Form SD INTEL CORP

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

Specialized Disclosure Report

INTEL CORPORATION

(Exact name of the registrant as specified in its charter)

| Delaware | 000-06217 | 94-1672743 | ||

| (State or other jurisdiction of incorporation) |

(Commission File Number) |

(IRS Employer Identification No.) | ||

| 2200 Mission College Boulevard, Santa Clara, California | 95054-1549 | |||

| (Address of principal executive offices) | (Zip code) | |||

| Suzan A. Miller (408) 765-8080 | ||||

| (Name and telephone number, including area code, of the person to contact in connection with this report.) | ||||

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

| x | Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2015 |

Introduction

This Specialized Disclosure Report on Form SD (Form SD) of Intel Corporation (Intel or we) for the year ended December 31, 2015 is presented to comply with Rule 13p-1 under the Securities Exchange Act of 1934, as amended (the Rule). The Rule was adopted by the Securities and Exchange Commission (SEC) to implement reporting and disclosure requirements related to “conflict minerals” as directed by the Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010 (Dodd-Frank Act). Conflict minerals are defined by the SEC as columbite-tantalite (coltan), cassiterite, gold, wolframite, or their derivatives, which are limited to tantalum, tin, and tungsten. The Rule imposes certain reporting obligations on SEC registrants whose products contain conflict minerals that are necessary to the functionality or production of their products (such minerals are referred to as “necessary conflict minerals”), excepting conflict minerals that, prior to January 31, 2013, were located “outside of the supply chain” (as defined in the Rule). For products that contain necessary conflict minerals, the registrant must conduct in good faith a reasonable country of origin inquiry designed to determine whether any of the conflict minerals originated in the Democratic Republic of the Congo (DRC) or an adjoining country, collectively defined as the “Covered Countries.” If, based on such inquiry, the registrant knows or has reason to believe that any of the necessary conflict minerals contained in its products originated or may have originated in a Covered Country and knows or has reason to believe that those necessary conflict minerals may not be solely from recycled or scrap sources, the registrant must conduct due diligence in order to determine if the necessary conflict minerals contained in those products did or did not directly or indirectly finance or benefit armed groups in the Covered Countries. Products that do not contain necessary conflict minerals that directly or indirectly finance or benefit armed groups in the Covered Countries are considered “DRC conflict free.” We also use the term “conflict-free” to refer to suppliers, supply chains, smelters and refiners if their sources of conflict minerals did not or do not directly or indirectly finance or benefit armed groups in the Covered Countries. Numerous terms in this Form SD are defined in the Rule and the reader is referred to that source and to SEC Release No. 34-67716 issued by the SEC on August 22, 2012 for such definitions.

Company Overview

We design and manufacture advanced integrated digital technology platforms. A platform consists of a microprocessor and chipset, and may be enhanced by additional hardware, software, and services. We sell these platforms primarily to original equipment manufacturers, original design manufacturers, and industrial and communications equipment manufacturers in the computing and communications industries. Our platforms are used across the compute continuum, in notebooks (including Ultrabook™ devices), 2 in 1 systems, desktops, servers, tablets, phones, and the Internet of Things (including wearables, retail devices, and manufacturing devices). We also develop and sell software and services primarily focused on security and technology integration.

On December 28, 2015, we completed the acquisition of Altera Corporation (Altera), a global semiconductor company that designs and sells programmable semiconductors and related products. Altera® products are included within the scope of this Form SD.

Overview of Intel’s Conflict Minerals Program

As a semiconductor manufacturer, we are knowledgeable of the design of our products including the materials needed to construct them. We design the manufacturing processes to build those products and in some cases, design the detailed materials to manufacture those products. As a result, we know that many of our hardware products contain tantalum, tin, tungsten and/or gold that is necessary to the functionality or production of those products. Conflict minerals are obtained from sources worldwide, and our desire is not to eliminate those originating in the Covered Countries but rather to obtain conflict minerals from sources that do not directly or indirectly finance or benefit armed groups in the Covered Countries. We believe that it is important for us and other companies to support responsible in-region mineral sourcing from the Covered Countries in order to not negatively affect the economies of such countries. Intel is a founding member of the Public Private Alliance for Responsible Minerals Trade (PPA). We support the “Solutions for Hope” project that provides suppliers with tantalum from conflict-free sources in the DRC, and we are an associate member of the ITRI Tin Supply Chain Initiative (iTSCi) that establishes traceability in the upstream mineral chain in the DRC, Rwanda and Burundi.

We are an industry leader in the conflict minerals subject area, where we have worked extensively for over eight years to put in place processes and systems to develop conflict-free supply chains for Intel and our industry. We recognize that broad collaborative efforts among governments, non-governmental organizations and industry are needed to solve this complex problem. Intel is a member of the Conflict-Free Sourcing Initiative (CFSI, unique member code INTC), an initiative of the Electronic Industry Citizenship Coalition (EICC) and the Global e-Sustainability Initiative (GeSI). In that role, we collaborate with companies in the electronics and other industries that use necessary conflict minerals (e.g. jewelry, automotive, medical instrumentation, and others) to help create conflict-free supply chains. Since 2013, we have manufactured microprocessors that are DRC conflict free for tantalum, tin, tungsten and gold, and we are continuing our pursuit of conflict-free supply chains for these conflict minerals.

2

Conflict Minerals Sourcing Policy

Intel’s policy with respect to the sourcing of conflict minerals is as follows:

Conflict minerals originating from the DRC are sometimes mined and sold, “under the control of armed groups”, to “finance conflict characterized by extreme levels of violence”. Some of these minerals can make their way into the supply chains of the products used around the world, including those in the electronics industry. Intel’s suppliers acquire and use conflict minerals from multiple sources worldwide. As part of Intel’s commitment to corporate responsibility and respecting human rights in our own operations and in our global supply chain, it is Intel’s goal to use tantalum, tin, tungsten and gold in our products that do not directly or indirectly finance or benefit armed groups in the Covered Countries while continuing to support responsible mineral sourcing in the region.

We expect our suppliers to have in place policies and due diligence measures that will enable us to reasonably assure that products and components supplied to us containing conflict minerals are DRC conflict free. We further expect our suppliers to comply with the EICC Code of Conduct and conduct their business in alignment with Intel’s supply chain responsibility expectations.

In support of this policy, we will:

| • | Exercise due diligence with relevant suppliers consistent with the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas and encourage our suppliers to do likewise with their suppliers. |

| • | Provide, and expect our suppliers to cooperate in providing, due diligence information to confirm the tantalum, tin, tungsten and gold in our supply chain are conflict-free. |

| • | Collaborate with our suppliers and others on industry-wide solutions to enable products that are DRC conflict free. |

| • | Commit to transparency in the implementation of this policy by making available reports on our progress to relevant stakeholders and the public. |

The full text of our Conflict Minerals Sourcing Policy is available at www.intel.com/conflictfree. The content of any website referred to in this Form SD is included for general information only and is not incorporated by reference in this Form SD.

Supply Chain Description

Most of our hardware products, primarily microprocessors, chipsets and their packages, are manufactured in our own network of fabrication facilities (fabs). Although many of our hardware products contain conflict minerals, we do not purchase ore or unrefined conflict minerals from mines. We are many steps removed in the supply chain from the mining of the conflict minerals and are therefore considered a “downstream” purchaser. We purchase materials used in our products from a large network of suppliers; some of those materials contribute necessary conflict minerals to our products. The origin of conflict minerals cannot be determined with any certainty once the ores are smelted, refined and converted to ingots, bullion or other conflict minerals-containing derivatives. The smelters and refiners (sometimes referred to as “facilities”) are consolidating points for ore and are in the best position in the total supply chain to know the origin of the ores. We rely on our suppliers to assist with our reasonable country of origin inquiry and due diligence efforts, including the identification of smelters and refiners, for the conflict minerals contained in the materials which they supply to us. We are more knowledgeable about the source and chain of custody of the necessary conflict minerals contained in products we fully manufacture in our fabs as compared to products which we manufacture but also include ready-made component parts we purchase from third parties or products that are manufactured for us by other companies.

3

SECTION 1 - CONFLICT MINERALS DISCLOSURE

| Item 1.01 | Conflict Minerals Disclosure and Report |

Description of Reasonable Country of Origin Inquiry Efforts

For 2015, the reasonable country of origin inquiry (RCOI) efforts performed by Intel and Altera included conducting a supply chain survey of our direct suppliers to obtain country of origin information for the necessary conflict minerals in our products using the Conflict Minerals Reporting Template (CMRT). Prior to our acquisition of Altera on December 28, 2015, Altera maintained its own conflict minerals program, including conducting its RCOI and due diligence efforts separately from Intel.

The Intel and Altera supply chain surveys requested our respective suppliers to identify the smelters and refiners and countries of origin of the conflict minerals in products they supply to us. We each compared the smelters and refiners identified in the surveys against the lists of facilities which have received a conflict-free designation by the CFSI’s Conflict-Free Smelter Program (CFSP) or other independent third party audit program such as the London Bullion Market Association’s Responsible Gold Programme and the Responsible Jewellery Council’s Chain-of-Custody Certification program. If a smelter or refiner in Intel’s supply chain was not listed as having received a “conflict-free” designation, Intel proactively attempted to contact such facility to request country of origin information for the conflict minerals that it processed. We documented country of origin information for the smelters and refiners identified by the supply chain surveys as provided from multiple sources including the supply chain surveys, independent third party audit programs and directly from smelters and refiners that Intel contacted.

There is significant overlap between our RCOI efforts and our due diligence measures performed. Our due diligence measures performed, including measures conducted separately by Altera prior to our acquisition, are discussed further in the Conflict Minerals Report filed as Exhibit 1.01 hereto.

Below is a summary of the country of origin information collected from our respective suppliers as a result of our RCOI efforts.

| Conflict Mineral |

Countries of origin and other sources may include the following: | |

| Tantalum | Australia, Austria, Bolivia, Brazil, Burundi, Canada, China, DRC, Estonia, Ethiopia, Germany, India, Japan, Kazakhstan, Malaysia, Mozambique, Namibia, Nigeria, Peru, Russian Federation, Rwanda, Sierra Leone, Thailand, United States and recycled or scrap sources | |

| Tin | Australia, Belgium, Bolivia, Brazil, Canada, Chile, China, DRC, Germany, Indonesia, Japan, Malaysia, Peru, Philippines, Poland, Rwanda, Singapore, Thailand, United States and recycled or scrap sources | |

| Tungsten | Australia, Bolivia, Brazil, Canada, China, Colombia, Germany, Japan, Mexico, Peru, Portugal, Russian Federation, Rwanda, Spain, Thailand, United States, Vietnam and recycled or scrap sources | |

| Gold | Argentina, Australia, Belgium, Brazil, Canada, Chile, China, Côte d’Ivoire, England, Germany, Guyana, Indonesia, Italy, Japan, Laos People’s Democratic Republic, Mexico, Papua New Guinea, Peru, Philippines, Portugal, Republic of Korea, Russian Federation, South Africa, Spain, Suriname, Switzerland, Taiwan, Thailand, United States and recycled or scrap sources | |

Conclusion Based on Reasonable Country of Origin Inquiry

We have concluded in good faith that during 2015:

| a) | Intel and Altera manufactured and contracted with others to manufacture products as to which conflict minerals are necessary to the functionality or production of our products. |

| b) | Based on a reasonable country of origin inquiry, we know or have reason to believe that a portion of the necessary conflict minerals contained in Intel and Altera products originated or may have originated in the Covered Countries and know or have reason to believe that those necessary conflict minerals may not be solely from recycled or scrap sources. |

As a result of the above conclusion, we performed due diligence measures on the source and chain of custody of the necessary conflict minerals in our products, as described in the Conflict Minerals Report.

4

Conflict Minerals Disclosure

This Form SD and the Conflict Minerals Report, filed as Exhibit 1.01 hereto, are publicly available at www.intc.com and www.intel.com/conflictfree as well as the SEC’s EDGAR database at www.sec.gov.

| Item 1.02 | Exhibit |

The Conflict Minerals Report required by Item 1.01 is filed as Exhibit 1.01 to this Form SD.

SECTION 2 – EXHIBITS

| Item 2.01 | Exhibits |

Exhibit 1.01 – Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form SD.

Intel, the Intel logo, and Ultrabook are trademarks of Intel Corporation or its subsidiaries in the U.S. and/or other countries.

5

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

| INTEL CORPORATION (Registrant) | ||||

| By: | /s/ Brian M. Krzanich |

May 19, 2016 | ||

| Brian M. Krzanich Chief Executive Officer |

Date | |||

6

Exhibit 1.01

CONFLICT MINERALS REPORT

INTEL CORPORATION

IN ACCORD WITH RULE 13P-1 UNDER THE SECURITIES EXCHANGE ACT OF 1934

This Conflict Minerals Report (Report) of Intel Corporation (Intel or we) for the year ended December 31, 2015 is presented to comply with Rule 13p-1 under the Securities Exchange Act of 1934, as amended (the Rule). Numerous terms in this Report are defined in the Rule and our Specialized Disclosure Report on Form SD and the reader is referred to those sources and to SEC Release No. 34-67716 issued by the Securities and Exchange Commission on August 22, 2012 for such definitions.

Pursuant to the Rule, we undertook due diligence measures on the source and chain of custody of the conflict minerals necessary to the functionality or production of our products which we had reason to believe may have originated from the Democratic Republic of the Congo (DRC) or an adjoining country (collectively defined as the “Covered Countries”) and which may not have come from recycled or scrap sources, to determine whether such products were “DRC conflict free.” In this Report, we also refer to suppliers, supply chains, smelters and refiners as “conflict-free” if their sources of conflict minerals did not or do not directly or indirectly finance or benefit armed groups in the Covered Countries.

We completed our acquisition of Altera Corporation (Altera) on December 28, 2015, and Altera® products are included within the scope of this Report. The due diligence measures conducted by Altera, prior to the completion of the acquisition, on the source and chain of custody of the necessary conflict minerals in its products are included in “Description of Due Diligence Measures Performed” below, and the results of these measures are included in “Results of Our Due Diligence Measures” below. Given that the completion of the acquisition occurred very late in 2015, Intel did not have the opportunity to integrate Altera’s conflict minerals program during the reporting period. As of the date of this Report, Altera’s conflict minerals program is in the process of being integrated into our conflict minerals program, which is described in “Design of Conflict Minerals Program” below.

Design of Conflict Minerals Program

The design of Intel’s conflict minerals program is in conformity with the Organisation for Economic Co-operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, Second Edition, and related Supplements on Tin, Tantalum and Tungsten and on Gold (collectively, “OECD Guidance”), specifically as it relates to our position in the minerals supply chain as a “downstream” purchaser. Summarized below are the design components of our conflict minerals program as they relate to the five-step framework from the OECD Guidance:

| 1. | Maintain strong company management systems: |

| • | Conflict Minerals Sourcing Policy: Maintain a supply chain policy for conflict minerals originating from the Democratic Republic of the Congo and adjoining countries that includes our commitment to exercise due diligence consistent with the OECD Guidance. That policy is included in our Form SD and available at www.intel.com/conflictfree. |

| • | Internal Conflict Minerals team: Operate an internal “Conflict Minerals” team led by our Global Supply Management organization to implement our Conflict Minerals Sourcing Policy. We regularly review such implementation efforts with our Chief Executive Officer (CEO) and senior management of our Technology and Manufacturing Group (TMG). |

| • | Supply chain control system: Employ a supply chain system of controls and transparency through the use of due diligence tools such as the Conflict Minerals Reporting Template (CMRT), a supply chain survey designed by the Conflict-Free Sourcing Initiative (CFSI) to identify the smelters and refiners that process the necessary conflict minerals contained in a company’s products and the country of origin of those conflict minerals. We employ a database to assess due diligence information and maintain records relating to our conflict minerals program for at least five years, in accordance with our record retention guidelines. |

| • | Supplier engagement: Feature requirements related to conflict minerals in our standard template for supplier contracts and specifications so that current and future suppliers are obligated to comply with our policies on conflict minerals, including participation in a supply chain survey and related due diligence activities. We communicate our Conflict Minerals Sourcing Policy and contractual requirements to relevant suppliers annually. |

| • | Company grievance mechanism: Enable employees, suppliers and other stakeholders to report any concerns relating to our conflict minerals program through our online corporate responsibility reporting and grievance mechanism found on our conflict-free website (www.intel.com/conflictfree). |

| 2. | Identify and assess risks in our supply chain: |

| • | Identify smelters/refiners in our supply chain: Identify direct suppliers that supply products to Intel that may contribute necessary conflict minerals to our products. Conduct an annual supply chain survey requesting those direct suppliers to provide a conflict minerals declaration, using the CMRT, designed to identify the conflict minerals contained in the products they supply to Intel, the smelters and refiners that processed those conflict minerals and the country of origin of those conflict minerals. We evaluate the completeness and accuracy of the suppliers’ survey responses and contact suppliers whose survey response we identified contained incomplete or potentially inaccurate information in order to seek additional clarifying information. |

| • | Identify the scope of the risk assessment: Our risk assessment is designed to identify risks in our supply chain, including direct suppliers that do not meet our contractual requirements related to conflict minerals, and smelters and refiners that have not received a “conflict-free” designation from an independent third party audit program or that we have reason to believe may source conflict minerals from the Covered Countries. |

| • | Assess due diligence practices of smelters and refiners: Compare smelters and refiners identified by the supply chain survey against the list of facilities that have received a “conflict-free” designation from the CFSP or other independent third party audit program such as the London Bullion Market Association’s Responsible Gold Programme and the Responsible Jewellery Council’s Chain-of-Custody Certification program. If a smelter or refiner in our supply chain is not listed as having received a “conflict-free” designation, we attempt to contact such facility to request country of origin information for the conflict minerals that it processed. We document country of origin information for the smelters and refiners identified by the supply chain survey as provided from multiple sources including the supply chain survey, independent third party audit programs and directly from smelters and refiners that Intel contacts. |

| • | Carry out spot checks of smelters and refiners: Conduct spot checks of smelter and refiner due diligence practices by attempting to visit those facilities that had not received a “conflict-free” designation and which allowed our visit. Our smelter and refiner visits are designed to assess their due diligence practices and encourage and assist their participation in an independent third party audit program, such as the CFSP. |

| 3. | Execute a strategy to respond to identified risks: |

| • | Report findings to senior management: Provide progress reports to our CEO and TMG senior management summarizing information gathered during our annual supply chain survey, results from the risk assessment process and status of our risk mitigation efforts. |

| • | Devise and adopt a risk management plan: Maintain a risk management plan that includes due diligence reviews of suppliers, smelters and refiners that may be sourcing or processing conflict minerals from the Covered Countries which may not be from recycled or scrap sources. Our due diligence measures are significantly based on multi-industry due diligence initiatives to evaluate the procurement practices of the smelters and refiners that process and provide those conflict minerals to our supply chain. |

| • | Implement a risk management plan: Perform risk mitigation efforts to bring suppliers into conformity with our Conflict Minerals Sourcing Policy and contractual requirements, which efforts may include working with direct suppliers to consider an alternative source for the necessary conflict minerals. Attempt to contact smelter and refiner facilities that have not received a “conflict-free” designation from an independent third party audit program to encourage their participation in such a program, assess their due diligence practices and request country of origin and chain of custody information. |

| • | Ongoing risk monitoring: Monitor and track suppliers, smelters and refiners identified as not meeting the requirements set forth in our Conflict Minerals Sourcing Policy or contractual requirements to determine their progress in meeting those requirements. |

| 4. | Support the development and implementation of independent third party audits of smelters’ and refiners’ sourcing: |

| • | Support development and implementation of due diligence practices and tools such as the CMRT through our leadership in the CFSI’s Steering Committee and participation within CFSI sub-teams. |

| • | Support development and implementation of the CFSP by defining the terms of the CFSP audit protocol in conjunction with CFSI member companies and other industry groups. |

| • | Support independent third party audits of smelters and refiners by programs such as the CFSP through our membership in and financial support of the CFSI (unique member code INTC). |

| 5. | Report on supply chain due diligence: |

| • | Publicly communicate our Conflict Minerals Sourcing Policy on our company website at www.intel.com/conflictfree. |

| • | Report annually on our supply chain due diligence activities in our white paper titled “Intel’s Efforts to Achieve a ‘Conflict Free’ Supply Chain” and Corporate Social Responsibility Report available on our company website at www.intel.com/conflictfree. |

| • | As required by the Rule, we obtain an independent private sector audit of applicable sections of this Report and file a Form SD with the SEC. This information is publicly available on our company website at www.intel.com/conflictfree. |

The content of any website referred to in this Report is included for general information only and is not incorporated by reference in this Report.

Description of Due Diligence Measures Performed

Below is a description of the measures performed for this reporting period to exercise due diligence on the source and chain of custody of the necessary conflict minerals contained in our products which we had reason to believe may have originated from the Covered Countries and may not have come from recycled or scrap sources:

| • | Conducted a supply chain survey of suppliers which we identified may be supplying Intel (including suppliers for Altera® products) with products that contain necessary conflict minerals using the CFSI’s CMRT, requesting country of origin information regarding the necessary conflict minerals and identification of smelters and refiners that process such minerals. |

| • | Contacted surveyed suppliers on responses to supply chain surveys that we identified contained incomplete or potentially inaccurate information to seek additional clarifying information. |

| • | Received responses to the supply chain survey request from 100% of our surveyed suppliers. |

| • | Compared smelters and refiners identified by surveyed suppliers against the list of facilities that have received a “conflict-free” designation from the CFSP or other independent third party audit program. |

| • | Monitored and tracked surveyed suppliers, and smelters and refiners identified by surveyed suppliers, which we identified as not meeting the applicable conflict minerals policy or contractual requirements, to determine their progress in meeting those requirements. |

| • | Performed risk mitigation efforts with surveyed suppliers we identified to be not in conformity with the applicable conflict minerals policy or contractual requirements by working with them to bring them into compliance. |

| • | In 2015, Intel visited 19 smelters and refiners that had not received a “conflict-free” designation to collect country of origin information and encourage and assist their participation in the CFSP or other independent third party audit program. |

| • | Intel provided 12 progress reports to Intel TMG senior management and three progress reports to Intel’s CEO. Altera provided four progress reports to Altera’s Senior Vice President of Operations and Altera’s Chief Financial Officer. These progress reports summarized the status of the applicable conflict minerals program. |

| • | As required by the Rule, obtained an independent private sector audit of applicable sections of this Report, which is set forth as Exhibit A to this Report. |

Results of our Due Diligence Measures

Inherent Limitations on Due Diligence Measures

As a downstream purchaser of products which contain conflict minerals, our due diligence measures can provide only reasonable, not absolute, assurance regarding the source and chain of custody of the necessary conflict minerals. Our due diligence processes are based on the necessity of seeking data from our direct suppliers and those suppliers seeking similar information within their supply chains to identify the original sources of the necessary conflict minerals. We also rely, to a large extent, on information collected and provided by independent third party audit programs. Such sources of information, as well as our smelters and refiner facility visits, may yield inaccurate or incomplete information and may be subject to fraud.

Another complicating factor is the unavailability of country of origin and chain of custody information from our suppliers on a continuous, real-time basis. Under the Dodd-Frank Act and the Rule, a product is “DRC conflict free” if it meets the required standard every day of the reporting year; conversely, a product would “not be found to be DRC conflict free” if it does not meet the required standard even one day of the reporting year. The supply chain of commodities such as conflict minerals is a multi-step process operating more or less on a daily basis, with ore being delivered to smelters and refiners, with smelters and refiners smelting or refining ores into metal containing derivatives such as ingots, with the derivatives being shipped, sold and stored in numerous market locations around the world and with distributors and purchasers holding varying amounts of the derivatives in inventory for use. Since we do not have direct contractual relationships with smelters and refiners, we rely on our direct suppliers and the entire supply chain to gather and provide specific information about the date when the ore is smelted into a derivative and later shipped, stored, sold and first entered the stream of commerce. We directly seek sourcing data on a periodic basis from our direct suppliers as well as certain smelters and refiners. We ask that the data cover the entire reporting year, and we seek to use contract provisions requiring the suppliers to promptly update us in the event that the sourcing data changes.

Results of Reasonable Country of Origin Inquiry Efforts

For 2015, Intel and Altera conducted supply chain surveys of our direct suppliers that we identified may contribute necessary conflict minerals to our products, referred to as surveyed suppliers, using the CMRT. Intel and Altera surveyed 274 direct suppliers, composed of 252 direct Intel suppliers and 22 direct Altera suppliers. In some cases, Intel and Altera surveyed the same suppliers, and these suppliers’ responses were reviewed independently by Intel and Altera.

The results of our supply chain surveys and conclusion of our reasonable country of origin inquiry are as follows:

| • | 100% of Intel and Altera surveyed suppliers provided a response to each company’s supply chain survey request. This 100% response rate compares favorably to the response rates in 2014 for Intel and Altera, which were 99% and 100%, respectively. |

| • | The surveyed suppliers identified 273 operational smelter and refiner facilities which may process the necessary conflict minerals contained in the products provided to us. |

| • | We know or have reason to believe that a portion of the conflict minerals processed by 36 of these 273 smelters and refiners may have originated in the Covered Countries and may not be solely from recycled or scrap sources. |

Supplier Due Diligence Results

Intel and Altera evaluated the accuracy and completeness of survey responses. We identified 76 surveyed suppliers whose survey response contained incomplete or potentially inaccurate information. We used various methods to identify the incomplete or inaccurate information in the surveyed supplier’s response including verification checks conducted by third party software, a third party provider or by members of the applicable internal conflict minerals team. When an incomplete or inaccurate response was identified, we contacted the applicable surveyed supplier, identified the incomplete or inaccurate information and requested that the surveyed supplier correct the incomplete or potentially inaccurate information and provide an updated response. Nearly all of these 76 surveyed suppliers (75 out of 76) provided an updated CMRT which we determined, using the same evaluation criteria, to be complete and accurate.

Upon receiving a survey response identified to be complete and accurate, Intel and Altera separately evaluated each response for conformity with applicable conflict minerals policy or contractual requirements. We identified surveyed suppliers which were not fully compliant with all applicable requirements and monitored and tracked these suppliers’

progress in meeting the applicable requirements. We performed risk mitigation efforts by contacting each supplier, identifying actions items which we requested the supplier complete, and asking the supplier to provide an updated CMRT. Our risk mitigation efforts are specifically related to meeting the applicable conflict minerals sourcing policy or contractual requirements, with the goal of bringing each surveyed supplier into compliance with such requirements.

Smelter and Refiner Due Diligence Results

Intel and Altera conducted due diligence on the smelters and refiners which the surveyed suppliers identified may process the necessary conflict minerals contained in the products they provided to Intel or Altera. Our due diligence activities are dominated by a continual process to determine and monitor whether the identified smelters and refiners are operational and therefore may contribute necessary conflict minerals to our final products, and whether they have received a “conflict-free” designation or have begun participating in an independent third party audit program such as the CFSP. If a smelter or refiner in Intel’s supply chain was not listed as having received a “conflict-free” designation, Intel proactively attempted to contact such facility to request country of origin information for the conflict minerals that it processed as well as to encourage and assist their participation in the CFSP or other independent third party audit program.

In addition, in 2015, Intel visited 19 smelter and refiner facilities. 12 of these 19 smelter and refiner facilities later participated in and received a “conflict-free” designation from the CFSP. Of the 7 remaining facilities which have not yet received a “conflict-free” designation, Intel was able to receive sufficient information during a facility visit to determine the conflict minerals processed in all of these facilities either did not originate from the Covered Countries or did solely originate from recycled or scrap sources. In addition since our facility visit, 4 these 7 facilities have begun participating in the CFSP but have not yet received a conflict-free designation.

The surveyed suppliers identified an aggregate of 273 operational smelter and refiner facilities which may process the necessary conflict minerals contained in the products these surveyed suppliers provided to either Intel or Altera. Of those facilities, as of May 1, 2016:

| • | 213 have received a “conflict-free” designation from an independent third party audit program, and all tantalum smelters have received a “conflict-free” designation from the CFSP; |

| • | 30 have not received a “conflict-free” designation but have begun participating in an independent third party audit program; and |

| • | the remaining 30 facilities have not begun participating in an independent third party audit program. |

We were unable to ascertain the country of origin and/or chain of custody of all necessary conflict minerals processed by all of these 273 facilities because, for this reporting period, certain smelter and refiner facilities (1) had not yet received a “conflict-free” designation from an independent third party audit program, (2) provided country of origin or chain of custody information that we determined was insufficient or incomplete, (3) were unwilling to allow us to visit the facility to conduct an on-site review of such information, (4) did not respond to our requests for country of origin or chain of custody information, or (5) did not have contact details available to establish communication to request country of origin or chain of custody information.

Nonetheless, as a result of our due diligence activities summarized above, we determined the following:

| • | All 36 smelters and refiners which we know or have reason to believe may source conflict minerals from the Covered Countries which may not be solely from recycled or scrap sources have received a “conflict-free” designation from the CFSP, an independent third party audit program. |

| • | We have no reason to believe that any of the 273 smelter and refiner facilities directly or indirectly finance or benefit armed groups in the Covered Countries. |

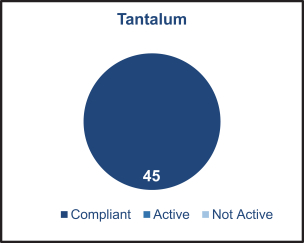

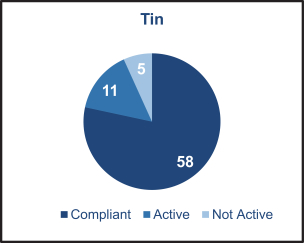

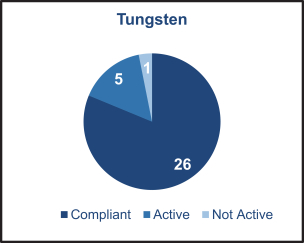

The charts below summarize, as of May 1, 2016, the participation status of operational smelter and refiner facilities, identified by the surveyed suppliers, in an independent third party audit program. The charts indicate the numbers of such smelter and refiner facilities that:

| (i) | have received a “conflict-free” designation from an independent third party audit program (referred to as “Compliant”), |

| (ii) | have begun participating in an independent third party audit program (referred to as “Active”), or |

| (iii) | have not begun participating in an independent third party audit program (referred to as “Not Active”). |

Independent Third Party Audit Program Status of Identified Smelters and Refiners

Additional information regarding the smelter and refiner facilities is available in Table 1 below.

Products

For this reporting period, we identified the following products which we manufactured or contracted with others to manufacture that may contain necessary conflict minerals (defined as any tantalum, tin, tungsten or gold that is necessary to the functionality or production of our products):

| • | “Client Microprocessors and Chipsets”: Desktop, mobile and embedded microprocessors and associated chipsets that are solely manufactured by Intel. Microprocessors in this product category consist of the following: Celeron®, Pentium®, Intel® Core™ M, Intel® Core i3™, Intel® Core™ i5, Intel® Core™ i7, Intel® Quark™, and Intel® Atom™ processors (except Intel® Atom™ processors for servers, storage and communications). |

| • | “Server Microprocessors and Chipsets Solely Manufactured by Intel”: Server microprocessors that contain integrated circuits (ICs) solely manufactured by Intel and associated chipsets. Microprocessors in this product category consist of the following: Intel® Xeon Processor E3™ Family, Intel® Xeon Processor E5™ Family, Intel® Xeon Processor D™ Family, and Intel® Atom™ processors for servers and storage. |

| • | “All Other Products”: All other Intel® products that may contain necessary conflict minerals that we manufactured or contracted with others to manufacture, which products are comprised of the following: |

| • | Other Server Products: Enterprise branded microprocessors, motherboards, server and micro-server systems which contain IC components purchased by Intel including Intel® Xeon Phi™, Intel® Xeon® Processor E7™ Family, and Itanium®. |

| • | Networking, Wireless and Mobile Communication Products: Ethernet network adapters, controllers and wireless products which enable the computers and networks to exchange data including Thunderbolt™ technology, Intel® Centrino® technology, Intel® WiMAX, Intel® WiFi products and Intel® XMM™ slim modems. |

| • | Boards and Other Components: Printed circuit boards and other components including Intel® Galileo boards, Intel® Edison boards, Intel® Curie™ boards, and Intel® NUC (next unit of computing) and Intel® Compute Stick |

| • | Storage Products: Memory products including Intel® Solid-State Drives (Intel® SSDs) |

| • | Altera® Products: Altera® Stratix™, Arria™ and Cyclone™ field programmable gate arrays (FPGAs); MAX™ complex programmable logic devices (CPLDs); and Altera® Enpirion™ power solutions. |

Product Determination

On the basis of our due diligence measures as described in this Report, we have made the following product determinations in good faith for this reporting period.

DRC Conflict Free

Our Client Microprocessors and Chipsets products and Server Microprocessors and Chipsets Solely Manufactured by Intel products are DRC conflict free. Our surveyed suppliers have identified the smelters and refiners in the supply chain that are sources of the necessary conflict minerals for these products. All of these smelters and refiners identified by our surveyed suppliers which contribute necessary conflict minerals to these products have received a “conflict-free” designation from the CFSP or other independent third party audit program which resulted in our reasonable determination that these products are DRC conflict free.

Insufficient Information to Determine Whether All Other Products are DRC Conflict Free

We do not have sufficient information from suppliers or other sources regarding all of the smelters and refiners that processed the necessary conflict minerals in All Other Products to conclude whether those conflict minerals originated in the Covered Countries and, if so, whether those conflict minerals were from recycled or scrap sources or other conflict-free sources. While we have no reason to believe the conflict minerals in our All Other Products directly or indirectly benefit armed groups in the Covered Countries based on our due diligence measures performed, we cannot describe these products as DRC conflict free under the federal securities laws. Our efforts to determine the mine or location of origin of the necessary conflict minerals in our All Other Products with the greatest possible specificity consisted of the due diligence measures described in this Report. In particular, because independent third party audit programs validate whether sufficient evidence exists regarding country, mine and/or location of origin of the conflict minerals that the audited smelter or refiner facilities have processed, we relied on the information made available by such programs for the smelters and refiners in our supply chain.

Table 1 below lists the facilities which, to the extent known, processed the necessary conflict minerals in All Other Products.

| Metal |

Smelter or Refiner Facility Name† |

Location of Facility† | ||

| Gold | Advanced Chemical Company | United States | ||

| Gold | Aida Chemical Industries Co., Ltd. * | Japan | ||

| Gold | Al Etihad Gold Refinery DMCC | United Arab Emirates | ||

| Gold | Allgemeine Gold-und Silberscheideanstalt A.G. * | Germany | ||

| Gold | Almalyk Mining and Metallurgical Complex (AMMC) * | Uzbekistan | ||

| Gold | AngloGold Ashanti Córrego do Sítio Mineração * | Brazil | ||

| Gold | Argor-Heraeus S.A. * | Switzerland | ||

| Gold | Asahi Pretec Corp. * | Japan | ||

| Gold | Asahi Refining Canada Ltd. * | Canada | ||

| Gold | Asahi Refining USA Inc. * | United States | ||

| Gold | Asaka Riken Co., Ltd. * | Japan | ||

| Gold | Atasay Kuyumculuk Sanayi Ve Ticaret A.S. | Turkey | ||

| Gold | Aurubis AG * | Germany | ||

| Gold | Bangko Sentral ng Pilipinas (Central Bank of the Philippines) * | Philippines | ||

| Gold | Boliden AB * | Sweden | ||

| Gold | C. Hafner GmbH + Co. KG * | Germany | ||

| Gold | Caridad | Mexico | ||

| Gold | CCR Refinery - Glencore Canada Corporation * | Canada | ||

| Gold | Cendres + Métaux S.A. | Switzerland | ||

| Gold | Chimet S.p.A. * | Italy | ||

| Gold | Chugai Mining | Japan | ||

| Gold | Daejin Indus Co., Ltd. | Republic of Korea | ||

| Gold | Daye Non-Ferrous Metals Mining Ltd. * | China | ||

| Gold | DODUCO GmbH * | Germany | ||

| Gold | Dowa * | Japan | ||

| Gold | DSC (Do Sung Corporation) | Republic of Korea | ||

| Gold | Eco-System Recycling Co., Ltd. * | Japan | ||

| Gold | Elemetal Refining, LLC * | United States | ||

| Gold | Emirates Gold DMCC * | United Arab Emirates | ||

| Gold | Faggi Enrico S.p.A. | Italy | ||

| Gold | Gansu Seemine Material Hi-Tech Co., Ltd. | China | ||

| Gold | Geib Refining Corporation | United States | ||

| Gold | Great Wall Precious Metals Co., Ltd. of CBPM | China | ||

| Gold | Guangdong Jinding Gold Limited | China | ||

| Gold | Guoda Safina High-Tech Environmental Refinery Co., Ltd. | China | ||

| Gold | Hangzhou Fuchunjiang Smelting Co., Ltd. | China | ||

| Gold | Heimerle + Meule GmbH * | Germany | ||

| Gold | Heraeus Ltd. Hong Kong * | China | ||

| Gold | Heraeus Precious Metals GmbH & Co. KG * | Germany | ||

| Gold | Hunan Chenzhou Mining Co., Ltd. | China | ||

| Gold | Hwasung CJ Co., Ltd. | Republic of Korea | ||

| Gold | Inner Mongolia Qiankun Gold and Silver Refinery Share Co., Ltd. * | China | ||

| Gold | Ishifuku Metal Industry Co., Ltd. * | Japan | ||

| Gold | Istanbul Gold Refinery * | Turkey | ||

| Gold | Japan Mint * | Japan | ||

| Gold | Jiangxi Copper Co., Ltd. * | China | ||

| Gold | JSC Ekaterinburg Non-Ferrous Metal Processing Plant * | Russian Federation | ||

| Gold | JSC Uralelectromed * | Russian Federation | ||

| Gold | JX Nippon Mining & Metals Co., Ltd. * | Japan | ||

| Gold | Kaloti Precious Metals | United Arab Emirates | ||

| Gold | Kazakhmys Smelting LLC | Kazakhstan | ||

| Gold | Kazzinc * | Kazakhstan | ||

| Gold | Kennecott Utah Copper LLC * | United States |

| Metal |

Smelter or Refiner Facility Name† |

Location of Facility† | ||

| Gold | KGHM Polska Miedź Spółka Akcyjna * | Poland | ||

| Gold | Kojima Chemicals Co., Ltd. * | Japan | ||

| Gold | Korea Zinc Co., Ltd. | Republic of Korea | ||

| Gold | Kyrgyzaltyn JSC | Kyrgyzstan | ||

| Gold | L’azurde Company For Jewelry | Saudi Arabia | ||

| Gold | Lingbao Gold Co., Ltd. | China | ||

| Gold | Lingbao Jinyuan Tonghui Refinery Co., Ltd. | China | ||

| Gold | LS-NIKKO Copper Inc. * | Republic of Korea | ||

| Gold | Luoyang Zijin Yinhui Gold Refinery Co., Ltd. | China | ||

| Gold | Materion * | United States | ||

| Gold | Matsuda Sangyo Co., Ltd. * | Japan | ||

| Gold | Metalor Technologies (Hong Kong) Ltd. * | China | ||

| Gold | Metalor Technologies (Singapore) Pte., Ltd. * | Singapore | ||

| Gold | Metalor Technologies (Suzhou) Ltd. | China | ||

| Gold | Metalor Technologies S.A. * | Switzerland | ||

| Gold | Metalor USA Refining Corporation * | United States | ||

| Gold | Metalúrgica Met-Mex Peñoles S.A. De C.V. * | Mexico | ||

| Gold | Mitsubishi Materials Corporation * | Japan | ||

| Gold | Mitsui Mining and Smelting Co., Ltd. * | Japan | ||

| Gold | MMTC-PAMP India Pvt., Ltd. * | India | ||

| Gold | Morris and Watson | New Zealand | ||

| Gold | Moscow Special Alloys Processing Plant * | Russian Federation | ||

| Gold | Nadir Metal Rafineri San. Ve Tic. A.Ş. * | Turkey | ||

| Gold | Navoi Mining and Metallurgical Combinat * | Uzbekistan | ||

| Gold | Nihon Material Co., Ltd. * | Japan | ||

| Gold | Ögussa Österreichische Gold- und Silber-Scheideanstalt GmbH * | Austria | ||

| Gold | Ohura Precious Metal Industry Co., Ltd. * | Japan | ||

| Gold | OJSC “The Gulidov Krasnoyarsk Non-Ferrous Metals Plant” (OJSC Krastsvetmet) * | Russian Federation | ||

| Gold | OJSC Novosibirsk Refinery * | Russian Federation | ||

| Gold | PAMP S.A. * | Switzerland | ||

| Gold | Penglai Penggang Gold Industry Co., Ltd. | China | ||

| Gold | Prioksky Plant of Non-Ferrous Metals * | Russian Federation | ||

| Gold | PT Aneka Tambang (Persero) Tbk * | Indonesia | ||

| Gold | PX Précinox S.A. * | Switzerland | ||

| Gold | Rand Refinery (Pty) Ltd. * | South Africa | ||

| Gold | Republic Metals Corporation * | United States | ||

| Gold | Royal Canadian Mint * | Canada | ||

| Gold | Sabin Metal Corp. | United States | ||

| Gold | Samduck Precious Metals | Republic of Korea | ||

| Gold | SAMWON Metals Corp. | Republic of Korea | ||

| Gold | SAXONIA Edelmetalle GmbH | Germany | ||

| Gold | Schone Edelmetaal B.V. * | Netherlands | ||

| Gold | SEMPSA Joyería Platería S.A. * | Spain | ||

| Gold | Shandong Tiancheng Biological Gold Industrial Co., Ltd. | China | ||

| Gold | Shandong Zhaojin Gold & Silver Refinery Co., Ltd. * | China | ||

| Gold | Sichuan Tianze Precious Metals Co., Ltd. * | China | ||

| Gold | Singway Technology Co., Ltd. * | Taiwan | ||

| Gold | So Accurate Group, Inc. | United States | ||

| Gold | SOE Shyolkovsky Factory of Secondary Precious Metals * | Russian Federation | ||

| Gold | Solar Applied Materials Technology Corp. * | Taiwan | ||

| Gold | Sumitomo Metal Mining Co., Ltd. * | Japan | ||

| Gold | T.C.A S.p.A * | Italy | ||

| Gold | Tanaka Kikinzoku Kogyo K.K. * | Japan | ||

| Gold | The Refinery of Shandong Gold Mining Co., Ltd. * | China | ||

| Gold | Tokuriki Honten Co., Ltd. * | Japan | ||

| Gold | Tongling Nonferrous Metals Group Co., Ltd. | China |

| Metal |

Smelter or Refiner Facility Name† |

Location of Facility† | ||

| Gold | Torecom | Republic of Korea | ||

| Gold | Umicore Brasil Ltda. * | Brazil | ||

| Gold | Umicore Precious Metals Thailand * | Thailand | ||

| Gold | Umicore S.A. Business Unit Precious Metals Refining * | Belgium | ||

| Gold | United Precious Metal Refining, Inc. * | United States | ||

| Gold | Valcambi S.A. * | Switzerland | ||

| Gold | Western Australian Mint trading as The Perth Mint * | Australia | ||

| Gold | WIELAND Edelmetalle GmbH | Germany | ||

| Gold | Yamamoto Precious Metal Co., Ltd. * | Japan | ||

| Gold | Yokohama Metal Co., Ltd. * | Japan | ||

| Gold | Yunnan Copper Industry Co., Ltd. | China | ||

| Gold | Zhongyuan Gold Smelter of Zhongjin Gold Corporation * | China | ||

| Gold | Zijin Mining Group Co., Ltd. Gold Refinery * | China | ||

| Tantalum | Changsha South Tantalum Niobium Co., Ltd. * | China | ||

| Tantalum | Conghua Tantalum and Niobium Smeltry * | China | ||

| Tantalum | D Block Metals, LLC * | United States | ||

| Tantalum | Duoluoshan * | China | ||

| Tantalum | Exotech Inc. * | United States | ||

| Tantalum | F&X Electro-Materials Ltd. * | China | ||

| Tantalum | FIR Metals & Resource Ltd. * | China | ||

| Tantalum | Global Advanced Metals Aizu * | Japan | ||

| Tantalum | Global Advanced Metals Boyertown * | United States | ||

| Tantalum | Guangdong Zhiyuan New Material Co., Ltd. * | China | ||

| Tantalum | H.C. Starck Co., Ltd. * | Thailand | ||

| Tantalum | H.C. Starck GmbH Goslar * | Germany | ||

| Tantalum | H.C. Starck GmbH Laufenburg * | Germany | ||

| Tantalum | H.C. Starck Hermsdorf GmbH * | Germany | ||

| Tantalum | H.C. Starck Inc. * | United States | ||

| Tantalum | H.C. Starck Ltd. * | Japan | ||

| Tantalum | H.C. Starck Smelting GmbH & Co. KG * | Germany | ||

| Tantalum | Hengyang King Xing Lifeng New Materials Co., Ltd. * | China | ||

| Tantalum | Hi-Temp Specialty Metals, Inc. * | United States | ||

| Tantalum | Jiangxi Dinghai Tantalum & Niobium Co., Ltd. * | China | ||

| Tantalum | JiuJiang JinXin Nonferrous Metals Co., Ltd. * | China | ||

| Tantalum | Jiujiang Tanbre Co., Ltd. * | China | ||

| Tantalum | Jiujiang Zhongao Tantalum & Niobium Co., Ltd. * | China | ||

| Tantalum | KEMET Blue Metals * | Mexico | ||

| Tantalum | KEMET Blue Powder * | United States | ||

| Tantalum | King-Tan Tantalum Industry Ltd. * | China | ||

| Tantalum | LSM Brasil S.A. * | Brazil | ||

| Tantalum | Metallurgical Products India Pvt., Ltd. * | India | ||

| Tantalum | Mineração Taboca S.A. * | Brazil | ||

| Tantalum | Mitsui Mining & Smelting * | Japan | ||

| Tantalum | Molycorp Silmet A.S. * | Estonia | ||

| Tantalum | Ningxia Orient Tantalum Industry Co., Ltd. * | China | ||

| Tantalum | Plansee SE Liezen * | Austria | ||

| Tantalum | Plansee SE Reutte * | Austria | ||

| Tantalum | QuantumClean * | United States | ||

| Tantalum | Resind Indústria e Comércio Ltda. * | Brazil | ||

| Tantalum | RFH Tantalum Smeltry Co., Ltd. * | China | ||

| Tantalum | Solikamsk Magnesium Works OAO * | Russian Federation | ||

| Tantalum | Taki Chemicals * | Japan | ||

| Tantalum | Telex Metals * | United States | ||

| Tantalum | Tranzact, Inc. * | United States | ||

| Tantalum | Ulba Metallurgical Plant JSC * | Kazakhstan | ||

| Tantalum | XinXing HaoRong Electronic Material Co., Ltd. * | China |

| Metal |

Smelter or Refiner Facility Name† |

Location of Facility† | ||

| Tantalum | Yichun Jin Yang Rare Metal Co., Ltd. * | China | ||

| Tantalum | Zhuzhou Cemented Carbide * | China | ||

| Tin | Alpha * | United States | ||

| Tin | An Thai Minerals Co., Ltd. | Vietnam | ||

| Tin | An Vinh Joint Stock Mineral Processing Company | Vietnam | ||

| Tin | Chenzhou Yunxiang Mining and Metallurgy Co., Ltd. | China | ||

| Tin | China Tin Group Co., Ltd. * | China | ||

| Tin | CNMC (Guangxi) PGMA Co., Ltd. | China | ||

| Tin | Cooperativa Metalurgica de Rondônia Ltda. * | Brazil | ||

| Tin | CV Dua Sekawan | Indonesia | ||

| Tin | CV Gita Pesona * | Indonesia | ||

| Tin | CV Serumpun Sebalai * | Indonesia | ||

| Tin | CV United Smelting * | Indonesia | ||

| Tin | CV Venus Inti Perkasa * | Indonesia | ||

| Tin | Dowa * | Japan | ||

| Tin | Electro-Mechanical Facility of the Cao Bang Minerals & Metallurgy Joint Stock Company | Vietnam | ||

| Tin | Elmet S.L.U. * | Spain | ||

| Tin | EM Vinto * | Bolivia | ||

| Tin | Estanho de Rondônia S.A. | Brazil | ||

| Tin | Fenix Metals * | Poland | ||

| Tin | Gejiu Jinye Mineral Company | China | ||

| Tin | Gejiu Kai Meng Industry and Trade LLC | China | ||

| Tin | Gejiu Non-Ferrous Metal Processing Co., Ltd. * | China | ||

| Tin | Gejiu Yunxin Nonferrous Electrolysis Co., Ltd. | China | ||

| Tin | Gejiu Zili Mining And Metallurgy Co., Ltd. | China | ||

| Tin | Huichang Jinshunda Tin Co., Ltd. | China | ||

| Tin | Jiangxi Ketai Advanced Material Co., Ltd. * | China | ||

| Tin | Magnu’s Minerais Metais e Ligas Ltda. * | Brazil | ||

| Tin | Malaysia Smelting Corporation (MSC) * | Malaysia | ||

| Tin | Melt Metais e Ligas S.A. * | Brazil | ||

| Tin | Metallic Resources, Inc. * | United States | ||

| Tin | Metallo-Chimique N.V. * | Belgium | ||

| Tin | Mineração Taboca S.A. * | Brazil | ||

| Tin | Minsur * | Peru | ||

| Tin | Mitsubishi Materials Corporation * | Japan | ||

| Tin | Nankang Nanshan Tin Manufactory Co., Ltd. | China | ||

| Tin | Nghe Tinh Non-Ferrous Metals Joint Stock Company | Vietnam | ||

| Tin | O.M. Manufacturing (Thailand) Co., Ltd. * | Thailand | ||

| Tin | O.M. Manufacturing Philippines, Inc. * | Philippines | ||

| Tin | Operaciones Metalurgical S.A. * | Bolivia | ||

| Tin | PT Aries Kencana Sejahtera * | Indonesia | ||

| Tin | PT Artha Cipta Langgeng * | Indonesia | ||

| Tin | PT ATD Makmur Mandiri Jaya * | Indonesia | ||

| Tin | PT Babel Inti Perkasa * | Indonesia | ||

| Tin | PT Bangka Prima Tin * | Indonesia | ||

| Tin | PT Bangka Tin Industry * | Indonesia | ||

| Tin | PT Belitung Industri Sejahtera * | Indonesia | ||

| Tin | PT BilliTin Makmur Lestari * | Indonesia | ||

| Tin | PT Bukit Timah * | Indonesia | ||

| Tin | PT Cipta Persada Mulia * | Indonesia | ||

| Tin | PT DS Jaya Abadi * | Indonesia | ||

| Tin | PT Eunindo Usaha Mandiri * | Indonesia | ||

| Tin | PT Inti Stania Prima * | Indonesia | ||

| Tin | PT Justindo * | Indonesia | ||

| Tin | PT Mitra Stania Prima * | Indonesia | ||

| Tin | PT Panca Mega Persada * | Indonesia |

| Metal |

Smelter or Refiner Facility Name† |

Location of Facility† | ||

| Tin | PT Prima Timah Utama * | Indonesia | ||

| Tin | PT Refined Bangka Tin * | Indonesia | ||

| Tin | PT Sariwiguna Binasentosa * | Indonesia | ||

| Tin | PT Stanindo Inti Perkasa * | Indonesia | ||

| Tin | PT Sukses Inti Makmur * | Indonesia | ||

| Tin | PT Sumber Jaya Indah * | Indonesia | ||

| Tin | PT Timah (Persero) Tbk Kundur * | Indonesia | ||

| Tin | PT Timah (Persero) Tbk Mentok * | Indonesia | ||

| Tin | PT Tinindo Inter Nusa * | Indonesia | ||

| Tin | PT Tommy Utama * | Indonesia | ||

| Tin | PT Wahana Perkit Jaya * | Indonesia | ||

| Tin | Resind Indústria e Comércio Ltda. * | Brazil | ||

| Tin | Rui Da Hung * | Taiwan | ||

| Tin | Soft Metais Ltda. * | Brazil | ||

| Tin | Thaisarco * | Thailand | ||

| Tin | Tuyen Quang Non-Ferrous Metals Joint Stock Company | Vietnam | ||

| Tin | VQB Mineral and Trading Group JSC * | Vietnam | ||

| Tin | White Solder Metalurgia e Mineração Ltda. * | Brazil | ||

| Tin | Yunnan Chengfeng Non-ferrous Metals Co., Ltd. | China | ||

| Tin | Yunnan Tin Company Limited * | China | ||

| Tungsten | A.L.M.T. TUNGSTEN Corp. * | Japan | ||

| Tungsten | Chenzhou Diamond Tungsten Products Co., Ltd. * | China | ||

| Tungsten | Chongyi Zhangyuan Tungsten Co., Ltd. * | China | ||

| Tungsten | Dayu Jincheng Tungsten Industry Co., Ltd. | China | ||

| Tungsten | Fujian Jinxin Tungsten Co., Ltd. * | China | ||

| Tungsten | Ganzhou Huaxing Tungsten Products Co., Ltd. * | China | ||

| Tungsten | Ganzhou Seadragon W & Mo Co., Ltd. * | China | ||

| Tungsten | Ganzhou Yatai Tungsten Co., Ltd. * | China | ||

| Tungsten | Global Tungsten & Powders Corp. * | United States | ||

| Tungsten | Guangdong Xianglu Tungsten Co., Ltd. * | China | ||

| Tungsten | H.C. Starck GmbH * | Germany | ||

| Tungsten | H.C. Starck Smelting GmbH & Co.KG * | Germany | ||

| Tungsten | Hunan Chenzhou Mining Co., Ltd. * | China | ||

| Tungsten | Hunan Chunchang Nonferrous Metals Co., Ltd. * | China | ||

| Tungsten | Hydrometallurg, JSC * | Russian Federation | ||

| Tungsten | Japan New Metals Co., Ltd. * | Japan | ||

| Tungsten | Jiangwu H.C. Starck Tungsten Products Co., Ltd. | China | ||

| Tungsten | Jiangxi Gan Bei Tungsten Co., Ltd. * | China | ||

| Tungsten | Jiangxi Minmetals Gao’an Non-ferrous Metals Co., Ltd. | China | ||

| Tungsten | Jiangxi Tonggu Non-ferrous Metallurgical & Chemical Co., Ltd. | China | ||

| Tungsten | Jiangxi Xinsheng Tungsten Industry Co., Ltd. | China | ||

| Tungsten | Jiangxi Xiushui Xianggan Nonferrous Metals Co., Ltd. * | China | ||

| Tungsten | Jiangxi Yaosheng Tungsten Co., Ltd. | China | ||

| Tungsten | Kennametal Huntsville * | United States | ||

| Tungsten | Malipo Haiyu Tungsten Co., Ltd. * | China | ||

| Tungsten | Niagara Refining LLC * | United States | ||

| Tungsten | Nui Phao H.C. Starck Tungsten Chemicals Manufacturing LLC * | Vietnam | ||

| Tungsten | Tejing (Vietnam) Tungsten Co., Ltd. * | Vietnam | ||

| Tungsten | Wolfram Bergbau und Hütten AG * | Austria | ||

| Tungsten | Xiamen Tungsten (H.C.) Co., Ltd. * | China | ||

| Tungsten | Xiamen Tungsten Co., Ltd. * | China | ||

| Tungsten | Xinhai Rendan Shaoguan Tungsten Co., Ltd. * | China |

Based on our due diligence, the above smelter and refiner facilities process conflict minerals from one or more of the following countries of origin: Angola, Argentina, Australia, Austria, Belgium, Bolivia, Brazil, Burundi, Cambodia, Canada, Central African Republic, Chile, China, Colombia, Côte D’Ivoire, Czech Republic, Djibouti, DRC, Ecuador, Egypt, Estonia, Ethiopia, France, Germany, Guyana, Hungary, India, Indonesia, Ireland, Israel, Japan, Kazakhstan, Kenya, Laos People’s Democratic Republic, Luxembourg, Madagascar, Malaysia, Mongolia, Myanmar, Mozambique, Namibia, Netherlands, Nigeria, Peru, Portugal, Republic of Korea, Republic of Congo, Russian Federation, Rwanda, Sierra Leone, Singapore, Slovakia, South Africa, Spain, South Sudan, Suriname, Switzerland, Taiwan, United Republic of Tanzania, Thailand, Uganda, United Kingdom, United States, Uruguay, Vietnam, Zambia

| † | Smelter and refiner facility names and locations as reported by the CFSI as of May 1, 2016. |

| * | Denotes smelters and refiners which have received a “conflict-free” designation from an independent third party audit program as of May 1, 2016. |

Future Due Diligence Measures

During the reporting period for the calendar year ending December 31, 2016, we are continuing to engage in the activities described above in “Design of Conflict Minerals Program.” In our efforts to attain a conflict-free supply chain for our products, we intend to continue to contact smelters and refiners identified in our supply chain survey process that have not yet received a “conflict-free” designation and request their participation in the CFSP or other independent third party audit program in order for them to obtain such a “conflict-free” designation. Altera’s conflict minerals program will be integrated into Intel’s conflict minerals program in calendar year 2016.

Independent Private Sector Audit of this Report

We obtained an independent private sector audit of this Report by Ernst & Young LLP, which is set forth as Exhibit A to this Report.

Intel and the Intel logo, Intel Atom, Intel Core, Intel Xeon, Intel Xeon Phi, Celeron, Curie, Itanium, Pentium, Quark, Thunderbolt, and XMM are trademarks of Intel Corporation or its subsidiaries in the U.S. and/or other countries.

Exhibit A

Report of Independent Accountants

Board of Directors and Stockholders of Intel Corporation

We have examined whether the design of Intel Corporation’s (the “Company”) due diligence framework as set forth in the Design of Conflict Minerals Program section of the Conflict Minerals Report for the reporting period from January 1 to December 31, 2015, is in conformity, in all material respects, with the criteria set forth in the Organisation of Economic Co-Operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, Second Edition 2013, (“OECD Due Diligence Guidance”), and whether the Company’s description of the due diligence measures it performed, as set forth in Description of Due Diligence Measures Performed section of the Conflict Minerals Report for the reporting period from January 1 to December 31, 2015, is consistent, in all material respects, with the due diligence process that the Company undertook.

Management is responsible for the design of the Company’s due diligence framework and the description of the Company’s due diligence measures set forth in the Conflict Minerals Report, and performance of the due diligence measures. Our responsibility is to express an opinion on the design of the Company’s due diligence framework and on the description of the due diligence measures the Company performed, based on our examination. Our examination was conducted in accordance with attestation standards established by the American Institute of Certified Public Accountants and the standards applicable to attestation engagements contained in Government Auditing Standards, issued by the Comptroller General of the United States, and, accordingly, included examining, on a test basis, evidence about the design of the Company’s due diligence framework and the description of the due diligence measures the Company performed, and performing such other procedures as we considered necessary in the circumstances. We believe that our examination provides a reasonable basis for our opinion.

Our examination was not conducted for the purpose of evaluating:

| • | The consistency of the due diligence measures that the Company performed with either the design of the Company’s due diligence framework or the OECD Due Diligence Guidance |

| • | The completeness of the Company’s description of the due diligence measures performed |

| • | The suitability of the design or operating effectiveness of the Company’s due diligence process |

| • | Whether a third party can determine from the Conflict Minerals Report if the due diligence measures the Company performed are consistent with the OECD Due Diligence Guidance |

| • | The Company’s reasonable country of origin inquiry (RCOI), including the suitability of the design of the RCOI, its operating effectiveness, or the results thereof |

| • | The Company’s conclusions about the source or chain of custody of its conflict minerals, those products subject to due diligence, or the DRC Conflict Free status of its products |

Accordingly, we do not express an opinion or any other form of assurance on the aforementioned matters or any other matters included in any section of the Conflict Minerals Report other than the design of the Company’s due diligence framework as set forth in the Design of Conflict Minerals Program section and the Company’s description of the due diligence measures it performed, as set forth in the Description of Due Diligence Measures Performed section referenced in the first paragraph above.

In our opinion, the design of the Company’s due diligence framework for the reporting period from January 1 to December 31, 2015, as set forth in the Design of Conflict Minerals Program section of the Conflict Minerals Report is in conformity, in all material respects, with the OECD Due Diligence Guidance, and the Company’s description of the due diligence measures it performed as set forth in the Description of Due Diligence Measures Performed section of the Conflict Minerals Report for the reporting period from January 1 to December 31, 2015, is consistent, in all material respects, with the due diligence process that the Company undertook.

/s/ Ernst & Young LLP

Portland, Oregon

May 19, 2016

Serious News for Serious Traders! Try StreetInsider.com Premium Free!

You May Also Be Interested In

- Intel (INTC) earnings preview: Still a show me story

- Intel (INTC) PT Lowered to $37 at HSBC, 'Foundry uncertainties an ongoing concern'

- Citi picks one chip stock to sell off and one to trade higher after earnings

Create E-mail Alert Related Categories

SEC FilingsSign up for StreetInsider Free!

Receive full access to all new and archived articles, unlimited portfolio tracking, e-mail alerts, custom newswires and RSS feeds - and more!

Tweet

Tweet Share

Share