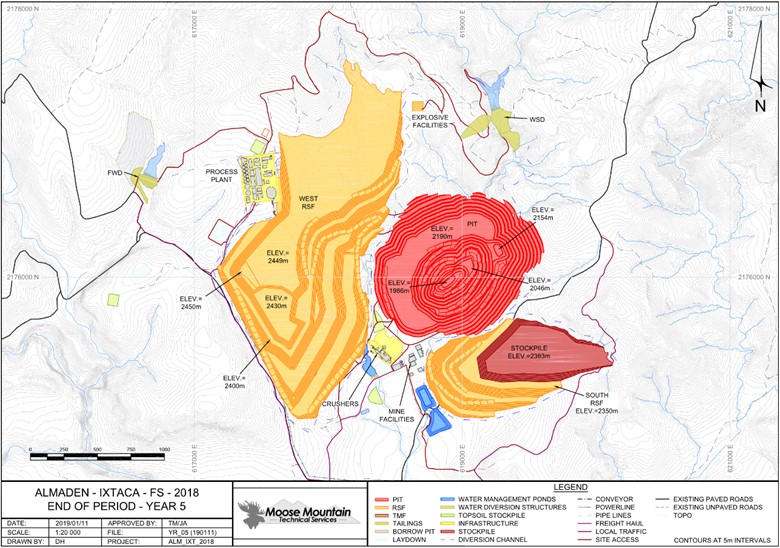

| Figure 16-19 | End of Year 5 | 217 |

| Figure 16-20 | End of Year 11 (Life of Mine) | 218 |

| Figure 16-21 | Org Chart | 223 |

| Figure 17-1 | Summarized flowsheet for Ixtaca – Block Flow Diagram | 225 |

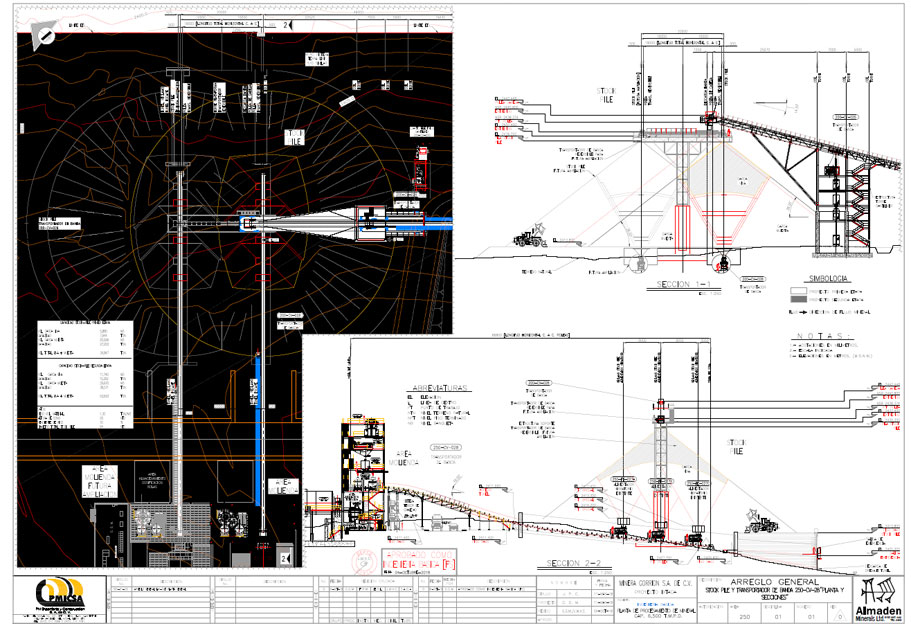

| Figure 17-2 | Crushing And Ore Sort Layout | 230 |

| Figure 17-3 | Stockpile Layout and Section | 231 |

| Figure 17-4 | Processing Plant Layout | 232 |

| Figure 17-5 | Grinding and Gravity Concentration Section 1-1 | 233 |

| Figure 18-1 | Ixtaca Project Roads | 239 |

| Figure 18-2 | Water Balance Flow Schematic | 241 |

| Figure 18-3 | Overall Site Water Management Plan – Year 10 | 242 |

| Figure 18-4 | West Tailings and Rock Storage Facility General Arrangement - LOM | 245 |

| Figure 18-5: | West T/RSF LOM Layout | 246 |

| Figure 18-6 – | West Tailings and Rock Storage Facility Foundation Preparation | 248 |

| Page 19 |

|  |

| Ixtaca Feasibility Study – Technical Report |

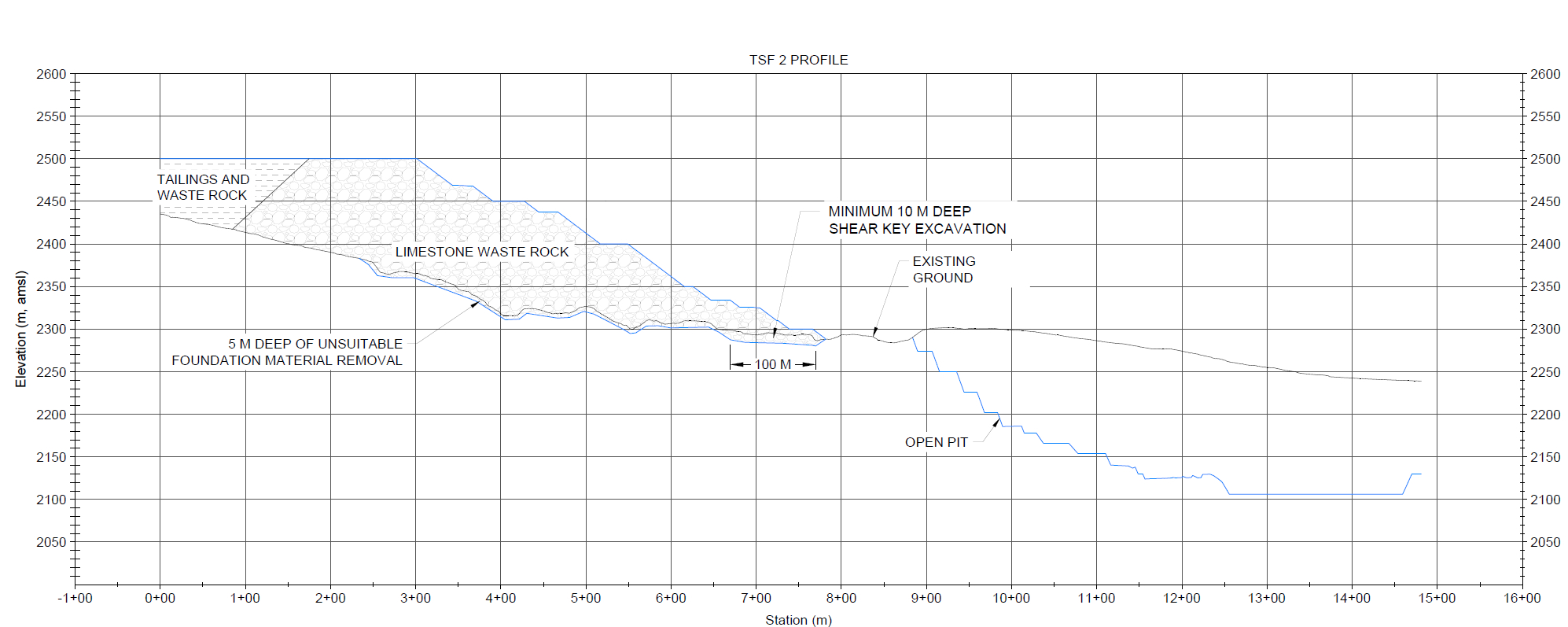

| Figure 18-7 | West Tailings and Rock Storage Facility Northern Portion Cross Section - LOM | 249 |

| Figure 18-8 | West Tailings and Rock Storage Facility Southern Portion Cross Section - LOM | 249 |

| Figure 18-9 | Typical Underdrain Configuration | 250 |

| Figure 20-1 | Surface and Ground Water Quality Sampling Sites | 257 |

| Figure 26-1 | Section View of Au>=$0.5 below the FS pit - looking South -East | 299 |

| Page 20 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| 1.0 | Summary |

| 1.1 | Introduction |

This Technical Report on the Feasibility Study (“FS”) of the Ixtaca Gold-Silver Project (the “Project”) has been prepared for Almaden Minerals Ltd. (“Almaden” or “the Company”) by Moose Mountain Technical Services (“MMTS”) in conjunction with APEX Geoscience Ltd., Giroux Consultants Ltd, (“GCL”) and SRK Consulting (U.S.), Inc (“SRK”). The Ixtaca Project is 100% owned by Almaden, subject to a 2% NSR owned by Almadex Minerals Ltd. (“Almadex”), and encompasses the Ixtaca Zone Deposit (Ixtaca Gold-Silver Deposit) that includes the Ixtaca Main, North, and Chemalaco Zones of the Tuligtic Property.

All currency amounts are referred to in U.S. dollars (USD) unless otherwise indicated.

The FS uses:

| · | An updated resource model; |

| · | The Rock Creek Mill with average throughput of 7,650 tonnes per day; |

| · | A throughput ramp-up to 15,300 tonnes per day of mill feed in Year 5; |

| · | Base case metal prices of $US 1275/oz gold and $US 17/oz silver (75:1 silver-to-gold ratio). |

FS highlights:

| · | Average annual production of 108,500 ounces gold and 7.06 million ounces silver (203,000 gold equivalent ounces, or 15.2 million silver equivalent ounces) over first 6 years; |

| · | After-tax IRR of 42% and after-tax payback period of 1.9 years; |

| · | After-tax NPV of $310 million at a 5% discount rate; |

| · | Initial Capital of $174 million; |

| · | Conventional open pit mining with a Proven and Probable Mineral Reserve of 1.39 million ounces of gold and 85.2 million ounces of silver (See Table 1-2); |

| · | Pre-concentration uses ore sorting to produce a total of 48 million tonnes of mill feed averaging 0.77 g/t gold and 47.9 g/t silver (1.41 g/t gold equivalent over life of mine; 2.03 g/t gold equivalent over first 6 years); |

| · | Average LOM annual production of 90,800 ounces gold and 6.14 million ounces silver (173,000 gold equivalent ounces, or 12.9 million silver equivalent ounces); |

| · | Operating cost $716 per gold equivalent ounce, or $9.55 per silver equivalent ounce; |

| · | All-in Sustaining Costs (“AISC”), including operating costs, sustaining capital, expansion capital, private and public royalties, refining and transport of $850 per gold equivalent ounce, or $11.30 per silver equivalent ounce. |

| · | Elimination of tailings dam by using filtered tailings significantly reduces the project footprint and water usage. |

| Page 21 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| 1.2 | Property Description and Location |

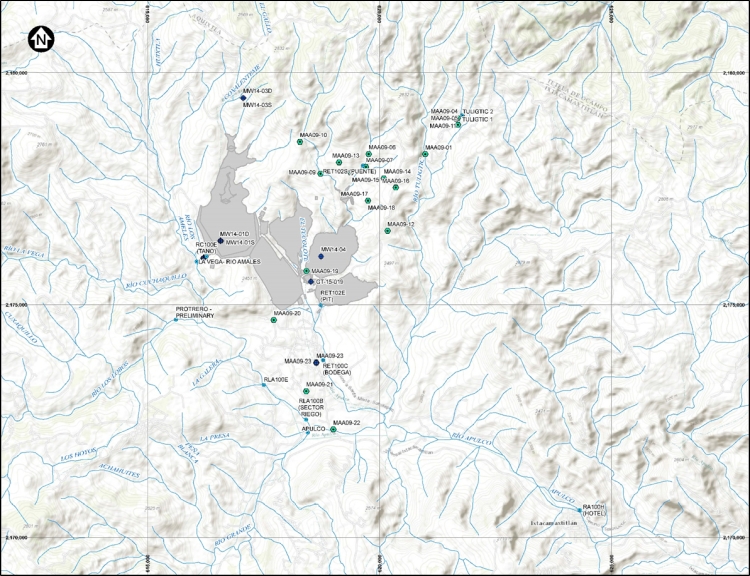

The Tuligtic Property (the “Property”) is held 100 percent (%) by Compania Minera Gorrión S.A. de C.V. (“Minera Gorrión”), a wholly owned subsidiary of Almaden Minerals Ltd. (together referred to as “Almaden”). The Property originally consisted of approximately 14,000 hectares, but during 2015 Almaden filed an application to reduce the aggregate claim size to those areas still considered prospective. The Tuligtic Property currently comprises seven mineral claims totalling 7,220 hectares (ha) located within Puebla State, 80 kilometres (km) north of Puebla City, and 130km east of Mexico City. Almadex Minerals Ltd. holds a 2% Net Smelter Return Royalty (NSR) on the Property.

| 1.3 | Accessibility, Climate, Local Resources, Infrastructure, Physiography |

The Tuligtic Property is road accessible and is located within Puebla State, 80 kilometres (km) north of Puebla City, and 130km east of Mexico City. The Ixtaca Deposit within the Tuligtic Property is located 8km northwest of the town of San Francisco Ixtacamaxtitlán, the county seat of the municipality of Ixtacamaxtitlán, Puebla State.

The topography on the Tuligtic Property is generally moderate to steep hills with incised stream drainages. Elevation ranges from 2,300 metres (m) above sea level in the south to 2,800m in the north. Vegetation is dominantly cactus and pines and the general area is somewhat cultivated with subsistence vegetables, bean and corn crops. The region has a temperate climate with average temperatures ranging from 16°C in June to 12°C in December. The area experiences an average of 600 to 720 mm of precipitation annually with the majority falling during the rainy season, between June and September.

Electricity is available on the Property from the national electricity grid that services nearby towns such as Santa Maria and Zacatepec.

Almaden has secured through purchase agreements with numerous independent owners approximately 1,139 hectares required for the proposed production plan. This was completed through friendly land purchase agreements with locals, considering fair market value. There are no communities that require relocation as part of the Project development. Mineral Claim owners have the right to obtain the temporary occupancy, or creation of land easements required to carry out exploration and mining operations, under the Federal Mining Law.

| 1.4 | History |

Throughout the Property there is evidence that surficial clay deposits have once been mined prior to Almaden’s acquisition of the project. Almaden acquired the Cerro Grande claims of the Tuligtic Property by staking in 2001 following the identification of surficial clay deposits that have been interpreted to represent high-level epithermal alteration. Subsequent geologic mapping, rock, stream silt, soil sampling, and induced polarization (IP) geophysical surveys identified porphyry copper and epithermal gold targets within an approximately 5 x 5km area of intensely altered rock. In July 2010, Almaden initiated a diamond drilling program to test epithermal alteration within the Tuligtic Property, resulting in the discovery of the Ixtaca Zone. The first hole, TU-10-001 intersected 302.42 metres (m) of 1.01g/t Au and 48g/t Ag and multiple high grade intervals including 44.35m of 2.77g/t Au and 117.7g/t Ag.

| Page 22 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| 1.5 | Geological Setting and Mineralization |

The Tuligtic Property covers a roughly 5 by 5 kilometre area of high level epithermal alteration characterised by intense kaolinite-alunite alteration and silicification in volcanic rocks. This alteration is interpreted to represent the upper portion of a well preserved epithermal system.

The epithermal system is hosted by both volcanic rocks and older carbonate units. Minor disseminated and vein mineralisation is hosted by the volcanic rocks (referred to as tuff, ash and volcanics). The bulk of the deposit is hosted by the carbonate units as vein swarms.

Within the Tuligtic Property, variably cherty and bedded light grey to dark coloured limestone (referred to as limestone) of the Late Jurassic to Early Cretaceous Upper Tamaulipas formation is underlain by transitional calcareous clastic rocks including minor brown grainstones, and thinly bedded grey, black and green coloured shaley units (referred to as shale or black shale). The brown grainstone marks the transition between limestone and shale. During the Laramide orogeny, this entire carbonate package was intensely deformed into a series of thrust-related east verging anticlines. The shale units appear to occupy the cores of the anticlines while the limestone units occupy the cores of major synclines at the Ixtaca Zone. The carbonate units are crosscut by intensely altered intermediate composition dykes. The deformed Mesozoic sedimentary sequence is discordantly overlain by epithermal altered Cenozoic bedded crystal tuff of the upper Coyoltepec subunit (referred to as volcanic, ash and tuff).

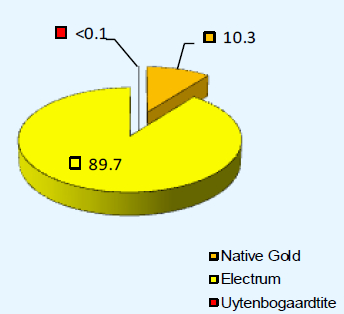

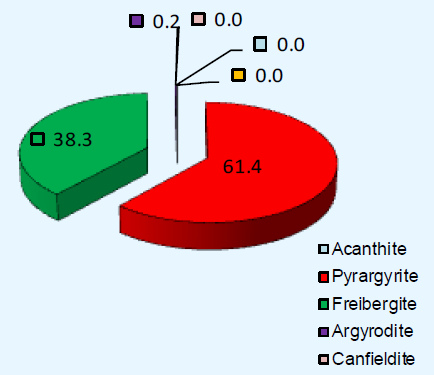

The Ixtaca deposit is a low sulphidation epithermal vein system. Most of the gold silver mineralisation occurs as zones of high grade vein and veinlets (vein swarms) in the carbonate basement units. A small portion of the gold silver mineralisation occurs above the unconformity as disseminated mineralisation in the altered volcanic rocks. The mineralisation is not oxidised and is hosted by classic banded and colloform low-sulphidation style carbonate-quartz veining. Spatially widespread polished section and SEM mineralogic studies of mineralised epithermal veins demonstrate that the gold is dominantly hosted by electrum (an alloy of gold and silver) and the gold-silver sulphide uytenbogaardtite (Ag3AuS2). Apart from electrum and uytenbogaardite, the dominant silver minerals are silver rich polybasite, pyrargerite, proustite and naumannite. The ore minerals are accompanied by minor pyrite, galena (no silver detected in the SEM work on the galena) and sphalerite. The mineral assemblage is very similar to other precious metal low sulphidation vein systems worldwide with low base metal contents.

To date two main vein orientations have been identified in the Ixtaca deposit:

| · | 060 degrees trending sheeted veins hosted by limestone; |

| · | 330 degrees trending veins hosted by shale; |

The bulk of the resource and over 80% of the recoverable metal in the FS is hosted by the limestone in the Main Ixtaca and Ixtaca North zones as swarms of sheeted and anastomosing high grade banded epithermal veins. There is no disseminated mineralisation within the host rock to the vein swarms, which is barren and unaltered limestone. To the northeast of the limestone hosted mineralisation, the Chemalaco zone, a 330 striking and west dipping vein zone hosted by shale, also forms part of the deeper resource.

The Main Ixtaca and Ixtaca North vein swarms are spatially associated with two altered and mineralised sub parallel ENE (060 degrees) trending, sub-vertical to steeply north dipping dyke zones. The Main Ixtaca dyke zone is approximately 100m wide and consists of a series of 2m to over 20m true width dykes. The Ixtaca North dyke zone is narrower and comprises a steeply north-dipping zone of two or three discrete dykes ranging from 5 to 20m in width.

| Page 23 |

|  |

| Ixtaca Feasibility Study – Technical Report |

Individual veins within the Main Ixtaca and Ixtaca North vein zones cannot be separately modelled. Wireframes were created that constrain the higher grade, more densely veined areas, however as the vein swarms are anastomosing and sheeted in nature, these wireframes include significant barren limestone material enclosed by veins within the vein swarm.

The Main and North zones have been defined over 650m and tested over 1000m strike length with high-grade mineralization intersected to depths up to 350m vertically from surface. The strike length of the Chemalaco Zone has been extended to 450m with high-grade mineralization intersected to a vertical depth of 550m, or approximately 700m down-dip. In 2016 Almaden conducted a drill program to test for additional veins to the north of the Ixtaca North Zone. This program resulted in better definition of the Ixtaca North zone and successfully demonstrated that limestone mineralisation remains open to the north and at depth.

The Chemalaco Zone dips moderately-steeply at approximately 22 degrees to the WSW. An additional sub-parallel zone has been defined underneath the Chemalaco Zone dipping 25 to 50 degrees to the WSW, intersected to a vertical depth of 250m, approximately 400m down-dip over a 250m strike length. The Chemalaco zone remains open to depth and along strike to the northwest. Additional parallel veins further to the east have been identified in core and the zone remains open in this direction as well.

| 1.6 | Exploration |

Between 2001 and 2013, Almaden’s exploration at the Tuligtic Property included geologic mapping and prospecting, alteration mineralogical characterization, rock and soil geochemical sampling, ground magnetics, IP and resistivity, Controlled Source Audio-frequency Magnetotelluric (CSAMT), and Controlled Source Induced Polarization (CSIP) geophysical surveys resulting in the identification of additional anomalous zones including the Ixtaca, Ixtaca East, Caleva, Azul, Sol zones, Tano, and SE Alteration zones. Since 2010, a total of 590 diamond drillholes have been drilled at the Tuligtic Property, totalling 192,121 m (not including geotechnical holes). During this timeframe the Company focussed on Ixtaca Zone Deposit resource and development work which has meant that many of the epithermal targets have not yet been tested by drilling.

| 1.7 | Drilling |

The 230 holes drilled between July, 2010 and November 13, 2012 totalled 83,346m and identified the Main Ixtaca, Ixtaca North and Chemalaco zones. Diamond drilling at 25 to 50m section spacing defined the Main Ixtaca and Ixtaca North as NE-oriented sub-vertical zones and a strike length of approximately 650m. High-grade mineralization was intersected to depths of 200 to 300m vertically from surface. The Chemalaco Zone was identified as dipping moderately-steeply over a strike length of 350m along a series of five ENE (070 degrees) oriented sections spaced at intervals of 50 to 100m. High grade mineralization having a true-width ranging from less than 30 and up to 60m was intersected beneath approximately 30m of tuff to a vertical depth of 550m, or approximately 600m down-dip.

During 2013 and subsequent to the November 13, 2012 cut-off of the maiden mineral Resource Estimate, Almaden drilled 198 holes totalling 55,467m. A total of 79 holes were drilled at the Main Ixtaca Zone, 40 holes at the Ixtaca North Zone and 79 holes at the Chemalaco Zone. Drilling during 2013 focused on expanding the deposit and upgrading resources previously categorized as Inferred to higher confidence Measured and Indicated categories.

| Page 24 |

|  |

| Ixtaca Feasibility Study – Technical Report |

Drilling during 2014 and 2015, subsequent to the 2014 Resource Estimate, Almaden had completed 52 additional drill holes totalling 17,128m (49 within the Ixtaca Deposit and 3 exploration drill holes outside the Ixtaca Deposit. Of the holes drilled within the Ixtaca Deposit during 2014 through 2016, 4 were metallurgical holes that twinned existing holes. The remainder were exploration holes testing mineralized zones at depth.

Drilling during 2014 through 2016 comprised 86 additional drill holes totalling 28,131m (including 3 exploration drill holes at the (Casa) Azul Zone, and 1 at the Tano Zone). Of the holes drilled within the Ixtaca Deposit during 2014, 2015, and 2016, 4 were metallurgical holes that twinned existing holes and 27 were geotechnical holes. During 2016 a total of 33 holes totalling 10,514m further delineated and expanded the Ixtaca North Zone mineralization as well as identifying new veins to the north and at depth. The remainder were exploration holes testing mineralized zones at depth below the PEA pit described in this report. Past drilling at the Casa Azul zone intersected porphyritic intrusive and limestone-skarn mineralization returning locally elevated zinc, copper and silver values.

Drilling during 2017 through 2018 comprised 76 additional drill holes totalling 25,176m. Of the holes drilled within the Ixtaca Deposit during 2017 and 2018, 4 were metallurgical holes that twinned existing holes and 11 were geotechnical holes. During 2017 and 2018 a total of 21 additional holes were drilled in the Main zone, 18 in the Ixtaca North zone, and 5 additional holes in the Chemalaco Zone. The remainder were exploration holes drilled at surface in the surrounding areas.

| 1.8 | Sample Preparation, Analyses and Security |

All strongly altered or epithermal-mineralized intervals of core have been sampled. Almaden employs a maximum sample length of 2 to 3m in unmineralized lithologies, and a maximum sample length of 1m in mineralized lithologies. During the years 2010 and 2011 Almaden employed a minimum sample length of 20cm. The minimum sample length was increased to 50cm from 2012 onwards to ensure the availability of sufficient material for replicate analysis. Drill core is half-sawn using industry standard diamond core saws. After cutting, half the core is placed in a new plastic sample bag and half are placed back in the core box. Sample numbers are written on the outside of the sample bags and a numbered tag placed inside the bag. Sample bags are sealed using a plastic cable tie. Sample numbers are checked against the numbers on the core box and the sample book.

ALS Minerals (ALS) sends its own trucks to the Project to take custody of the samples at the Santa Maria core facility and transports them to its sample preparation facility in Guadalajara or Zacatecas, Mexico. Prepared sample pulps are then forwarded by ALS personnel to the ALS North Vancouver, British Columbia laboratory for analysis.

Drill core samples have been subject to gold determination via a 50 gram (g) AA finish FA fusion with a lower detection limit of 0.005ppm Au (5ppb) and upper limit of 10ppm Au (ALS method Au-AA24). Over limit gold values (>10ppm Au) are subject to gravimetric analysis (ALS method Au-GRA22). Silver, base metal and pathfinder elements for drill core samples are analyzed by 33-element ICP-AES, with a 4-acid digestion, a lower detection limit of 0.5ppm Ag and upper detection limit of 100ppm Ag (ALS method ME-ICP61). Over limit silver values (>100ppm Ag) are subject to 4-acid digestion ICP-AES analysis with an upper limit of 1,500ppm Ag (ALS method ME-OG62). Ultra-high grade silver values (>1,500ppm Ag) are subject to gravimetric analysis with an upper detection limit of 10,000ppm Ag (Ag-GRA22).

| Page 25 |

|  |

| Ixtaca Feasibility Study – Technical Report |

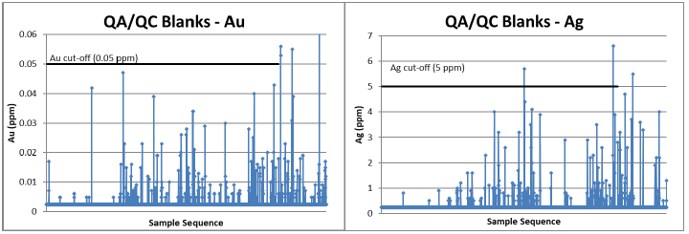

Drill core samples are subject to Almaden’s internal QA/QC program that includes the insertion of analytical standard, blank and duplicate samples into the sample stream. A total of fifteen QA/QC samples are present in every 100 samples sent to the laboratory. QA/QC sample results are reviewed following receipt of each analytical batch. QA/QC samples falling outside established limits are flagged and subject to review and possibly re-analysis, along with the ten preceding and succeeding samples.

| 1.9 | Data Verification |

Mr. Kristopher J. Raffle, P.Geo., first visited the Tuligtic Property from October 17 to October 20, 2011. Additional visits to the Tuligtic Property have been carried out by Mr. Raffle on September 23, 2012 and November 20, 2013. During each of the property visits Mr. Raffle completed a traverse of the Ixtaca Zone, observed the progress of ongoing diamond drilling operations, and recorded the location of select drill collars. Almaden’s complete drill core library has been made available and Mr. Raffle reviewed mineralized intercepts from a series of holes across the Ixtaca Zone. Mr. Raffle has collected quartered drill core samples as ‘replicate’ samples from select reported mineralized intercepts.

Based on the results of the traverses, drill core review, and ‘replicate’ sampling Mr. Raffle has no reason to doubt the reported exploration results. The analytical data is considered to be representative of the drill samples and suitable for inclusion in the Resource Estimate. In addition to the in-house Quality Assurance Quality Control (QAQC) measures employed by Almaden, Kris Raffle, P.Geo. of APEX Geoscience Ltd., completed an independent review of Almaden’s drillhole and QAQC databases. The review included an audit of approximately 8% of drill core analyses used in the mineral resource estimate. A total of 10,885 database gold and silver analyses were verified against original analytical certificates. Similarly, 10% of the original drill collar coordinates and down hole orientation survey files were checked against those recorded in the database; and select drill sites were verified in the field by Kris Raffle, P.Geo. The QAQC audit included independent review of blank, field duplicate and certified standard analyses. All QAQC values falling outside the limits of expected variability were flagged and followed through to ensure completion of appropriate reanalyses. No discrepancies were noted within the drillhole database, and all QAQC failures were dealt with and handled with appropriate reanalyses.

| 1.10 | Metallurgy |

Metallurgical test work and mineralogy has been undertaken on each of the Ixtaca Zone metallurgical domains between 2012 and 2018 at a number of laboratories.

There are 3 distinct metallurgical domains hosting precious metal mineralization at Ixtaca:

| · | Limestone ore contains most of the economic mineralization and contributes 75% of metal production in the FS (90% of metal production in the payback period). |

| · | Volcanic ore contributes 12% of metal production in the FS. |

| · | Black Shale ore contributes 13% of metal production in the FS. |

| Page 26 |

|  |

| Ixtaca Feasibility Study – Technical Report |

The testwork has consistently demonstrated that economic mineralization responds well to processing by pre-concentration with XRT ore sorting, gravity concentration, intensive leaching of gravity concentrate, flotation, flotation concentrate regrind, leaching with 24 hours Carbon-in-Leach (CIL) to complete gold leaching and 72 hours of agitated leach to complete silver leaching.

The majority of economic mineralization is fine grained, requiring a primary grind P80 of 75 μm for liberation, and regrind prior to leaching.

Test work has demonstrated repeatable good overall recoveries for gold and silver in the primary Limestone ore domain. Silver over all recoveries from the volcanic and black shale domains is good. Gold recoveries in volcanic and black shale are poor due to refractory mineralization in the volcanic and preg-robbing organic carbon in the black shale. Ongoing test work indicates that gold recovery improvements in the black shale can be achieved with organic carbon rejection by carbon pre-flotation or flotation cleaning using an organic carbon depressant. Good carbon rejection and subsequent leach recovery was also achieved by ultra fine gravity concentration of black shale concentrates.

| 1.11 | Resource Estimate |

On January 31, 2013 the Company announced a maiden resource on the Ixtaca Zone, which was followed by a resource update on January 22, 2014 and another on May 17, 2017. Since that time an additional 104 holes have been completed, and this data is also included in the Mineral Resource Estimate which has been prepared in accordance with NI 43-101 by Gary Giroux, P.Eng., qualified person ("QP") under the meaning of NI 43-101, and summarised in Table 1-1. The data available for the resource estimation consisted of 649 drill holes assayed for gold and silver. Wireframes constraining mineralised domains were constructed based on geologic boundaries defined by mineralisation intensity and host rock type. Higher grade zones occur where there is a greater density of epithermal veining. These higher grade domains have good continuity and are cohesive in nature.

Of the total drill holes, 558 intersected the mineralised solids and were used to make the resource estimate. Capping was completed to reduce the effect of outliers within each domain. Uniform down hole 3 meter composites were produced for each domain and used to produce semivariograms for each variable. Grades were interpolated into blocks 10 x 10 x 6 meters in dimension by ordinary kriging. Specific gravities were determined for each domain from drill core. Estimated blocks were classified as either Measured, Indicated or Inferred based on drill hole density and grade continuity.

Table 1-1 shows the Measured, Indicated and Inferred Mineral Resource Statement with the Base Case 0.3 g/t AuEq Cut-Off highlighted from the 8 July 2018 Resource Statement. Also shown are the 0.5, 0.7 and 1.0 g/t AuEq cut-off results. AuEq calculation is based on average prices of $1250/oz gold and $18/oz silver.

Table 1-1 Ixtaca Zone Measured, Indicated and Inferred Mineral Resource Statement

| MEASURED RESOURCE | |||||||

| AuEq Cut-off | Tonnes > Cut-off | Grade>Cut-off | Contained Metal x 1,000 | ||||

| (g/t) | (tonnes) | Au (g/t) | Ag (g/t) | AuEq (g/t) | Au (oz) | Ag (oz) | AuEq (oz) |

| 0.30 | 43,380,000 | 0.62 | 36.27 | 1.14 | 862 | 50,590 | 1,591 |

| Page 27 |

|  |

| Ixtaca Feasibility Study – Technical Report |

| 0.50 | 32,530,000 | 0.75 | 44.27 | 1.39 | 788 | 46,300 | 1,454 |

| 0.70 | 25,080,000 | 0.88 | 51.71 | 1.63 | 711 | 41,700 | 1,312 |

| 1.00 | 17,870,000 | 1.06 | 61.69 | 1.95 | 608 | 35,440 | 1,118 |

| INDICATED RESOURCE | |||||||

| AuEq Cut-off | Tonnes > Cut-off | Grade>Cut-off | Contained Metal x 1,000 | ||||

| (g/t) | (tonnes) | Au (g/t) | Ag (g/t) | AuEq (g/t) | Au (oz) | Ag (oz) | AuEq (oz) |

| 0.30 | 80,760,000 | 0.44 | 22.67 | 0.77 | 1,145 | 58,870 | 1,994 |

| 0.50 | 48,220,000 | 0.59 | 30.13 | 1.02 | 913 | 46,710 | 1,586 |

| 0.70 | 29,980,000 | 0.74 | 37.79 | 1.29 | 715 | 36,430 | 1,240 |

| 1.00 | 16,730,000 | 0.96 | 47.94 | 1.65 | 516 | 25,790 | 888 |

| INFERRED RESOURCE | |||||||

| AuEq Cut-off | Tonnes > Cut-off | Grade>Cut-off | Contained Metal x 1,000 | ||||

| (g/t) | (tonnes) | Au (g/t) | Ag (g/t) | AuEq (g/t) | Au (oz) | Ag (oz) | AuEq (oz) |

| 0.30 | 40,410,000 | 0.32 | 16.83 | 0.56 | 412 | 21,870 | 726 |

| 0.50 | 16,920,000 | 0.44 | 25.43 | 0.80 | 237 | 13,830 | 436 |

| 0.70 | 7,760,000 | 0.57 | 33.80 | 1.06 | 142 | 8,430 | 264 |

| 1.00 | 3,040,000 | 0.79 | 43.64 | 1.42 | 77 | 4,270 | 139 |

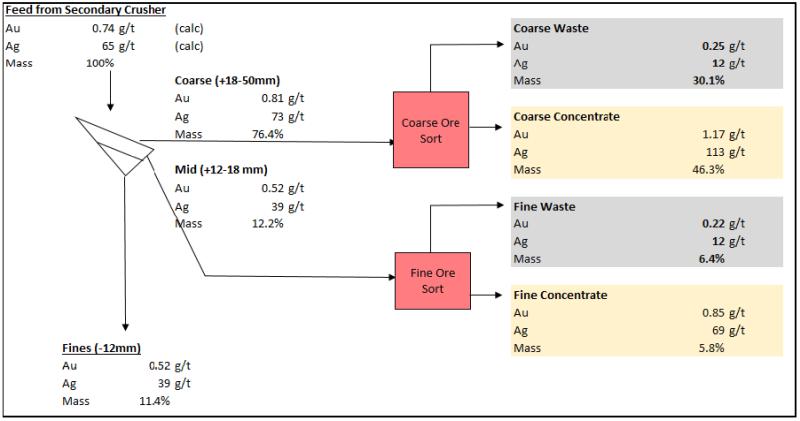

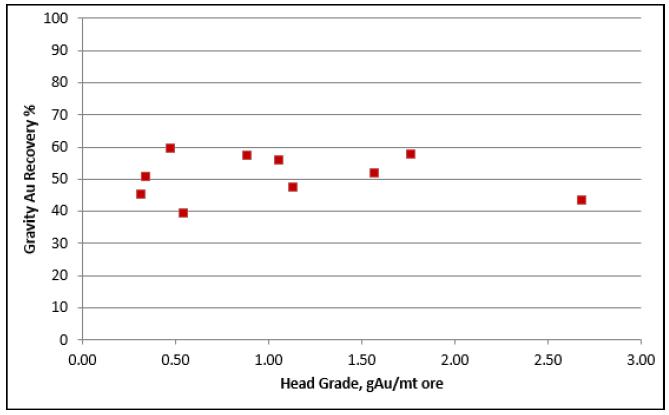

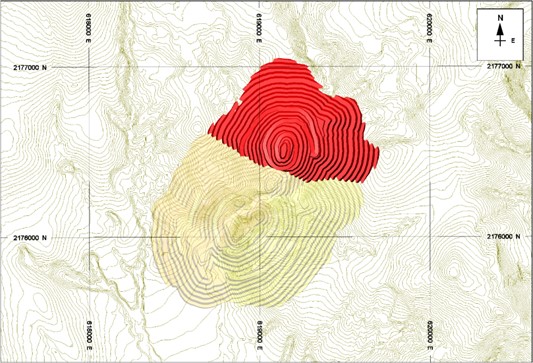

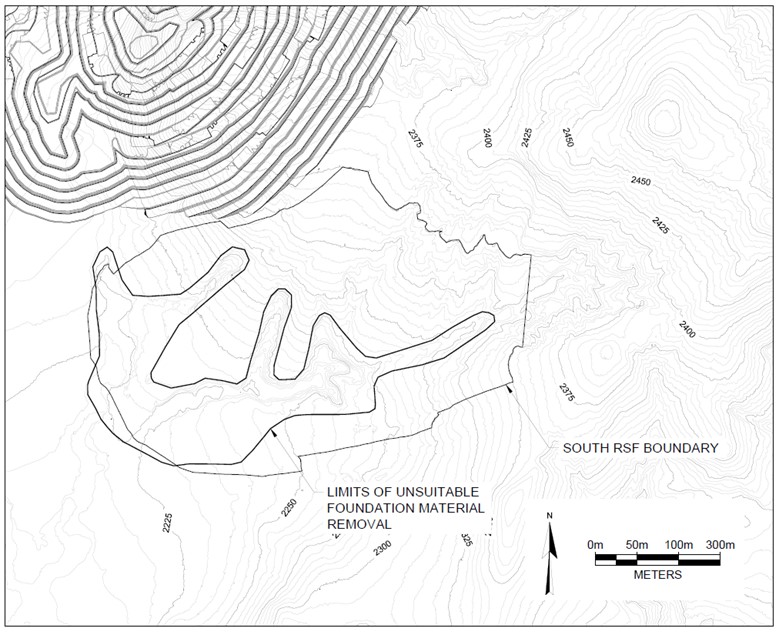

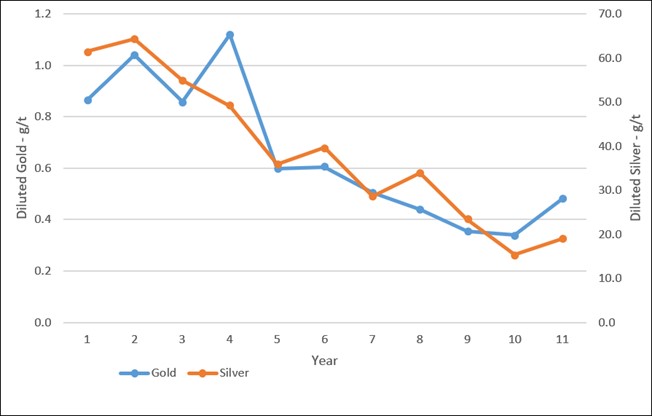

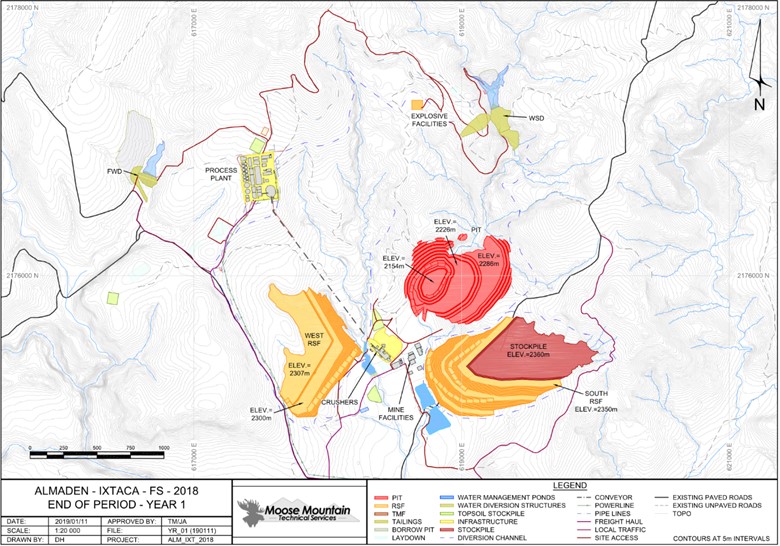

| 1. | Ixtaca Mineral Resources Estimate have an effective date of 8 July 2018. The Qualified person for the estimate is Gary Giroux, P.Eng. |