Form 6-K FIRST MAJESTIC SILVER For: May 05

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 6-K

REPORT OF FOREIGN PRIVATE ISSUER

PURSUANT TO RULE 13a-16 OR 15d-16

OF THE SECURITIES EXCHANGE ACT OF 1934

For the month of May 2021

Commission File Number: 001-34984

First Majestic Silver Corp.

(Translation of registrant’s name into English)

925 West Georgia Street, Suite 1800

Vancouver, B.C. V6C 3L2

Canada

(Address of principal executive offices)

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F.

Form 20-F ☐ Form 40-F ☒

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(1) ☐

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(7) ☐

DOCUMENTS FILED AS PART OF THIS FORM 6-K

| Exhibit |

Description | |

| 99.1 | Technical Report | |

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| FIRST MAJESTIC SILVER CORP. | ||||

| Date: May 5, 2021 | ||||

| By: | /s/ Connie Lillico | |||

| Name: Connie Lillico | ||||

| Title: Corporate Secretary | ||||

Exhibit 99.1

Technical Report on the Jerritt Canyon Gold Mine, Elko County, Nevada, USA

SLR Project No: 233.03396.R0000

Prepared by

SLR Consulting (Canada) Ltd.

55 University Ave., Suite 501

Toronto, ON M5J 2H7

for

First Majestic Silver Corp.

1800 – 925 West Georgia Street

Vancouver, BC

V6C 3L2

Effective Date – December 31, 2020

Signature Date - April 30, 2021

| Prepared by:

Ryan Rodney, C.P.G.

Gordon L. Fellows, P.E.

Chelsea Hamilton, P.Eng.

Andrew P. Hampton, M.Sc., P.Eng.

Jeremy Scott Collyard, MMSA QP

Peer Reviewed by:

Luke Evans, M.Sc., P.Eng.

Jason J. Cox, P.Eng.

Lance Engelbrecht, P.Eng.

Deborah A. McCombe, P.Geo. |

Approved by:

Project Manager

Grant A. Malensek, M.Eng., P.Eng.

Project Director

Richard J. Lambert, P.E., P.Eng. |

FINAL

| Distribution: | 1 copy – First Majestic Silver Corp. |

1 copy – SLR Consulting (Canada) Ltd.

| CONTENTS |

||||||

| 1.0 |

SUMMARY | 1-9 | ||||

| 1.1 |

Executive Summary | 1-9 | ||||

| 1.2 |

Economic Analysis | 1-18 | ||||

| 1.3 |

Technical Summary | 1-25 | ||||

| 2.0 |

INTRODUCTION | 2-1 | ||||

| 2.1 |

Sources of Information | 2-1 | ||||

| 2.2 |

List of Abbreviations | 2-3 | ||||

| 3.0 |

RELIANCE ON OTHER EXPERTS | 3-1 | ||||

| 4.0 |

PROPERTY DESCRIPTION AND LOCATION | 4-2 | ||||

| 4.1 |

Property Description and Location | 4-2 | ||||

| 4.2 |

Land Tenure | 4-5 | ||||

| 5.0 |

ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 5-1 | ||||

| 5.1 |

Accessibility | 5-1 | ||||

| 5.2 |

Physiography | 5-1 | ||||

| 5.3 |

Climate |

5-1 | ||||

| 5.4 |

Local Resources |

5-1 | ||||

| 5.5 |

Infrastructure | 5-2 | ||||

| 6.0 |

HISTORY | 6-1 | ||||

| 6.1 |

Prior Ownership | 6-1 | ||||

| 6.2 |

Production History | 6-1 | ||||

| 6.3 |

Exploration | 6-9 | ||||

| 7.0 |

GEOLOGICAL SETTING AND MINERALIZATION | 7-1 | ||||

| 7.1 |

Regional and Local Geology | 7-1 | ||||

| 7.2 |

Mineralization | 7-5 | ||||

| 8.0 |

DEPOSIT TYPES |

8-1 | ||||

| 9.0 |

EXPLORATION | 9-1 | ||||

| 9.1 |

Exploration Potential | 9-3 | ||||

| 10.0 |

DRILLING | 10-1 | ||||

| 10.1 |

Underground Drilling | 10-1 | ||||

| 10.2 |

Surface Drilling | 10-9 | ||||

| 10.3 |

Drilling After April 29, 2020 | 10-21 | ||||

| 11.0 |

SAMPLE PREPARATION, ANALYSES, AND SECURITY | 11-1 | ||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | i | |||

| 11.1 |

Drill Sample Handling and Logging Procedures | 11-1 | ||||

| 11.2 |

Sampling Method and Approach | 11-1 | ||||

| 11.3 |

Sample Preparation and Analysis | 11-4 | ||||

| 11.4 |

Quality Assurance/Quality Control | 11-6 | ||||

| 12.0 |

DATA VERIFICATION | 12-1 | ||||

| 12.1 |

Historical Database Verifications | 12-1 | ||||

| 12.2 |

Recent Data Verification | 12-1 | ||||

| 13.0 |

MINERAL PROCESSING AND METALLURGICAL TESTING | 13-1 | ||||

| 14.0 |

MINERAL RESOURCE ESTIMATE | 14-1 | ||||

| 14.1 |

Summary | 14-1 | ||||

| 14.2 |

Topography | 14-3 | ||||

| 14.3 |

Description of the Databases | 14-5 | ||||

| 14.4 |

Mineralization Wireframes | 14-7 | ||||

| 14.5 |

Compositing Methods and Grade Capping | 14-13 | ||||

| 14.6 |

Bulk Density | 14-14 | ||||

| 14.7 |

Variography | 14-14 | ||||

| 14.8 |

Block Model Construction | 14-18 | ||||

| 14.9 |

Interpolation Strategy | 14-21 | ||||

| 14.10 |

Block Model Validation | 14-23 | ||||

| 14.11 |

Mineral Resource Classification Criteria | 14-34 | ||||

| 14.12 |

Cut-off Grade | 14-37 | ||||

| 14.13 |

Reasonable Prospects for Eventual Economic Extraction | 14-37 | ||||

| 14.14 |

Mineral Resource Estimate | 14-37 | ||||

| 14.15 |

Factors that May Affect the Mineral Resource Estimate | 14-40 | ||||

| 15.0 |

MINERAL RESERVE ESTIMATE | 15-1 | ||||

| 15.1 |

Summary | 15-1 | ||||

| 15.2 |

Dilution | 15-3 | ||||

| 15.3 |

Extraction | 15-3 | ||||

| 15.4 |

Cut-Off Grade | 15-4 | ||||

| 16.0 |

MINING METHODS | 16-1 | ||||

| 16.1 |

Stoping Methods | 16-4 | ||||

| 16.2 |

Mine Development | 16-4 | ||||

| 16.3 |

Geomechanics, Ground Support | 16-4 | ||||

| 16.4 |

Backfill | 16-4 | ||||

| 16.5 |

Groundwater Control | 16-5 | ||||

| 16.6 |

Mining Equipment | 16-15 | ||||

| 16.7 |

Production Rate | 16-16 | ||||

| 16.8 |

Production Schedule | 16-17 | ||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | ii | |||

| 17.0 |

RECOVERY METHODS |

17-1 | ||||

| 17.1 |

Processing Plant |

17-1 | ||||

| 18.0 |

PROJECT INFRASTRUCTURE |

18-1 | ||||

| 18.1 |

Road Access |

18-1 | ||||

| 18.2 |

Water Sources |

18-1 | ||||

| 18.3 |

Power |

18-1 | ||||

| 18.4 |

Sewage and Waste Disposal |

18-1 | ||||

| 18.5 |

Ore Stockpiles |

18-1 | ||||

| 18.6 |

Tailings Storage Facility |

18-2 | ||||

| 18.7 |

Water Treatment Plants |

18-14 | ||||

| 19.0 |

MARKET STUDIES AND CONTRACTS |

19-1 | ||||

| 19.1 |

Markets |

19-1 | ||||

| 19.2 |

Supply and Services Contracts |

19-1 | ||||

| 20.0 |

ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT |

20-1 | ||||

| 20.1 |

Environmental Studies |

20-1 | ||||

| 20.2 |

Project Permitting & Current Status |

20-1 | ||||

| 20.3 |

Social or Community Requirements |

20-9 | ||||

| 20.4 |

Mine Closure Requirements |

20-9 | ||||

| 21.0 |

CAPITAL AND OPERATING COSTS |

21-1 | ||||

| 21.1 |

Capital Costs |

21-1 | ||||

| 21.2 |

Operating Costs |

21-1 | ||||

| 22.0 |

ECONOMIC ANALYSIS |

22-1 | ||||

| 22.1 |

Economic Criteria |

22-1 | ||||

| 22.2 |

Cash Flow |

22-2 | ||||

| 22.3 |

Sensitivity Analysis |

22-5 | ||||

| 23.0 |

ADJACENT PROPERTIES |

23-1 | ||||

| 24.0 |

OTHER RELEVANT DATA AND INFORMATION |

24-1 | ||||

| 25.0 |

INTERPRETATION AND CONCLUSIONS |

25-1 | ||||

| 25.1 |

Geology and Mineral Resources |

25-1 | ||||

| 25.2 |

Mining and Mineral Reserves |

25-2 | ||||

| 25.3 |

Mineral Processing and Metallurgical Testing |

25-2 | ||||

| 25.4 |

Infrastructure |

25-3 | ||||

| 25.5 |

Tailings and Water Management Facilities |

25-3 | ||||

| 25.6 |

Environmental Considerations |

25-4 | ||||

| 25.7 |

Safety |

25-5 | ||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | iii | |||

| 26.0 |

RECOMMENDATIONS |

26-1 | ||||

| 26.1 |

Geology and Mineral Resources |

26-1 | ||||

| 26.2 |

Mining and Mineral Reserves |

26-1 | ||||

| 26.3 |

Mineral Processing and Metallurgical Testing |

26-1 | ||||

| 26.4 |

Infrastructure |

26-1 | ||||

| 26.5 |

Tailings and Water Management Facilities |

26-2 | ||||

| 26.6 |

Environmental Considerations |

26-2 | ||||

| 26.7 |

Safety |

26-2 | ||||

| 27.0 |

REFERENCES |

27-1 | ||||

| 28.0 |

DATE AND SIGNATURE PAGE |

28-1 | ||||

| 29.0 |

CERTIFICATE OF QUALIFIED PERSON |

29-1 | ||||

| 29.1 |

Ryan Rodney |

29-1 | ||||

| 29.2 |

Gordon L. Fellows |

29-2 | ||||

| 29.3 |

Chelsea Hamilton |

29-3 | ||||

| 29.4 |

Andrew P. Hampton |

29-4 | ||||

| 29.5 |

Jeremy Scott Collyard |

29-5 | ||||

TABLES

| Table 1-1: |

Summary of Mineral Resources (effective date December 31, 2020, Imperial Units) |

1-9 | ||||

| Table 1-2: |

Summary of Mineral Resources (effective date December 31, 2020, Metric Units) |

1-10 | ||||

| Table 1-3: |

Summary of Mineral Reserves (effective date December 31, 2020, Imperial Units) |

1-10 | ||||

| Table 1-4: |

Summary of Mineral Reserves (effective date December 31, 2020, Metric Units) |

1-11 | ||||

| Table 1-5: |

After-Tax Cash Flow Summary |

1-21 | ||||

| Table 1-6: |

Cash Flow Analysis |

1-23 | ||||

| Table 1-7: |

After-Tax Sensitivity Analysis |

1-24 | ||||

| Table 1-8: |

Sustaining Capital Cost Estimate |

1-31 | ||||

| Table 1-9: |

Operating Cost Estimate |

1-31 | ||||

| Table 4-1: |

Summary of Claims |

4-5 | ||||

| Table 4-2: |

Summary of Claim Payments |

4-5 | ||||

| Table 6-1: |

Mine Production History |

6-2 | ||||

| Table 6-2: |

Production by JCG from 2015 to December 2020 |

6-3 | ||||

| Table 6-3: |

Jerritt Canyon Process Plant Production |

6-6 | ||||

| Table 6-4: |

Summary of Chip Sampling on Jerritt Canyon Property |

6-19 | ||||

| Table 6-5: |

Historical Underground Drilling by Deposit |

6-20 | ||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | iv | |||

| Table 10-1: |

Underground Drilling by JCG |

10-1 | ||||

| Table 10-2: |

Composited Intercepts for Underground Drilling Results (2018-2020) |

10-9 | ||||

| Table 10-3: |

2016-2019 Surface Exploration Drilling Totals |

10-9 | ||||

| Table 10-4: |

2019 North Generator Drilling Results |

10-17 | ||||

| Table 10-5: |

2019 Extension Drilling Results – Coulee and Smith Areas |

10-19 | ||||

| Table 10-6: |

Exploration Drilling Results April 30, 2020 through December 31, 2020 |

10-21 | ||||

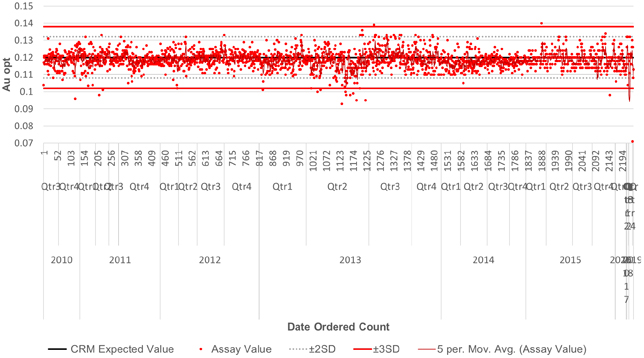

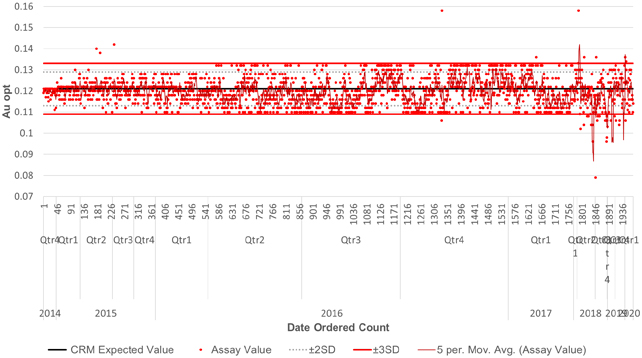

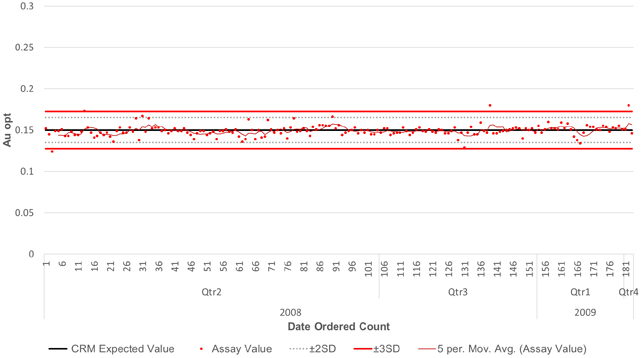

| Table 11-1: |

Summary of QA/QC Submittals: 2008 to 2020 |

11-6 | ||||

| Table 11-2: |

2010 to 2020 Certified Reference Material and Statistics |

11-8 | ||||

| Table 12-1: |

Previous Database Audits |

12-1 | ||||

| Table 13-1: |

Annual Mill Production Data 1981 to 2020 |

13-1 | ||||

| Table 13-2: |

Monthly Mill Production Data 2018 to 2020 |

13-4 | ||||

| Table 14-1: |

Summary of Mineral Resources (effective date December 31, 2020, Imperial Units) |

14-2 | ||||

| Table 14-2: |

Summary of Mineral Resources (effective date December 31, 2020, Metric Units) |

14-2 | ||||

| Table 14-3: |

Drill Holes by Deposit |

14-5 | ||||

| Table 14-4: |

Assay Statistics of Jerritt Canyon Deposits |

14-5 | ||||

| Table 14-5: |

Assay Statistics for Mineralized Wireframe Domains |

14-7 | ||||

| Table 14-6: |

Composite Statistics for Mineralized Wireframe Domains |

14-14 | ||||

| Table 14-7: |

Variography Parameters |

14-16 | ||||

| Table 14-8: |

Summary of the Block Model Origins and Block Sizes |

14-19 | ||||

| Table 14-9: |

Search Ellipsoid Radii |

14-21 | ||||

| Table 14-10: |

Block Model Versus Wireframe Volume Comparisons |

14-25 | ||||

| Table 14-11: |

Statistics of Composite Grades Versus Block Grades |

14-31 | ||||

| Table 14-12: |

Statistics of Secondary Estimation Check |

14-32 | ||||

| Table 14-13: |

Summary of the Vulcan Block Model Attributes |

14-33 | ||||

| Table 14-14: |

Summary of Reconciliation, January 2016 to March 2020 |

14-34 | ||||

| Table 14-15: |

Mineral Resource Estimate (effective date December 31, 2020, Imperial Units) |

14-38 | ||||

| Table 14-16: |

Mineral Resource Estimate (effective date December 31, 2020, Metric Units) |

14-39 | ||||

| Table 15-1: |

Summary of Mineral Reserves (effective date December 31, 2020, Imperial Units) |

15-1 | ||||

| Table 15-2: |

Summary of Mineral Reserves (effective date December 31, 2020, Metric Units) |

15-2 | ||||

| Table 15-3: |

Summary of Cut-Off Grade Factors – March 31, 2020 |

15-4 | ||||

| Table 16-1: |

Hydrogeologic Units in the Jerritt Canyon District |

16-6 | ||||

| Table 16-2: |

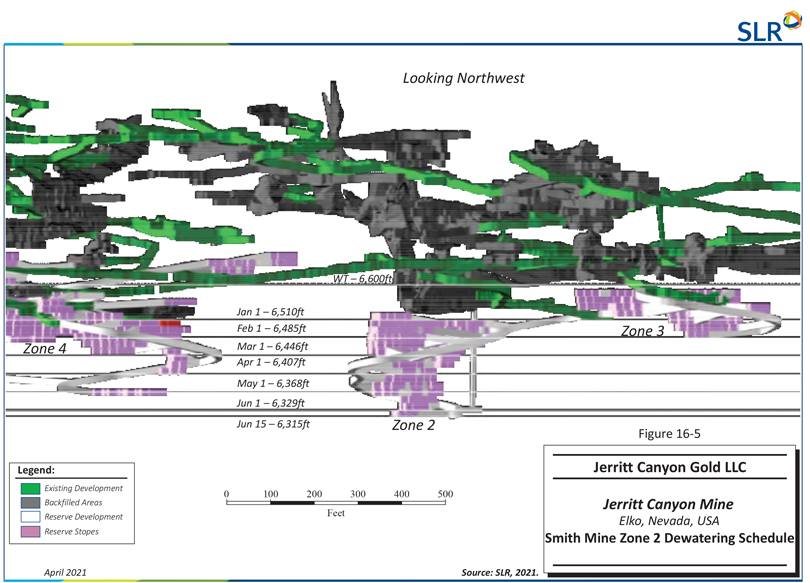

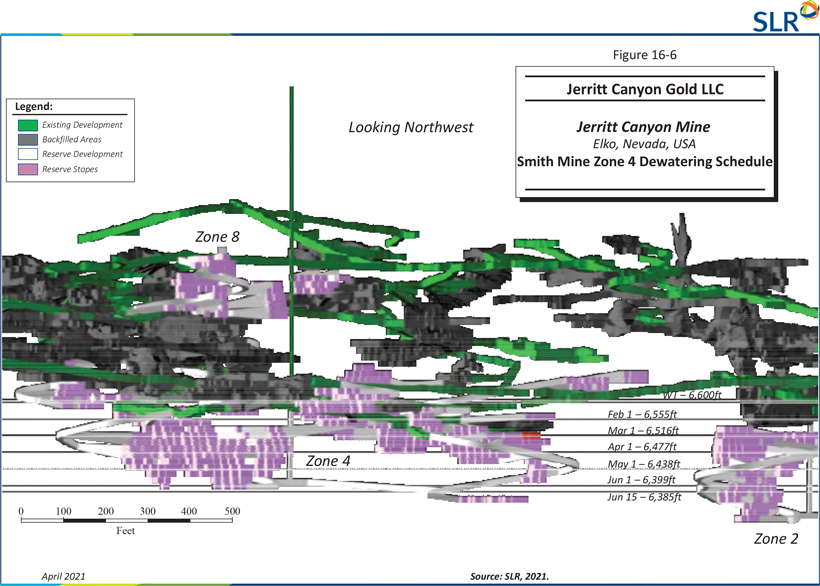

Smith Mine Dewatering Schedule |

16-11 | ||||

| Table 16-3: |

Contractor Primary Mining Fleet |

16-16 | ||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | v | |||

| Table 16-4: |

Historical Mine Production 2018 to 2020 |

16-16 | ||||

| Table 16-5: |

Reserve Production Schedule |

16-17 | ||||

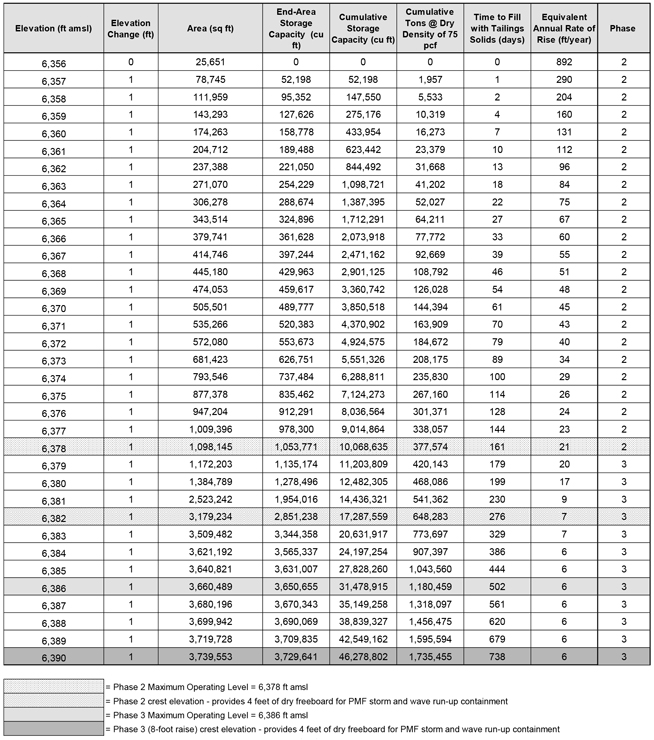

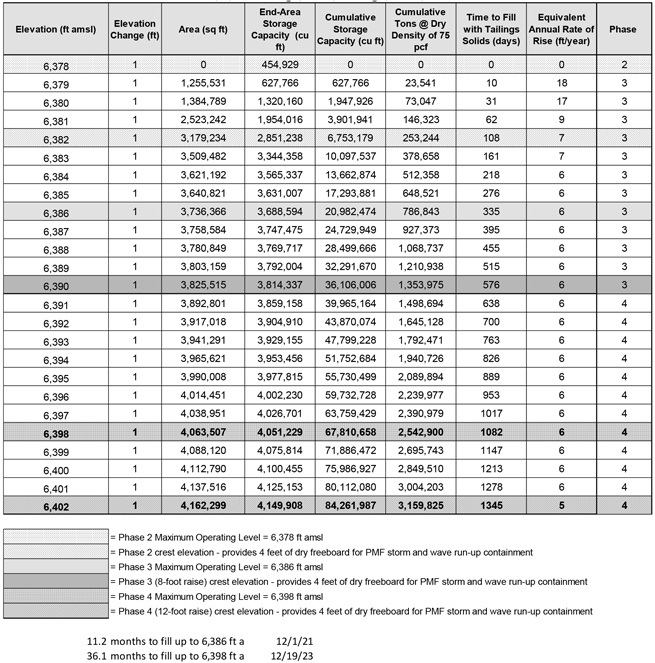

| Table 18-1: |

Maximum Operating Elevations and Storage for TSF 2 Phases 1 to 4 |

18-6 | ||||

| Table 18-2: |

TSF 2 Phase 3 – Stage, Area, Storage, Time, Rate-of-Rise Characteristics |

18-11 | ||||

| Table 18-3: |

TSF 2 Phases 2, 3, & 4 – Stage, Area, Storage, Time, Rate-of-Rise Characteristics |

18-12 | ||||

| Table 20-1: |

Operating Permits |

20-2 | ||||

| Table 20-2: |

2019 AWP Reclamation Costs |

20-10 | ||||

| Table 20-3: |

Bonds Held as of December 8, 2020 |

20-11 | ||||

| Table 21-1: |

Sustaining Capital Cost Estimate |

21-1 | ||||

| Table 21-2: |

Operating Cost Estimate |

21-1 | ||||

| Table 22-1: |

After-Tax Cash Flow Summary |

22-3 | ||||

| Table 22-2: |

Cash Flow Analysis |

22-5 | ||||

| Table 22-3: |

After-Tax Sensitivity Analysis |

22-6 | ||||

FIGURES

| Figure 1-1: |

After-Tax NPV Sensitivity Graph |

1-25 | ||||

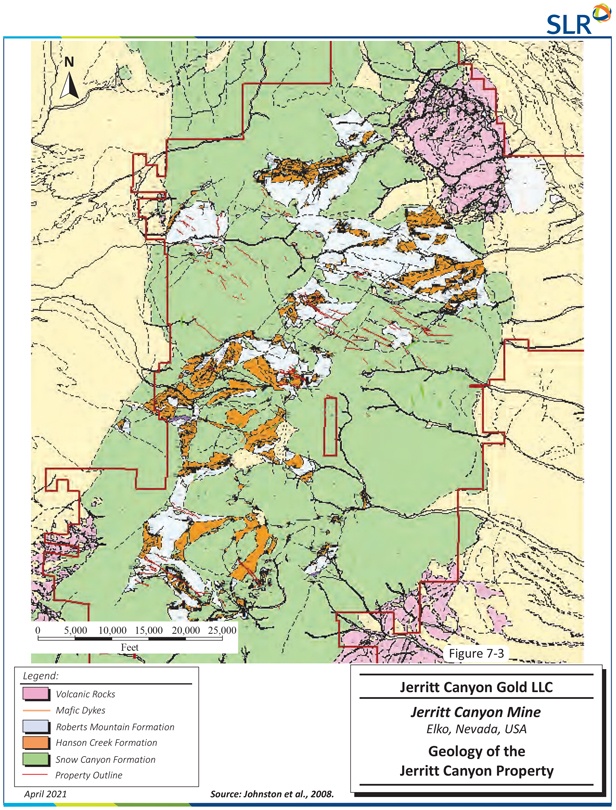

| Figure 4-1: |

Location of the Jerritt Canyon Property |

4-3 | ||||

| Figure 4-2: |

Property Map |

4-4 | ||||

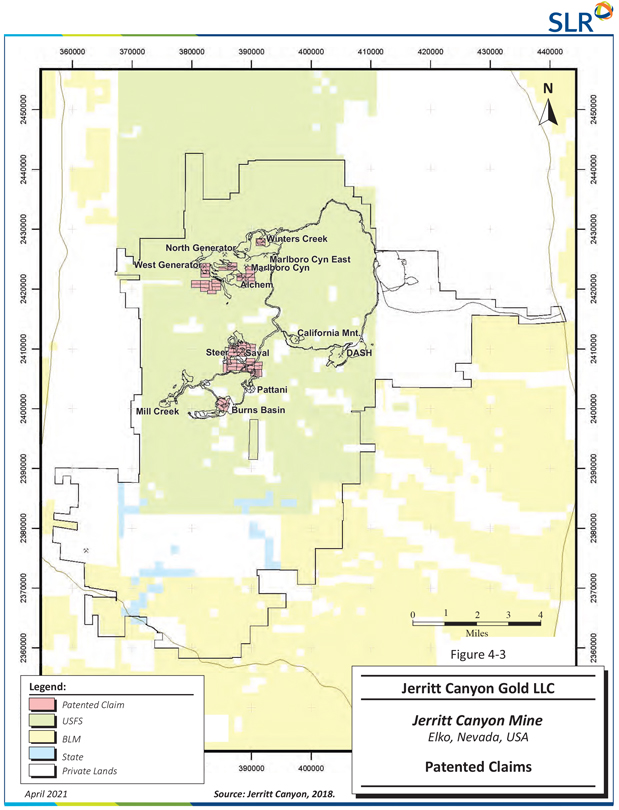

| Figure 4-3: |

Patented Claims |

4-6 | ||||

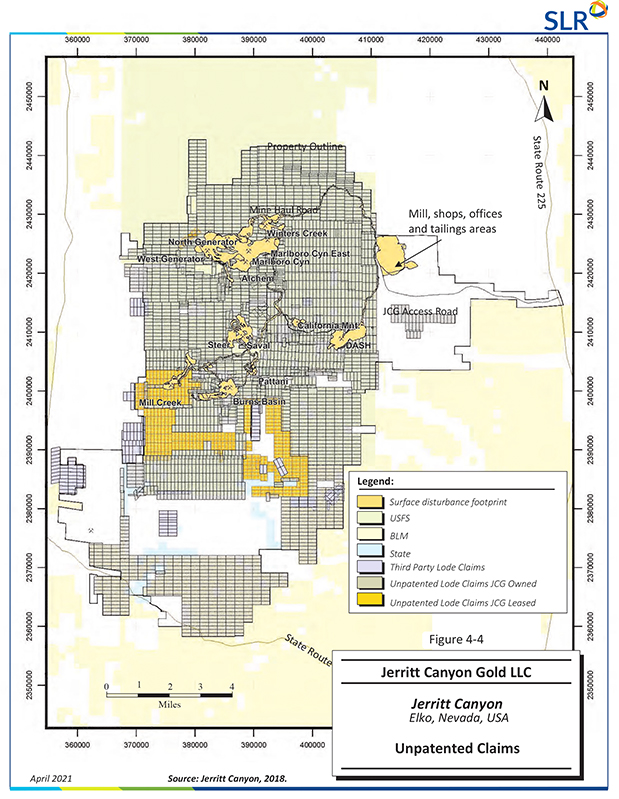

| Figure 4-4: |

Unpatented Claims |

4-7 | ||||

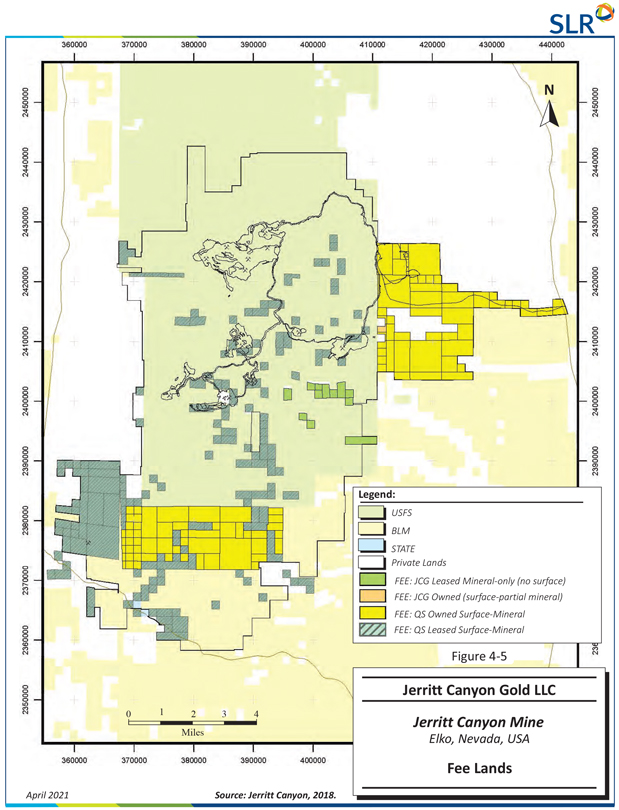

| Figure 4-5: |

Fee Lands |

4-8 | ||||

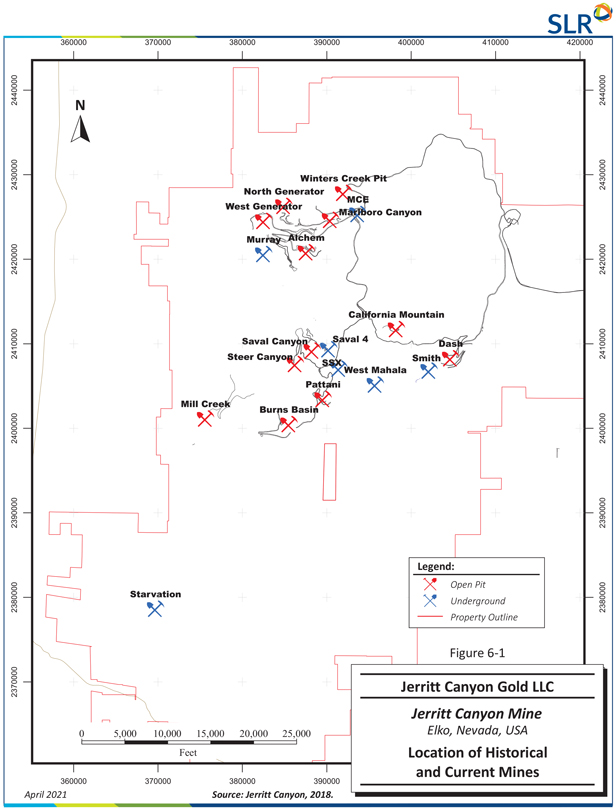

| Figure 6-1: |

Location of Historical and Current Mines |

6-4 | ||||

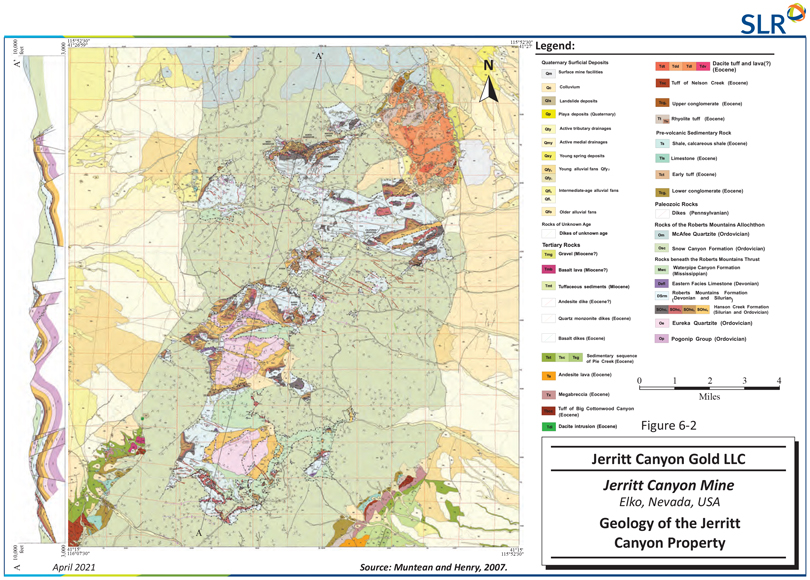

| Figure 6-2: |

Geology of the Jerritt Canyon Property |

6-10 | ||||

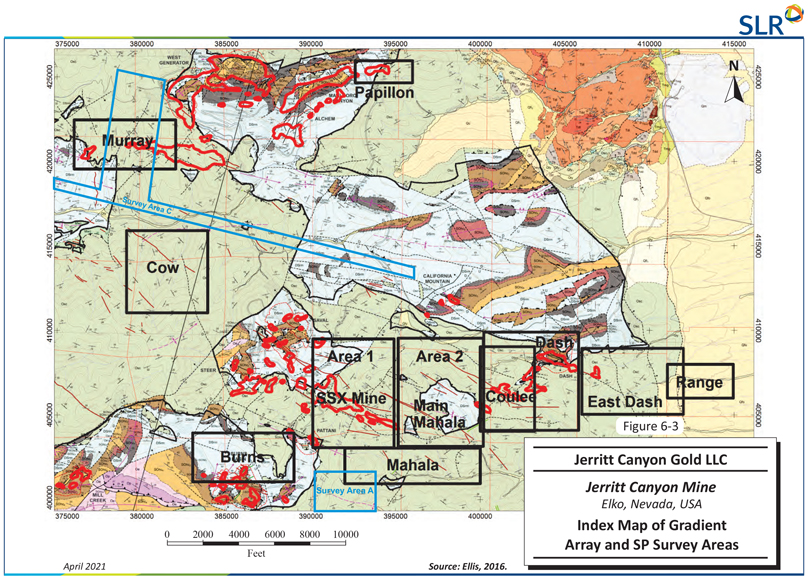

| Figure 6-3: |

Index Map of Gradient Array and SP Survey Areas |

6-12 | ||||

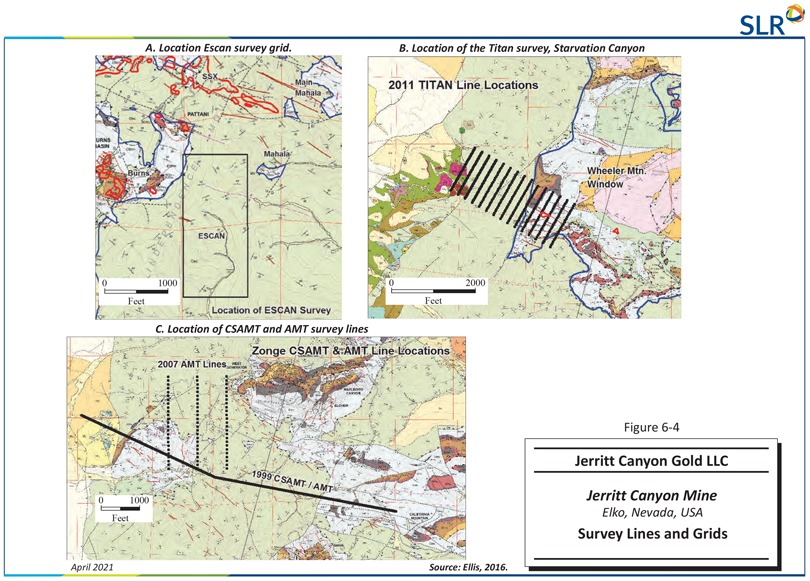

| Figure 6-4: |

Survey Lines and Grids |

6-14 | ||||

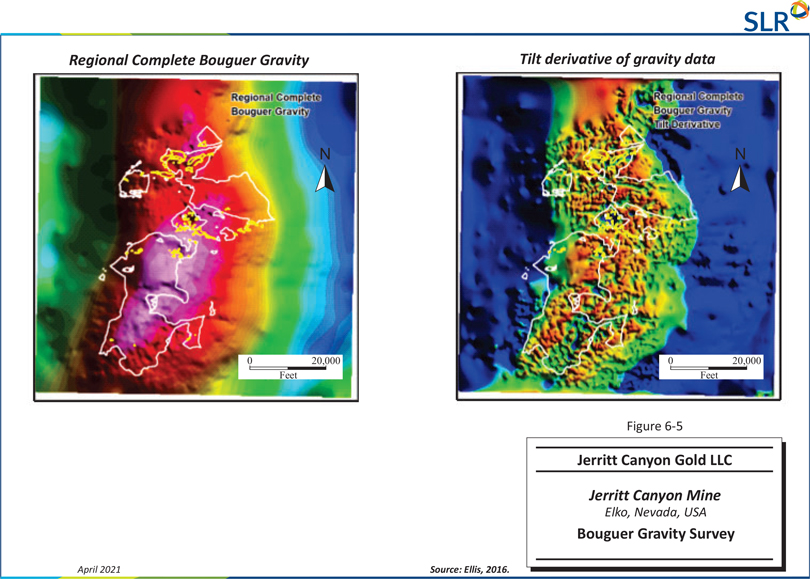

| Figure 6-5: |

Bouguer Gravity Survey |

6-16 | ||||

| Figure 6-6: |

Location of Airborne Surveys |

6-18 | ||||

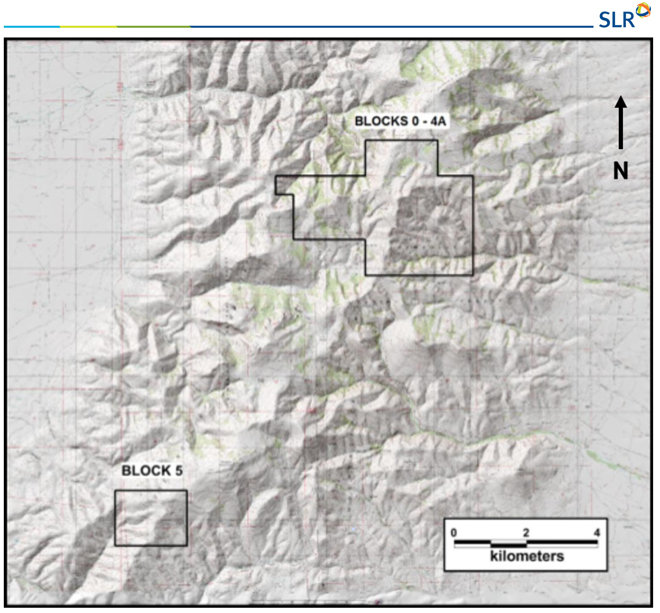

| Figure 7-1: |

Location of the Jerritt Canyon Property and Nevada Gold Belts |

7-2 | ||||

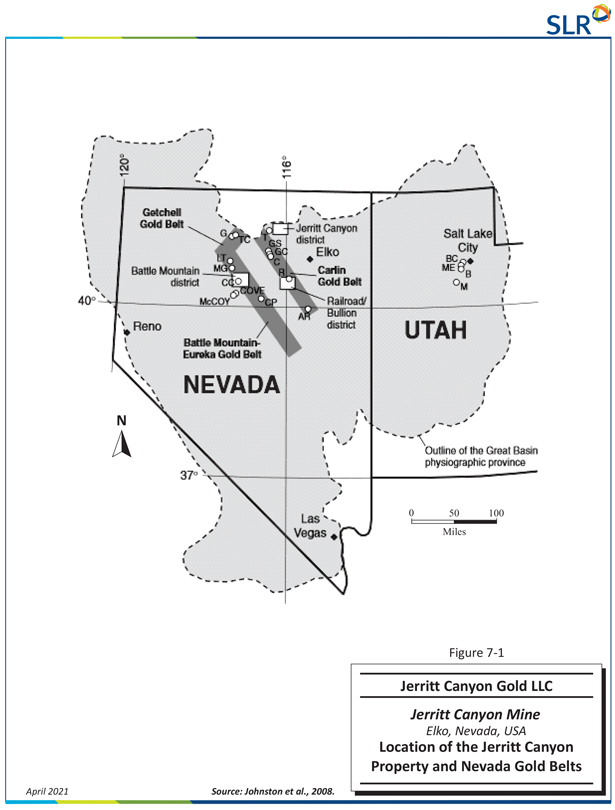

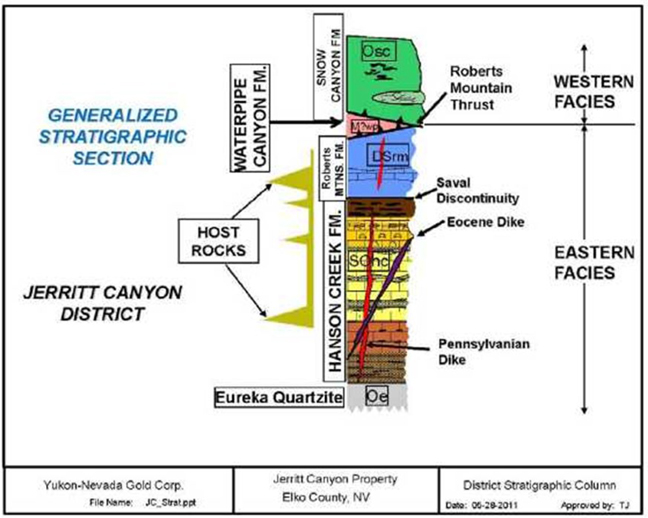

| Figure 7-2: |

Tectonostratigraphic Column of the Jerritt Canyon Property |

7-3 | ||||

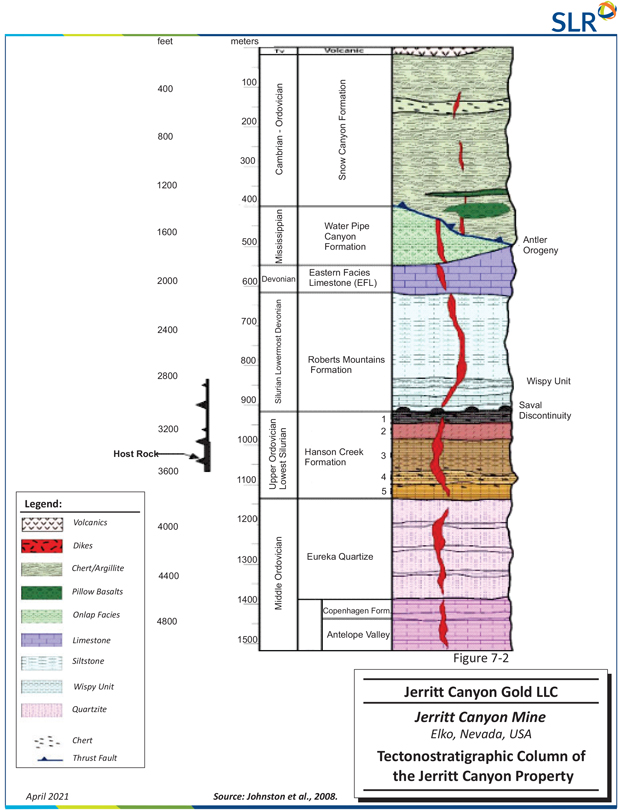

| Figure 7-3: |

Geology of Jerritt Canyon Property |

7-4 | ||||

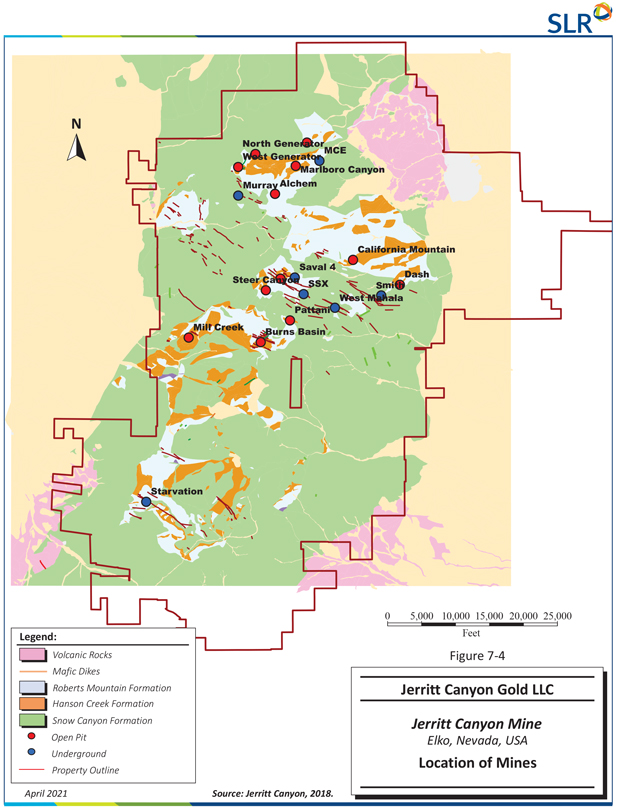

| Figure 7-4: |

Location of Mines |

7-6 | ||||

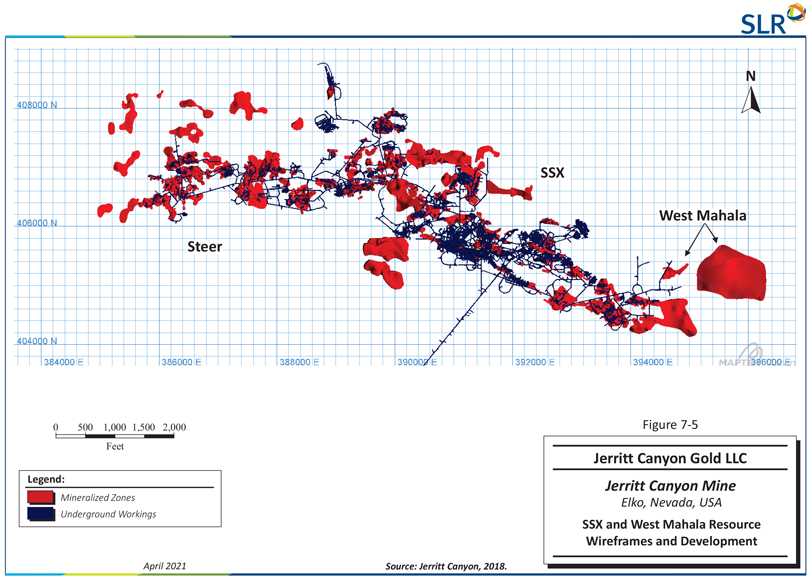

| Figure 7-5: |

SSX and West Mahala Resource Wireframes and Development |

7-8 | ||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | vi | |||

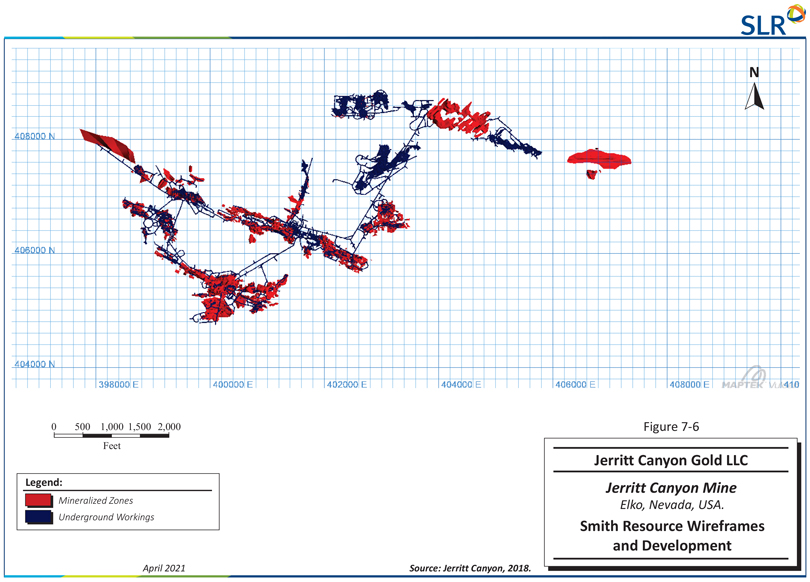

| Figure 7-6: |

Smith Resource Wireframes and Development | 7-10 | ||||

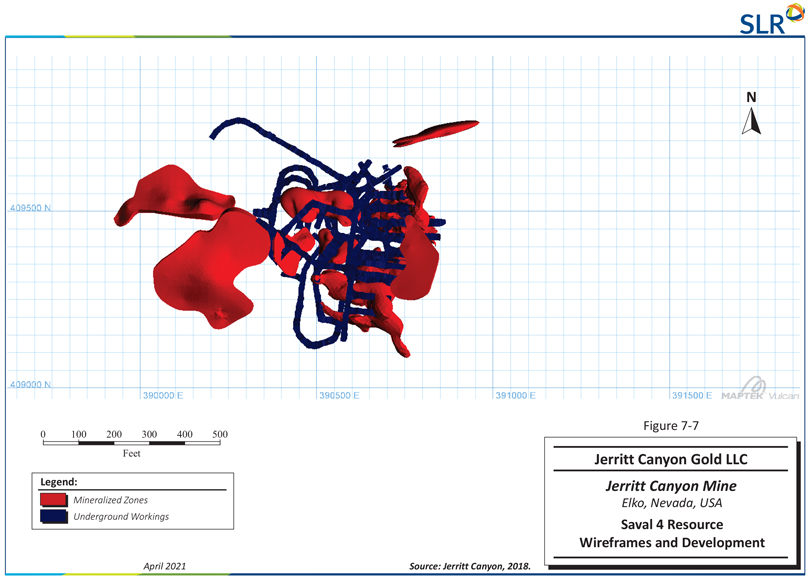

| Figure 7-7: |

Saval 4 Resource Wireframes and Development | 7-12 | ||||

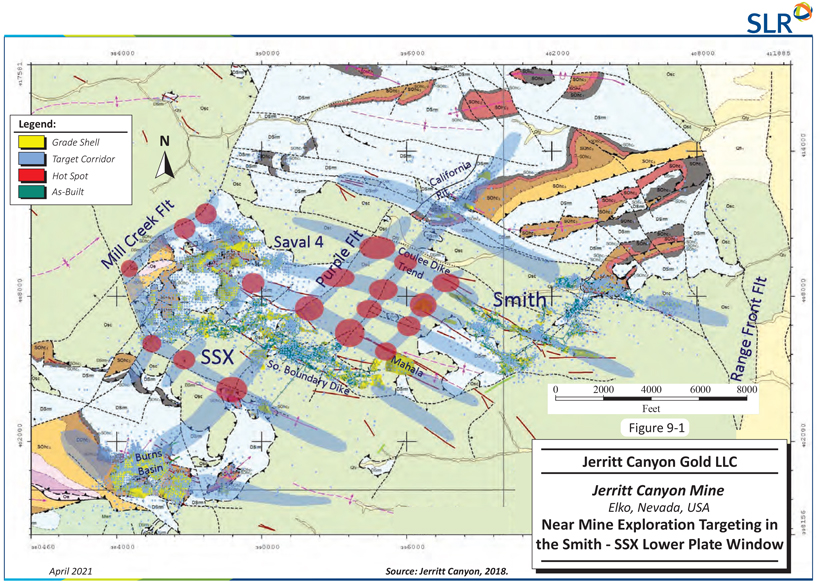

| Figure 9-1: |

Near-Mine Exploration Targeting in the Smith–SSX Lower Plate Window | 9-4 | ||||

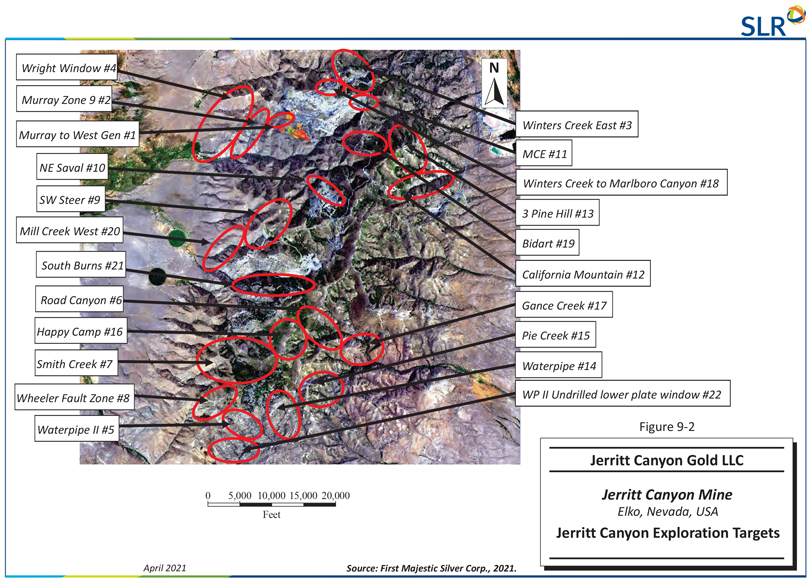

| Figure 9-2: |

Jerritt Canyon Exploration Targets | 9-6 | ||||

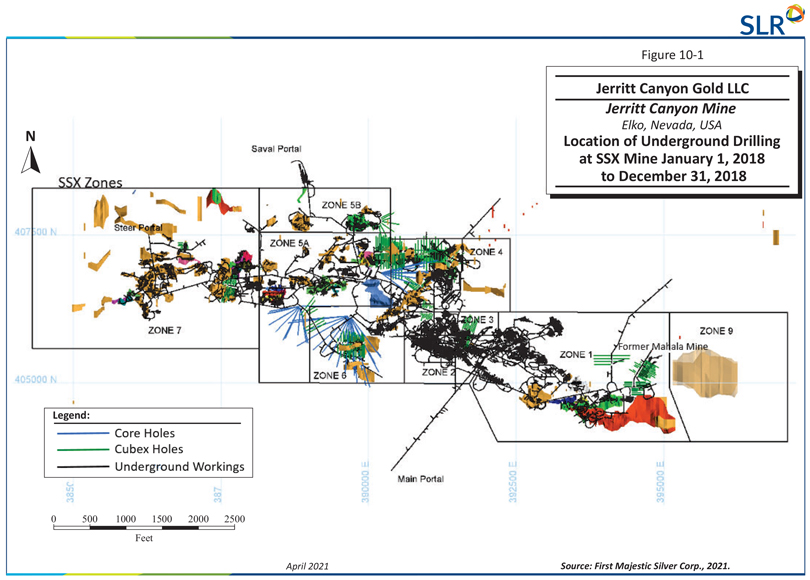

| Figure 10-1: |

Location of Underground Drilling at SSX Mine January 1, 2018 to December 31, 2018 | 10-3 | ||||

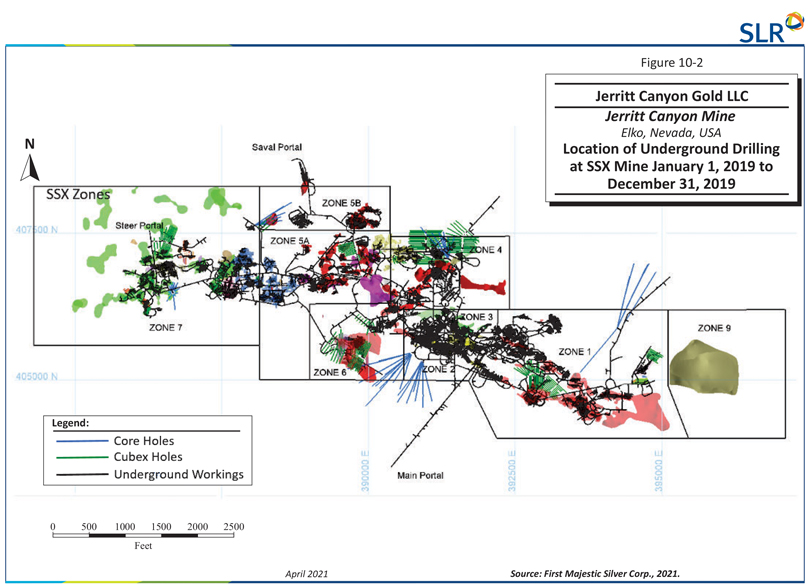

| Figure 10-2: |

Location of Underground Drilling at SSX Mine January 1, 2019 to December 31, 2019 | 10-4 | ||||

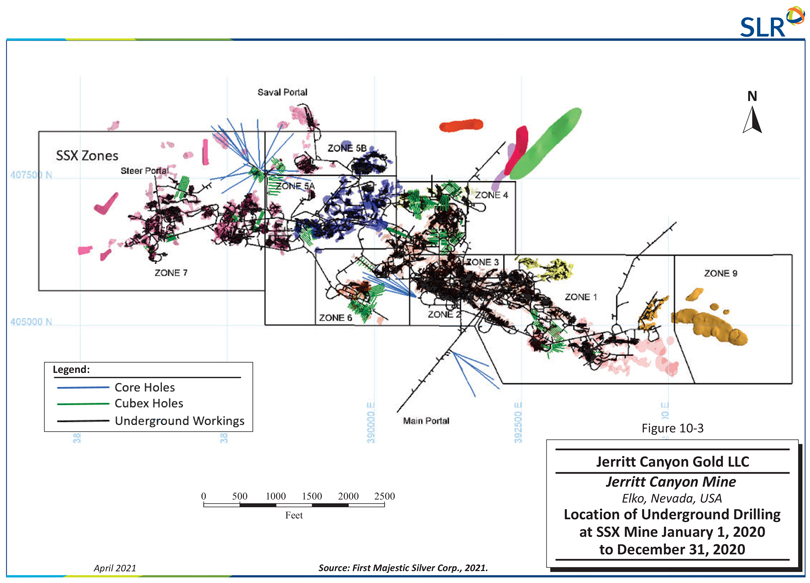

| Figure 10-3: |

Location of Underground Drilling at SSX Mine January 1, 2020 to December 31, 2020 | 10-5 | ||||

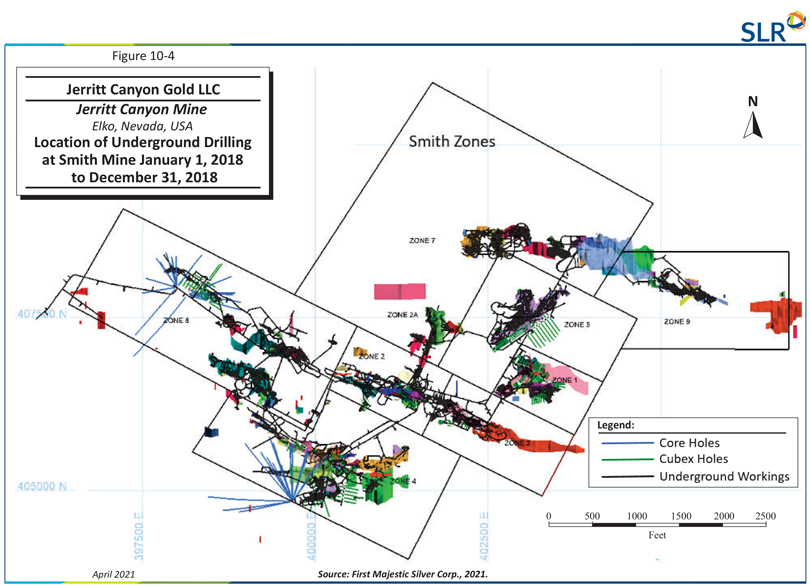

| Figure 10-4: |

Location of Underground Drilling at Smith Mine January 1, 2018 to December 31, 2018 | 10-6 | ||||

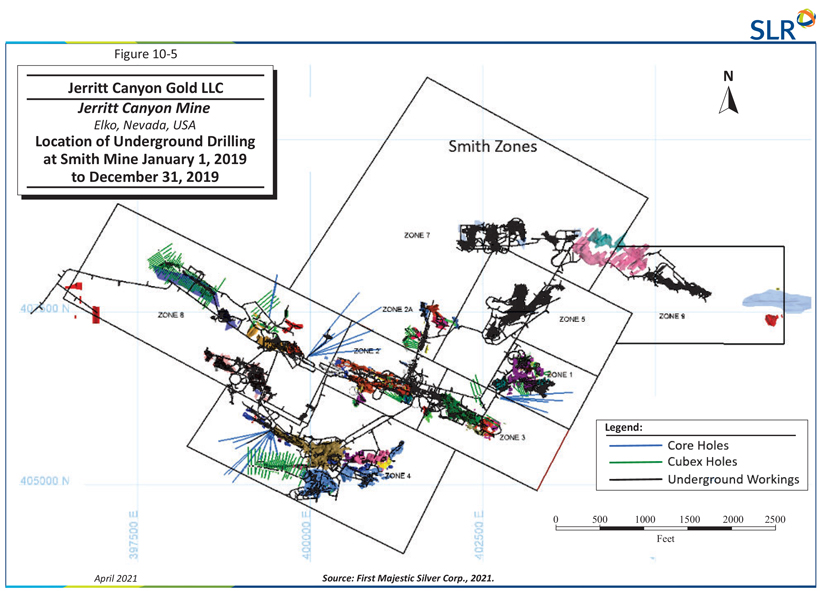

| Figure 10-5: |

Location of Underground Drilling at Smith Mine January 1, 2019 to December 31, 2019 | 10-7 | ||||

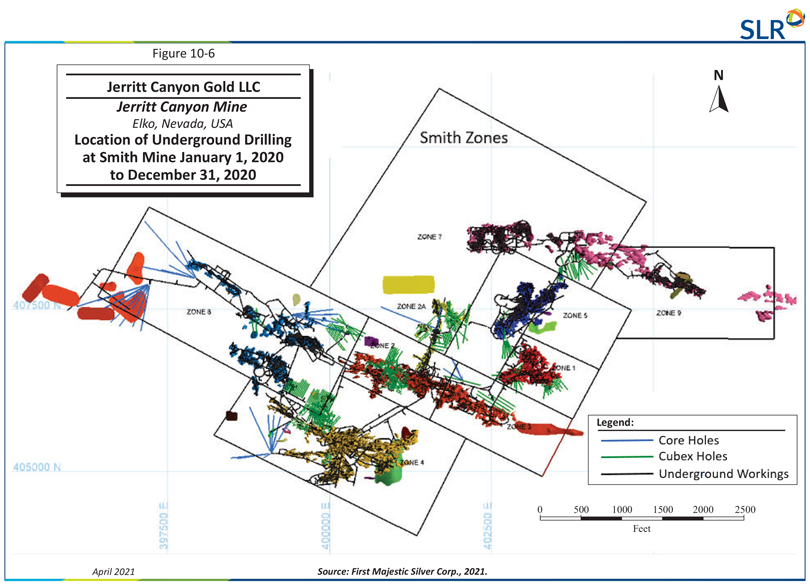

| Figure 10-6: |

Location of Underground Drilling at Smith Mine January 1, 2020 to December 31, 2020 | 10-8 | ||||

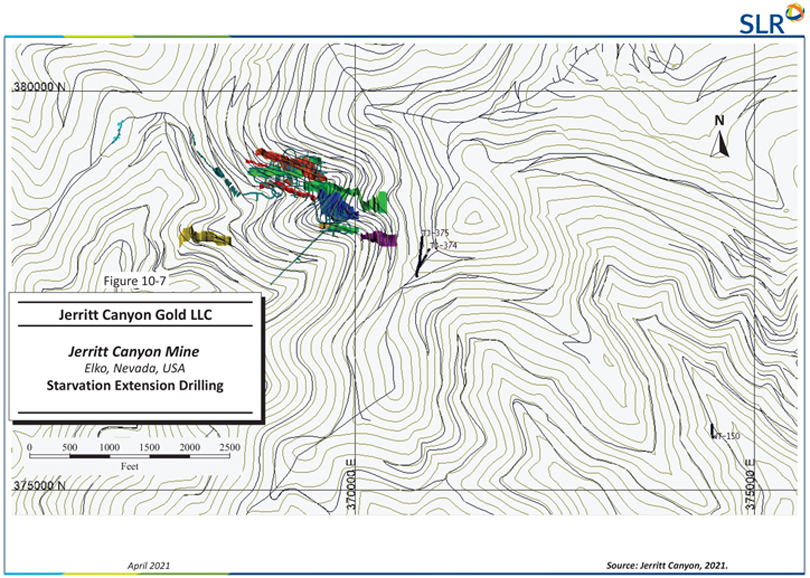

| Figure 10-7: |

Starvation Extension Drilling | 10-12 | ||||

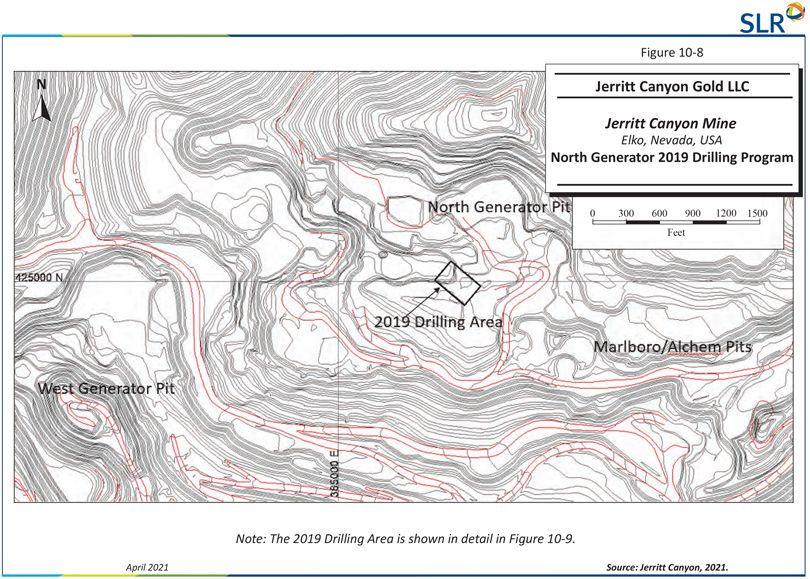

| Figure 10-8: |

North Generator 2019 Drilling Program |

10-13 | ||||

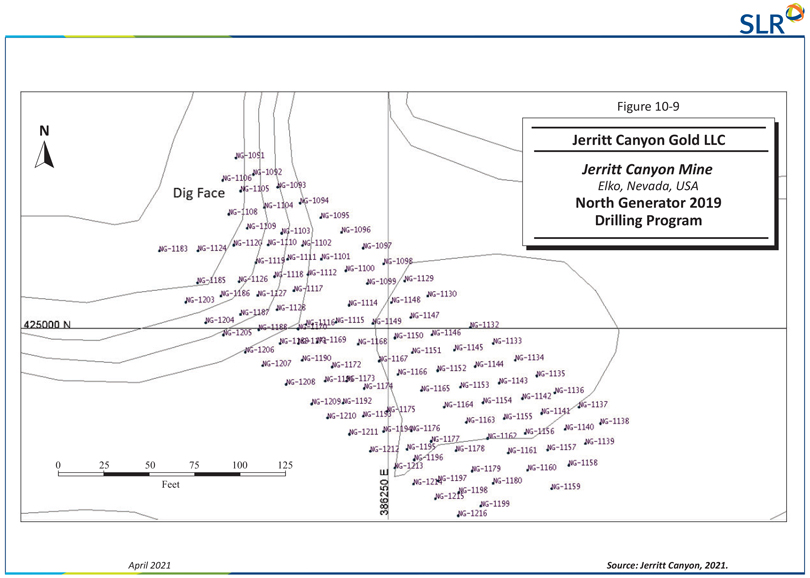

| Figure 10-9: |

North Generator 2019 Drilling Program |

10-14 | ||||

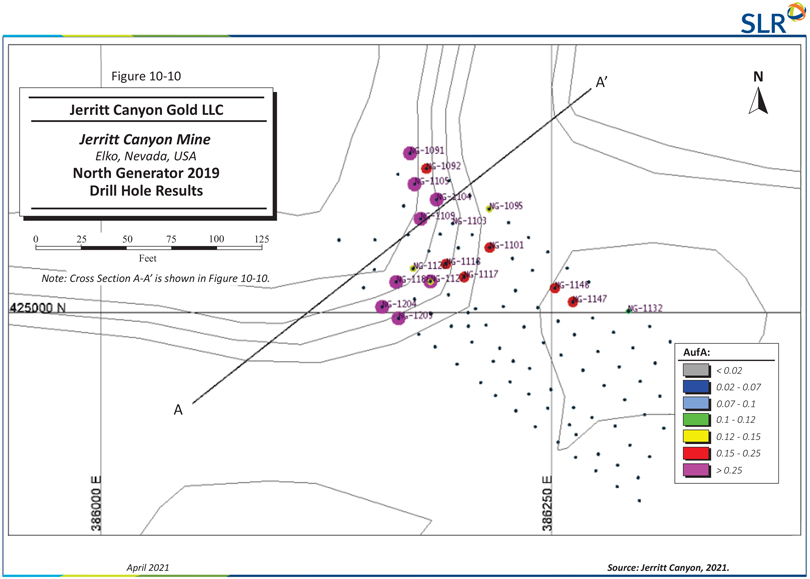

| Figure 10-10: |

North Generator 2019 Drill Hole Results |

10-15 | ||||

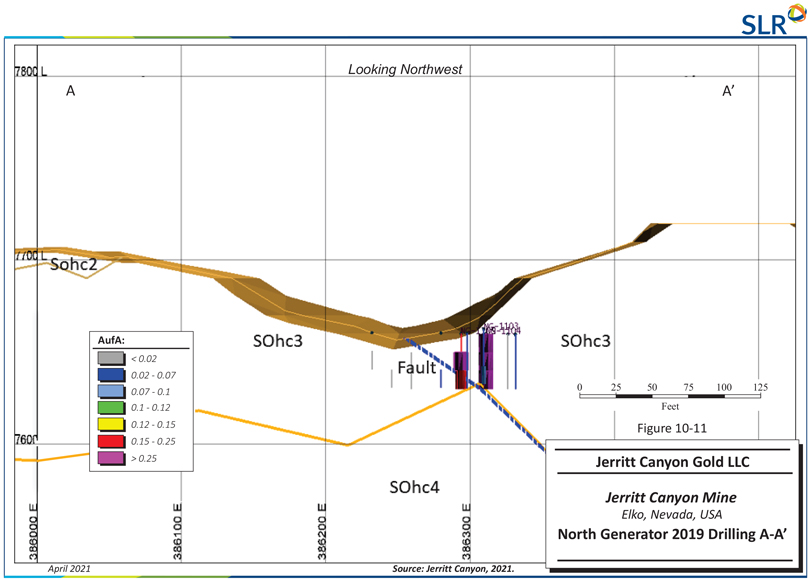

| Figure 10-11: |

North Generator 2019 Drilling A-A’ |

10-16 | ||||

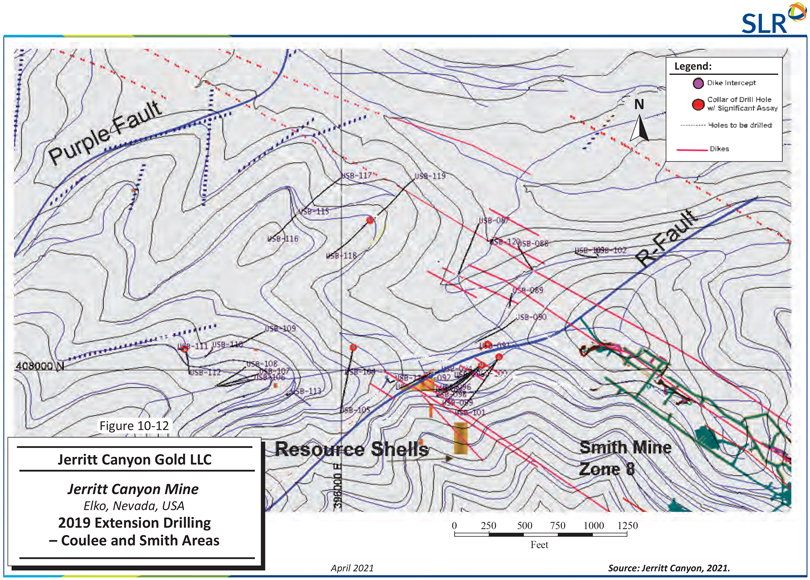

| Figure 10-12: |

2019 Extension Drilling – Coulee and Smith Areas |

10-18 | ||||

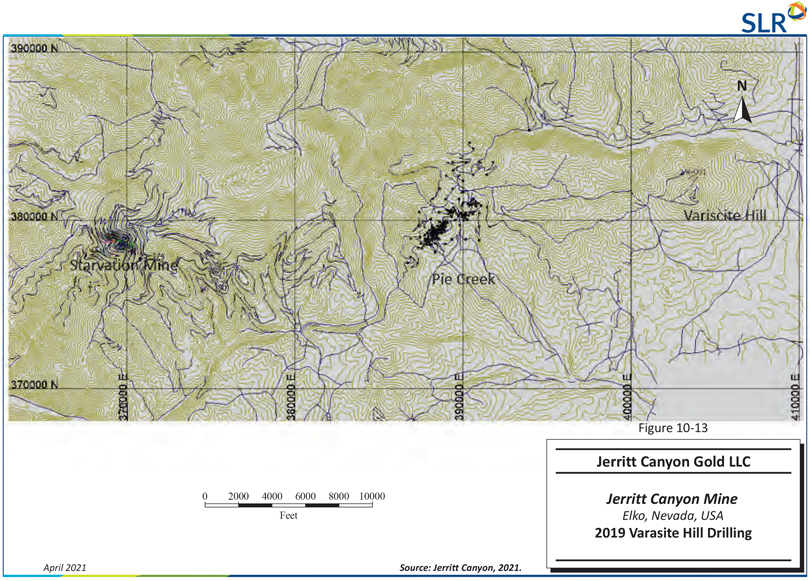

| Figure 10-13: |

2019 Varasite Hill Drilling |

10-20 | ||||

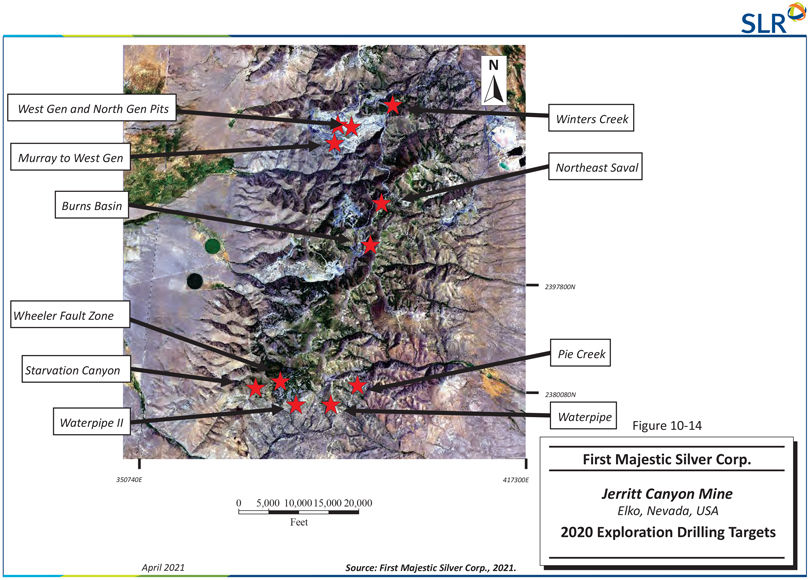

| Figure 10-14: |

2020 Exploration Drilling Targets |

10-24 | ||||

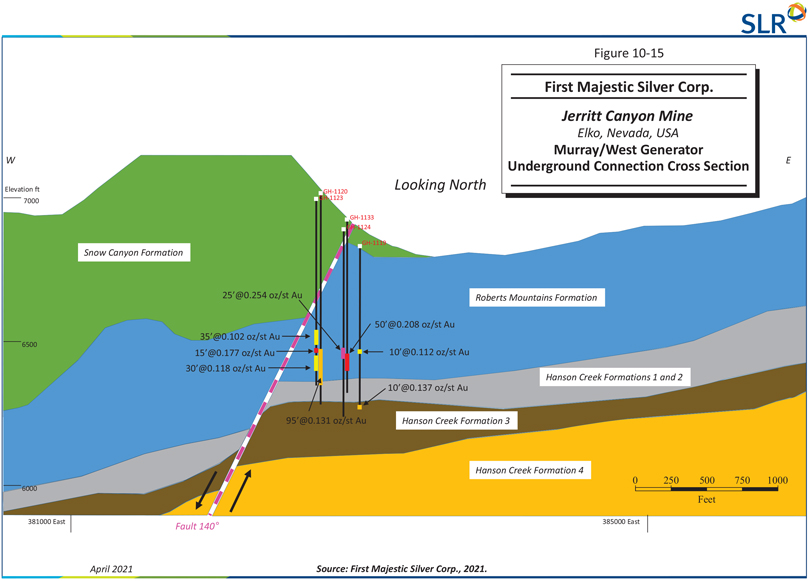

| Figure 10-15: |

Murray/West Generator Underground Connection Cross Section |

10-25 | ||||

| Figure 11-1: |

Jerritt Canyon Control Chart of CRM SK52 - Underground Samples | 11-9 | ||||

| Figure 11-2: |

Jerritt Canyon Control Chart of CRM SK78- Underground Samples | 11-9 | ||||

| Figure 11-3: |

Jerritt Canyon Control Chart of In House Standard JCQ05 - Surface Samples | 11-10 | ||||

| Figure 11-4: |

Jerritt Canyon Control Chart of CRM SK78 Surface Samples | 11-10 | ||||

| Figure 11-5: |

Jerritt Canyon Z-Score Chart of Underground CRM Samples | 11-11 | ||||

| Figure 11-6: |

Jerritt Canyon Z-Score Chart of Surface CRM samples | 11-11 | ||||

| Figure 11-7: |

Jerritt Canyon Blank Results for Underground Samples | 11-12 | ||||

| Figure 11-8: |

Jerritt Canyon Blank Results for Surface Samples | 11-13 | ||||

| Figure 11-9: |

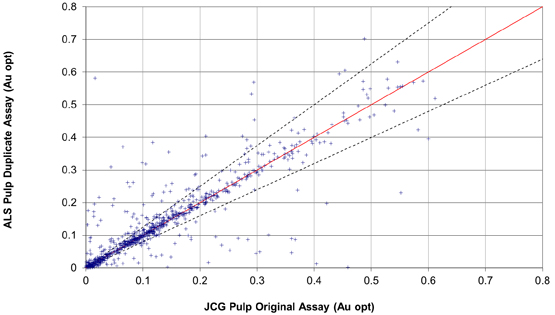

ALS Underground Coarse Reject Duplicates | 11-14 | ||||

| Figure 11-10: |

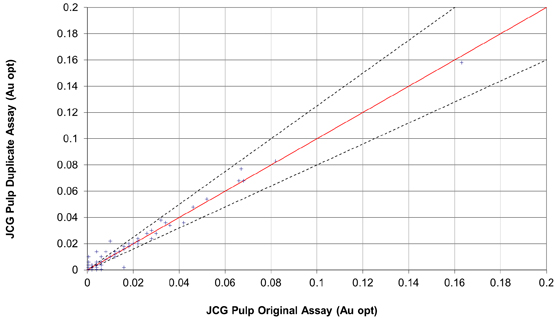

JCG Assay Laboratory Underground Pulp Duplicates |

11-14 | ||||

| Figure 11-11: |

ALS Surface Coarse Reject Duplicates |

11-15 | ||||

| Figure 11-12: |

JCG Assay Laboratory Surface Pulp Duplicates |

11-15 | ||||

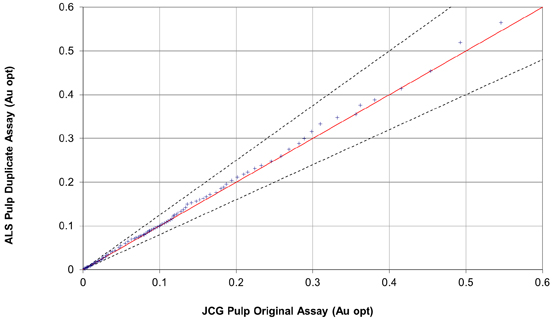

| Figure 11-13: |

Scatter Plot of JCG versus ALS Pulp Duplicate Pairs |

11-16 | ||||

| Figure 11-14: |

Q-Q plot of JCG versus ALS Pulp Duplicate Pairs |

11-17 | ||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | vii | |||

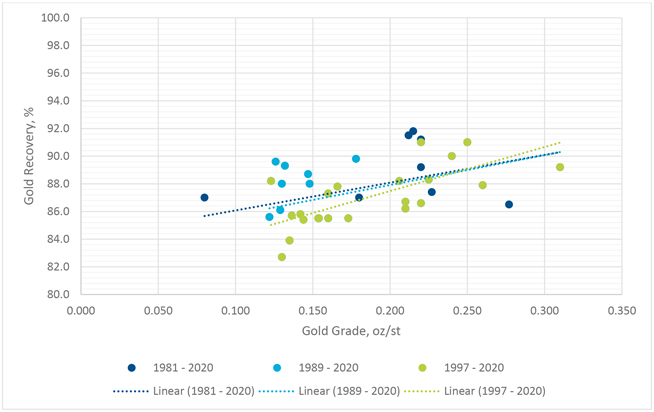

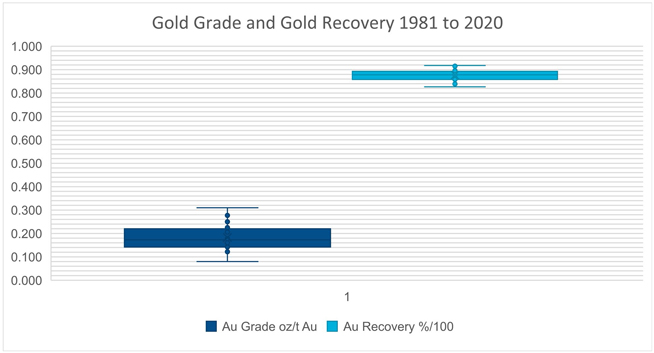

| Figure 13-1: |

Historical Gold Feed Grade versus Recovery 1981 to 2020 | 13-3 | ||||

| Figure 13-2: |

Plot of Historical Gold Grade and Recovery from 1981 to 2020 | 13-4 | ||||

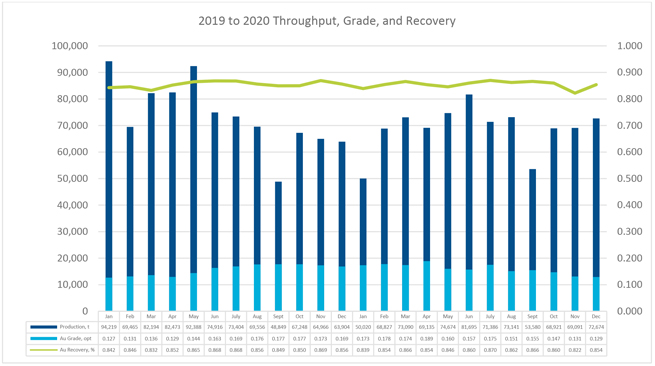

| Figure 13-3: |

Monthly Mill Throughput, Feed Grade, and Recovery for 2019 to 2020 | 13-6 | ||||

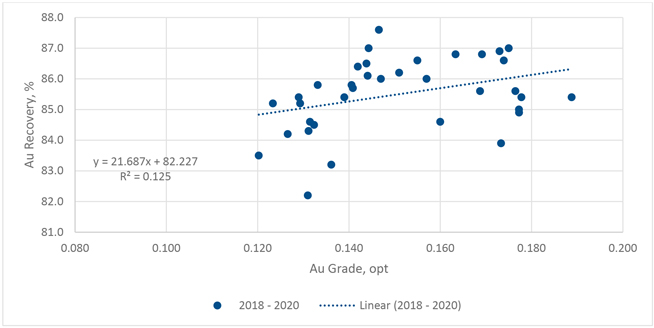

| Figure 13-4: |

Mill Feed Grade versus Recovery for the Period 2019 to 2020 | 13-6 | ||||

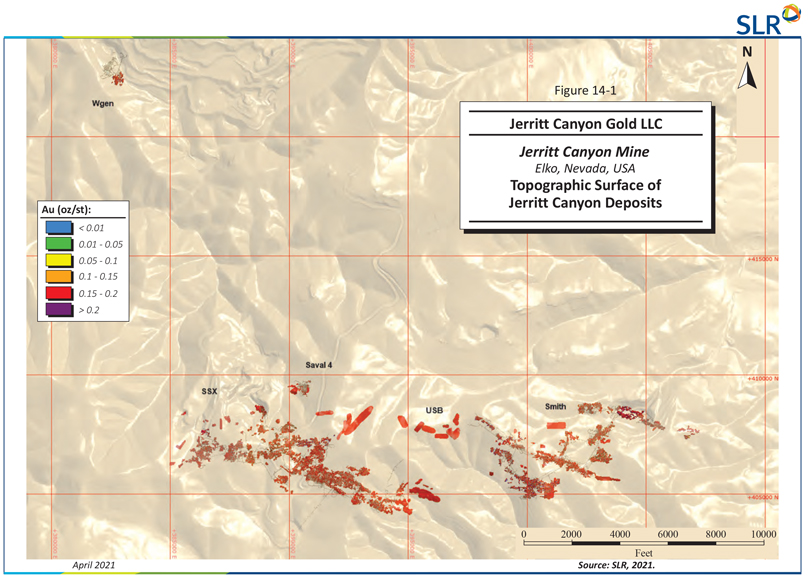

| Figure 14-1: |

Topographic Surface of Jerritt Canyon Deposits | 14-4 | ||||

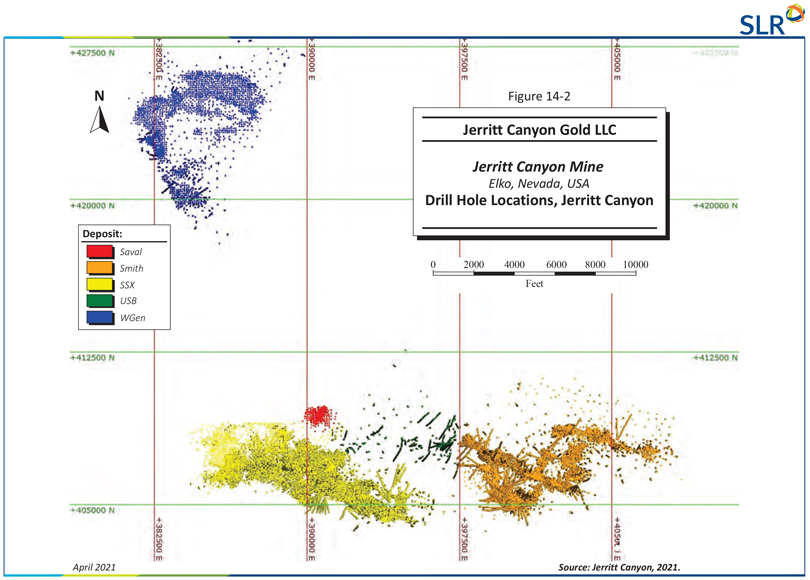

| Figure 14-2: |

Drill Hole Locations, Jerritt Canyon | 14-6 | ||||

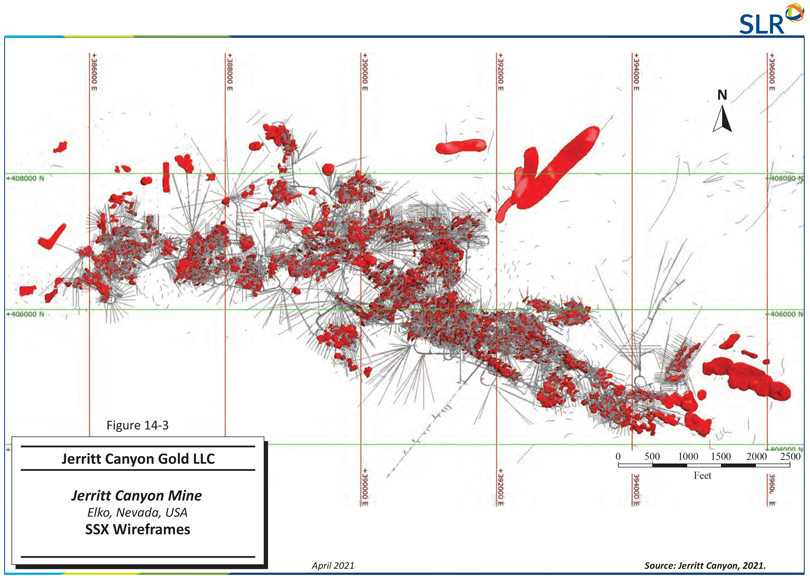

| Figure 14-3: |

SSX Wireframes | 14-8 | ||||

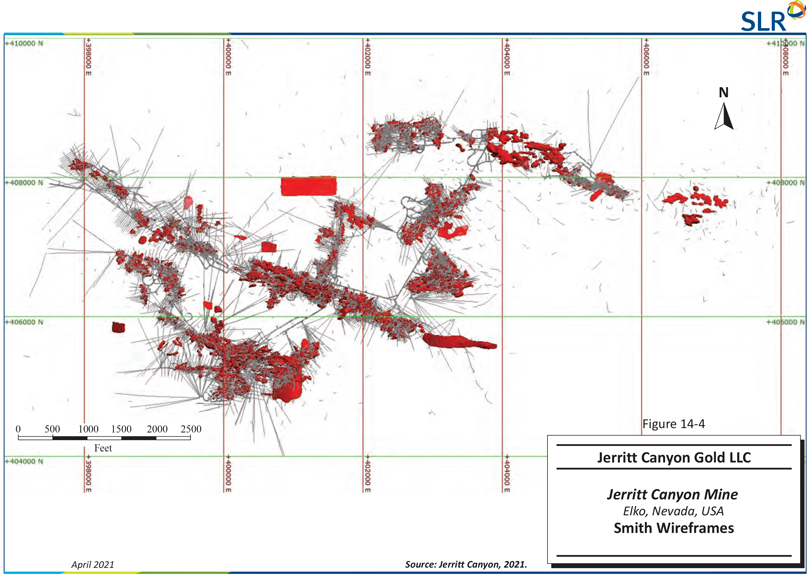

| Figure 14-4: |

Smith Wireframes | 14-9 | ||||

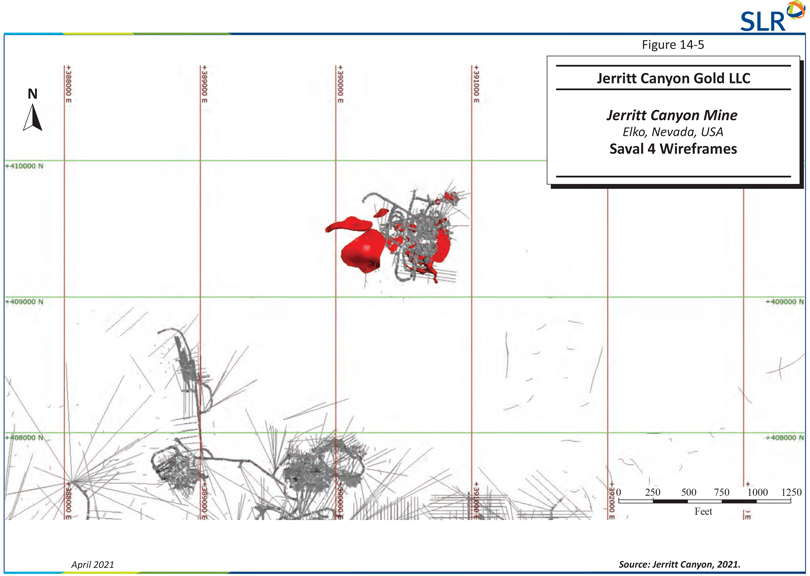

| Figure 14-5: |

Saval 4 Wireframes | 14-10 | ||||

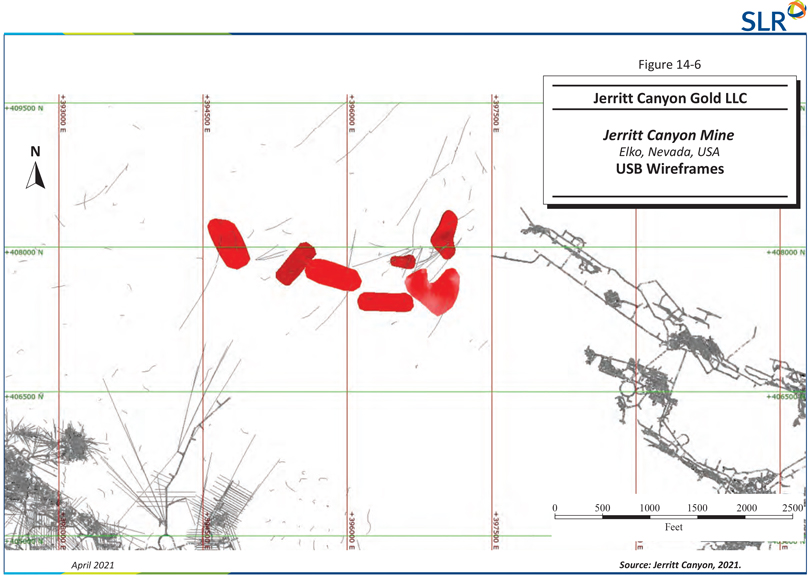

| Figure 14-6: |

USB Wireframes | 14-11 | ||||

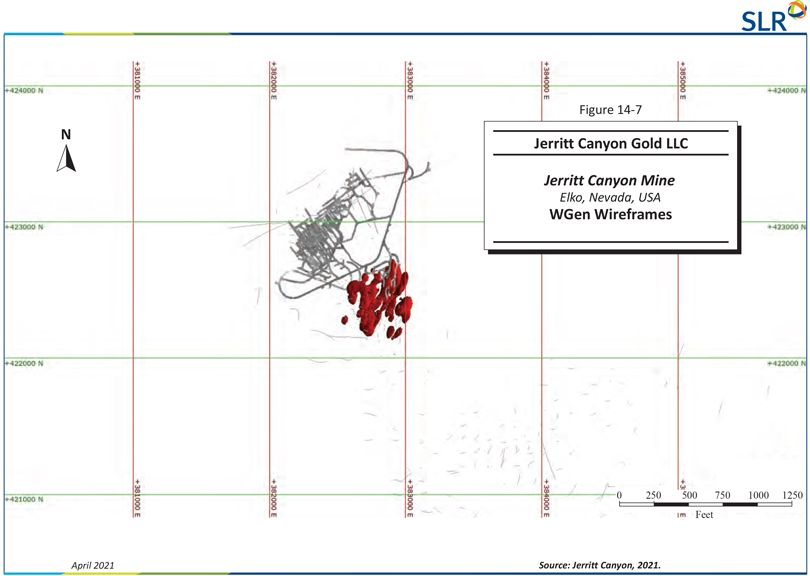

| Figure 14-7: |

WGen Wireframes | 14-12 | ||||

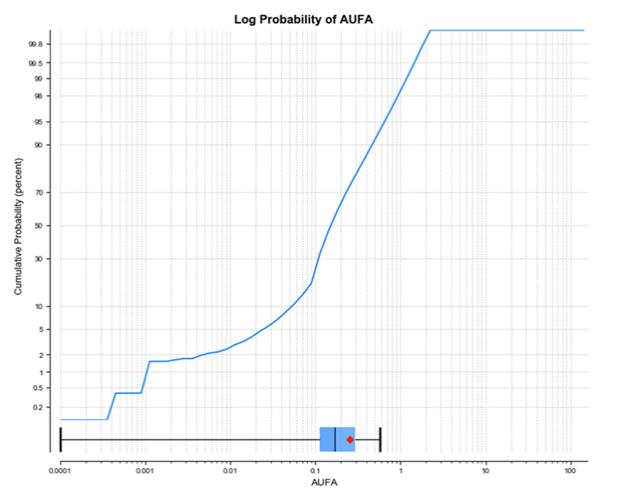

| Figure 14-8: |

Jerritt Canyon Assay Log Probability | 14-13 | ||||

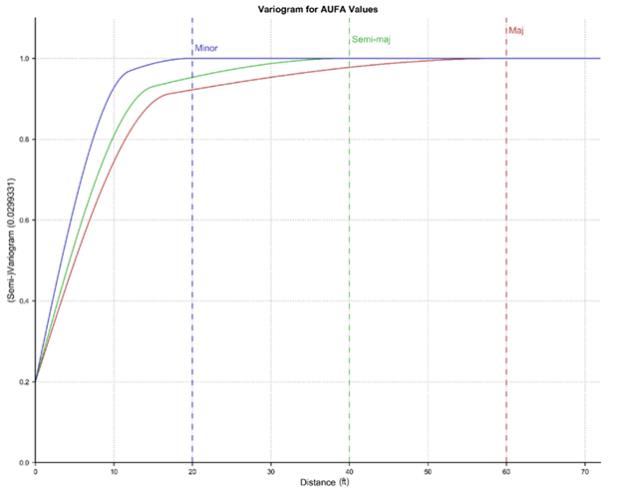

| Figure 14-9: |

Variograms in Major, Semi-Major, and Minor Directions for SSX Zone 5 | 14-18 | ||||

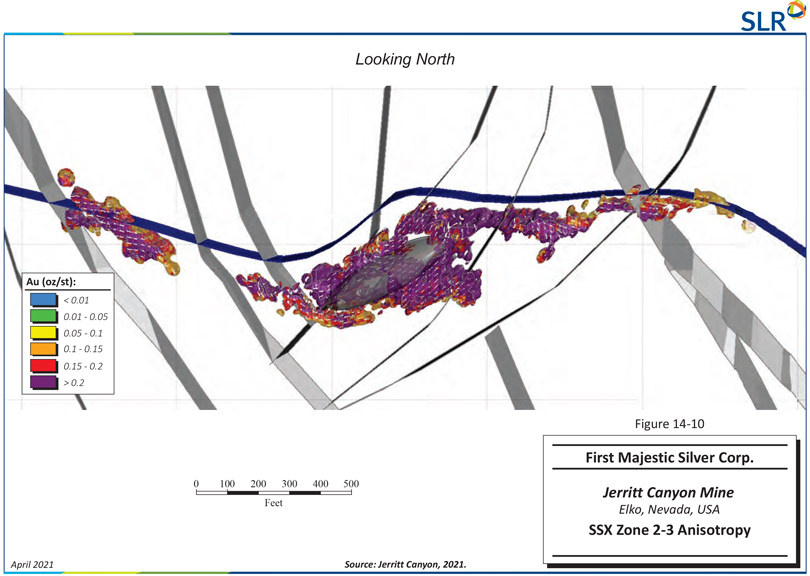

| Figure 14-10: |

SSX Zone 2-3 Variable Ellipsoid Orientation |

14-22 | ||||

| Figure 14-11: |

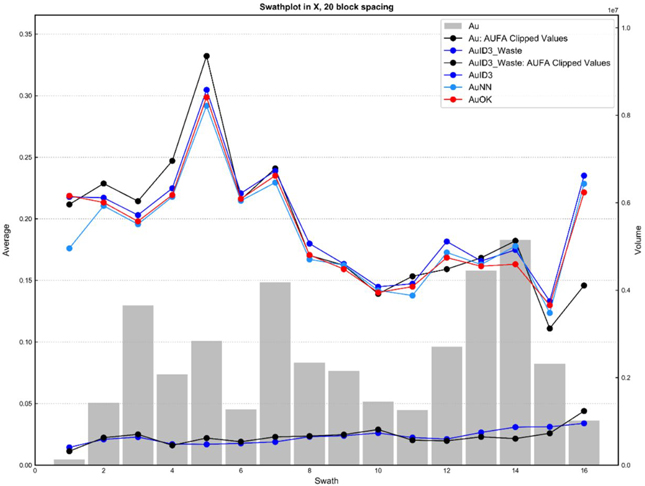

East West (x) Swath Plot SSX 19 |

14-23 | ||||

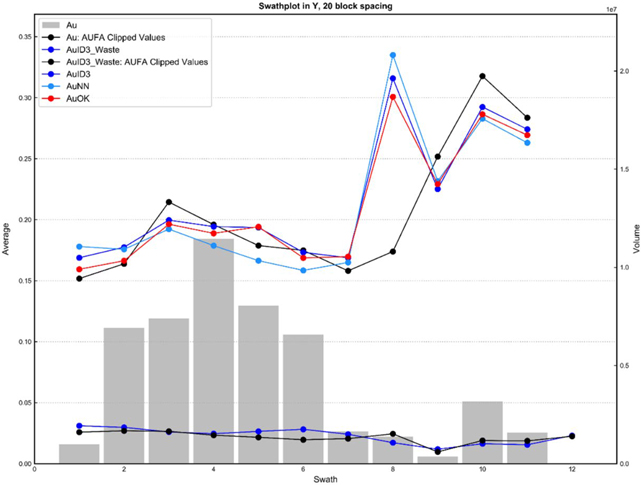

| Figure 14-12: |

North South (Y) Swath Plot SSX 19 |

14-24 | ||||

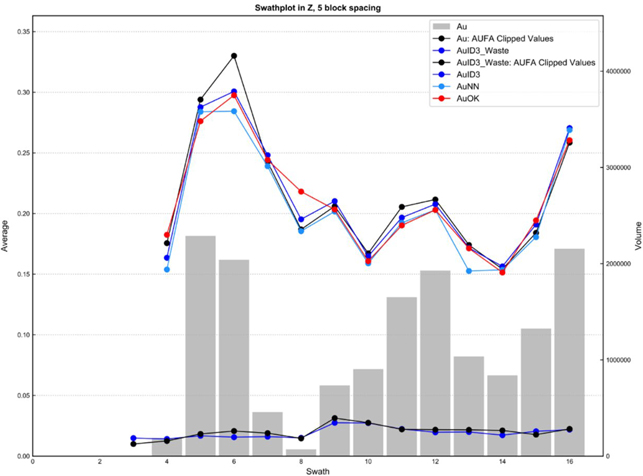

| Figure 14-13: |

Vertical (Z) Swath Plot SSX 19 |

14-25 | ||||

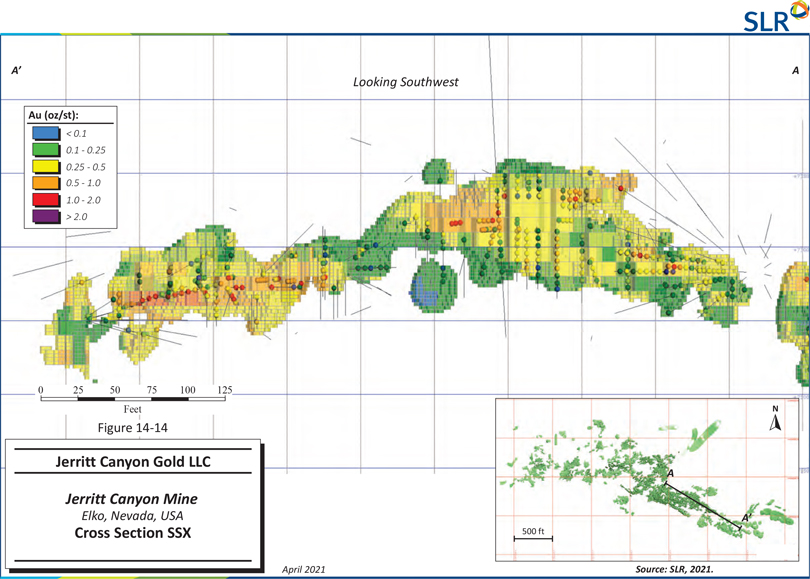

| Figure 14-14: |

Cross Section SSX |

14-27 | ||||

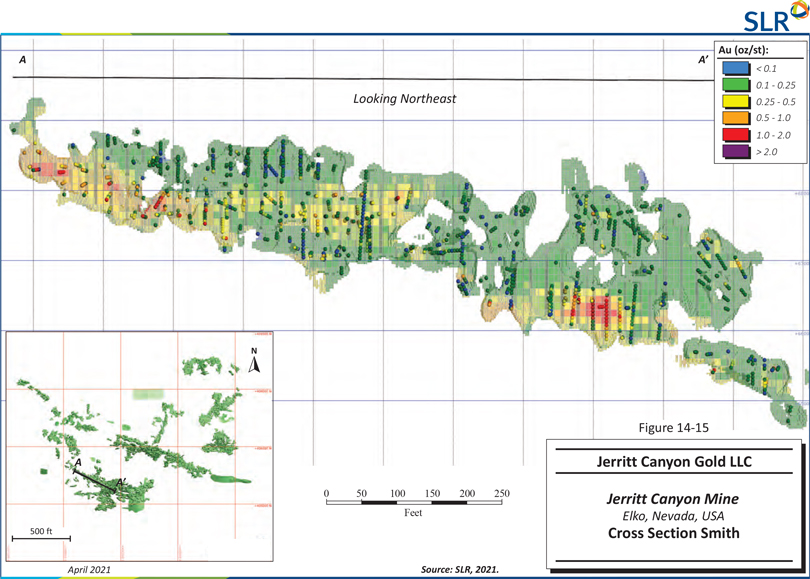

| Figure 14-15: |

Cross Section Smith |

14-28 | ||||

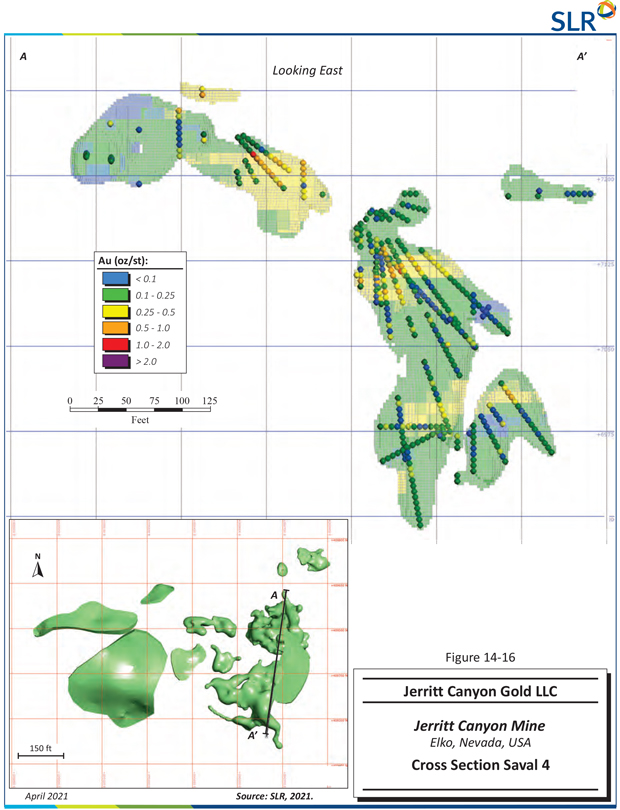

| Figure 14-16: |

Cross Section Saval 4 |

14-29 | ||||

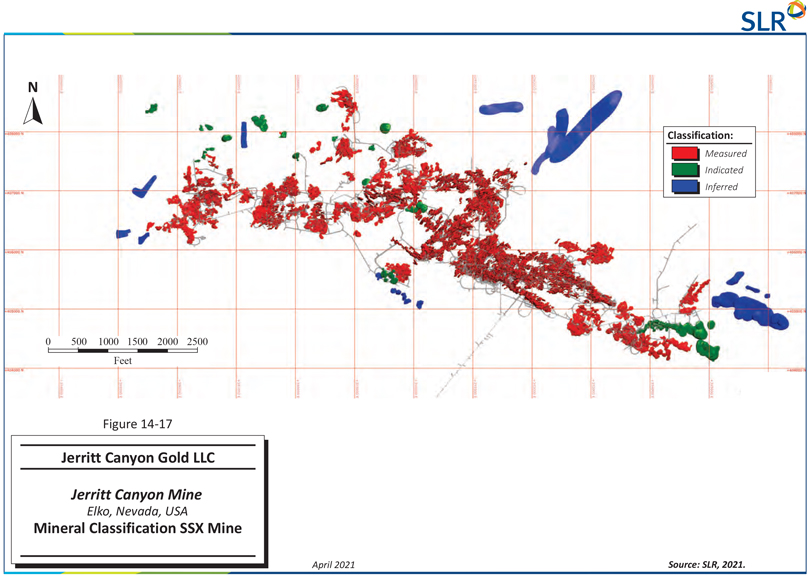

| Figure 14-17: |

Mineral Classification SSX Mine |

14-36 | ||||

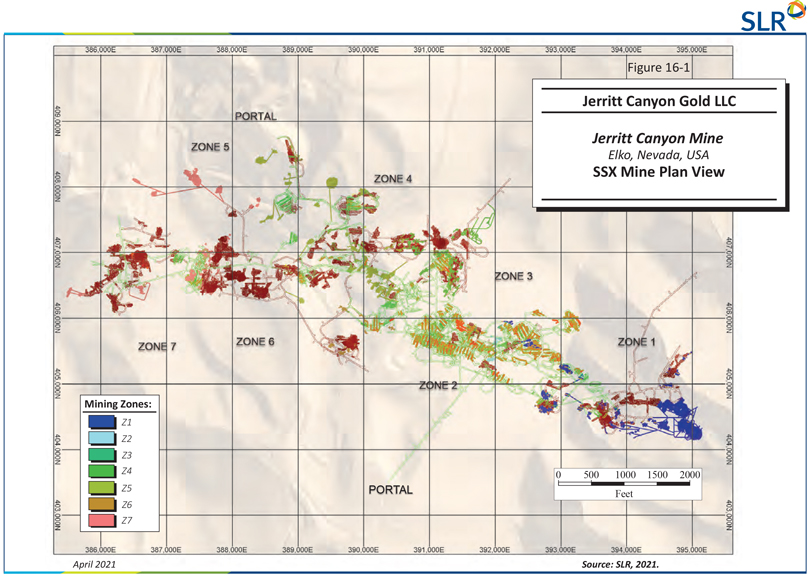

| Figure 16-1: |

SSX Mine Plan View | 16-2 | ||||

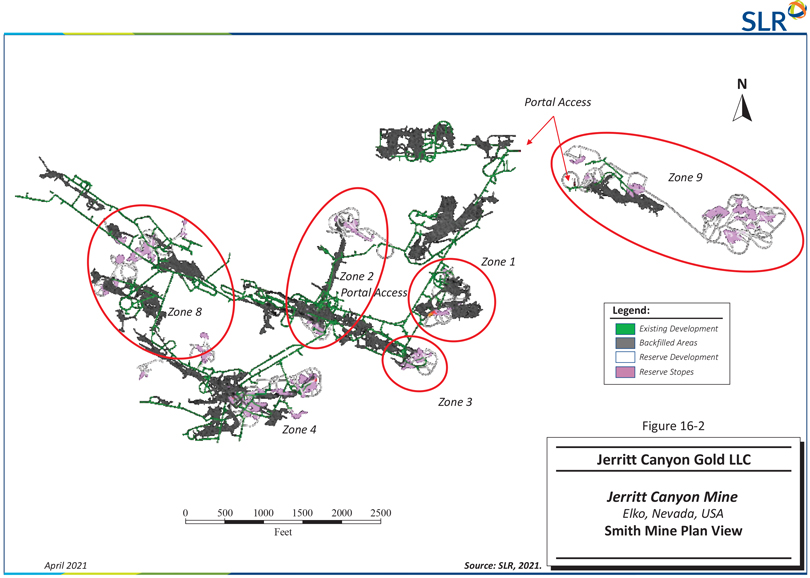

| Figure 16-2: |

Smith Mine Plan View | 16-3 | ||||

| Figure 16-3: |

Jerritt Mine Lithology | 16-6 | ||||

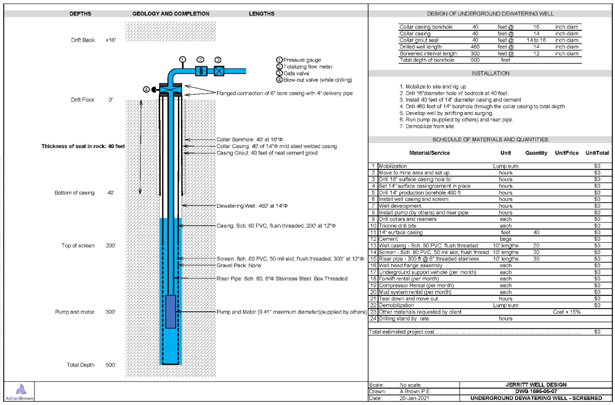

| Figure 16-4: |

Typical Dewatering Well | 16-11 | ||||

| Figure 16-5: |

Smith Mine Zone 2 Dewatering Schedule | 16-12 | ||||

| Figure 16-6: |

Smith Mine Zone 4 Dewatering Schedule | 16-13 | ||||

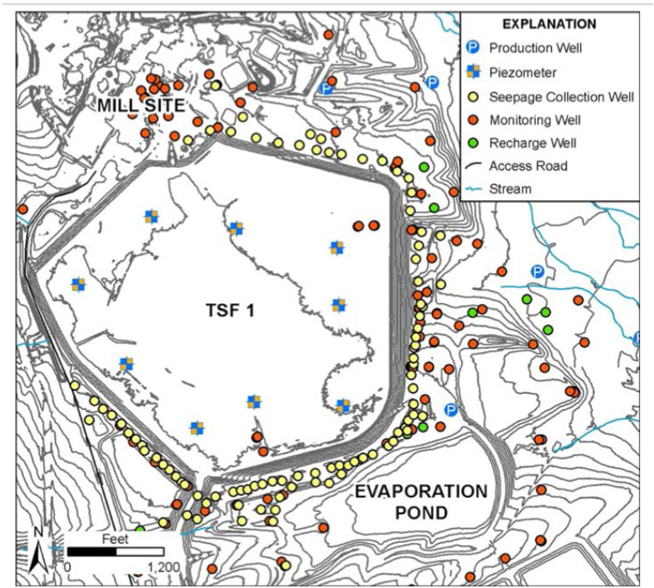

| Figure 16-7: |

TSF 1 Seepage Control Wells | 16-15 | ||||

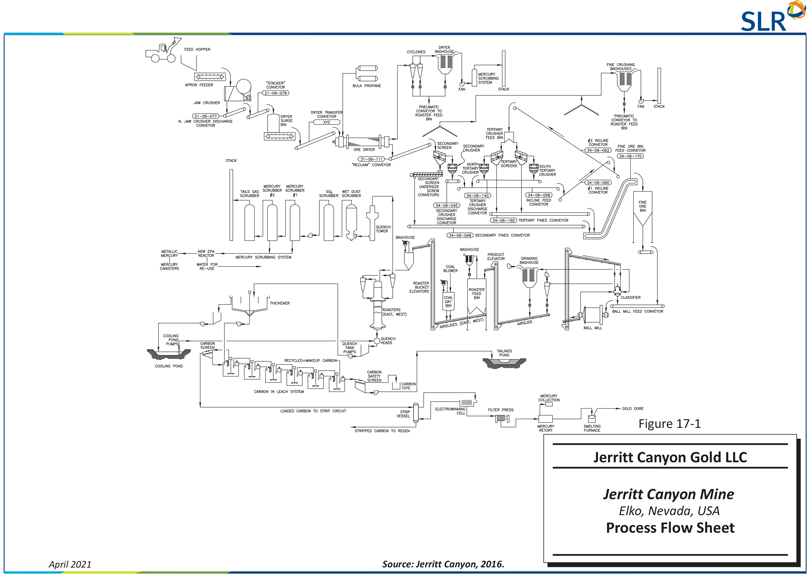

| Figure 17-1: |

Process Flow Sheet | 17-5 | ||||

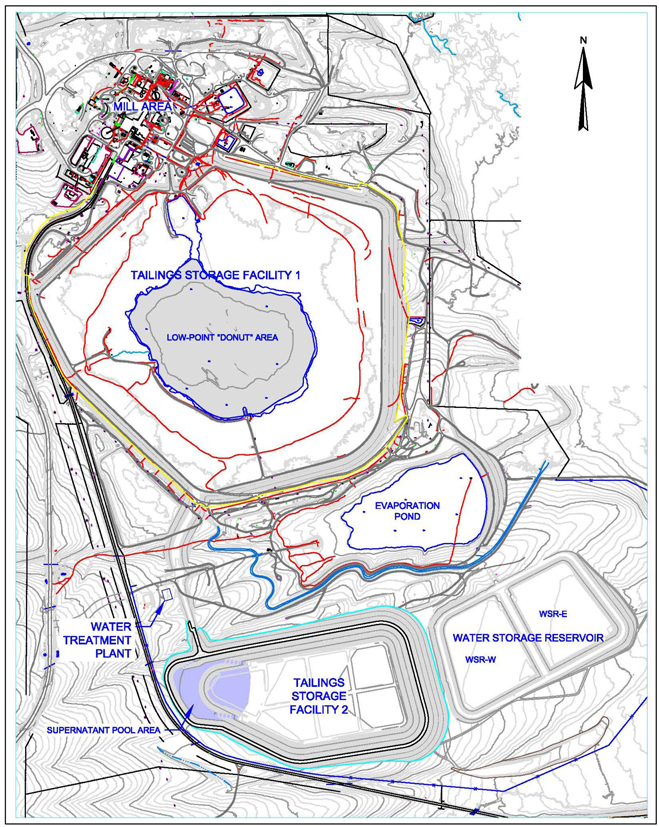

| Figure 18-1: |

General Layout of Jerritt Canyon Tailings and Water Management Facilities | 18-3 | ||||

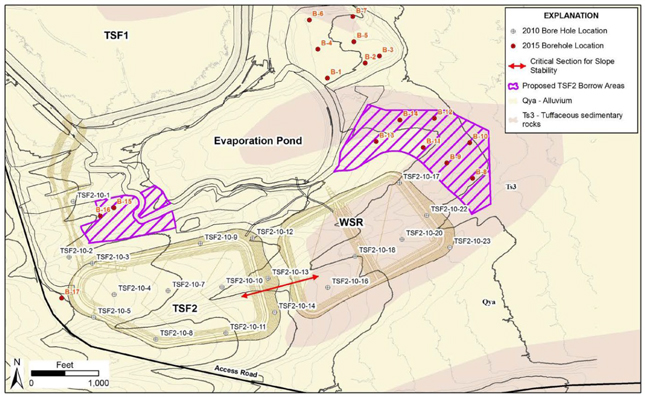

| Figure 18-2: |

TSF 2 Borehole Location and Geology (SRK, 2015) | 18-7 | ||||

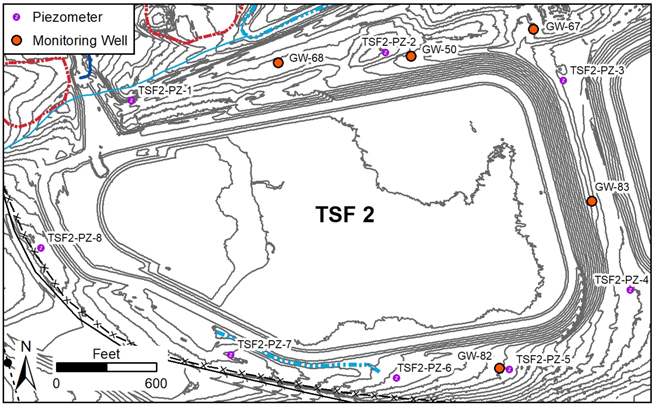

| Figure 18-3: |

Locations of TSF 2 Piezometers and Monitoring Wells | 18-8 | ||||

| Figure 22-1: |

After-Tax NPV Sensitivity Graph | 22-7 | ||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | viii | |||

| 1.0 | SUMMARY |

| 1.1 | Executive Summary |

SLR Consulting Ltd. (SLR) was retained by Jerritt Canyon Gold LLC (JCG) to prepare an independent Technical Report (the Technical Report) on the Jerritt Canyon Gold Mine (Jerritt Canyon or the Mine), located in northeast Nevada, USA. The purpose of this Technical Report is to support the disclosure of Mineral Resource and Mineral Reserve estimates for the underground portion of the Mine. This Technical Report conforms to NI 43-101 Standards of Disclosure for Mineral Projects. SLR qualified persons visited the Mine on April 20, 2021. On April 30, 2021, First Majestic Silver Corp. (First Majestic) acquired all of the issued and outstanding shares of JCG. As such, First Majestic now indirectly owns and operates Jerritt Canyon, through the owner and operator JCG.

First Majestic is a publicly traded company with a portfolio of operating mines and projects. Jerritt Canyon is a long term producer, currently with two mines planning to produce, on average, 2,300 tons per day (stpd) from underground operations primarily using the cut and fill mining method. The two mines include the SSX-Steer Complex (SSX) and Smith. The existing processing plant is operating at a rate of 826,230 tons of ore per annum in 2020 (with capacity for more) and includes primary crushing, drying, secondary and tertiary crushing, dry grinding, roasting and thickening, using a carbon in leach (CIL) for gold recovery and electrowinning for gold refining.

Table 1-1 and Table 1-2 lists the Mineral Resources summary for Jerritt Canyon with an effective date of December 31, 2020, in Imperial and Metric units, respectively. The Mineral Resource and Mineral Reserve estimates conform to Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition and Standards for Mineral Resources and Mineral Reserves (CIM (2014) definitions). Mineral Resources are exclusive of Mineral Reserves.

Table 1-1: Summary of Mineral Resources (effective date December 31, 2020, Imperial Units)

Jerritt Canyon

| Category | Tonnage (000 tons) |

Grade (oz/st Au) |

Contained Metal (000 oz Au) | |||

| Measured |

4,811 | 0.159 | 767 | |||

| Indicated |

406 | 0.160 | 65 | |||

| Measured and Indicated | 5,217 | 0.160 | 832 | |||

| Inferred | 1,950 | 0.171 | 334 | |||

Notes:

| 1. | CIM (2014) definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are exclusive of Mineral Reserves. |

| 3. | Mineral Resources are estimated using an average gold price of $1,700/oz Au. |

| 4. | Mineral Resources are constrained using minimum thickness mining shapes reflecting the geometries of cut and fill mining methods. |

| 5. | Mineral Resources are reported at a cut-off grade of 0.11 oz/st Au, accounting for mining costs of $102/st, milling costs of $45/st, general and administrative costs of $18/st, and a metal recovery of 86%. |

| 6. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| 7. | Numbers may not add due to rounding. |

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-9 | |||

Table 1-2: Summary of Mineral Resources (effective date December 31, 2020, Metric Units)

Jerritt Canyon

| Category | Tonnage (000 t) |

Grade (g/t Au) |

Contained Metal (000 oz Au) | |||

| Measured |

4,365 | 5.47 | 767 | |||

| Indicated |

368 | 5.49 | 65 | |||

| Measured and Indicated | 4,733 | 5.47 | 832 | |||

| Inferred | 1,769 | 5.87 | 334 | |||

Notes:

| 1. | CIM (2014) definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are exclusive of Mineral Reserves. |

| 3. | Mineral Resources are estimated using an average gold price of $1,700/oz Au. |

| 4. | Mineral Resources are constrained using minimum thickness mining shapes reflecting the geometries of cut and fill mining methods. |

| 5. | Mineral Resources are reported at a cut-off grade of 3.77 g/t Au, accounting for mining costs of $102/st, milling costs of $45/st, general and administrative costs of $18/st, and a metal recovery of 86%. |

| 6. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| 7. | Numbers may not add due to rounding. |

The QP is not aware of any other environmental, permitting, legal, title, taxation, socio-economic, marketing, political, or other relevant factors that could materially affect the Mineral Resource estimate aside from those identified in Section 20 of this Technical Report which are being mitigated by further work by JCG.

Table 1-3 and Table 1-4 present the Mineral Reserves summary as of December 31, 2020 in Imperial and Metric units, respectively. Mineral Reserves are reported based on their elevation relative to the natural water table which is found approximately 6,600 feet above sea level (FASL) or 2,012 metres above sea level (MASL).

Table 1-3: Summary of Mineral Reserves (effective date December 31, 2020, Imperial Units)

Jerritt Canyon

| Category | Tonnage (000 tons) |

Grade (oz/st Au) |

Contained Metal (000 oz Au) | |||

| Above 6,600 FASL | ||||||

| Proven |

1,059 | 0.18 | 187 | |||

| Smith |

193 | 0.17 | 33 | |||

| SSX |

866 | 0.18 | 154 | |||

| Probable |

689 | 0.19 | 129 | |||

| Smith |

54 | 0.18 | 10 | |||

| SSX |

635 | 0.19 | 119 | |||

|

Subtotal Proven + Probable |

1,748 | 0.18 | 316 | |||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-10 | |||

| Category | Tonnage (000 tons) |

Grade (oz/st Au) |

Contained Metal (000 oz Au) | |||

| Below 6,600 FASL | ||||||

| Proven |

915 | 0.22 | 200 | |||

| Smith |

808 | 0.22 | 180 | |||

| SSX |

107 | 0.19 | 20 | |||

| Probable |

897 | 0.21 | 186 | |||

| Smith |

380 | 0.26 | 101 | |||

| SSX |

516 | 0.17 | 86 | |||

| Subtotal Proven + Probable |

1,811 | 0.21 | 387 | |||

| Total Proven |

1,974 | 0.20 | 388 | |||

| Total Probable |

1,585 | 0.20 | 316 | |||

| Total Proven +Probable | 3,559 | 0.20 | 703 | |||

Notes:

| 1. | CIM (2014) definitions were followed for Mineral Reserves. |

| 2. | Mineral Reserves are estimated at a cut-off grade of 0.128 oz/st Au which assumes $102/st mining cost, $45/st processing cost, $18/st G&A cost and 86% metallurgical recovery. |

| 3. | Mineral Reserves are estimated using an average long term gold price of US$1,500/oz Au. |

| 4. | A minimum mining width of 15 ft was used assuming a cut and fill mining method. |

| 5. | Bulk density is 0.0794 t/ft3. |

| 6. | Numbers may not add due to rounding. |

Table 1-4: Summary of Mineral Reserves (effective date December 31, 2020, Metric Units)

Jerritt Canyon

| Category | Tonnage (000 t) |

Grade (g/t Au) |

Contained Metal (000 oz Au) | |||

| Above 2,012 MASL | ||||||

| Proven |

961 | 6.1 | 187 | |||

| Smith |

175 | 5.9 | 33 | |||

| SSX |

786 | 6.1 | 154 | |||

| Probable |

625 | 6.4 | 129 | |||

| Smith |

49 | 6.2 | 10 | |||

| SSX |

576 | 6.4 | 119 | |||

|

Subtotal Proven + Probable |

1,585 | 6.2 | 316 | |||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-11 | |||

| Category | Tonnage (000 t) |

Grade (g/t Au) |

Contained Metal (000 oz Au) | |||

|

Below 2,012 MASL | ||||||

| Proven |

830 | 7.5 | 200 | |||

| Smith |

733 | 7.7 | 180 | |||

| SSX |

97 | 6.4 | 20 | |||

| Probable |

813 | 7.1 | 186 | |||

| Smith |

345 | 9.1 | 101 | |||

| SSX |

468 | 5.7 | 86 | |||

| Subtotal Proven + Probable |

1,643 | 7.3 | 387 | |||

| Total Proven |

1,791 | 6.7 | 388 | |||

| Total Probable |

1,438 | 6.8 | 316 | |||

| Total Proven +Probable |

3,229 | 6.8 | 703 | |||

Notes:

| 1. | CIM (2014) definitions were followed for Mineral Reserves. |

| 2. | Mineral Reserves are estimated at a cut-off grade of 4.39 g/t Au which assumes $112/t mining cost, $50/t processing cost, $20/t G&A cost and 86% metallurgical recovery. |

| 3. | Mineral Reserves are estimated using an average long-term gold price of US$1,500/oz Au. |

| 4. | A minimum mining width of 4.6 m was used assuming a cut and fill mining method. |

| 5. | Bulk density is 2.544 t/m3. |

| 6. | Numbers may not add due to rounding. |

The QP is not aware of any mining, metallurgical, infrastructure, permitting, or other relevant factors that could materially affect the Mineral Reserve estimate, aside from those identified in Section 20 of this Technical Report which are being mitigated by further work by JCG.

| 1.1.1 | Conclusions |

The QPs offer the following conclusions:

| 1.1.1.1 | Geology and Mineral Resources |

| · | JCG geologists have a good understanding of the regional, local, and deposit geology and controls on mineralization. |

| · | Exploration and development sampling and analysis programs involve industry standard practices, providing generally reasonable results. The drill hole database was verified by the QP and is suitable for Mineral Resource estimation work. The resulting data can effectively be used for the estimation of Mineral Resources and Mineral Reserves. |

| · | The methods and procedures utilized to gather geological, assaying, density, and other information are reasonable and meet generally accepted industry standards. |

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-12 | |||

| · | Sampling and assaying have been carried out using industry standard quality assurance/quality control (QA/QC) practices. These practices include, but are not limited to, sampling, assaying, chain of custody of the samples, secure sample storage, use of third-party laboratories, and use of standards, blanks, and duplicates. |

| · | Since 2015, Jerritt Canyon has made considerable advances in the compilation and interpretation of historical geophysical and geochemical datasets resulting in the identification of 17 high priority target areas. The property holds significant exploration potential, particularly in the southern portion. |

| · | Since January 1, 2015 through December 31, 2020, JCG has drilled a total of 18,533 holes between reverse circulation (RC) and core from underground drilling sites, comprising 2,800,695 ft. This has enabled Jerritt Canyon to increase the size and confidence of the existing resources. |

| · | The geological wireframes are reasonable and plausible interpretations of the drill results. |

| · | The resource model has been prepared using appropriate methodology and assumptions, including: |

| o | Treatment of high grade assays |

| o | Compositing length |

| o | Customized search parameters |

| o | Bulk density |

| o | Cut-off grade |

| o | Classification |

| · | As of December 31, 2020 and at a cut-off grade of 0.11 oz/st Au, the Measured and Indicated Mineral Resources at Jerritt Canyon total 5.217 Mst grading 0.160 oz/st Au containing approximately 832,000 ounces of gold (oz Au). In addition, Inferred Mineral Resources are estimated at 1.950 Mst grading 0.171 oz/st Au containing approximately 334,000 oz Au. |

| · | Mineral Resource estimates have been prepared utilizing acceptable estimation methodologies in accordance with CIM MRMR Best Practice Guidelines. The classification of Measured, Indicated, and Inferred Mineral Resources conforms to CIM (2014) definitions. |

| 1.1.1.2 | Mining and Mineral Reserves |

| · | Mining operations at Jerritt Canyon are well established and carried out by an experienced mining contractor at Smith and SSX using the cut and fill mining method. |

| · | A significant portion of the Mineral Reserves are located below the current water table. There is a dewatering plan in place for the mine below the 6,600 FASL water table, which allows for the inclusion of Mineral Reserves below this elevation. |

| · | Groundwater flows in the Roberts Mountain and Hanson Creek formations (the principle aquifers) are controlled primarily by the openness and continuity of fractures and joints with the primary water bearing strata being the ore zones. Faulting and tectonic displacement of the materials in the Jerritt Canyon District is extensive. |

| · | The main faults trend west northwest - east southeast, and in general are permeable water conduits. Complementary faults and displacement sets at right angles, south southwest – north |

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-13 | |||

| northeast, are generally highly myolinitized, and tend to form a barrier to groundwater flow and compartmentalize groundwater. |

| · | Dewatering goals of the current operation are to reduce the water level to the pre 2008 level of approximately 6,535 FASL. Currently, pumping is underway to dewater the existing workings. This consists of the operation of two dewatering wells and a barge to dewater Zones 2 and 4. The wells are each pumping at approximately 700 gallons per minute (gpm) while the barge pumps at approximately 400 gpm. Two additional, 500 ft deep underground dewatering wells have been designed. |

| · | It is anticipated that over time Smith will be dewatered at a rate of 2,100 gpm. All pumped groundwater will continue to be conveyed to the water treatment plant (WTP) which has a capacity of 1,400 gpm. Any flows over 1,400 gpm will be routed to Zone 9 prior to treatment. Following treatment, the water is pumped to an underground injection well field consisting of three 1,200 ft deep injection wells located on USFS land. |

| · | Another aspect of Jerritt Canyon mine water/groundwater management is pollution control from Tailings Storage Facility 1 (TSF 1). Initially, TSF 1 was lined with compacted native soils. In addition, there are 90 seepage control wells, 14 freshwater recharge wells receiving water from the tailings WTP, and greater than 80 down gradient monitoring wells (Wanner et al, 2017). |

| · | Production is limited by mine capacity, and production forecasting is based on mining rates of 800 stpd for Smith and 1,200 stpd for SSX. There is potential for increased production from Smith once dewatering is advanced and more headings are available. |

| 1.1.1.3 | Mineral Processing and Metallurgical Testing |

| · | Historical gold grade-recovery relationships for three different time periods, 1) 1981 to 2020, 2)1989 to 2020 and 3) 1997 to 2020 were plotted. The first period is inception to date, the second period begins when the roaster was commissioned, and the third period begins when chlorination was discontinued. The inception to date line and the 1989 to 2020 lines are essentially the same. The 1997 to 2020 line indicates a slightly higher sensitivity of gold recovery to feed grade. The QP notes that the data are scattered and the correlations of the three lines are low suggesting that variables other than head grade, including sulfide sulfur oxidation, total organic carbon (TOC), and roaster performance contribute to changes in gold recovery. |

| · | SLR notes that the process operating data indicate very consistent plant feed and operational performance and, with the low correlation between grade and recovery, the use of near term historical averages would provide a reasonable gold recovery value for planning purposes. The operation is currently using a constant average gold recovery of 86% for the life of mine (LOM) plan and budget. The consistency in recovery could be affected by changes in mineralogical characteristics as new ore-types are encountered in the future. |

| · | The design recovery of the whole ore roaster using oxygen instead of air was 87% to 90%. Pilot plant testing of the oxygen roasted calcine by Dorr Oliver (1987) achieved an average gold recovery of 88%. SLR notes that the process continues to operate consistently in the design range depending primarily on roaster performance, as some of the mineralized materials are reported to have zero gold recovery without oxidation. |

| · | The main deleterious elements are arsenic and mercury. The processing plant is designed with the appropriate gas cleaning systems including mercury scrubbing from the gas streams and mercury collection from the refinery retort condenser. |

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-14 | |||

| 1.1.1.4 | Infrastructure |

| · | Jerritt Canyon is a mature operation that has been operating for nearly 40 years, and as a result the requisite infrastructure is in place including: |

| o | Access Roads |

| o | Power supply and distribution |

| o | Office buildings |

| o | Warehouse facilities |

| o | Maintenance shops |

| o | Laboratory facilities |

| o | Communication networks |

| o | Onsite security |

| o | TSFs |

| o | Water management systems |

| 1.1.1.5 | Tailings and Water Management Facilities |

| · | TSF 1 is currently inactive and in the process of being closed and reclaimed under a Final Plan for Permanent Closure (FPPC) approved by the State of Nevada regulatory agencies. The TSF 1 FPPC consists of regrading the top impoundment surface to promote runoff and preclude surface water impoundment, placing a working cover impoundment surface on which an high-density polyethylene (HDPE) liner will be installed, installing a three foot thick alluvial growth media cover, and revegetating the final surface with an approved seed mix. As of the date of this Technical Report, the following reclamation and closure activities have been completed on TSF 1: |

| o | Outer embankment slopes have been graded, covered, and revegetated. |

| o | Working cover and HDPE liner have been installed over 70% of the 300 acre impoundment surface. |

| o | Growth media has been installed over approximately 30% of the 300 acre impoundment surface. |

| · | For active tailings management, Jerritt Canyon is currently depositing tailings with a 40:60, solids/water, ratio into TSF 2 Phase 2. TSF 2 is an HDPE lined impoundment with a leak collection and recovery system (LCRS), which is designed and constructed to meet or exceed the most current environmental and engineering standards. As part of the TSF 2 monitoring program, Jerritt Canyon measures pumped flows from the LCRS, hydraulic head development above the TSF 2 secondary HDPE liner, and surrounding groundwater depths, and the presence (or absence) of process solution in the vadose zone underlying TSF 2. |

| · | TSF 2 Phase 3 is currently being constructed as an eight foot raise. Construction and commissioning of TSF 2 Phase 3 is expected in May 2021 and will only provide an additional seven months of tailings storage until December 2021, approximately. |

| · | TSF 2 Phase 4 is planned for construction during 2021 and will allow storage of an additional 1.7 Mst of tailings. Due to the short operational life of Phase 3, TSF 2 Phase 4 must be constructed |

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-15 | |||

| and commissioned before December 2021. This construction will require approximately 1.5 million cubic yards of compacted fill excavated from approved borrow source over one mile east of TSF 2. Assuming a planned production rate of 2,350 stpd, TSF 2 Phase 4 will be filled to capacity by December 2023. The Jerritt Canyon Water Pollution Control Permit authorizes up to 3.0 Mst of dry tailings to be produced per annum (approximately 8,200 stpd). If the average deposition rate is increased above 2,350 stpd, the timeline for filling TSF 2 Phase 4 to capacity will be shortened proportionally. |

| · | Jerritt Canyon plans to convert the existing WSR to TSF 3 for tailings disposal after TSF 2 is filled to capacity. TSF 3 will store approximately of 2.4 Mst of tailings and provide 2.6 years of tailings storage at an assumed average production rate of 2,350 stpd. Since TSF 3 would be commissioned before January 2024, additional tailings storage (beyond TSF 3) would need to be permitted and constructed before the end of 2025 to ensure a new facility is ready for tailings disposal by the middle of 2026. Likewise, if the average deposition rate is increased above 2,350 stpd, the timeline for filling TSF 3 and needing additional tailings storage beyond TSF 3 will be shortened proportionally. |

| · | The feasibility of converting the WSR into TSF 3 in a timely manner relies on the removal of 372 million gallons (Mgal) of process solution which is currently stored within the WSR by the end of 2022. Within the next two years, this volume will require removal via active and passive evaporation and/or treatment via the process WTP. If this volume cannot be removed by the end of 2022, other locations or methods of tailings disposal will need to be permitted, approved, and constructed. |

| · | Currently, the process WTP only removes approximately 200 gpm of process solution from the site-wide water balance inventory as permeate. Under these conditions, a significant increase in the WTP capacity is needed to eliminate positive water balances during the winter and spring. At this stage, the exact increase is unknown, but may be three to four times the current treatment rate for costing purposes. |

| 1.1.1.6 | Environmental Considerations |

| · | All of the necessary permits and approvals to operate are either in place or in the process of being renewed or modified. |

| · | Jerritt Canyon has multiple violations related to their environmental permits including air quality, water supply, surface water, and Underground Injection Control (UIC). |

| · | Although environmental permitting requirements are being exceeded, JCG is actively mitigating these issues. Persisting exceedances would likely result in corrective actions and/or fines and not result in the revocation of operational permits due to the social and economic considerations of this operation. |

| 1.1.1.7 | Safety |

| · | The large number of Mine Safety and Health Administration (MSHA) citations and extended shutdowns imposed during 2017 have been resolved and JCG continues to adhere to MSHA’s regulations. |

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-16 | |||

| 1.1.2 | Recommendations |

The QPs offer the following recommendations:

| 1.1.2.1 | Geology and Mineral Resources |

| 1. | Explore the 17 high priority exploration targets. The QP concurs with First Majestic’s plans to carry out a multi-year exploration program that will include a significant amount of surface and underground drilling that will cost approximately US$10 million to US$15 million annually. |

| 2. | Continue drilling to expand Mineral Resources. |

| 3. | Continue to convert Inferred Mineral Resources to Indicated Mineral Resources. |

| 4. | Update the block models on a regular basis. |

| 5. | Improve mineralized material tracking and reconciliation procedures. |

| 1.1.2.2 | Mining and Mineral Reserves |

| 1. | The dewatering system does not have a backup power supply. Any type of long term power loss can cause the operation to flood and damage infrastructure. A backup power system is recommended for site to keep critical infrastructure running and prevent damage. |

| 2. | Consider and assess the viability of surface water wells. This could reduce the risk of flooding underground workings in the event of a site power grid interruption. |

| 3. | Adopt long term planning and Mineral Reserve estimation processes, initiated by a mining method optimization trade-off study, and carry out multiple mining method planning exercises with the intention of reducing operating cut-off grades. |

| 4. | Adjust mobile mining fleet as necessary to achieve reduced mining heights. |

| 5. | Review cut-off grades and modifying factors as part of the planning process and optimize them where appropriate. |

| 6. | Explore and evaluate the old workings of the mines to determine which areas are accessible. Much of the resource of the mine is located in these areas. Determine if new development is required or rehabilitation of old workings is feasible. If areas are not accessible, then the resource/reserves should be adjusted to reflect the update. |

| 1.1.2.3 | Mineral Processing and Metallurgical Testing |

| 1. | Complete metallurgical testing of samples from the various mining sources that represent the current and future feed to the processing plant in order to develop more accurate estimates for future gold recovery and to provide information to support blending of plant feed with respect to sulfide sulfur, TOC concentrations, and other variables that contribute to plant performance. Metallurgical testing of two main ore bodies is currently planned, including characterization and roast-CIL leach testing at various grind sizes. The estimated cost of the program is US$150,000. |

| 1.1.2.4 | Infrastructure |

| 1. | Construction of the additional TSF capacity and increased WTP capacity are critical to operation of the Mine. These projects should be completed as soon as possible, as planned. |

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-17 | |||

| 1.1.2.5 | Tailings and Water Management Facilities |

| 1. | Accelerate the removal of surplus process water from the system by the process WTP and forced-air (i.e. active) evaporation. The process WTP needs to treat and remove its original design rate of 700 gpm from the water inventory in order to empty the WSR within one year to prepare it for conversion to TSF 3 before the end of 2023 or preferably sooner. |

| 2. | Explore the feasibility of designing a downstream raise of the TSF 2 embankment (Phase 5 Raise). Depending on results of embankment stability analyses, which will dictate the additional raise height, TSF 2 Phase 5 could provide multiple years of additional tailings storage. |

| 3. | Investigate and identify ‘green field’ areas near the existing process facilities and mill site where future TSFs may be permitted, designed, constructed, and operated. Due to the multiple-year lead times for permitting such facilities, investigation and conceptual designs need to be initiated as soon as possible. |

| 4. | Regardless of which option is eventually selected for future tailings storage, Jerritt Canyon should start the permitting process for additional tailings storage in the near future, before TSF 2 Phase 4 is filled to capacity in 2023 and assuming the WSR cannot be emptied within the next year. |

| 1.1.2.6 | Environmental Considerations |

| 1. | JCG should continue to mitigate the environmental regulatory exceedances and challenges related to air and water quality to achieve compliance with all their environmental permits. |

| 2. | To maintain a strong working relationship with regulators, JCG should actively develop a permitting strategy and plan that involves seeking permit approvals and modifications on a regular basis. |

| 1.1.2.7 | Safety |

| 1. | Efforts to alleviate air quality concerns in the processing facilities and provide working areas that can be accessed without wearing respirators should be a top priority and pursued vigorously. |

| 1.2 | Economic Analysis |

This section has been optionally included in this Technical Report although JCG is a producing company, SSX and Smith are currently in production, and there is no planned material expansion.

The economic analysis contained in this Technical Report is based on the Mineral Reserves, economic assumptions provided by JCG for SSX and Smith, and the capital and operating costs as presented in Section 21 of this Technical Report.

| 1.2.1 Physicals |

||

|

· Mine life: |

5 years (between 2021 and 2025): | |

|

· Underground ore tonnes mined: |

3.559 Mst | |

|

· Gold grade: |

0.20 oz/st Au | |

|

· Processed: |

||

| o Total Ore Feed: |

3.559 Mst | |

| o Gold grade: |

0.20 oz/st Au | |

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-18 | |||

|

· Contained Metal: |

||

| o Gold: |

703,164 oz Au | |

|

· Average LOM Recovery: |

||

| o Gold recovery |

86% | |

|

· Recovered Metal: |

||

| o Gold: |

604,721 oz Au | |

|

· Payable Metal: |

||

| o Gold: |

604,721 oz Au | |

| 1.2.2 | Revenue |

Revenue is estimated based on the following LOM weighted average metal prices:

|

· Gold price: |

US$1,500/oz Au |

| 1.2.3 | Capital Costs |

| · | LOM sustaining capital costs of US$42.8 million, including closure costs. |

| · | Closure costs of US$5.3 million were estimated annually based on US$1.50/st milled. |

| 1.2.4 | Operating Costs |

| · | LOM unit operating cost average of: |

| o Mine Development: |

US$12.99/st mined | |

| o Underground Mining: |

US$88.69/st mined | |

| o Processing: |

US$45.00/st milled | |

| o G&A: |

US$18.00/st milled | |

|

· Total unit operating costs: |

US$164.68/st milled. | |

|

· LOM operating costs: |

US$586.1 million. | |

| 1.2.5 | Taxation and Royalties |

| · | The Corporate Federal income tax rate in Nevada is 21% and State income tax rate is 5% for an average realized effective income tax rate of 24.95%. |

| · | Nevada Select (ELY Gold) royalty rate: 0.5% NSR |

| · | NouHgt Technologies royalty rate: 0.225% NSR (based on mill throughput and realized gold price) |

| · | 3Leaseholder land royalties: average $1.05 million/yr |

| 1.2.6 | Cash Flow |

SLR reviewed the JCG LOM after-tax cash flow model to confirm the economics of the LOM plan. The model is based on JCG’s JCG Model Ver2.0 file, which includes Measured and Indicated material, as well

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-19 | |||

as material from other areas on the Mine site, and credit for tolling. The JCG model does not take into account the following components:

| · | Financing costs |

| · | Existing working capital |

| · | Insurance |

| · | Overhead cost for a corporate office |

SLR has used JCG’s model as a reference for capital and operating cost rates but has created a standalone cash flow model to represent only the Mineral Reserve material. The cash flow summary is presented in Table 1-5. All costs are in Q4 2020 US dollars with no allowance for inflation.

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-20 | |||

Table 1-5: After-Tax Cash Flow Summary

Jerritt Canyon Mine

| 2021 | 2022 | 2023 | 2024 | 2025 | 2026 | |||||||||||||||||||||||||||||

| INPUTS | UNITS | TOTAL | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 | Year 6 | ||||||||||||||||||||||||||

|

MINING |

||||||||||||||||||||||||||||||||||

|

Underground |

||||||||||||||||||||||||||||||||||

| Operating Days |

365 | days | 1,770 | 365 | 365 | 365 | 365 | 310 | ||||||||||||||||||||||||||

| Tonnes milled per day |

tons / day | 2,011 | 1,997 | 2,051 | 2,001 | 2,001 | 2,001 | |||||||||||||||||||||||||||

| Smith Production |

tons | 1,434,644 | 291,086 | 292,022 | 291,963 | 291,891 | 267,681 | - | ||||||||||||||||||||||||||

| Au |

oz/t | 0.23 | 0.19 | 0.24 | 0.21 | 0.22 | 0.28 | - | ||||||||||||||||||||||||||

| Waste |

tons | 928,101 | 392,416 | 238,916 | 181,456 | 68,656 | 46,657 | - | ||||||||||||||||||||||||||

| Total Moved |

tons | 2,362,745 | 683,502 | 530,938 | 473,419 | 360,548 | 314,338 | - | ||||||||||||||||||||||||||

| SSX Production |

tons | 2,124,349 | 437,999 | 456,743 | 438,347 | 438,412 | 352,848 | - | ||||||||||||||||||||||||||

| Au |

oz/t | 0.18 | 0.18 | 0.19 | 0.18 | 0.18 | 0.17 | - | ||||||||||||||||||||||||||

| Waste |

tons | 330,794 | 72,906 | 141,591 | 66,892 | 36,296 | 13,109 | - | ||||||||||||||||||||||||||

| Total Moved |

tons | 2,455,143 | 510,905 | 598,334 | 505,240 | 474,708 | 365,957 | - | ||||||||||||||||||||||||||

| Total Production |

tons | 3,558,993 | 729,085 | 748,765 | 730,310 | 730,303 | 620,529 | - | ||||||||||||||||||||||||||

| Au |

oz/t | 0.20 | 0.18 | 0.21 | 0.20 | 0.19 | 0.22 | |||||||||||||||||||||||||||

| Waste |

tons | 1,258,894 | 465,322 | 380,507 | 248,348 | 104,952 | 59,766 | - | ||||||||||||||||||||||||||

|

Total Moved |

tons | 4,817,887 | 1,194,407 | 1,129,271 | 978,658 | 835,255 | 680,295 | - | ||||||||||||||||||||||||||

|

PROCESSING |

||||||||||||||||||||||||||||||||||

| Mill Feed |

tons | 3,558,993 | 729,085 | 748,765 | 730,310 | 730,303 | 620,529 | - | ||||||||||||||||||||||||||

| Au |

oz/t | 0.20 | 0.18 | 0.21 | 0.20 | 0.19 | 0.22 | - | ||||||||||||||||||||||||||

| Contained Au |

oz | 703,164 | 131,514 | 153,894 | 143,550 | 140,759 | 133,447 | - | ||||||||||||||||||||||||||

| Mill Recovery |

||||||||||||||||||||||||||||||||||

| Au |

86% | % | 86 | % | 86 | % | 86 | % | 86 | % | 86 | % | 86 | % | 86 | % | ||||||||||||||||||

| Net Recovery |

||||||||||||||||||||||||||||||||||

| Au |

% | 86 | % | 86 | % | 86 | % | 86 | % | 86 | % | 86 | % | 86 | % | |||||||||||||||||||

| Total Average Recovery |

% | 86 | % | 86 | % | 86 | % | 86 | % | 86 | % | 86 | % | - | ||||||||||||||||||||

| Total Recovered |

||||||||||||||||||||||||||||||||||

|

Au |

oz | 604,721 | 113,102 | 132,349 | 123,453 | 121,053 | 114,764 | - | ||||||||||||||||||||||||||

|

REVENUE |

||||||||||||||||||||||||||||||||||

| Metal Prices |

Input Units | |||||||||||||||||||||||||||||||||

| Au |

US$ | 1500 /oz Au | US$/oz Au | $ | 1,500.00 | $ | 1,500 | $ | 1,500 | $ | 1,500 | $ | 1,500 | $ | 1,500 | $ | 1,500 | |||||||||||||||||

| Au Payable Percentage |

100% | US$ ‘000 | 100 | % | 100 | % | 100 | % | 100 | % | 100 | % | 100 | % | 100 | % | ||||||||||||||||||

| Au Gross Revenue |

US$ ‘000 | $ | 907,081 | $ | 169,653 | $ | 198,523 | $ | 185,180 | $ | 181,580 | $ | 172,146 | $ | - | |||||||||||||||||||

| Total Gross Revenue |

US$ ‘000 | $ | 907,081 | $ | 169,653 | $ | 198,523 | $ | 185,180 | $ | 181,580 | $ | 172,146 | $ | - | |||||||||||||||||||

| Treatment |

$ | 0.40 | US$/oz | $ | 242 | $ | 45 | $ | 53 | $ | 49 | $ | 48 | $ | 46 | $ | - | |||||||||||||||||

| Transport |

$ | 1,500.00 | US$/shipment (12/yr) | $ | 379 | $ | 78 | $ | 78 | $ | 78 | $ | 78 | $ | 66 | $ | - | |||||||||||||||||

| Early Settlement fees |

$ | - | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | ||||||||||||||||||||

| Total charges |

$ | 621 | $ | 123 | $ | 131 | $ | 128 | $ | 127 | $ | 112 | $ | - | ||||||||||||||||||||

| Gross NSR |

$ | 906,460 | $ | 169,529 | $ | 198,392 | $ | 185,052 | $ | 181,453 | $ | 172,034 | $ | - | ||||||||||||||||||||

|

Royalties |

||||||||||||||||||||||||||||||||||

| Nevada Select Royalty Inc |

0.5% | US$ ‘000 | $ | 4,532 | $ | 848 | $ | 992 | $ | 925 | $ | 907 | $ | 860 | $ | - | ||||||||||||||||||

| NouHgt Technologies, LLC |

0.225 | US$ ‘000 | $ | 801 | $ | 164 | $ | 168 | $ | 164 | $ | 164 | $ | 140 | $ | - | ||||||||||||||||||

| Leaseholder Roylties |

US$ ‘000 | $ | 5,092 | $ | 1,050 | $ | 1,050 | $ | 1,050 | $ | 1,050 | $ | 892 | $ | - | |||||||||||||||||||

| Total Royalties |

US$ ‘000 | $ | 10,425 | $ | 2,062 | $ | 2,210 | $ | 2,140 | $ | 2,122 | $ | 1,892 | $ | - | |||||||||||||||||||

|

Net Smelter Return |

US$ ‘000 | $ | 896,035 | $ | 167,468 | $ | 196,181 | $ | 182,913 | $ | 179,331 | $ | 170,142 | $ | - | |||||||||||||||||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-21 | |||

| INPUTS | UNITS | TOTAL |

|

2021

Year 1 |

|

|

2022

Year 2 |

|

|

2023

Year 3 |

|

|

2024

Year 4 |

|

|

2025

Year 5 |

|

|

2026

Year 6 |

| ||||||||||||||

| OPERATING COST |

||||||||||||||||||||||||||||||||||

| Mining (Underground) |

$ | 101.68 | US$/t milled | $ | 101.68 | $ | 101.68 | $ | 101.68 | $ | 101.68 | $ | 101.68 | $ | 101.68 | $ | 101.68 | |||||||||||||||||

| Processing |

$ | 45.00 | US$/t milled | $ | 45.00 | $ | 45.00 | $ | 45.00 | $ | 45.00 | $ | 45.00 | $ | 45.00 | $ | 45.00 | |||||||||||||||||

| G&A |

$ | 18.00 | US$/t milled | $ | 18.00 | $ | 18.00 | $ | 18.00 | $ | 18.00 | $ | 18.00 | $ | 18.00 | $ | 18.00 | |||||||||||||||||

| Total Unit Operating Cost |

US$/t milled | $ | 164.68 | $ | 164.68 | $ | 164.68 | $ | 164.68 | $ | 164.68 | $ | 164.68 | $ | 164.68 | |||||||||||||||||||

| Mining (Underground) |

US$ ‘000 | $ | 361,867 | $ | 74,131 | $ | 76,132 | $ | 74,256 | $ | 74,255 | $ | 63,094 | $ | - | |||||||||||||||||||

| Processing |

US$ ‘000 | $ | 160,155 | $ | 32,809 | $ | 33,694 | $ | 32,864 | $ | 32,864 | $ | 27,924 | $ | - | |||||||||||||||||||

| G&A |

US$ ‘000 | $ | 64,062 | $ | 13,124 | $ | 13,478 | $ | 13,146 | $ | 13,145 | $ | 11,170 | $ | - | |||||||||||||||||||

| Total Operating Cost |

$969.18/oz Au | US$ ‘000 | $ | 586,084 | $ | 120,063 | $ | 123,304 | $ | 120,265 | $ | 120,264 | $ | 102,187 | $ | - | ||||||||||||||||||

| Operating Cashflow |

US$ ‘000 | $ | 309,950 | $ | 47,404 | $ | 72,877 | $ | 62,647 | $ | 59,067 | $ | 67,955 | $ | - | |||||||||||||||||||

| CAPITAL COST |

||||||||||||||||||||||||||||||||||

| Direct Cost |

||||||||||||||||||||||||||||||||||

| Safety, Health & Environmental |

US$ ‘000 | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | |||||||||||||||||||

| Heavy Mobile Equipment |

US$ ‘000 | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | |||||||||||||||||||

| Expansion |

US$ ‘000 | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | |||||||||||||||||||

| Modernization |

US$ ‘000 | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | |||||||||||||||||||

| Other |

US$ ‘000 | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | |||||||||||||||||||

| Total Direct Cost |

US$ ‘000 | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | |||||||||||||||||||

| Sustaining Cost |

||||||||||||||||||||||||||||||||||

| Mine Capital |

US$ ‘000 | $ | 21,354 | $ | 4,375 | $ | 4,493 | $ | 4,382 | $ | 4,382 | $ | 3,723 | $ | - | |||||||||||||||||||

| Exploration Capital |

US$ ‘000 | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | $ | - | |||||||||||||||||||

| Tailings Facility |

US$ ‘000 | $ | 9,000 | $ | 9,000 | $ | - | $ | - | $ | - | $ | - | $ | - | |||||||||||||||||||

| Processing Plant |

US$ ‘000 | $ | 3,559 | $ | 729 | $ | 749 | $ | 730 | $ | 730 | $ | 621 | $ | - | |||||||||||||||||||

| Reclamation and closure |

$ | 1.50 | US$ ‘000 | $ | 5,338 | $ | 1,094 | $ | 1,123 | $ | 1,095 | $ | 1,095 | $ | 931 | $ | - | |||||||||||||||||

| Sustaining Exploration Diamond Drilling |

$ | 1.00 | US$ ‘000 | $ | 3,559 | $ | 729 | $ | 749 | $ | 730 | $ | 730 | $ | 621 | $ | - | |||||||||||||||||

| Total Sustaining Cost |

US$ ‘000 | $ | 42,810 | $ | 15,926 | $ | 7,113 | $ | 6,938 | $ | 6,938 | $ | 5,895 | $ | - | |||||||||||||||||||

| Working Capital |

US$ ‘000 | $ | (1,284 | ) | $ | (17,519 | ) | $ | (3,668 | ) | $ | 1,339 | $ | 236 | $ | 403 | $ | 17,925 | ||||||||||||||||

| All in Sustaining Cost |

$1037.85/oz Au | US$ ‘000 | $ | 627,610 | $ | 118,471 | $ | 126,750 | $ | 128,542 | $ | 127,438 | $ | 108,485 | $ | 17,925 | ||||||||||||||||||

| CASH FLOW |

||||||||||||||||||||||||||||||||||

| Net Pre-Tax Cashflow |

US$ ‘000 | $ | 268,424 | $ | 48,996 | $ | 69,431 | $ | 54,371 | $ | 51,894 | $ | 61,657 | $ | (17,925 | ) | ||||||||||||||||||

| Cumulative Pre-Tax Cashflow |

US$ ‘000 | $ | 48,996 | $ | 118,428 | $ | 172,798 | $ | 224,692 | $ | 286,349 | $ | 268,424 | |||||||||||||||||||||

| Depreciation |

US$ ‘000 | $ | 42,810 | $ | 2,979 | $ | 5,401 | $ | 7,422 | $ | 10,839 | $ | 16,171 | $ | - | |||||||||||||||||||

| Taxes |

US$ ‘000 | $ | 65,319 | $ | 10,811 | $ | 16,555 | $ | 13,505 | $ | 11,760 | $ | 12,688 | $ | - | |||||||||||||||||||

| After-Tax Cashflow |

US$ ‘000 | $ | 203,105 | $ | 38,185 | $ | 52,876 | $ | 40,865 | $ | 40,134 | $ | 48,969 | $ | (17,925 | ) | ||||||||||||||||||

| Cumulative After-Tax Cashflow |

US$ ‘000 | $ | 38,185 | $ | 91,061 | $ | 131,926 | $ | 172,061 | $ | 221,029 | $ | 203,105 | |||||||||||||||||||||

|

All-In Sustaining Cost |

US$/oz | $ | 1,041 | $ | 1,203 | $ | 986 | $ | 1,031 | $ | 1,052 | $ | 943 | |||||||||||||||||||||

| PROJECT ECONOMICS |

||||||||||||||||||||||||||||||||||

| Pre-tax NPV at 5% discounting |

5.0 | % | US$ ‘000 | $234,234 | ||||||||||||||||||||||||||||||

| Pre-tax NPV at 7.5% discounting |

7.5 | % | US$ ‘000 | $219,617 | ||||||||||||||||||||||||||||||

| Pre-tax NPV at 10% discounting |

10.0 | % | US$ ‘000 | $206,383 | ||||||||||||||||||||||||||||||

| After-Tax NPV at 5% discounting |

5.0 | % | US$ ‘000 | $177,639 | ||||||||||||||||||||||||||||||

| After-Tax NPV at 7.5% discounting |

7.5 | % | US$ ‘000 | $166,719 | ||||||||||||||||||||||||||||||

| After-tax NPV at 10% discounting |

10.0 | % | US$ ‘000 | $156,816 | ||||||||||||||||||||||||||||||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-22 | |||

| 1.2.7 | Cash Flow Analysis |

Mine economics have been evaluated using the discounted cash flow method, using mid-year discounting convention, and taking into account annual processed tonnages and gold grades. The associated process recovery, metal price, operating costs, royalties, and capital expenditures were also considered.

The economic analysis confirmed that the Jerritt Canyon Mineral Reserves are economically viable. The pre-tax net present value (NPV) at a 5% base discount rate is US$234 million and the after-tax NPV at a 5% base discount is US$178 million.

The summary of the results of the cash flow analysis is presented in Table 1-6.

Table 1-6: Cash Flow Analysis

Jerritt Canyon

| Item | Discount Rate | Units | Value | |||

| Pre-tax NPV at 5% discount |

5% | US$ million | 234 | |||

| Pre-tax NPV at 7.5% discount |

7.5% | US$ million | 220 | |||

| Pre-tax NPV at 10% discount |

10% | US$ million | 206 | |||

| After-Tax NPV at 5% discount |

5% | US$ million | 178 | |||

| After-Tax NPV at 7.5% discount |

7.5% | US$ million | 167 | |||

| After-tax NPV at 10% discount |

10% | US$ million | 157 | |||

The undiscounted pre-tax cash flow is US$268 million, and the undiscounted after-tax cash flow is US$203 million. For this cash flow analysis, the internal rate of return (IRR) and payback are not applicable as there is no negative initial cash flow (no initial investment to be recovered).

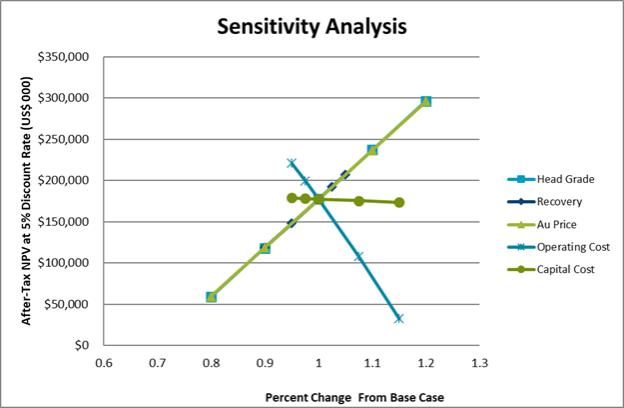

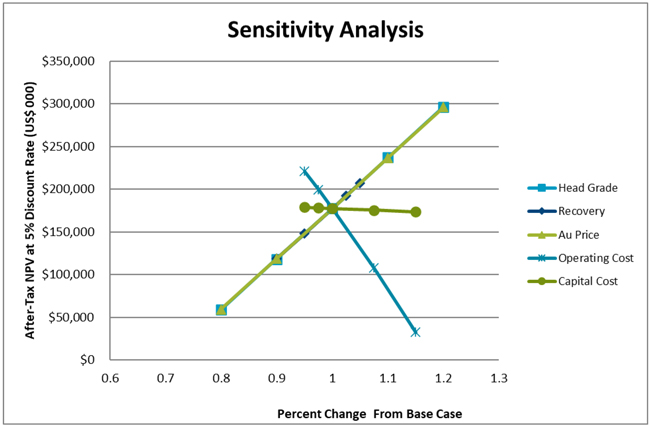

| 1.2.8 | Sensitivity Analysis |

Project risks can be identified in both economic and non-economic terms. Key economic risks were examined by running cash flow sensitivities on after-tax NPV at a 5% discount rate. The following items were examined:

| · | Metal price |

| · | Head grade |

| · | Metallurgical recovery |

| · | Operating costs |

| · | Capital costs |

After-tax sensitivity over the base case has been calculated for -20% to +20% (for head grade), -10% to +5% (for recoveries), -20% to +20% (for metal prices), and -5% to +15% (operating costs and capital costs) variations to determine the most sensitive parameter of this project. The after-tax NPV is most sensitive to head grade and metal prices, followed by operating costs, and is least sensitive to capital costs.

The sensitivities are presented in Table 1-7 and Figure 1-1.

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-23 | |||

Table 1-7: After-Tax Sensitivity Analysis

Jerritt Canyon

| Head Grade (oz/st Au) |

NPV at 5% (US$ million) | |||

| 80% |

0.16 | 58.8 | ||

| 90% |

0.18 | 118.2 | ||

| 100% | 0.20 | 177.6 | ||

| 110% |

0.22 | 237.1 | ||

| 120% |

0.24 | 296.5 | ||

| Recovery (% Au) |

NPV at 5% (US$ million) | |||

| 90% |

0.77 | 118.5 | ||

| 98% |

0.82 | 148.1 | ||

| 100% | 0.86 | 177.6 | ||

| 103% |

0.88 | 192.4 | ||

| 105% |

0.90 | 207.2 | ||

| Metal Price (US$/oz Au) |

NPV at 5% (US$ million) | |||

| 80% |

1,200 | 59.3 | ||

| 90% |

1,350 | 118.5 | ||

| 100% | 1,500 | 177.6 | ||

| 110% |

1,650 | 236.8 | ||

| 120% |

1,800 | 295.9 | ||

| Operating Costs (US$ million) |

NPV at 5% (US$ million) | |||

| 95.0% |

528.9 | 221.0 | ||

| 97.5% |

557.1 | 199.6 | ||

| 100.0% | 586.1 | 177.6 | ||

| 107.5% |

677.3 | 107.9 | ||

| 115.0% |

775.1 | 32.4 | ||

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-24 | |||

| Total Capital Costs (US$ million) |

NPV at 5% (US$ million) | |||

| 95.0% |

40.7 | 179.0 | ||

| 97.5% |

41.7 | 178.3 | ||

| 100.0% | 42.8 | 177.6 | ||

| 107.5% |

46.0 | 175.5 | ||

| 115.0% |

49.2 | 173.5 | ||

Figure 1-1: After-Tax NPV Sensitivity Graph

| 1.3 | Technical Summary |

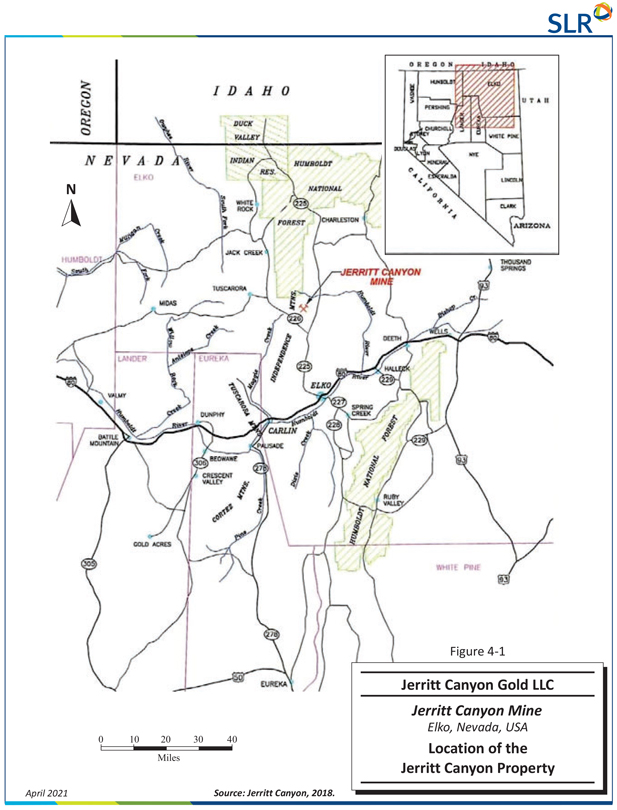

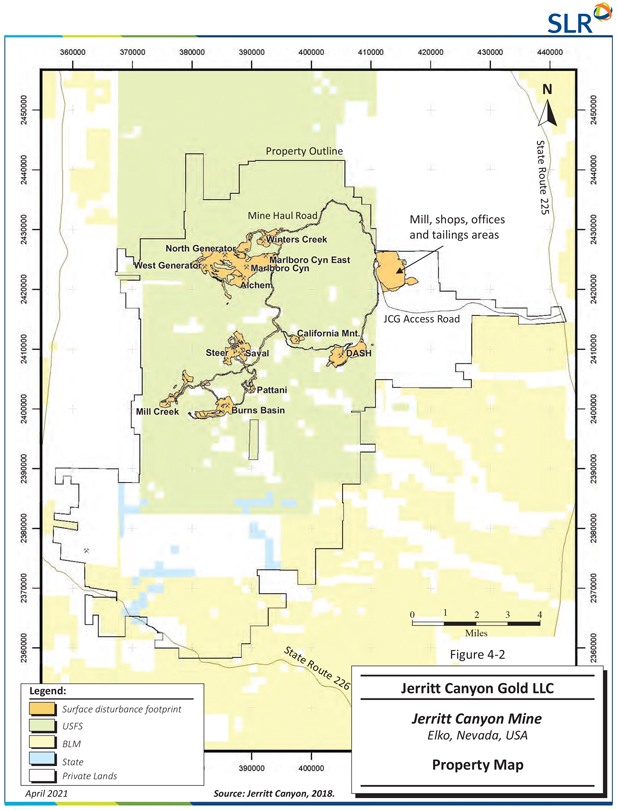

| 1.3.1 | Property Description and Location |

The Jerritt Canyon property is located in Elko County, northeastern Nevada. The mill site, shops, and administration and security buildings are located approximately 50 miles north of the town of Elko. The property forms an irregular area that extends approximately 21 miles north-south and 17 miles east-west at its widest and is approximately 76,160 acres. The property is bounded by 116° 10’ west and 115° 78” west longitude and 41° 23’ north and 41° 46’ north latitude. The property boundaries have been surveyed and are located in the field with wooden stakes.

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-25 | |||

The operations are located on a combination of public and private lands, with the deposits and mining related surface facilities being located primarily on mining claims in United States Forest Service (USFS) land within the Humboldt-Toiyabe National Forest. The process facilities, offices, shops, and tailings dams are located on private land owned by JCG. Additional claims in the southern part of the land package are mostly located on private land with some located on land administered by the United States Bureau of Land Management (BLM).

| 1.3.2 | Land Tenure |

Land tenure on the Jerritt Canyon property includes patented claims, unpatented claims, and fee land. The property covers a large area that extends approximately 21 miles north-south and 17 miles east-west at its widest and is approximately 76,160 acres.

| 1.3.3 | History |

The Jerritt Canyon deposit was discovered by Food Machinery Corporation (FMC) in 1972. In 1976, Meridian Gold LLC (Meridian) and Freeport Minerals Company formed a joint venture to explore and develop the gold deposits in the Jerritt Canyon area and, in 1980, mining commenced with production from the North Generator and Marlboro Canyon open pit mines. The first gold production from the property occurred in July 1981.

Open pit mining was conducted from early 1981 until late 1999, with the mining carried out in the areas of Marlboro Canyon, Alchem, Lower North Generator Hill, Upper North Generator Hill, West Generator, Burns Basin, Mill Creek, Pattani Springs, California Mountains, Dash, Winters Creek, Steer Canyon, and Saval Canyon. The annual production from these areas ranged from approximately 40,000 ounces to 1.4 million ounces.

Underground operations started in 1997 at SSX, and continued until 2008 with production from the Steer, Murray, MCE, Smith, West Generator, and Saval deposits. In 2009, a new mine plan was prepared. Underground mining from the Smith deposit recommenced in late January 2010 and underground mining at SSX recommenced in early October 2010.

From the start of mining in 1980 to the end of December 2020, approximately of 9.7 Moz Au were produced from approximately 49 Mst of ore mined at an average grade of 0.199 oz/st Au.

| 1.3.4 | Geology and Mineralization |

The Jerritt Canyon district is located in the Great Basin, north and northeast of the Carlin Trend of gold deposits. Carlin type gold mineralization at Jerritt Canyon is hosted by silty carbonate or carbonaceous siliciclastic rocks originally deposited as shelf sedimentary rocks during the Paleozoic. The Paleozoic host rocks have been imbricated, faulted, and folded through several orogenic events through the Paleozoic and Mesozoic. An early phase of intrusive igneous activity is represented by west-northwest mafic igneous dikes of Paleozoic age. Carlin type gold deposits were emplaced in the Middle to Late Eocene during an initial phase of extensional tectonics at which time high potassium calc-alkaline magmatic rocks were emplaced. Mafic and intermediate igneous dikes were emplaced during this phase of igneous activity and trend north-northeast.

The occurrence and distribution of gold mineralization at Jerritt Canyon is controlled by both lithology and structure. Deposits at Jerritt Canyon are mostly stratabound or fault hosted. Gold occurs as very fine, micron-size, particles in pyrite and arsenian pyrite.

| First Majestic Silver Corp. | Jerritt Canyon Gold Mine, SLR Project No: 233.03396.R0000

| ||||

| NI 43-101 Technical Report - April 30, 2021 | 1-26 | |||

| 1.3.5 | Exploration Status |

Exploration completed at Jerritt Canyon has included desktop compilation and interpretation of historical datasets, target identification, and RC and core drilling. Jerritt Canyon is primarily drilled from underground drilling sites. From June 23, 2015 through to December 31, 2020, Jerritt Canyon drilled a total of 279,954 ft in 406 core holes and a total of 2,340,646 ft in 16,773 RC holes underground.

| 1.3.6 | Mineral Resources |

The technical work for this report was initiated in March 2020. Wireframe and block modelling for the underground SSX, Smith, WGen, USB, and Saval 4 Deposits were completed by JCG and provided to SLR for verification and audit.

Wireframe and block modelling for Jerritt Canyon were completed by JCG geologists and provided to SLR for verification and audit. A total of five deposits are the focus of this resource update: SSX, Smith, WGen, USB, and Saval 4. Two deposits, Smith and SSX, were broken into separate domains for easier handling in the modelling process. As a result, a total of 17 mineralized wireframe models were built for SSX Zone 1, SSX Zone 2-3, SSX Zone 4, SSX Zone 5, SSX Zone 6, SSX Zone 7, SSX Zone 9, Smith Zone 1, Smith Zone 2-3, Smith Zone 4, Smith Zone 5, Smith Zone 7, Smith Zone 8, Smith Zone 9, Saval 4, USB and WGen. All wireframes are based on approximately a 0.10 oz/st Au cut-off.

Sample information for the diamond drill holes and RC holes was composited into nominal equal lengths of five feet using the run-length compositing algorithm of the Leapfrog Edge modelling software package. Composited assay values were created on an individual zone basis. JCG capped the assays to 1.8 oz/st Au prior to compositing.

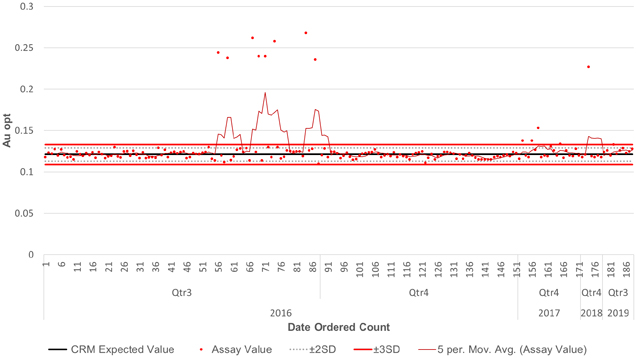

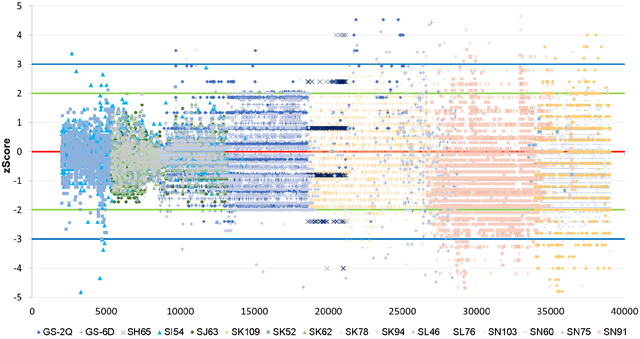

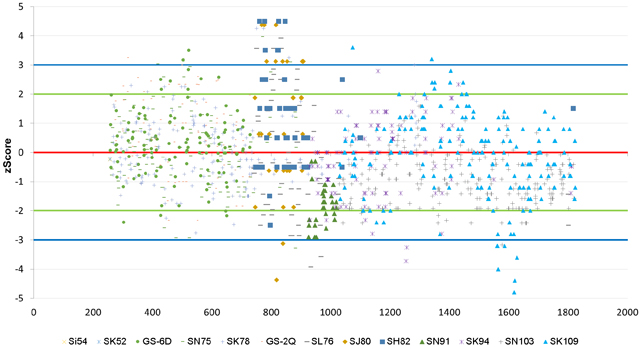

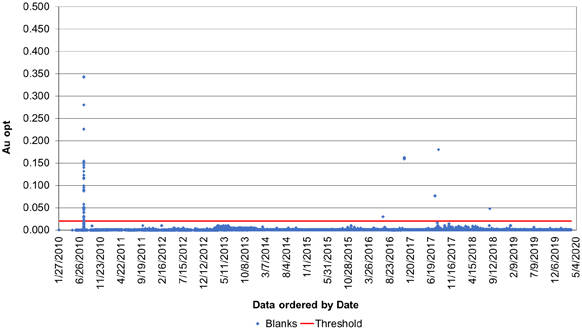

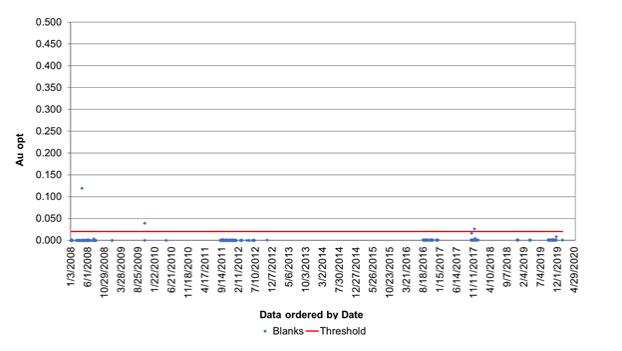

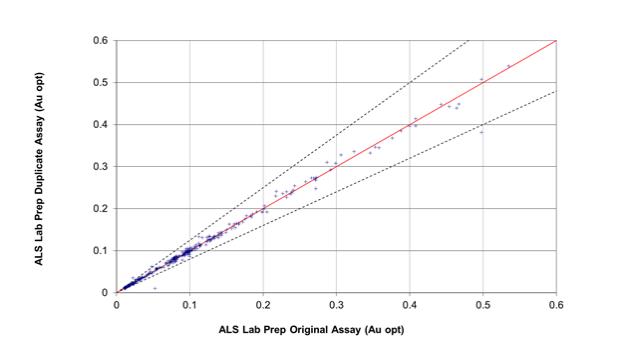

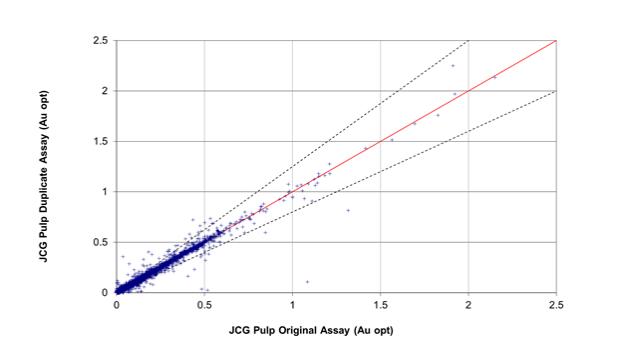

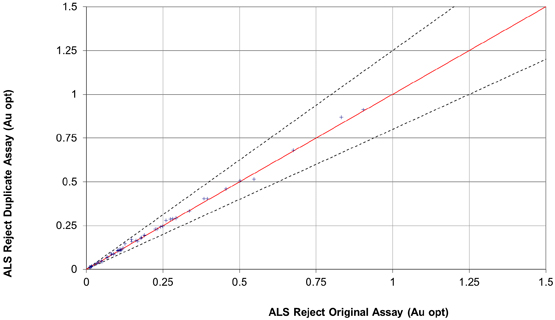

A total of 11 different block models were created for each of the different wireframe models. Parent block sizes for all models are 10ft x 10ft x 10ft with sub-block sizes at 2.5ft x 2.5ft x 2.5ft. One interpolation pass was carried out to estimate the grades into the separate block models. Gold grades were estimated into the blocks using Ordinary Kriging interpolation algorithm with Leapfrog Edge.