Form 8-K AUGUSTA GOLD CORP. For: Jun 29

Exhibit 99.1

MINERAL RESOURCE ESTIMATE FOR THE

REWARD PROJECT, NYE COUNTY, NEVADA, USA

| Prepared For: | CR Reward LLC & Augusta Gold Corp. Suite 555 – 999, Canada Place Vancouver, BC V6C 3E1 Canada |

|

| Prepared by: | APEX Geoscience Ltd. #100, 11450-160th Street NW Edmonton AB T5M 3Y7 Canada |

|

| Kappes, Cassiday & Associates 7950 Security Circle Reno, NV USA 89506 |

|

Michael Dufresne, M.Sc., P. Geol., P.Geo.

Timothy D. Scott, BA.Sc., RM SME

Effective Date: May 31st, 2022

Signing Date: June 29th, 2022

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

Contents

| 1 | Summary | 1 | ||

| 1.1 | Issuer and Purpose | 1 | ||

| 1.2 | Authors, Contributors and Site Inspection | 1 | ||

| 1.3 | Project Setting | 2 | ||

| 1.4 | Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements | 2 | ||

| 1.5 | Geology and Mineralization | 4 | ||

| 1.6 | History | 5 | ||

| 1.7 | Drilling and Sampling | 5 | ||

| 1.8 | Data Verification | 6 | ||

| 1.9 | Metallurgical Testing | 7 | ||

| 1.10 | Current Mineral Resource | 7 | ||

| 1.11 | Conclusions | 10 | ||

| 1.12 | Recommendations | 10 | ||

| 2 | Introduction | 11 | ||

| 2.1 | Issuer and Purpose | 11 | ||

| 2.2 | Authors, Contributors and Site Inspection | 12 | ||

| 2.3 | Sources of Information | 14 | ||

| 2.4 | Units of Measure | 14 | ||

| 3 | Reliance on Other Experts | 15 | ||

| 4 | Property Description and Location | 15 | ||

| 4.1 | Description and Location | 15 | ||

| 4.2 | Property and Title in Nevada | 15 | ||

| 4.2.1 | Mineral Title | 15 | ||

| 4.2.2 | Surface Rights | 16 | ||

| 4.2.3 | Environmental Regulations | 18 | ||

| 4.2.4 | Water Rights | 18 | ||

| 4.3 | Ownership | 18 | ||

| 4.4 | Mineral Properties | 19 | ||

| 4.4.1 | Claim Status | 19 | ||

| 4.4.2 | Claim Retention Obligations | 19 | ||

| 4.4.3 | Encumbrances | 25 | ||

| 4.5 | Mineral Lease Agreements | 25 | ||

| 4.5.1 | Connolly Lease | 25 | ||

| 4.5.2 | Webster Lease | 25 | ||

| 4.5.3 | Orser–McFall Lease | 26 | ||

| 4.5.4 | Van Meeteren et al Lease | 26 | ||

| 4.6 | Encumbrances | 26 | ||

| 4.7 | Surface Ownership | 26 | ||

| 4.8 | Water Rights | 27 | ||

| 4.9 | Permitting Considerations | 27 | ||

| 4.10 | Environmental Considerations | 27 | ||

| 4.11 | Comments on Property Description and Location | 28 | ||

| 5 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 28 | ||

| 5.1 | Accessibility | 28 | ||

| Effective Date: May 31st, 2022 |  | i |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

| 5.2 | Site Topography, Elevation and Vegetation | 28 | ||

| 5.3 | Climate | 29 | ||

| 5.4 | Local Resources and Infrastructure | 29 | ||

| 6 | History | 30 | ||

| 6.1 | Exploration History | 30 | ||

| 6.2 | Production History | 30 | ||

| 7 | Geological Setting and Mineralization | 33 | ||

| 7.1 | Regional Geology | 33 | ||

| 7.2 | Local Geology | 34 | ||

| 7.3 | Stratigraphy | 37 | ||

| 7.3.1 | Late Proterozoic | 38 | ||

| 7.3.2 | Proterozoic-Cambrian | 40 | ||

| 7.3.3 | Cambrian | 40 | ||

| 7.4 | Structure | 41 | ||

| 7.4.1 | Good Hope Fault Zone | 41 | ||

| 7.5 | Alteration | 44 | ||

| 7.6 | Oxidation (Redox) | 44 | ||

| 7.7 | Mineralization | 45 | ||

| 7.7.1 | Description of Mineralization: Good Hope Deposit | 45 | ||

| 7.7.2 | Description of Mineralization: Gold Ace Mineralized Zone | 47 | ||

| 7.7.3 | Description of Mineralization: Exploration Update | 49 | ||

| 8 | Deposit Types | 50 | ||

| 9 | Exploration | 51 | ||

| 9.1 | Introduction | 51 | ||

| 9.2 | CR Reward Exploration (2015-Present) | 51 | ||

| 10 | Drilling | 52 | ||

| 10.1 | Drill Methods, Logging and Surveys | 55 | ||

| 10.1.1 | Gexa (1987) | 55 | ||

| 10.1.2 | Pathfinder (1991) | 55 | ||

| 10.1.3 | Barrick (1995-1996) and Glamis (1998-2000) | 55 | ||

| 10.1.4 | Canyon (2006-2007) | 56 | ||

| 10.1.5 | Atna (2011-2013) | 56 | ||

| 10.2 | CR Reward Core Drilling Program (2017-2018) | 56 | ||

| 10.3 | Twin Holes | 59 | ||

| 10.4 | Comments on Drilling | 60 | ||

| 11 | Sample Preparation, Analyses and Security | 60 | ||

| 11.1 | Pre-CR Reward Drill Sampling, Analysis and Security | 60 | ||

| 11.1.1 | Gexa (1987) | 60 | ||

| 11.1.2 | Barrick (1995-1996) | 61 | ||

| 11.1.3 | Glamis (1998-2000) | 61 | ||

| 11.1.4 | Canyon (2006-2007) | 61 | ||

| 11.1.5 | Atna (2011-2013) | 62 | ||

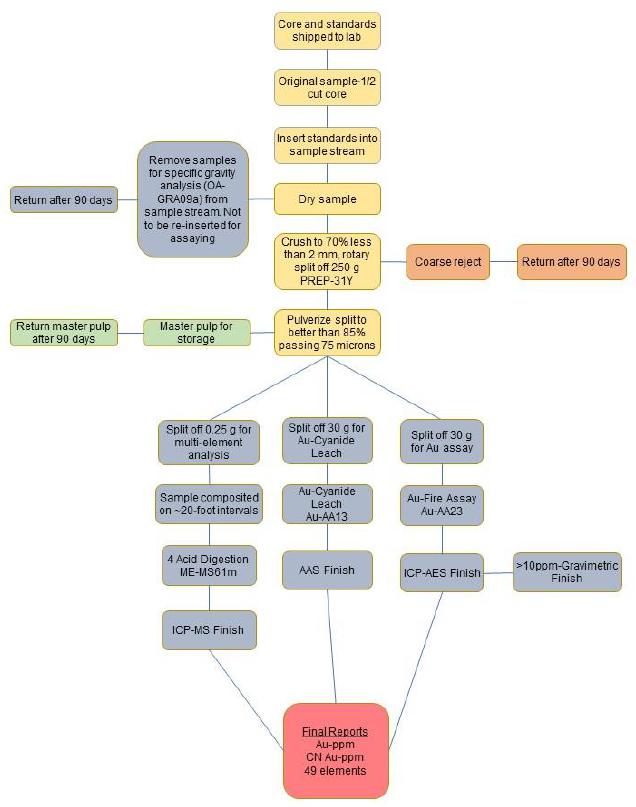

| 11.2 | CR Reward Sampling, Analysis and Security (2017-2018) | 63 | ||

| 11.2.1 | Diamond Drill Core Sample Preparation and Analysis | 64 | ||

| 11.3 | CR Reward QAQC Results (2017-2018) | 66 | ||

| 11.3.1 | Blanks | 66 | ||

| Effective Date: May 31st, 2022 |  | ii |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

| 11.3.2 | Standard Reference Materials | 67 | |||

| 11.3.3 | Duplicates | 69 | |||

| 11.4 | Comments on Sample Preparation, Analyses and Security | 69 | |||

| 12 | Data Verification | 70 | |||

| 12.1 | Verification Program | 70 | |||

| 12.1.1 | Protocols and Error Tracking of Pre-CR Reward Drill Holes | 70 | |||

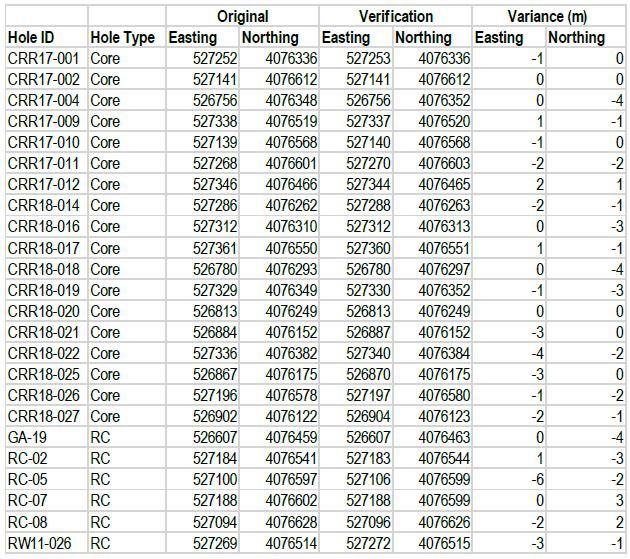

| 12.2 | Collar Data Verification | 71 | |||

| 12.3 | Down-Hole Survey Data Verification | 72 | |||

| 12.4 | Assay Verification | 72 | |||

| 12.5 | Author and QP Site Visits | 73 | |||

| 13 | Mineral Processing and Metallurgical Testing | 78 | |||

| 13.1 | 1998 Rayrock Column Tests – Drill Core | 78 | |||

| 13.2 | 1998 Rayrock Column Tests – Trench Samples | 79 | |||

| 13.3 | 2007 McClelland Bottle Roll Tests | 79 | |||

| 13.4 | McClelland 2008 Column Test Campaign | 80 | |||

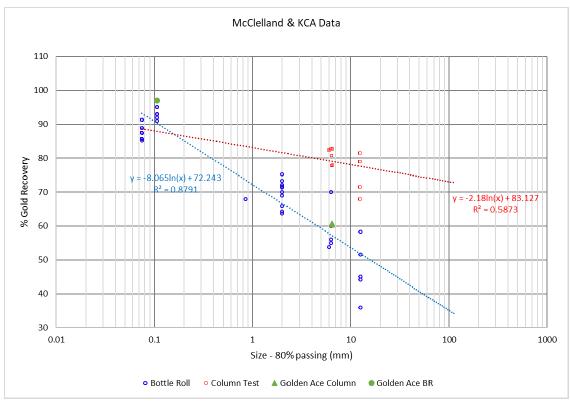

| 13.4.1 | 2008 Column Test Results | 82 | |||

| 13.4.2 | 2008 Bottle Roll Test Results at Crush Size and at 200 Mesh | 82 | |||

| 13.4.3 | 2008 Bottle Roll Size versus Recovery on Composite 5 | 84 | |||

| 13.4.4 | Drain-Down Data | 84 | |||

| 13.4.5 | Conclusions from 2008 McClelland Program | 84 | |||

| 13.5 | 2018 Kappes Cassidy Associates Test Program | 84 | |||

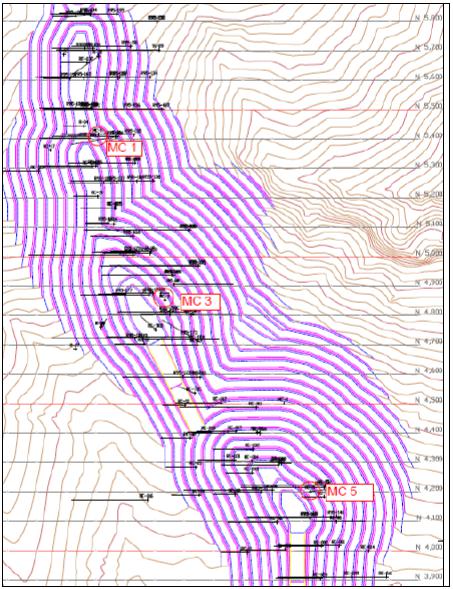

| 13.5.1 | 2018 KCA Composite Generation | 86 | |||

| 13.5.2 | 2018 Physical Characterization | 86 | |||

| 13.5.3 | 2018 KCA Pulverized Bottle Roll Tests | 88 | |||

| 13.5.4 | KCA 2018 Column Leach Tests | 97 | |||

| 13.5.5 | 2018 KCA Program Conclusions | 99 | |||

| 13.6 | Analysis and Discussion | 99 | |||

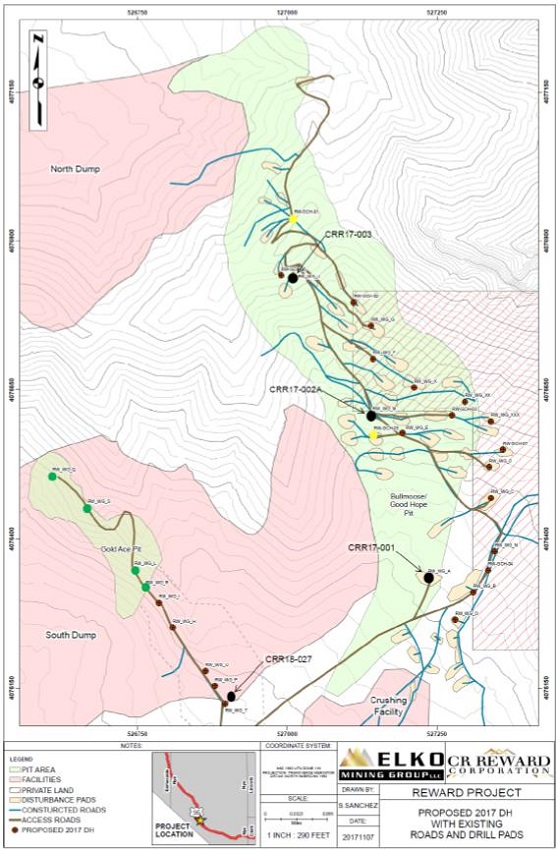

| 13.6.1 | Crush Size and Grade versus Recovery | 99 | |||

| 13.6.2 | Leach Cycle | 101 | |||

| 13.6.3 | Reagent Consumptions | 101 | |||

| 13.6.3.1 | Cyanide | 101 | |||

| 13.6.3.2 | Lime | 101 | |||

| 13.6.4 | Conclusions and Key Design Parameters | 101 | |||

| 14 | Mineral Resource Estimates | 103 | |||

| 14.1 | Introduction | 103 | |||

| 14.2 | Data | 105 | |||

| 14.2.1 | Drill Hole Data | 105 | |||

| 14.2.2 | APEX Micromine Database Validation | 107 | |||

| 14.3 | Geological Model and Domains | 108 | |||

| 14.3.1 | Good Hope Deposit | 108 | |||

| 14.3.1.1 | Low-Grade Alteration Domain (LG) | 109 | |||

| 14.3.1.2 | High Grade Gold Shell (HG) | 109 | |||

| 14.3.2 | Gold Ace Zone | 110 | |||

| 14.4 | Drill Hole Flagging and Compositing | 110 | |||

| 14.4.1 | Sample Width Analysis | 110 | |||

| 14.4.2 | Remnant Analysis | 111 | |||

| Effective Date: May 31st, 2022 |  | iii |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

| 14.5 | Capping | 113 | ||

| 14.6 | Variography and Grade Continuity | 116 | ||

| 14.7 | Bulk Density | 118 | ||

| 14.8 | Block Model | 122 | ||

| 14.8.1 | Block Model Parameters | 122 | ||

| 14.8.2 | Volumetric Checks | 124 | ||

| 14.9 | Grade Estimation | 124 | ||

| 14.9.1 | Estimation Methodology | 124 | ||

| 14.10 | Model Validation | 128 | ||

| 14.10.1 | Visual Validation | 128 | ||

| 14.10.2 | Statistical Validation | 130 | ||

| 14.11 | Mineral Resource Classification | 136 | ||

| 14.11.1 | 2019 CIM and SK 1300 Definitions | 136 | ||

| 14.11.2 | Classification Criteria | 138 | ||

| 14.12 | Evaluation of Reasonable Prospects for Eventual Economic Extraction | 138 | ||

| 14.13 | Mineral Resource Statement | 140 | ||

| 14.14 | Discussion of Mineral Resources Modelling, Risks and Uncertainties | 144 | ||

| 23 | Adjacent Properties | 145 | ||

| 23.1 | Bullfrog | 145 | ||

| 23.2 | Sterling and Crown | 146 | ||

| 24 | Other Relevant Data and Information | 147 | ||

| 25 | Interpretation and Conclusions | 147 | ||

| 25.1 | Introduction | 147 | ||

| 25.2 | Mineral Tenure, Surface Rights, Water Rights, Royalties/Agreements | 147 | ||

| 25.3 | Geology | 148 | ||

| 25.4 | Exploration, Drilling and Analytical Data Collection in Support of Mineral Resource Estimation | 149 | ||

| 25.5 | Metallurgical Test work | 149 | ||

| 25.6 | Mineral Resource Estimate | 150 | ||

| 25.7 | Risks and Uncertainties | 150 | ||

| 25.8 | Conclusions | 151 | ||

| 26 | Recommendations | 152 | ||

| 27 | References | 154 | ||

| 28 | Date and Signature | 160 | ||

| 29 | Certificate of Author | 161 | ||

Tables

| Table 1.1. Reward Conceptual Open Pit Parameters | 9 |

| Table 1.2. Reward Project Mineral Resource Estimate at May 31, 2022 | 9 |

| Table 1.3. Estimated budget for the recommended PFS | 10 |

| Table 4.1. Summary of the Reward Project Claims | 20 |

| Table 6.1. Project Exploration History | 30 |

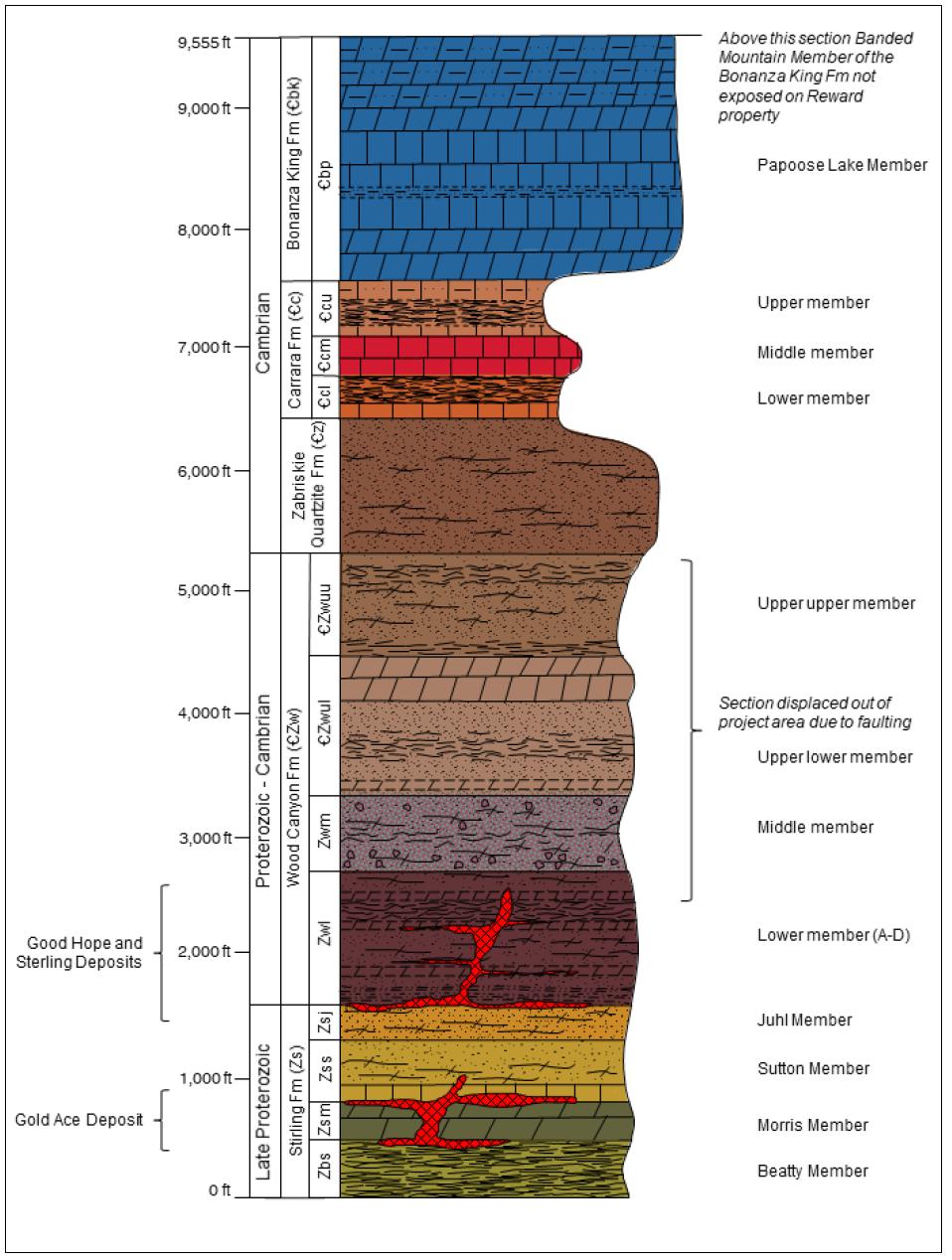

| Table 7.1. Stratigraphy and Unit Thickness of the Bare Mountains Complex | 37 |

| Table 10.1. Reward Drilling Summary | 53 |

| Table 10.2. CR Reward Drill Hole Collars (2017-2018) | 57 |

| Effective Date: May 31st, 2022 |  | iv |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

| Table 10.3. Results of CR Reward Drill Holes (2017-2018) | 58 |

| Table 10.4. Results of Reward Twin Holes | 60 |

| Table 11.1. Summary Results of Blank Material from the 2017-2018 Drill Program | 67 |

| Table 11.2. Summary Results of Standards from the 2017-2018 Drill Program | 67 |

| Table 12.1. Drill Hole Coordinate Comparison | 74 |

| Table 12.2. Significant Intercepts of Drill Holes Reviewed During Mr. Dufresne’s Inspection of the CR Reward Core Facility | 75 |

| Table 13.1. 1998 Rayrock Drill Core Column Tests Results | 79 |

| Table 13.2. 1998 Rayrock Surface Trench Column Test Gold Recovery | 80 |

| Table 13.3. 1998 10 Mesh Reverse Circulation Drill Holes Bottle Roll Results | 80 |

| Table 13.4. 2008 McClelland Sample/Drill Hole Composite Information | 81 |

| Table 13.5. 2008 McClelland Summary Column Test Results | 83 |

| Table 13.6. 2008 McClelland Bottle Roll Tests – Gold Recovery % | 84 |

| Table 13.7. 2008 McClelland Bottle Roll Size versus Gold Recovery – Composite 5 | 85 |

| Table 13.8. 2008 McClelland Drain-Down Data from Column Tests | 85 |

| Table 13.9. 2018 KCA Composite Head Screen Analyses – Gold and Silver | 88 |

| Table 13.10. 2018 KCA Composite Head Screen Analyses – Mercury and Copper | 88 |

| Table 13.11. 2018 Hazen Bond Impact Work and Abrasion Index | 88 |

| Table 13.12. 2018 High-Grade Sample Intervals | 89 |

| Table 13.13. 2018 KCA Bottle Roll Test Results | 90 |

| Table 13.14. KCA 2018 Preliminary Agglomeration Test Work | 92 |

| Table 13.15. KCA 2018 Compacted Permeability Tests | 93 |

| Table 13.16. KCA 2018 Column Leach Tests | 98 |

| Table 14.1. Summary Statistics of Raw Gold Assays of Sample Intervals Flagged within the Good Hope and Gold Ace Estimation Domains | 107 |

| Table 14.2. Remnant Analysis comparing the Gold Statistics of Raw Assays and Uncapped Composite Samples with and without Orphans | 112 |

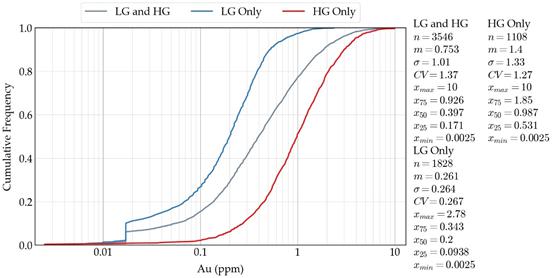

| Table 14.3. Summary Statistics of Gold Grade of Capped Composite Intervals Flagged within the Good Hope and Gold Ace Estimation Domains | 116 |

| Table 14.4. Gold Variogram Model Parameters | 117 |

| Table 14.5. Bulk Density Measurements, Good Hope Deposit and Gold Ace Zone | 119 |

| Table 14.6. Percentage of Blocks Flagged within each Formation for the Good Hope and Gold Ace Zones | 121 |

| Table 14.7. Project Block Model Size and Extents | 123 |

| Table 14.8. Wireframe versus Block Model Volume Comparison | 124 |

| Table 14.9. Estimation Search and Kriging Parameters | 125 |

| Table 14.10. Interpolation Search Restrictions | 138 |

| Table 14.11. Parameters for Pit Optimization for Mineral Resource Estimate | 139 |

| Table 14.12. Measured and Indicated Mineral Resource Statement | 140 |

| Table 14.13. Inferred Mineral Resource Statement | 141 |

| Table 14.14. Sensitivity Table, Measured and Indicated Mineral Resources, Good Hope | 141 |

| Table 14.15. Sensitivity Table, Inferred Mineral Resources, Good Hope | 142 |

| Table 14.16. Sensitivity Table, Indicated Mineral Resources, Gold Ace | 142 |

| Table 14.17. Sensitivity Table, Inferred Mineral Resources, Gold Ace | 143 |

| Effective Date: May 31st, 2022 |  | v |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

| Table 14.18. Sensitivity Table, Measured and Indicated Mineral Resources, Good Hope and Gold Ace | 143 |

| Table 14.19. Sensitivity Table, Inferred Mineral Resources, Good Hope and Gold Ace | 144 |

| Table 25.1. Reward Project Mineral Resource Estimate at May 31, 2022 | 152 |

| Table 26.1. Estimated budget for the recommended PFS | 153 |

Figures

| Figure 2.1. Project Location Map | 12 |

| Figure 4.1. Project Location Plan | 17 |

| Figure 4.2. CR Reward LLC Controller Mineral Claims at Reward Project | 23 |

| Figure 4.3. Detail of Reward Claims and Proposed Infrastructure for the Core Area | 24 |

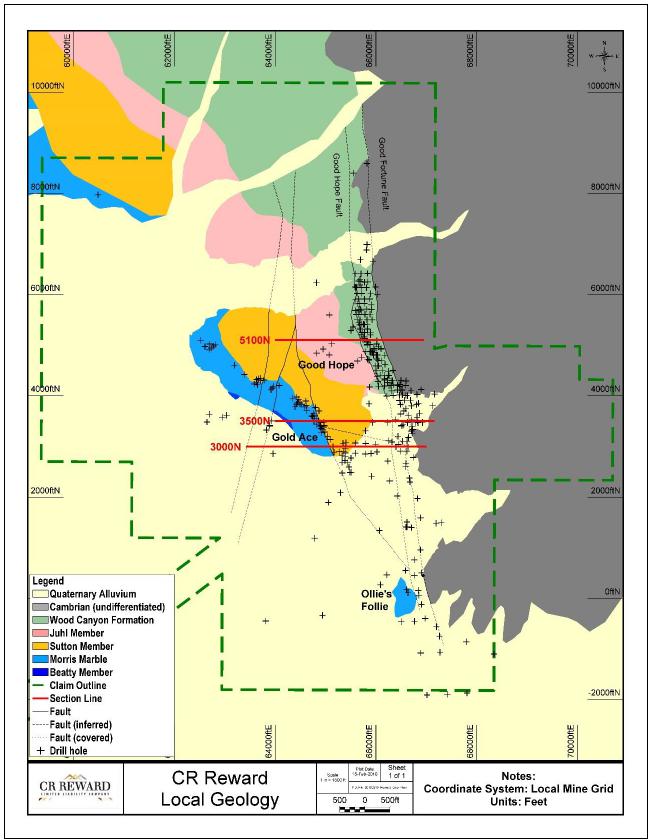

| Figure 7.1. Simplified Geology of the Bare Mountain Area | 34 |

| Figure 7.2. Simplified Geologic Map of Project Area | 35 |

| Figure 7.3. Local Geology Map | 36 |

| Figure 7.4. 3D Geological Schematic of the Main Rock Units and Faults | 37 |

| Figure 7.5. Lower Portion of the Bare Mountains Complex Stratigraphic Column Observed at the Project | 39 |

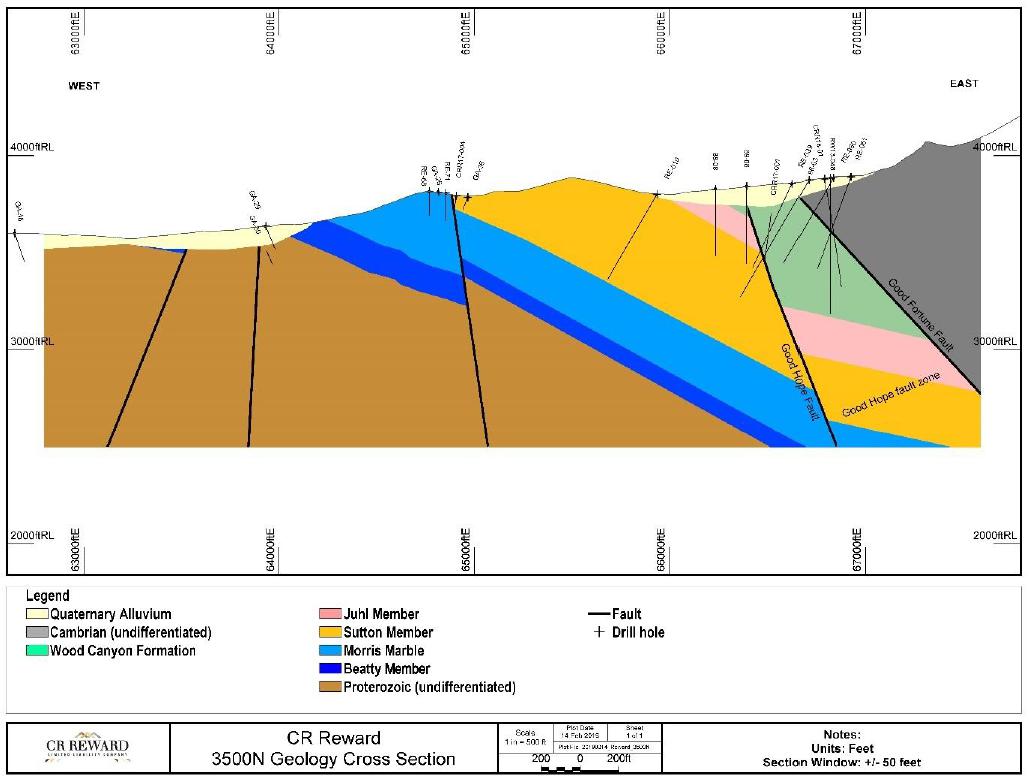

| Figure 7.6. 3500N Geology Cross-Section | 42 |

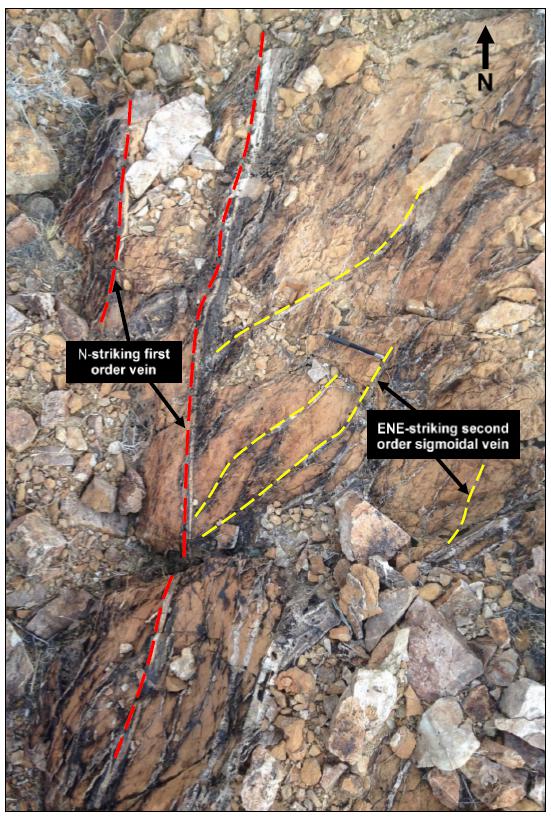

| Figure 7.7. Photo Highlighting Vein Orientation in Outcrop | 43 |

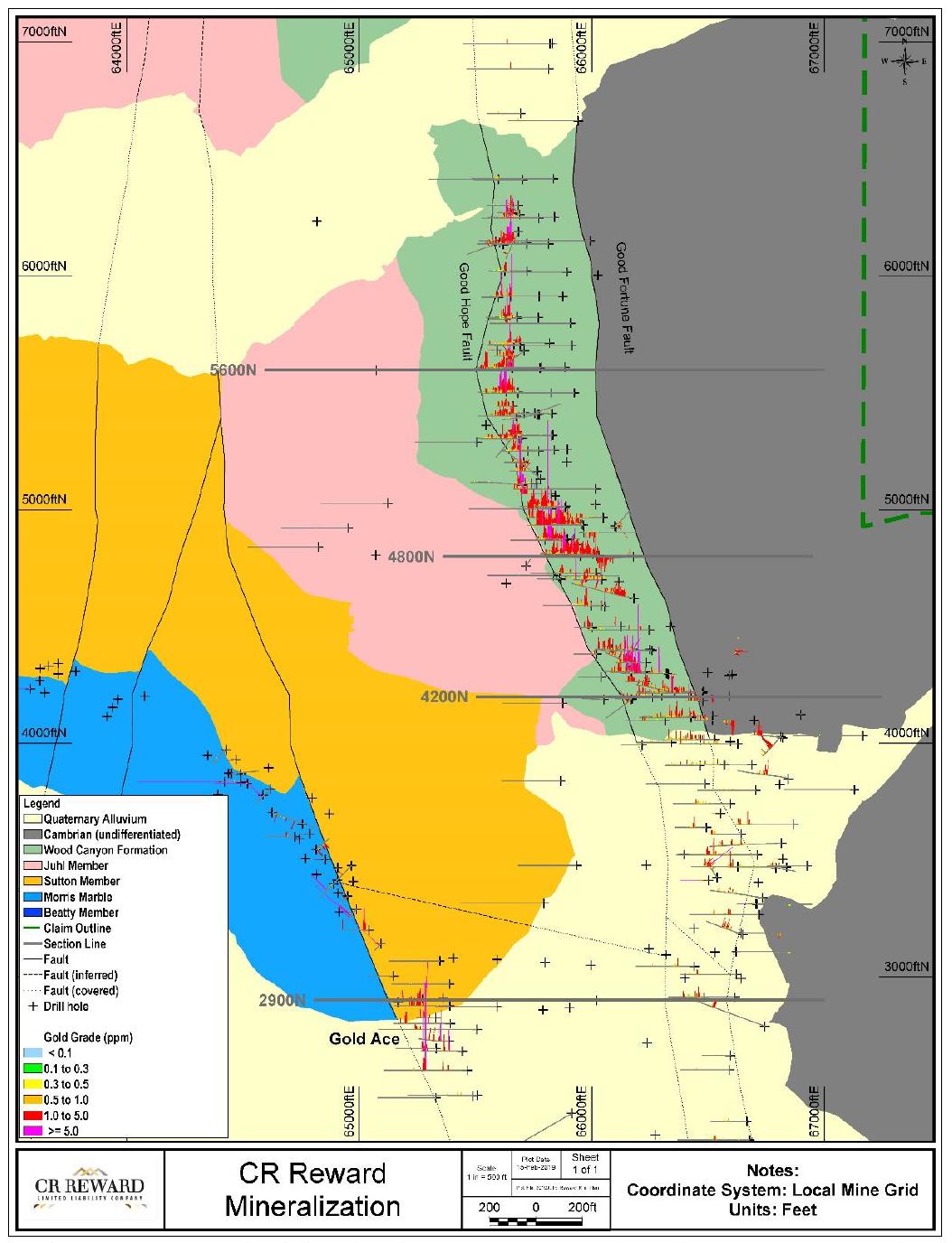

| Figure 7.8. Gold Mineralization at Reward Intersected by Drilling | 46 |

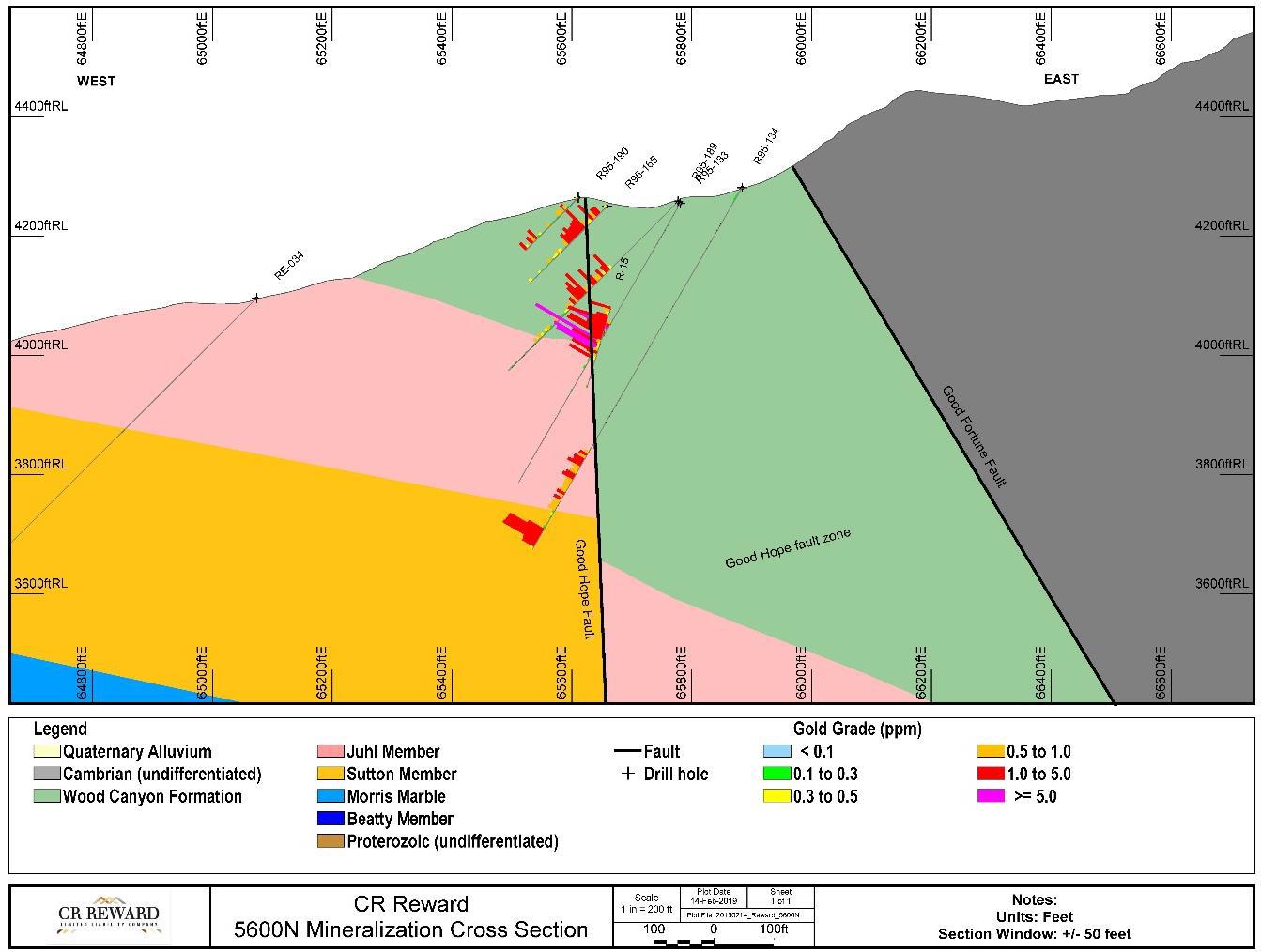

| Figure 7.9. Mineralization along Section 5600 N Looking North | 47 |

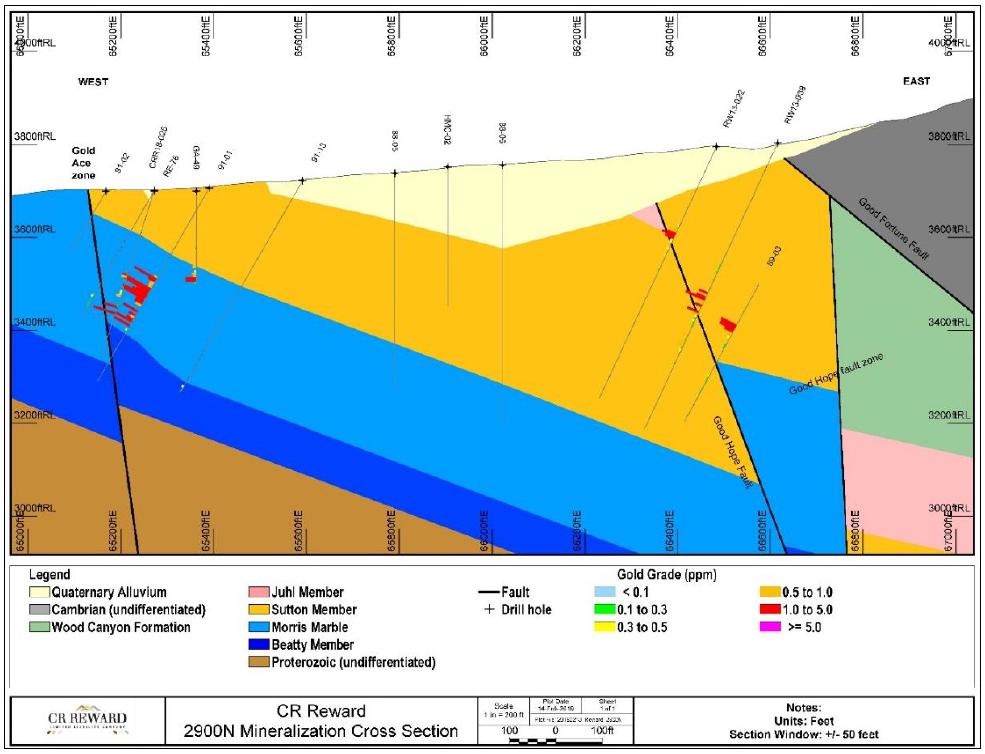

| Figure 7.10. Mineralization along Section 4200 N Looking North | 48 |

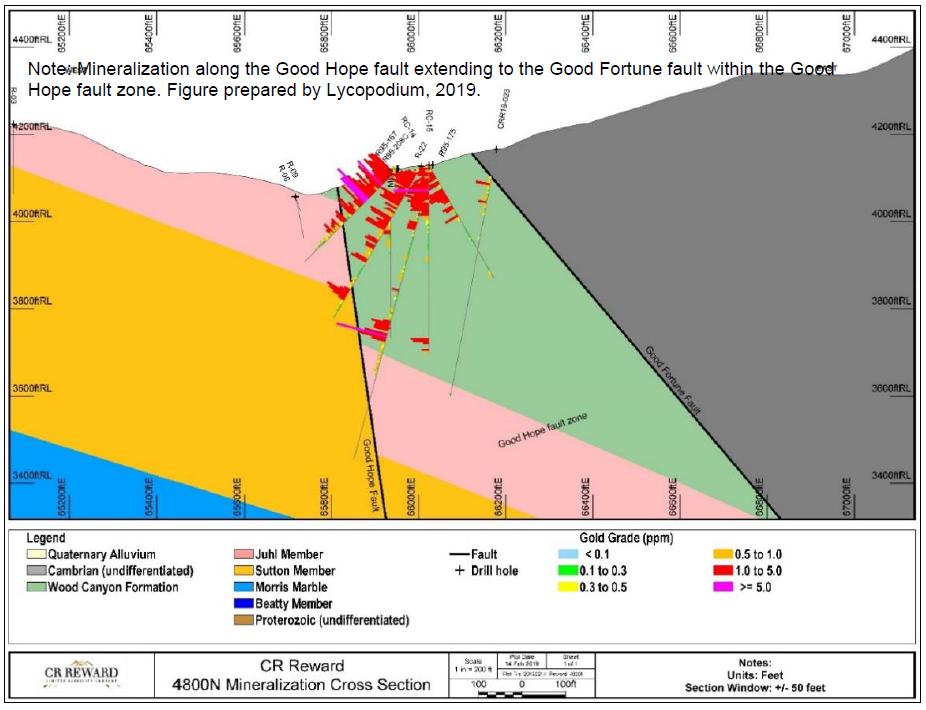

| Figure 7.11. Mineralization along Section 4800 N, Looking North | 48 |

| Figure 7.12. Mineralization along Section 2900 N Looking North | 49 |

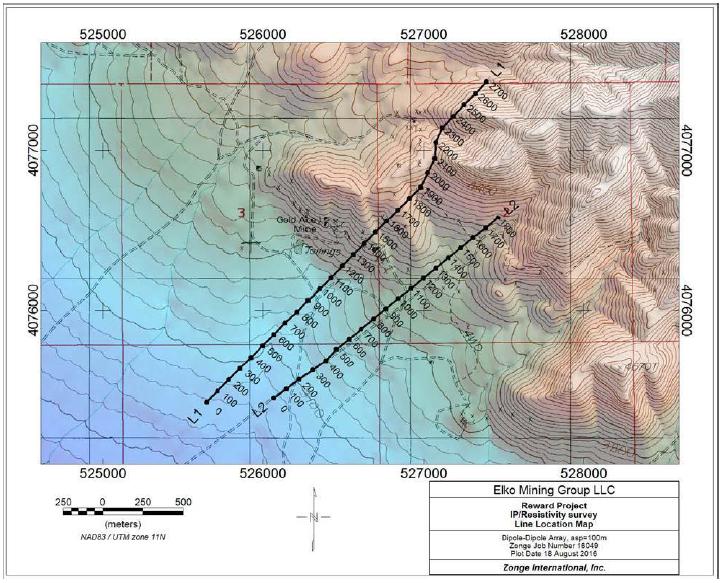

| Figure 9.1. Plan View of the Project Area Showing the Locations of the IP/Resistivity Survey Lines | 52 |

| Figure 10.1. Reward Drill Hole Locations | 54 |

| Figure 11.1. CR Reward Sample Flow Chart | 65 |

| Figure 11.2. Blank Results from 2017-2018 Drilling Sorted by Date Analyzed | 66 |

| Figure 11.3. CDN-GS-P6B Results from 2017-2018 Program Sorted by Date Analyzed | 68 |

| Figure 11.4. CDN-GS-2L Results from 2017-2018 Program Sorted by Date Analyzed | 68 |

| Figure 11.5. Duplicate Results from the 2017-2018 Program | 69 |

| Figure 12.1. Drill hole CRR17-009, Wood Canyon Formation Mineralized Interval of Phyllite and Oxidized Quartzite | 75 |

| Figure 12.2. Drill hole CRR18-014, Wood Canyon Formation Mineralized Interval of Brecciated/Re-healed Quartzite and Sheared and Foliated Phyllite | 76 |

| Figure 12.3. Drill Hole CRR18-024, Wood Canyon Formation Mineralized Interval of Quartzite | 77 |

| Figure 13.1. 1998 10 Mesh Bottle Roll Recovery Curves | 81 |

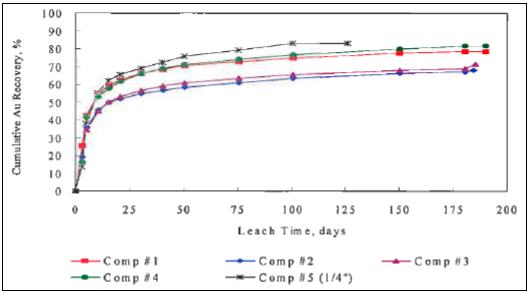

| Figure 13.2. 2008 McClelland Drill Hole Location Map | 82 |

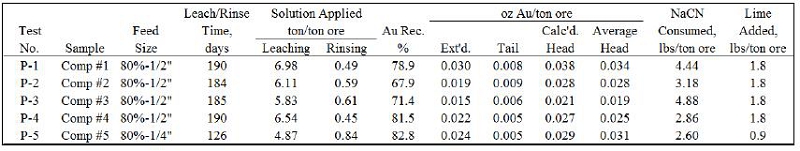

| Figure 13.3. 2008 McClelland 10 Gold Recovery Curves – Column Tests | 83 |

| Figure 13.4. 2008 McClelland Bottle Roll Tests Recovery Curves – Splits from Column Tests | 83 |

| Effective Date: May 31st, 2022 |  | vi |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

| Figure 13.5. 2008 McClelland Bottle Roll Size versus Gold Recovery – Composite 5 | 85 |

| Figure 13.6. 2018 KCA Metallurgical Sample Drill Hole Location Map | 87 |

| Figure 13.7. 2018 KCA Bottle Roll Test Results | 91 |

| Figure 13.8. KCA 2018 Column Leach Curves – Carbon Assays | 97 |

| Figure 13.9. KCA 2018 Column Leach Curves – Tonnes Solution per Tonne Ore | 99 |

| Figure 13.10. Size versus Recovery – 2018 KCA and 2008 McClelland Test Data | 100 |

| Figure 14.1. Mineral Resource Estimate Mineralized Domain Outlines | 104 |

| Figure 14.2. Histogram of the Raw Gold Assay Values of Sample Intervals Flagged within the Good Hope and Gold Ace Estimation Domains | 106 |

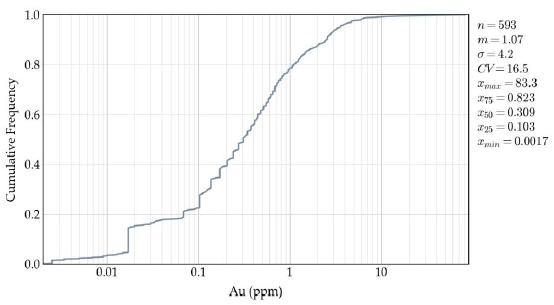

| Figure 14.3. Cumulative Frequency Plot of Raw Gold Assay Values of Sample Intervals Flagged within the Good Hope Zone Estimation Domains | 106 |

| Figure 14.4. Cumulative Frequency Plot of Raw Gold Assay Values of Sample Intervals Flagged within the Gold Ace Estimation Domain | 107 |

| Figure 14.5. Orthogonal View of LGand HG Estimation Domains, Good Hope Deposit | 109 |

| Figure 14.6. Orthogonal View of the LG Estimation Domain, Gold Ace Zone | 110 |

| Figure 14.7. Histogram of Sample Lengths within Estimation Domains for both the Good Hope and Gold Ace Zones | 111 |

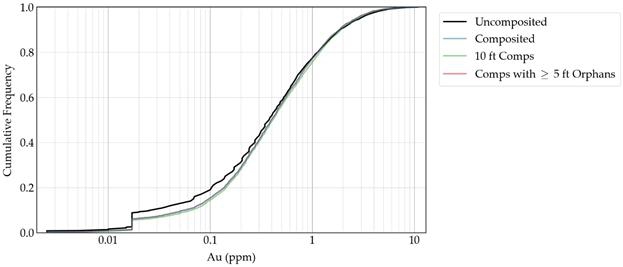

| Figure 14.8. Remnant Analysis Illustrating the Gold Distribution of Calculated Composite within the Good Hope Deposit | 112 |

| Figure 14.9. Orphan Analysis Illustrating the Gold Distribution of Calculated Composite within the Gold Ace Zone | 113 |

| Figure 14.10. Probability Plot of the Composited Gold Grade at the Good Hope Zone before Capping | 114 |

| Figure 14.11. Cumulative Frequency Plots of the Composited and Capped Gold Grade within the Good Hope Zone Estimation Domains | 114 |

| Figure 14.12. Probability Plot of the Composited Gold Grade at the Gold Ace Zone before Capping | 115 |

| Figure 14.13. Cumulative Frequency Plot of the Composited and Capped Gold Grade within Gold Ace Zone Estimation Domain | 115 |

| Figure 14.14. Calculated and Modelled Semi-Variogram of Gold within the Good Hope Zone. Dip Direction and Dip for each Principle Direction is in each Subplot Title | 117 |

| Figure 14.15. Calculated and Modelled Semi-Variogram of Gold within the Gold Ace Zone. Dip Direction and Dip for each Principle Direction is in each Subplot Title | 118 |

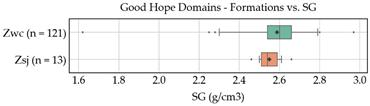

| Figure 14.16. Bulk Density Box Plots, Good Hope Deposit | 119 |

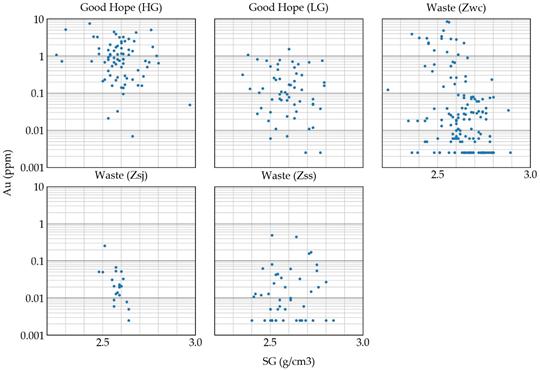

| Figure 14.17. Bulk Density Scatter Plots Showing 3D Solids vs. Gold Grade, Good Hope Deposit | 120 |

| Figure 14.18. Bulk Density Box Plots, Gold Ace Zone | 121 |

| Figure 14.19. Bulk Density Scatter Plots Showing 3D Solids vs. Gold Grade, Gold Ace Zone | 121 |

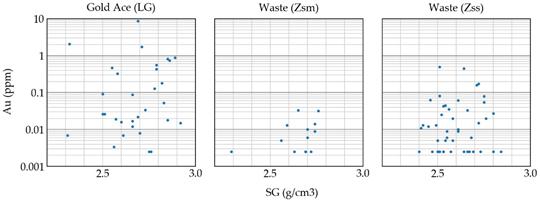

| Figure 14.20. Cumulative Frequency Plot Illustrating the Distance from each Block Centroid to the nearest Composite Sample within the Good Hope Zone | 122 |

| Figure 14.21. Cumulative Frequency Plot Illustrating the Distance from each Block Centroid to the nearest Composite Sample within the Gold Ace Zone | 123 |

| Effective Date: May 31st, 2022 |  | vii |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

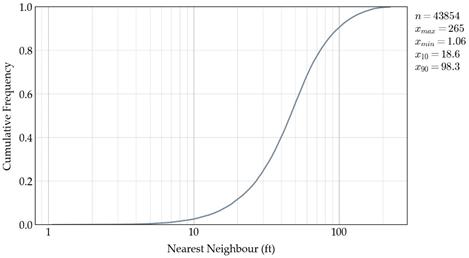

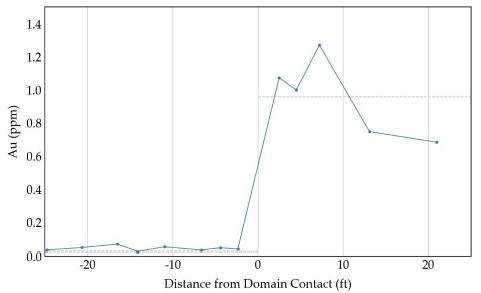

| Figure 14.22. Gold Grade Contact Plot Analysis, Good Hope LG and HG Grade Domain Contacts | 126 |

| Figure 14.23. Contact Plot Analysis, Good Hope Grade and Waste Domain Contacts | 127 |

| Figure 14.24. Contact Analysis, Gold Ace Grade and Waste Domain Contacts | 127 |

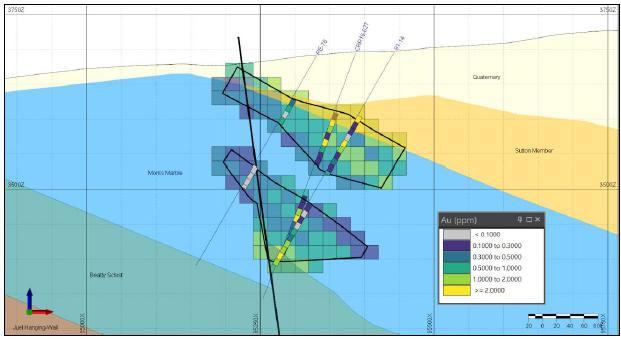

| Figure 14.25. Cross-Section 6000N, Showing Block Gold Estimates at the Good Hope Deposit | 128 |

| Figure 14.26. Cross-Section 4800N, Showing Block Gold Estimates at the Good Hope Deposit | 129 |

| Figure 14.27. Cross-Section 4100N, Showing Block Gold Estimates at the Good Hope Deposit | 129 |

| Figure 14.28. Cross-Section 2700N, Showing Block Gold Estimates at the Gold Ace Deposit | 130 |

| Figure 14.29. Swath Plots Showing Composite versus Estimated Gold Grade, Good Hope | 131 |

| Figure 14.30. Swath Plots Showing Composite versus Estimated, Gold Grade Gold Ace | 132 |

| Figure 14.31. Volume Variance Check, Good Hope | 133 |

| Figure 14.32. Volume Variance Check, Gold Ace | 134 |

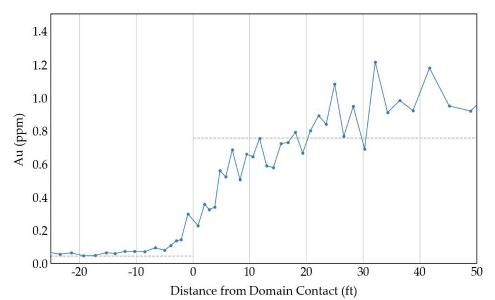

| Figure 14.33. Contact Analysis, Good Hope Grade and Waste Domain Boundary | 135 |

| Figure 14.34. Contact Analysis, Gold Ace Grade and Waste Domain Boundary | 135 |

| Figure 23.1. Adjacent Properties | 146 |

| Effective Date: May 31st, 2022 |  | viii |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

| 1 | Summary |

| 1.1 | Issuer and Purpose |

This Technical Report (the Technical Report) was prepared by APEX Geoscience Ltd. (APEX) and Kappes, Cassiday & Associates (KCA) for CR Reward LLC (CR Reward) and Augusta Gold Corp. (Augusta or the Company). Augusta is a publicly traded company listed on the Toronto Stock Exchange (TSX:G) in Canada and the OTCQB Venture Market (OTCQB:AUGG) in the United States of America (USA) focused on the exploration, advancement and development of gold properties in Nevada. CR Reward is a private Nevada limited liability company that is a wholly owned subsidiary of Augusta.

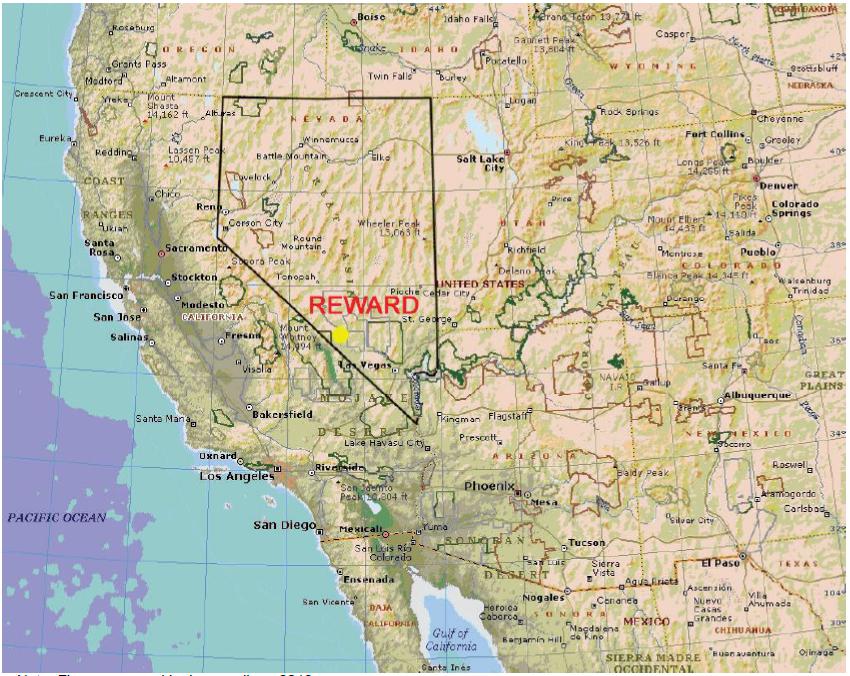

The Company engaged APEX in May, 2022 to complete an updated Mineral Resource Estimate (MRE) for the Reward Project under National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101) and an Initial Assessment of Mineral Resources in accordance with Item 1300 of Regulation S-K under the United States Securities Exchange Act of 1934, as amended (SK 1300). The focus of this Technical Report is an updated MRE for the Reward Project (Reward or the Project), a gold exploration project situated in Nye County, Nevada (NV), USA. The Project is located 11.3 km (7 miles) to the southeast of the Company’s Bullfrog project within the Walker Lane Trend, a prolifically mineralized belt that is host to numerous gold deposits and current and past producing mines in south-central Nevada.

This Technical Report summarizes a NI 43-101 and SK 1300 updated MRE for the Project and provides a technical summary of the relevant location, tenure, historical and geological information, a summary of the recent exploration work conducted by CR Reward and recommendations for future exploration programs. This Technical Report summarizes the technical information available up to the effective date of May 31, 2022.

This Technical Report has been prepared in accordance with the Canadian Securities Administration’s (CSA’s) NI 43-101 and guidelines for technical reporting Canadian Institute of Mining, Metallurgy and Petroleum (CIM) “Best Practices and Reporting Guidelines” for disclosing mineral exploration and in accordance with the requirements of SK 1300. The mineral resource has been estimated using the CIM “Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines”, dated November 29, 2019, and the CIM “Definition Standards for Mineral Resources and Mineral Reserves”, amended and adopted May 10th, 2014 and in accordance with the requirements of SK 1300.

| 1.2 | Authors, Contributors and Site Inspection |

This Technical Report has been prepared by Mr. Michael B. Dufresne, M.Sc., P. Geol., P. Geo., of APEX and Mr. Timothy D. Scott, BA.Sc., RM SME, of KCA. Both authors are independent and not employed by either Augusta or CR Reward and are Qualified Persons (QPs) as defined in NI 43-101 and as defined under SK 1300. Contributors to this Technical Report include Mr. Warren Black, M.Sc., P.Geo. and Mr. Steven Nicholls, BA.Sc., MAIG, all of APEX and who are independent and not employed by either Augusta or CR Reward. Neither APEX or KCA are affiliated with Augusta or CR Reward. Under the direct supervision of Mr. Dufresne, Mr. Black prepared the resource estimation statistical analysis, three-dimensional modelling, block modelling and resource estimations presented in Section 14. Mr. Steven Nicholls, BA.Sc., MAIG, a QP, and APEX’s senior resource geologist performed an internal audit of the MRE presented in Section 14. Mr. Dufresne takes responsibility for the MRE reported herein.

| Effective Date: May 31st, 2022 |  | 1 |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

Mr. Dufresne has visited the Project on two separate occasions in 2017 and 2019. During the site inspections, Mr. Dufresne reviewed drill core and verified the location of a number of drill collars. As a result of the site inspections, Mr. Dufresne can verify the land position, the geological setting and the mineralization that is the subject of this Technical Report. Mr. Scott visited the Project on September 22, 2018 and on May 16, 2022.

| 1.3 | Project Setting |

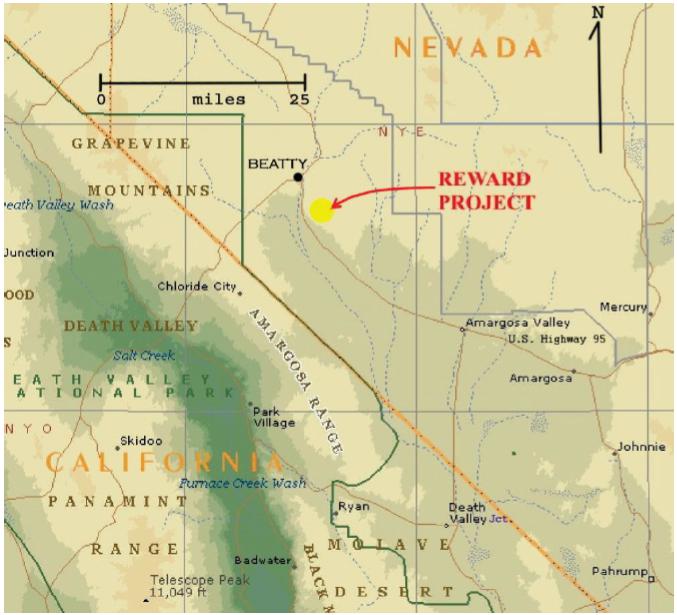

The Project is situated about 11.3 km (7 miles) south-southeast of the town of Beatty, NV about 3.2 km (2 miles) east of US Highway 95 in Nye County. The Project can be accessed from Beatty by paved road on Highway 95 followed by traveling two miles east on a gravel road. Several dirt roads diverge into various canyons of the Bare Mountains.

The Project is situated in the Amargosa Desert in southwestern Nevada on the southwestern flank of the Bare Mountains in the northern Amargosa Valley. The western flank of the Bare Mountains drains into the Amargosa Desert which is drained by the ephemeral Amargosa River. Beatty, on the Amargosa River, lies at 1,006 m (3,300 ft) elevation. Elevations in the Project area range from about 1,160 to 1,310 m (3,800 ft to 4,300 ft). Vegetation is sparse. The climate is typical of middle-elevation desert. Operations are planned to be conducted year-round.

The Project is currently serviced by an existing 14.4/24.9 kV power line owned and operated by Valley Electric. A water well provides water for exploration activities. Project employees will be recruited from the local area, including the communities of Beatty, Amargosa, and Pahrump, located within Nye County, and the regional urban centre of Las Vegas, located within Clark County.

The Project has sufficient land area, with adjacent public-domain lands also potentially available, to allow mine development, including space for the mining operations, waste rock disposal facilities (WRDs) and heap leach pads as envisaged in prior historical economic studies.

| 1.4 | Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements |

The Project area lies within Sections 1, 2, 3, 4, 9, 10, 11 and 16 of Township 13 South, Range 47 East and Sections 33, 34, and 35 of Township 12 South, Range 47 East, all referred to the Mount Diablo Baseline and Meridian.

| Effective Date: May 31st, 2022 |  | 2 |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

Canyon Resources Corporation (Canyon Resources) holds a 100% interest in the mineral claims that form the Project. In 2008, Canyon Resources assigned all of the patented and unpatented claims comprising the Project to an entity which was subsequently converted into CR Reward.

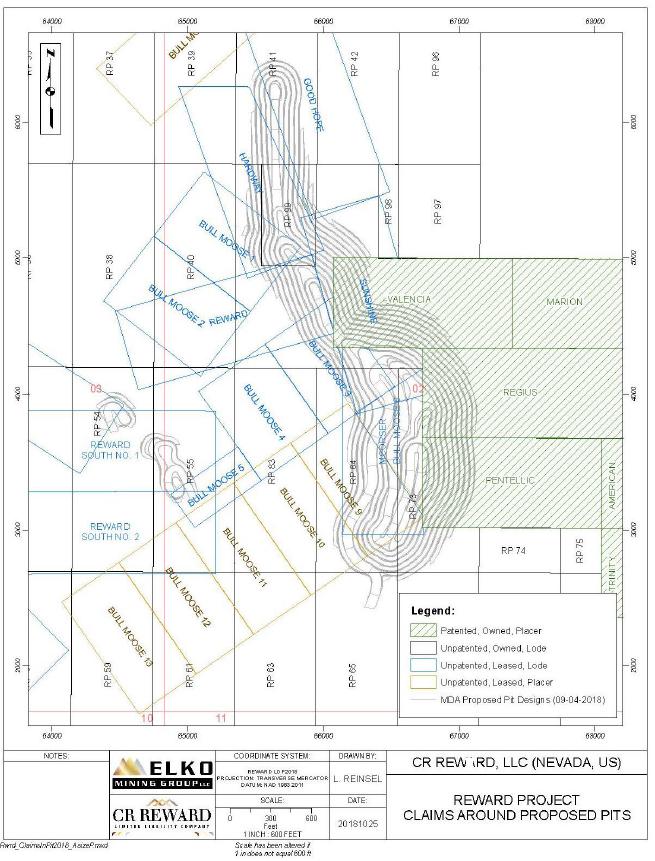

The Project encompasses 121 unpatented Bureau of Land Management (BLM) placer and lode mining claims and six patented placer mining claims, totalling approximately 2,333 net acres (944 hectares). Only the patented claims have been legally surveyed. Under United States mining law, claims may be renewed annually for an unlimited number of years upon a small payment per claim (currently $155 per claim due to the BLM and an aggregate $1,502 due to Nye County) and the same claim status—whether lode or placer—may be used for exploration or exploitation of the lodes or placers.

Several blocks of unpatented claims are leased by CR Reward from underlying owners, and are referred to as Connolly, Webster, Orser–McFall and Van Meeteren leases. These have the following royalties payable:

| • | A 3% Net Smelter Return (NSR) royalty is payable on any minerals mined from the Connolly Claims, but is reduced to 2% as CR Reward only owns a two-third interest in the Connolly Claims. Annual advance minimum royalty payments are payable under the Connolly Lease in an amount equal to $10,000/year. |

| • | A 3% NSR royalty is payable on any minerals mined from the Webster Claims but is (i) reduced to 1% on the Sunshine and Reward claims as the lessee only owns a one-third interest, and (ii) reduced to 1.5% on the Good Hope claim as CR Reward only owns a half interest in this claim. Annual advance minimum royalty payments are payable under the Webster Lease in an amount equal to $7,500/ year. |

| • | A 3% NSR royalty is payable on minerals mined from the Orser–McFall Claims but is reduced to 1.5% on the Good Hope claim as the lessee only owns a half interest in that claim. Annual advance minimum royalty payments are payable under the Orser–McFall Lease in an amount equal to $20,000/year. |

| • | A 3% NSR royalty is payable on minerals mined from the Van Meeteren Claims. Annual advance minimum royalty payments are payable under the Van Meeteren Lease in an amount equal to $15/acre from 2011 through 2020, for a total of $1,800/year, and $20/acre from and after 2021, for a total of $2,400/year. |

The Project area mainly consists of Federal public domain lands administered by the BLM. There are no State or private tracts within the Project area, except the six patented claims owned by CR Reward, all of which carry surface and mineral rights ownership.

The Project is not subject to any other back-in rights payments, agreements or encumbrances.

| Effective Date: May 31st, 2022 |  | 3 |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

Water rights have been obtained through a Water Lease agreement with Barrick Gold Corp’s (Barrick) Bullfrog mining operations. Under the Water Lease, CR Reward has the right to use 317.39 acre-ft of water annually under Application No. 61412, Certificate No. 16384 and Permit No. 76390 in exchange for paying Barrick USD$150.00/acre-ft of water per year for water actually pumped.

To the extent known to the QPs, there are no other significant factors and risks that may affect access, title, or the right or ability to perform work on the Project that have not been discussed in this Report.

| 1.5 | Geology and Mineralization |

Mineralization in the Good Hope Deposit and Golden Ace Zone can be classified as examples of a structurally controlled, locally disseminated, sediment hosted, mesothermal quartz vein gold deposit.

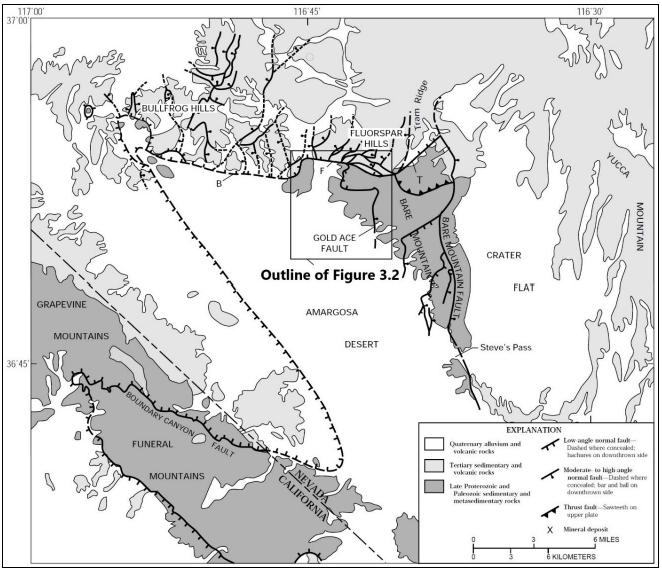

The Project is hosted within the Bare Mountain Complex which lies within an intricate tectonic setting of the Nevada Basin and Range Province.

The Bare Mountain Complex consist of up to 6,096 m (20,000 ft) of Upper Proterozoic to Paleozoic marine sedimentary rocks in the lower plate that have been juxtaposed against Miocene silicic volcanic sequences in the upper plate. The lower plate units were deformed through folding, thrust faulting, low and high angle normal faulting during a Mesozoic compression event, and have been metamorphosed from lower amphibolite to sub-greenschist grade. Two dominant normal fault sets have been mapped in the lower plate, including the moderately east-dipping Bare Mountain and Gold Ace faults, and shallowly southeast-dipping faults that cut or curve into east-dipping faults.

The Project is located on the southwestern flank of the Bare Mountain Complex and is underlain by moderately-deformed marine clastic and carbonate rocks of Late Proterozoic and Late Cambrian age that have been metamorphosed to greenschist grade. Tertiary and younger alluvium cover the lower slopes and the adjacent Armagosa Valley to the south and west. The east-dipping Gold Ace fault, locally termed the Good Hope fault zone, separates northeast dipping Late Proterozoic to Early Cambrian units in the footwall block from Middle to Late Cambrian units in the hanging wall block.

The gold mineralization in the Good Hope Deposit is spatially associated with, and along, the Good Hope fault zone, and is primarily hosted in altered and veined Wood Canyon Formation, and to a lesser extent, in the Juhl and Sutton Members of the Stirling Formation. Mineralization hosted along the contact between the Sutton and Morris Marble Members of the Stirling Formation is referred to as the Gold Ace Zone. Although there are small historic prospects along the Good Hope fault zone, most of the historic production came from the Gold Ace Zone.

| Effective Date: May 31st, 2022 |  | 4 |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

| 1.6 | History |

Historical exploration of the Project was completed by several other companies from 1976 to 2004, including Galli Exploration Associates (Galli Exploration), Teco Inc. (Teco), St. Joe Minerals Corporation (St Joe), Gexa Gold Corp (Gexa), Cloverleaf Gold Inc. (Cloverleaf), Homestake Mining Company (Homestake), Pathfinder Gold Corporation (Pathfinder), Bond Gold Exploration Inc. (Bond Gold), Barrick, US Nevada Gold Search (USNGS), Rayrock Mines, Inc (Rayrock), Glamis Gold, Ltd. (Glamis Gold), and Marigold Mining Company (Marigold Mining). Historical exploration included airborne geophysics, reverse circulation (RC) and core drilling, initial metallurgical testwork, mineral resource estimates and technical studies.

Canyon Resources acquired the Project in 2004, and together with Atna Resources Ltd. (Atna) and CR Reward, have completed data compilation and validation, ground induced polarization/resistivity geophysical surveys, RC and core drilling, mineral resource and mineral reserve estimates, metallurgical testwork, permitting studies, environmental baseline studies, and technical studies. The following permits and authorizations were granted to CR Reward in 2007:

| • | Plan of Operations authorized under N-82840. |

| • | Water Pollution Control Permit (WPCP); WPCP NEV2007101. |

| • | General construction permit; NVR100000 CSW-17415. |

| • | Water rights permitted by Nevada Division of Water Resources (NDWR) under Mining, Milling, & Domestic permit 76390. |

| • | Mining reclamation permit granted by the Bureau of Mining Regulation and Reclamation (BMRR) under mine site permit #0300. |

| • | Nevada Bureau of Air Pollution Control (BAPC) authorized Class II Air Quality permit AP1041-2492. |

| 1.7 | Drilling and Sampling |

A total of 376 drill holes, totalling 43,729.7 m (143,470 ft) have been completed at the Project between 1987 and 2018. Of this total, 35 are core holes totalling 4,094.4 m (13,433 ft) and 341 are RC holes totalling 39,635.3 m (130,037 ft).

For CR Reward’s 2017–2018 drill program, drill hole locations were established using hand-held global positioning system (GPS) instruments and upon completion of the program, the collar locations were re-surveyed by a licensed surveyor. Down-hole surveys were completed at regular intervals, usually 7.6 m (25 ft), using an EZ-Shot system that records the magnetic heading, dip of the hole and magnetic field in the hole. A total of 398 measurements were collected for the 28 holes drilled in 2017–2018. Core recovery during the core drilling was very good, exceeding 95% on average, with losses mainly in highly shattered zones.

| Effective Date: May 31st, 2022 |  | 5 |

Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA

There is limited documentation available detailing the sample preparation, analyses and security of historical drill sampling programs conducted from 1987 to 2000 by Homestake, Gexa, Pathfinder, Cloverleaf, USNGS and Barrick. RC drill holes completed in 2006–2007 were sampled on 1.5 m (5 ft) intervals, and cores on 0.9 m (3 ft) intervals. The 2011–2013 RC holes were also sampled at 1.5 m (5 ft) intervals.

Independent assay laboratories were used in the 2006-2007 Canyon Resources, the 2011-2013 Atna and 2017-2018 CR Reward programs, including ALS Chemex Laboratory in Sparks, Nevada (certified to ISO 9001:2000 for selected techniques), Inspectorate America Corporation (Inspectorate) in Sparks, Nevada (certified to ISO 9001:2000 for selected techniques), Florin Analytical Services (FAS) in Reno, Nevada (not certified).

The 2006–2007, 2011-2013 and the CR Reward 2017-2018 drilling programs included the submission of standard and blank materials as part of the Quality Assurance and Quality Control (QA/QC) program. Assay control protocols during these modern periods of drilling included the insertion of certified standards, blanks and duplicates at acceptable insertion rates for all of the data.

The sample collection, security, transportation, preparation, insertion of geochemical standards and blanks, and analytical procedures are within industry norms and best practices. The procedures used by CR Reward personnel are considered adequate to ensure that the results disclosed are accurate within scientific limitations and are not misleading. The procedures and assay control protocols employed by CR Reward in the 2017–2018 drill program are considered reasonable and acceptable for use in Mineral Resource estimation.

| 1.8 | Data Verification |

Keith Fowlow of CR Reward performed a comprehensive data verification program in 2017 consisting of collar and down-hole survey checks, and evaluation of assay values versus laboratory certificates or geologic logs where certificates were not available. Errors identified were corrected where applicable. For non-analytical drill hole information, CR Reward employed a protocol of continuous data checking to ensure accurate data transcription, including collar and down hole surveys, and geological and geotechnical information. The procedures employed are considered reasonable and are adequate with respect to ensuring data integrity.

Mr. Dufresne reviewed all aspects of the Reward drill hole database and available non-analytical procedures for historical and the CR Reward 2017–2018 drilling programs including the verification program by Mr. Fowlow. The drill hole database was validated using Micromine 2018 and was inspected visually in Excel files and on drill section. Mr. Dufresne has reviewed the adequacy of the exploration information and the visual, physical and geological characteristics of the Project and has found no significant issues or inconsistencies that would cause one to question the validity of the data. Mr. Dufresne, the QP, considers the CR Reward drill hole database, including the historical pre-2017 data and the 2017 to 2018 data, well validated and suitable for the preparation of the MRE presented in Section 14 of this Technical Report.

| Effective Date: May 31st, 2022 |  | 6 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

| 1.9 | Metallurgical Testing |

Metallurgical test work on the Project includes historical work completed by Rayrock Mines Inc. during 1998 and McClellend in 2007 and 2008 with confirmatory test work being performed by KCA in 2018. Metallurgical test work completed to date includes 34 bottle roll tests and 21 column tests along together with preliminary agglomeration and compacted permeability testing. Results from these tests show that the mineralization is amenable to cyanide leaching with reasonable reagent consumptions.

Metallurgical samples from historical and recent KCA test programs appear to be spatially representative for the Good Hope Deposit. Results from KCA’s 2018 test program confirmed the results from the 2007–2008 McClelland campaign with an average laboratory gold recovery of 81% for the Good Hope Deposit. The program also included bottle roll and duplicate column leach tests on the Gold Ace Zone. Results for Gold Ace show significantly lower column recoveries compared to the Good Hope Deposit.

Key design parameters from the metallurgical test work for the Good Hope Deposit include:

| • | Crush size P80 of ¼ inch. |

| • | Estimated field gold recovery of 79% including a 2% field deduction. Based on column tests, it is possible additional ounces may be realized during secondary leaching of ore from leaching upper lifts and during heap rinsing as it appears most columns were still slowly leaching at the termination of the columns. |

| • | Design leach cycle of 125 days. |

| • | Average field sodium cyanide consumption of 0.73 lb/st ore. |

| • | Average field lime consumption of 1.53 lb/st of material based on 100% CaO purity. |

| • | Cement agglomeration is not required up to heap heights of 262 ft. |

No deleterious elements are known from the processing perspective.

| 1.10 | Current Mineral Resource |

This Technical Report details an updated mineral resource estimate (MRE) for the Reward Project. The 2022 MRE for Reward was completed by Mr. Warren Black, M.Sc., P.Geo., of APEX under the direct supervision of Mr. Dufresne, M.Sc., P.Geol., P.Geo. and the QP who takes responsibility for the MRE contained herein. Mr. Steven Nicholls, BA.Sc., MAIG, a QP and APEX’s senior resource geologist performed an internal audit of the MRE in Section 14.

| Effective Date: May 31st, 2022 |  | 7 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

CR Reward and Augusta provided APEX with a drill hole database that consisted of analytical, geological, density, and collar survey information, initial estimation domains for the Good Hope Deposit and Gold Ace Zone, and a geological model that contained a stratigraphic and structural 3D interpretation. A block model size of 20 ft (X) by 20 ft (Y) by 20 ft (Z) was used for the gold estimation.

The assay data was examined using a combination of histograms, cumulative frequency plots, and summary statistics; this indicated gold samples generally exhibited a single assay population. Samples were composited to 10 ft lengths. Probability plots were used to evaluate grade statistics and determine whether capping was warranted. A capping level of 0.292 oz/st (10.01 grams per tonne [g/t]) Au was applied to samples in the Good Hope Deposit, and a cap level of 0.146 oz/st (5.01 g/t) Au to samples in the Gold Ace Zone. Semi-variograms for gold were modelled using the 10 ft composites flagged within the estimation domains. A bulk density of 2.59 g/cm3 was applied to all blocks in the Good Hope Deposit. As there is evidence for the need for a higher bulk density value for blocks flagged within the Morris Member in the Good Ace Zone, they were assigned a value of 2.70 g/cm3. However, as there is an insufficient number of bulk density measurements of the Sutton Member within the Gold Ace estimation domain, all other blocks at the Gold Ace Zone were assigned a bulk density of 2.59 g/cm3.

Ordinary kriging (OK) was used to estimate gold grades for those blocks that contained more than 1.56% mineralized material by volume. A block discretization of 2 (X) by 2 (Y) by 2 (Z) was applied to all blocks during estimation. A two-pass method was used. The first pass required a minimum of two drill holes, a maximum of 15 composites and no more than three composites from any one drill hole. Soft boundaries were used between the high and low-grade domains in the Good Hope Deposit, and mineralization and waste in the Good Hope Deposit and the Gold Ace Zone.

Estimation validation included visual inspection in plan view and in cross-section, examination of swath plots, review of mineralization/waste contact profiles and volume-variance effects. The estimate was found to be reasonable.

Mineral Resources were classified using a combination of assessment of geological confidence, data quality and grade continuity. Resource classification was determined using a three-pass strategy, where Measured was classified in the first run, Indicated in the second, and Inferred in the third run. A small portion of blocks at the northern (>6500 N) and southern (<2750 N) extents of the Good Hope Deposit were manually adjusted to Inferred as there is insufficient drilling density in the QP’s opinion to justify higher confidence classifications.

| Effective Date: May 31st, 2022 |  | 8 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

Reasonable prospects of eventual economic extraction were considered by constraining the estimate within a conceptual pit shell that used the assumptions in Table 1.1.

Table 1.1. Reward Conceptual Open Pit Parameters.

| Parameter | Unit (Imperial) | Cost (Imperial) | Unit (Metric) | Cost (Metric) |

| Gold Price | US$/oz | 1,700 | US$/g | 54.656 |

| Gold Metallurgical Recovery | % | 80 | % | 80 |

| Pit Wall Angles | ° | 48-58 | ° | 48-58 |

| Mining Cost | US$/st | 2.00 | US$/tonne | 2.20 |

| Processing Rate | Mst/a | 3 | Mtonne/a | 2.7 |

| Processing Cost | US$/st | $5.50 | US$/tonne | $6.06 |

| G & A Cost | US$/st | 0.75 | US$/tonne | 0.80 |

| Cut-off Grade (break even) | oz/st | 0.0047 | g/tonne | 0.158 |

| Royalty | % | 3 | % | 3 |

The MRE for the Reward Project is presented in Table 1.2 below.

Table 1.2. Reward Project Mineral Resource Estimate at May 31, 2022 Based on USD$1,700/oz. Au

| Classification | Tonnage (Mt) | Average Grade (g/t) | Contained Au (koz) |

| Good Hope | |||

|

Measured Indicated M&I Total |

6.19 10.76 16.94 |

0.86 0.69 0.75 |

169.9 240.0 409.9 |

| Inferred | 0.29 | 0.56 | 5.3 |

| Gold Ace | |||

|

Indicated Inferred |

0.83 1.03 |

0.63 0.73 |

16.8 21.8 |

| Reward (Combined Good Hope and Gold Ace) | |||

|

Measured Indicated M&I Total |

6.19 11.58 17.77 |

0.86 0.69 0.75 |

169.9 256.8 426.7 |

| Inferred | 1.23 | 0.68 | 27.1 |

Notes:

| 1. | Oxide estimated Mineral Resources are reported within a pit shell using the Lerch Grossman algorithm, a gold price of US$1,700/oz and a recovery of 80% for Au were utilized. |

| 2. | Mining costs for mineralized material and waste are US$2.20/tonne. |

| 3. | Processing and general and administration are US$6.06/tonne and US$0.83/tonne per tonne processed, respectively. |

| 4. | Due to rounding, some columns or rows may not compute as shown. |

| 5. | Estimated Mineral Resources are stated as in situ dry metric tonnes and are partially diluted. |

| 6. | The estimate of Mineral Resources may be materially affected by legal, title, taxation, socio-political, marketing, or other relevant issues. |

| 7. | The effective date of the Reward mineral resource estimate is May 31, 2022. |

| Effective Date: May 31st, 2022 |  | 9 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

| 1.11 | Conclusions |

Based upon a review of available information, historical and recent exploration data, the authors site visits and the current MRE for the Good Hope Deposit and Gold Ace Zone of the Reward Project, the authors view the Project as a property of merit prospective for the additional discovery, and future development, of potentially economic structurally-controlled, locally-disseminated, sediment-hosted, mesothermal quartz vein gold mineralization. This contention is supported by the following:

| • | The favourable geological setting of the Reward Project and its position within the Walker Land Trend, a prolifically mineralized belt that is host to numerous gold deposits and current and past producing mines in south-central Nevada. |

| • | Historical exploration and recent work by CR Reward has delineated a large zone of gold mineralization at Good Hope and Gold Ace and led to the calculation of the current MRE. |

| • | Recent metallurgical testwork indicates projected gold recoveries of 81% for the Good Hope Deposit. |

| 1.12 | Recommendations |

Based on the outcomes of this report and prior work conducted by CR Reward, it is recommended that CR Reward and Augusta proceed to a Preliminary Feasibility Study (PFS) for the Reward Project in order to examine opportunities to develop the Project. The PFS will be an update to a historical internal Feasibility Study (FS) prepared in 2019 on behalf of CR Reward and Waterton. The recommended PFS will incorporate current pricing for major equipment, contract mining costs, construction costs, major consumables, and labor costs.

The budget for completing a PFS for the Project is USD$1,100,000, including contingency, as summarized in Table 1.3 below.

Table 1.3. Estimated budget for the recommended PFS.

| Item | Cost USD$ |

| Primary Engineer, includes Process and Infrastructure | 420,000 |

| Mineral Resource Estimate | 20,000 |

| Mining and Mineral Reserve | 40,000 |

| Geotechnical and Earthworks | 110,000 |

| Power and Other Consulting | 400,000 |

| Contingency | 110,000 |

| Total | 1,100,000 |

| Effective Date: May 31st, 2022 |  | 10 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

| 2 | Introduction |

| 2.1 | Issuer and Purpose |

This Technical Report (the Technical Report) was prepared by APEX Geoscience Ltd. (APEX) and Kappes, Cassiday & Associates (KCA) for CR Reward LLC (CR Reward) and Augusta Gold Corp. (Augusta or the Company). Augusta is a publicly traded company listed on the Toronto Stock Exchange (TSX:G) in Canada and the OTCQB Venture Market (OTCQB:AUGG) in the United States of America (USA) focused on the exploration, advancement and development of gold properties in Nevada. CR Reward is a private Nevada limited liability company that is a wholly owned subsidiary of Augusta.

On June 13, 2022, Augusta acquired the Reward Project (Reward or the Project), from Waterton Nevada Splitter LLC (Waterton) by the purchase of CR Reward.

The Reward Project is considered to be an intermediate stage exploration project within a favourable geological setting, situated within the Walker Lane Trend, a prolifically mineralized belt this is host to numerous gold deposits and current and past producing mines in south-central Nevada. The Project is situated approximately 11.3 km (7 miles) south-southeast of the town of Beatty, NV, approximately 3.2 km (2 miles) east of US Highway 95 in Nye County (Figure 2.1). The Project encompasses 121 unpatented Bureau of Land Management (BLM) placer and lode mining claims and six patented placer mining claims, totalling approximately 2,333 net acres (944 hectares).

This Technical Report summarizes a National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101) and Item 1300 of Regulation S-K of the United States Securities Exchange Act of 1934, as amended (SK 1300) mineral resource estimation for the Reward Project and provides a technical summary of the relevant location, tenure, historical and geological information, a summary of the recent exploration work and recommendations for future exploration programs. This Technical Report summarizes the technical information available up to the effective date of May 31st, 2022.

This Technical Report has been prepared in accordance with the Canadian Securities Administration’s (CSA) NI 43-101 and guidelines for technical reporting Canadian Institute of Mining, Metallurgy and Petroleum (CIM) “Best Practices and Reporting Guidelines” for disclosing mineral exploration and in accordance with the requirements of SK 1300. The mineral resource has been estimated using the CIM “Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines” dated November 29, 2019, and the CIM “Definition Standards for Mineral Resources and Mineral Reserves” amended and adopted May 10th, 2014 and in accordance with the requirements of SK 1300.

| Effective Date: May 31st, 2022 |  | 11 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

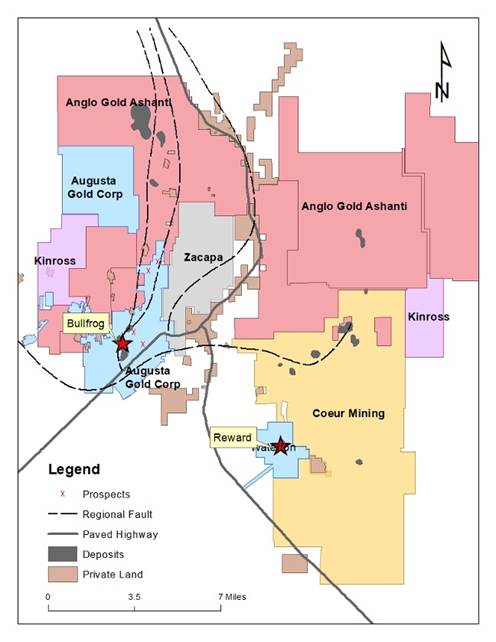

Figure 2.1. Project Location Map (Lycopodium, 2019).

Note: Figure prepared by Lycopodium, 2019.

| 2.2 | Authors, Contributors and Site Inspection |

This Technical Report has been prepared by Mr. Michael B. Dufresne, M.Sc., P. Geol., P. Geo., of APEX and Mr. Timothy D. Scott, RM SME, of KCA. Both authors are independent and not employed by either Augusta or CR Reward and are Qualified Persons (QPs) as defined in NI 43-101 and SK 1300. The CIM and NI 43-101 defines a QP as “an individual who is a geoscientist with at least five years of experience in mineral exploration, mine development or operation or mineral project assessment, or any combination of these; has experience relevant to the subject matter of the mineral project and the technical report; and is a member or licensee in good standing of a professional association.” SK 1300 defines a QP as “an individual who is (1) a mineral industry professional with at least five years of relevant experience in the type of mineralization and type of deposit under consideration and in the specific type of activity that person is undertaking on behalf of the registrant; and (2) an eligible member or licensee in good standing of a recognized professional organization at the time the technical report is prepared.”

| Effective Date: May 31st, 2022 |  | 12 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

Mr. Dufresne, M.Sc., P.Geol., P.Geo. takes responsibility for the preparation and publication of Sections 1.1 to 1.8, 1.10 to 12, 14 to 25.4, 25.6 and 25.8 to 27 and is co-responsible for section 25.7 of this Technical Report. Mr. Dufresne is a Professional Geologist with the Association of Professional Engineers and Geoscientists of Alberta (APEGA; membership number 48439), a Professional Geoscientist with the Association of Professional Engineers and Geoscientists of British Columbia (EGBC; membership number 37074) and has worked as a mineral exploration geologist for more than 35 years since his graduation from university. Mr. Dufresne has been involved in all aspects of mineral exploration and mineral resource estimations for precious and base metal mineral projects and deposits in Canada and internationally, including structurally-controlled, locally-disseminated, sediment-hosted, quartz vein gold mineralization in Nevada.

Mr. Timothy Scott, BA.Sc. Geological Engineering, takes responsibility for Sections 1.9, 13, 25.5 and is co-responsible for section 25.7 of this Technical Report. Mr. Scott visited the Project on September 22nd, 2018 and on May 16th, 2022. He inspected the access and associated infrastructure. Mr. Scott has worked for 35 years in all aspects of mineral processing and gold extraction; heap leaching; and design and construction of mineral processing and metals extraction facilities. He has held management positions at major mining companies as well as led the design, construction, and commissioning teams for the construction of five operating mines.

Contributors to this Technical Report include Mr. Warren Black, M.Sc., P.Geo. and Mr. Steven Nicholls, BA.Sc., MAIG, of APEX. Under the direct supervision of Mr. Dufresne, Mr. Black prepared the resource estimation statistical analysis, three-dimensional modelling, block modelling and resource estimations presented in Section 14. Mr. Black has a research background in the use of multivariate simulation for probabilistic mineral prospectivity modelling and has experience with exploration for precious and base metal deposits of various deposit types in North America. Mr. Steven Nicholls, BA.Sc., MAIG, QP, conducted a thorough audit of the Mineral Resource Estimate (MRE) and Section 14. Mr. Nicholls is a QP, as defined in NI 43-101 and SK 1300, and has worked as a geologist for more than 20 years since his graduation from university. Mr. Nicholls is APEX’s senior resource geologist and has extensive experience with exploration/resource estimation for, and the evaluation of, gold deposits of various types, including sediment-hosted mineralization.

Mr. Dufresne has visited the Project for data verification purposes on two separate occasions in 2017 and 2019. On August 2, 2017, Mr. Dufresne visited the Property and reviewed drill core at CR Reward’s office in Reno, NV. On August 12, 2019, Mr. Dufresne visited the Property and verified the location of a number of drill collars. On August 15, 2019, Mr. Dufresne performed an inspection of the Lovelock, NV, core facility and reviewed Reward Project drill core from the 2017-2018 drill program. No material field based exploration work has occurred at the Reward Project since the 2017-2018 drill program. Therefore, Mr. Dufresne considers the most recent site visit as current. As a result of the site visits, Mr. Dufresne can verify the land position, the geological setting and the mineralization that is the subject of this Technical Report.

| Effective Date: May 31st, 2022 |  | 13 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

| 2.3 | Sources of Information |

This Technical Report is largely based on sections derived from the 2019 Feasibility Study titled, “Reward Project Feasibility Study Report, Nevada, USA”, prepared for CR Reward by Lycopodium Minerals Canada Ltd. (Lycopodium; Lycopodium, 2019) and the 2019 Feasibility Study Technical Report titled, “Reward Project Feasibility Study, NI 43-101 Technical Report Nevada, USA,” prepared by Lycopodium and co-authored by Mr. Dufresne and Mr. Scott (Evans et al., 2019).

Additional sources of information are listed in Section 27, References. The sources of information and data used in this Technical Report are based on the compilation of proprietary and publicly available geological and geochemical data. The authors have deemed these reports, data, and information as valid contributions to the best of their knowledge.

Based on the site visits and review of the available literature and data, the authors take responsibility for the information herein.

| 2.4 | Units of Measure |

With respect to units of measure, unless otherwise stated, this Technical Report uses:

| • | Abbreviated shorthand consistent with the International System of Units (International Bureau of Weights and Measures, 2006). |

| • | ‘Bulk’ weight is presented in both United States short tons (“tons”; 2,000 lbs or 907.2 kg) and metric tonnes (“tonnes”; 1,000 kg or 2,204.6 lbs.). |

| • | Assay and analytical results for precious metals are quoted in parts per million (“ppm”), parts per billion (“ppb”), ounces per short ton (“opt” or ozt/st), where “ounces” refers to “troy ounces” and “ton” means “short ton”. Where ppm (also commonly referred to as grams per metric tonne [g/t]) have been converted to opt (or ozt/st), a conversion factor of 0.029166 (or 34.2857) was used. |

| • | Geographic coordinates are projected in the Universal Transverse Mercator (“UTM”) system relative to Zone 11 of the North American Datum (“NAD”) 1983. and, |

| • | Currency in United States dollars (USD$), unless otherwise specified (e.g., Canadian, CAD$. |

| Effective Date: May 31st, 2022 |  | 14 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

| 3 | Reliance on Other Experts |

The authors are not qualified to provide an opinion or comment on issues related to legal agreements, royalties, permitting and environmental matters. Accordingly, the authors of this Technical Report disclaim portions of the Technical Report particularly in Section 4, Property Description and Location.

The authors relied entirely on background information and details regarding CR Reward’s legal ownership (in Section 4.1) as provided in title reports prepared by CR Rewards legal counsel dated April 9-12, 2022 (Jensen, 2022a,b,c,d). Permitting as well as the legal and survey validation of the claims is not in the authors’ expertise and the QPs have relied on the Company’s representatives with respect to such information.

The authors have confirmed the claims are active and in good standing as of the Effective Date of this Report using the BLM’s MLRS register. The authors have no reason to question the validity or status of the mineral claims.

| 4 | Property Description and Location |

| 4.1 | Description and Location |

The Project is located in Nye County, Nevada, about seven miles south–southeast of the town of Beatty as shown in Figure 4.1. The Project area lies within Sections 1, 2, 3, 4, 9, 10, 11 and 16 of Township 13 South, Range 47 East, and Sections 33, 34, and 35 of Township 12 South, Range 47 East, all referred to the Mount Diablo Baseline and Meridian (CAM, 2012).

The Project is situated at an approximate latitude and longitude corresponding to 36° 50 minutes and 116° 42 minutes, respectively (CAM, 2012). The centre of the proposed open pit is located at 1,729,330 E, 13,375,050 N (UTM coordinates, NAD27, Zone 11, US feet).

The Project area falls within the USGS Carrara Canyon 1:24,000 scale topographic quadrangle map.

| 4.2 | Property and Title in Nevada |

| 4.2.1 | Mineral Title |

Information in this section is sourced from Papke and Davis (2019).

Federal (30 USC and 43 CFR) and Nevada (NRS 517) laws concerning mining claims on Federal land are based on an 1872 Federal law titled “An Act to Promote the Development of Mineral Resources of the United States.” Mining claim procedures still are based on this law, but the original scope of the law has been reduced by several legislative changes.

| Effective Date: May 31st, 2022 |  | 15 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

The Mineral Leasing Act of 1920 (30 USC Chapter 3A) provided for leasing of some non-metallic materials; and the Multiple Mineral Development Act of 1954 (30 USC Chapter 12) allowed simultaneous use of public land for mining under the mining laws and for lease operation under the mineral leasing laws. Additionally, the Multiple Surface Use Act of 1955 (30 USC 611-615) made “common variety” materials non-locatable; the Geothermal Steam Act of 1970 (30 USC Chapter 23) provided for leasing of geothermal resources; and the Federal Land Policy and Management Act of 1976 (the BLM Organic Act, 43 USC Chapter 35) granted the Secretary of the Interior broad authority to manage public lands. Most details regarding procedures for locating claims on Federal lands have been left to individual states, providing that state laws do not conflict with Federal laws (30 USC 28; 43 CFR 3831.1).

Mineral deposits are located either by lode or placer claims (43 CFR 3840). The locator must decide whether a lode or placer claim should be used for a given material; the decision is not always easy but is critical. A lode claim is void if used to acquire a placer deposit, and a placer claim is void if used for a lode deposit. The 1872 Federal law requires a lode claim for “veins or lodes of quartz or other rock in place” (30 USC 26; 43 CFR 3841.1), and a placer claim for all “forms of deposit, excepting veins of quartz or other rock in place” (30 USC 35). The maximum size of a lode claim is 457 m (1,500 ft) in length and 183 m (600 ft) in width, whereas an individual or company can locate a placer claim as much as 8 hectares (20 acres) in area.

Claims may be patented or unpatented. A patented claim is a lode or placer claim or mill site for which a patent has been issued by the Federal Government, whereas an unpatented claim means a lode or placer claim, tunnel right or mill site located under the Federal (30 USC) act, for which a patent has not been issued.

| 4.2.2 | Surface Rights |

Information in this section is sourced from Papke and Davis (2019).

About 85% of the land in Nevada is controlled by the Federal Government; most of this land is administered by the BLM, the US Forest Service (USFS), the US Department of Energy (DOE), or the US Department of Defence (DOD). Much of the land controlled by the BLM and the USFS is open to prospecting and claim location.

| Effective Date: May 31st, 2022 |  | 16 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

Figure 4.1. Project Location Plan.

Note: Figure prepared by Lycopodium, 2019.

Bureau of Land Management regulations regarding surface disturbance and reclamation require that a notice be submitted to the appropriate BLM Field Office for exploration activities in which five acres or fewer are proposed for disturbance (43 CFR 3809.1-1 through 3809.1-4). A Federal Plan of Operations is needed for all mining and processing activities, plus all activities exceeding five acres of proposed disturbance. A Plan of Operations is also needed for any bulk sampling in which 1,000 or more tons of presumed mineralized material are proposed for removal (43 CFR 3802.1 through 3802.6, 3809.1-4, 3809.1-5). The BLM also requires the posting of bonds for reclamation for any surface disturbance caused by more than casual use (43 CFR 3809.500 through 3809.560). The USFS has regulations regarding land disturbance in forest lands (36 CFR Subpart A). Both agencies also have regulations pertaining to land disturbance in proposed wilderness areas.

| Effective Date: May 31st, 2022 |  | 17 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

| 4.2.3 | Environmental Regulations |

Information in this section is sourced from Papke and Davis (2019).

All surface management activities, including reclamation, must comply with all pertinent Federal laws and regulations, and all applicable State environmental laws and regulations. The fundamental requirement, implemented in 43 CFR 3809, is that all hard-rock mining under a Plan of Operations or Notice on the public lands must prevent unnecessary or undue degradation. The Plan of Operations and any modifications to the approved Plan of Operations must meet the requirement to prevent unnecessary or undue degradation.

Authorization to allow the release of effluents into the environment must be in compliance with the Clean Water Act, Safe Drinking Water Act, Endangered Species Act, and other applicable Federal and State environmental laws, consistent with BLM’s multiple-use responsibilities under the Federal Land Policy and Management Act and fully reviewed in the appropriate National Environmental Policy Act (NEPA) document.

| 4.2.4 | Water Rights |

Information in this section is sourced from the State of Nevada Water Resources and the US Department of the Interior Bureau of Reclamation websites.

Allocation of water rights in Nevada uses two principles, prior appropriation, and beneficial use. Prior appropriation (also known as the "first in time, first in right") allows for the orderly use of the state's water resources by granting priority to senior water rights. This concept ensures that senior users are protected, even as new uses for water are allocated. Under the Revised Nevada Statutes (Chapters 533 and 534), all water can be appropriated for beneficial use. Irrigation, mining, recreation, commercial/industrial and municipal uses are examples of beneficial uses.

Water supplied by the Colorado River is managed and operated under numerous compacts, federal laws, court decisions and decrees, contracts, and regulatory guidelines collectively known as the "Law of the River." This collection of documents apportions the water and regulates the use and management of the Colorado River among the seven basin states (Wyoming, Colorado, Utah, New Mexico, California, Nevada and Arizona) and Mexico. The primary document is the 1922 Colorado River Compact.

| 4.3 | Ownership |

Canyon Resources Corporation (Canyon Resources), CR Reward’s predecessor, concluded lease agreements to four unpatented lode claims blocks from private owners in 2004 and 2005.

| Effective Date: May 31st, 2022 |  | 18 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

In 2006, Canyon Resources completed the acquisition of six patented placer claims from Barrick Gold Corporation (Barrick). Canyon Resources also staked 99 new unpatented lode claims during 2005 and 2006.

In 2008, Canyon Resources assigned all of the patented and unpatented claims comprising the Project to CR Reward, which was subsequently converted into a Nevada limited liability company. CR Reward holds a 100% interest in the mineral claims that form the Project, including 99 unpatented lode mineral claims and 6 patented placer claims (Table 4.1). The remaining 22 unpatented lode and placer claims are held through a number of lease agreements (Table 4.1).

On June 13th, 2022, Augusta acquired the Reward Project (Reward or the Project), from Waterton Nevada Splitter LLC (Waterton) by the purchase of CR Reward. Upon closing of the transaction, Waterton received USD$12.5 million cash and USD$15 million comprised of 7,800,000 Augusta shares, with the remaining payable at the time of Augusta’s next equity financing, in cash or shares, providing the additional amount of shares does not result in Waterton owning more than 9.99% of Augusta’s issued and outstanding shares. In addition, USD$17.5 million cash is to be paid within 90 days of closing of the transaction (Augusta Gold Corp., 2022).

| 4.4 | Mineral Properties |

| 4.4.1 | Claim Status |

The Project consists of 121 unpatented Bureau of Land Management (BLM) placer and lode mining claims and six patented placer mining claims (Jensen, 2022a,b,c,d), totalling approximately 2,333 net acres (Table 4.1). Figure 4.2 is an overview plan showing the entire package of claim locations. Figures 4.3 show details of the mineral claims in relation to the main mineralized zones at the Reward Project.

BLM and tax payments are up to date as of the effective date of this report.

Only patented claims have been legally surveyed.

| 4.4.2 | Claim Retention Obligations |

Under U.S. mining law, claims may be renewed annually for an unlimited number of years upon a small payment per claim (currently $165 per claim due to the BLM and an aggregate $1,502 due to Nye County) and the same claim status—whether lode or placer—may be used for exploration or exploitation of the lodes or placers.

State, Federal and local regulations involving environmental, mining and business activities must also be followed.

| Effective Date: May 31st, 2022 |  | 19 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

Table 4.1. Summary of the Reward Project Claims.

| Claim Name | BLM

NMC#/ Parcel # |

Claim Type | Location/ Section Number |

Area, Acres (nominal Number Unless patented) |

Control (% owned, or name of lessor) |

Year Staked or Patented |

Taxes or BLM Rentals Paid Until |

| American | 000-000-97 | Patented placer | 1 & 2 | 40 | 100% CR Reward LLC | 1916 | 31 Aug 2022 |

| Pentellic | 000-000-97 | Patented placer | 2 | 20 | 100% CR Reward LLC | 1916 | 31 Aug 2022 |

| Regius | 000-000-97 | Patented placer | 1 & 2 | 60 | 100% CR Reward LLC | 1916 | 31 Aug 2022 |

| Marion | 000-000-97 | Patented placer | 2 | 40 | 100% CR Reward LLC | 1916 | 31 Aug 2022 |

| Valencia | 000-000-97 | Patented placer | 2 | 20 | 100% CR Reward LLC | 1923 | 31 Aug 2022 |

| Trinity | 000-000-97 | Patented placer | 1 & 2 | 40 | 100% CR Reward LLC | 1925 | 31 Aug 2022 |

| Sunshine | NMC27580 | Unpatented lode | 2 | 20.66 | Connolly/Webster leases | 1957 | 31 Aug 2022 |

| Reward | NMC27581 | Unpatented lode | 2 & 3 | 20.66 | Connolly/Webster leases | 1957 | 31 Aug 2022 |

| Hardway | NMC853089 | Unpatented lode | 2 | 20.66 | Orser-McFall lease | 2003 | 31 Aug 2022 |

| Bull Moose #1 | NMC855150 | Unpatented lode | 2 & 3 | 12.39 | Orser-McFall lease | 2003 | 31 Aug 2022 |

| Bull Moose #2 | NMC855151 | Unpatented lode | 2 & 3 | 12.39 | Orser-McFall lease | 2003 | 31 Aug 2022 |

| Bull Moose #3 | NMC855152 | Unpatented lode | 2 | 11.02 | Orser-McFall lease | 2003 | 31 Aug 2022 |

| Bull Moose #4 | NMC862531 | Unpatented lode | 2 | 11.02 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| Bull Moose #5 | NMC855153 | Unpatented lode | 2 | 4.13 | Orser-McFall lease | 2003 | 31 Aug 2022 |

| Bull Moose #6 | NMC855154 | Unpatented lode | 2 | 13.77 | Orser-McFall lease | 2003 | 31 Aug 2022 |

| Reward South #1 | NMC868938 | Unpatented lode | 2 & 3 | 20.66 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| Reward South #2 | NMC868939 | Unpatented lode | 2 & 3 | 20.66 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| McOrser | NMC870349 | Unpatented lode | 2 | 20.66 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| April Gold Ace | NMC871261 | Unpatented lode | 3 | 20.66 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| Bull Moose #9 | NMC871255 | Unpatented placer | 2 | 11.47 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| Bull Moose #10 | NMC871256 | Unpatented placer | 2 | 11.47 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| Bull Moose #11 | NMC871257 | Unpatented placer | 2 | 11.47 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| Bull Moose #12 | NMC871258 | Unpatented placer | 2 & 3 | 11.47 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| Bull Moose #13 | NMC871259 | Unpatented placer | 2, 3 & 10 | 11.47 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| Bull Moose #14 | NMC871260 | Unpatented placer | 2, 3, 34, 35 | 19.97 | Orser-McFall lease | 2004 | 31 Aug 2022 |

| Good Hope | NMC853090 | Unpatented lode | 2 | 20.66 | Orser/McFall/Webster Lease | 2003 | 31 Aug 2022 |

| Double RS | NMC125600 | Unpatented placer | 3 & 10 | 80 | VanMeeteren et al lease | 1966 | 31 Aug 2022 |

| Durlers Hope | NMC124956 | Unpatented placer | 3 | 40 | VanMeeteren et al lease | 1966 | 31 Aug 2022 |

| RP 1 | NMC915581 | Unpatented lode | 33 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 2 | NMC915582 | Unpatented lode | 33 & 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 3 | NMC915583 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 4 | NMC915584 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 5 | NMC915585 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 6 | NMC915586 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 7 | NMC915587 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 8 | NMC915588 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 9 | NMC915589 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 10 | NMC915590 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 11 | NMC915591 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 12 | NMC915592 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 13 | NMC915593 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 14 | NMC915594 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| Effective Date: May 31st, 2022 |  | 20 |

| Technical Report - Mineral Resource Estimate Reward Project, Nye County, Nevada, USA |

| Claim Name | BLM

NMC#/ Parcel # |

Claim Type | Location/ Section Number |

Area, Acres (nominal Number Unless patented) |

Control (% owned, or name of lessor) |

Year Staked or Patented |

Taxes or BLM Rentals Paid Until |

| RP 15 | NMC915595 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 16 | NMC915596 | Unpatented lode | 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 17 | NMC915597 | Unpatented lode | 34 & 35 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 18 | NMC915598 | Unpatented lode | 34 & 35 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 19 | NMC915599 | Unpatented lode | 35 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 20 | NMC915600 | Unpatented lode | 35 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 21 | NMC915601 | Unpatented lode | 3, 4 & 33 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 22 | NMC915602 | Unpatented lode | 3 & 4 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 23 | NMC915603 | Unpatented lode | 3, 33,34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 24 | NMC915604 | Unpatented lode | 3 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 25 | NMC915605 | Unpatented lode | 3 & 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 26 | NMC915606 | Unpatented lode | 3 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 27 | NMC915607 | Unpatented lode | 3 & 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 28 | NMC915608 | Unpatented lode | 3 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 29 | NMC915609 | Unpatented lode | 3 & 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 30 | NMC915610 | Unpatented lode | 3 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 31 | NMC915611 | Unpatented lode | 3 & 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 32 | NMC915612 | Unpatented lode | 3 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 33 | NMC915613 | Unpatented lode | 3 & 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 34 | NMC915614 | Unpatented lode | 3 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 35 | NMC915615 | Unpatented lode | 3 & 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 36 | NMC915616 | Unpatented lode | 3 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 37 | NMC915617 | Unpatented lode | 3 & 34 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |

| RP 38 | NMC915618 | Unpatented lode | 3 | 20.66 | 100% CR Reward LLC | 2005 | 31 Aug 2022 |